In the realm of industrial innovations lies a realm where material intricacies shape the foundation of groundbreaking creations. Within this domain, meticulous attention to specifications unveils a tapestry of properties and potentials, guiding engineers and designers towards optimal solutions. Today, we delve into the technical fabric of a material, exploring its composition, characteristics, and applications.

Unveiling the Essence: At the heart of every technological advancement lies the careful selection of materials. Beyond mere substance, each material embodies a narrative of resilience, conductivity, or adaptability, waiting to be deciphered by the discerning eye. Within the intricate web of material science, the exploration of data sheets becomes a voyage of discovery, offering insights into the very essence of innovation.

Embarking on a Journey: As we navigate through the labyrinth of technical specifications, we unravel the threads that weave together the fabric of functionality and form. Through a lens of analysis and interpretation, we illuminate the path towards informed decision-making, where every parameter and property speaks volumes about performance and possibility.

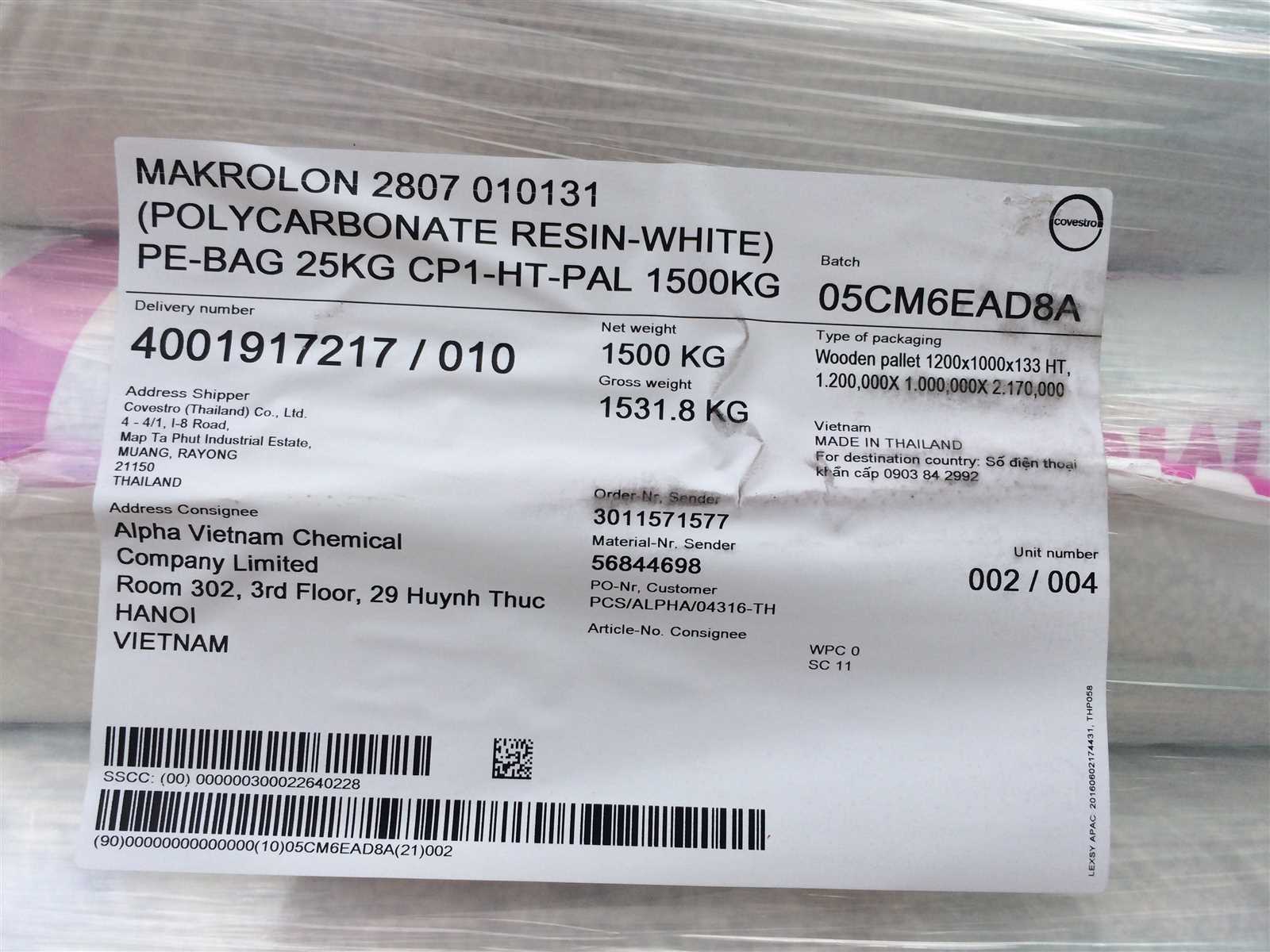

Unlocking the Potential of Polycarbonate: A Comprehensive Analysis

In this section, we delve into the myriad capabilities and applications of a high-performance thermoplastic polymer, offering an in-depth exploration of its properties, functionalities, and potential uses. Without explicitly naming it, we aim to provide a detailed overview of the material’s versatility, durability, and adaptability across various industries.

