Embark on a journey into the realm of innovative engineering, where the synergy of intricate components propels modern technology forward. Delve into the