The Versatile Nature of Advanced Thermoplastics

Advanced thermoplastics have emerged as a cornerstone in modern engineering, offering a myriad of solutions across diverse sectors. Within this realm, one particular polymer stands out for its remarkable attributes, serving as a cornerstone for innovation and advancement. Through a meticulous examination of its properties and performance metrics, we uncover the vast potential inherent within this material.

Exploring Applications Across Industries

From automotive components to electronic enclosures, the applications of this resilient polymer span a wide spectrum of industries. Its ability to withstand harsh environments, coupled with its optical clarity and high impact resistance, renders it indispensable in numerous contexts. By elucidating its diverse applications and highlighting its exceptional qualities, we illuminate the path toward harnessing its full potential.

Discovering the Versatility of Makrolon 2805: Essential Characteristics and Applications

In this section, we delve into the multifaceted world of a cutting-edge polymer renowned for its exceptional versatility and wide-ranging applications. Exploring the fundamental properties and diverse uses of this material offers valuable insights into its significance across various industries.

Key Properties:

- High Impact Resistance

- Outstanding Optical Clarity

- Exceptional Thermal Stability

- Superior Chemical Resistance

- Excellent Dimensional Stability

These remarkable properties collectively contribute to the unmatched performance and reliability of this polymer in demanding environments, ensuring optimal functionality and longevity in diverse applications.

Applications:

- Automotive Components

- Electronic Enclosures

- Medical Devices

- Architectural Glazing

- Sports Equipment

From enhancing safety in automotive structures to facilitating precision in medical instruments, the adaptability of this polymer fosters innovation and drives progress across a spectrum of industries, underscoring its indispensable role in modern manufacturing and design.

Optimizing Performance: Understanding Processing Guidelines and Recommendations

In the pursuit of enhancing performance and efficiency in working with advanced materials, it is crucial to delve into the intricacies of processing methods and recommendations. This section aims to elucidate the fundamental principles underlying optimal performance, offering insights into effective strategies and prudent guidelines.

Exploring the nuances of processing techniques unveils a realm where meticulous attention to detail and adherence to recommended practices become paramount. By comprehending the intricacies of material behavior under various processing conditions, manufacturers can fine-tune their approaches to achieve optimal results.

Effective utilization of processing guidelines necessitates a holistic understanding of the interplay between temperature, pressure, and time, among other variables. Delving into these dynamics empowers practitioners to navigate through challenges and capitalize on opportunities for enhanced performance.

Furthermore, embracing a proactive stance towards optimization involves continual refinement of methodologies and adaptation to evolving best practices. Through a combination of empirical observation and theoretical understanding, stakeholders can unlock the full potential of their endeavors.

Ensuring Safety and Compliance: Regulatory Considerations for High-Performance Polymer

In this section, we delve into the crucial aspect of ensuring safety and compliance when utilizing cutting-edge polymer materials like the one under discussion. Understanding and adhering to regulatory frameworks is paramount in guaranteeing the integrity and safety of products across various industries.

| Regulatory Body | Relevance | Key Considerations |

|---|---|---|

| Environmental Protection Agency (EPA) | Environmental Impact | Assessment of environmental impact, including factors such as recyclability and biodegradability. |

| Occupational Safety and Health Administration (OSHA) | Workplace Safety | Ensuring safe handling procedures, employee training, and exposure limits. |

| Food and Drug Administration (FDA) | Product Safety | Verification of material suitability for food contact applications, compliance with FDA regulations. |

| Consumer Product Safety Commission (CPSC) | Consumer Safety | Evaluation of potential hazards to consumers, including toxicity and flammability. |

| International Organization for Standardization (ISO) | Global Standards | Conformance to international standards such as ISO 10993 for biocompatibility. |

By addressing these regulatory considerations diligently, manufacturers and end-users can confidently integrate high-performance polymers into their products, ensuring both safety and compliance with industry standards.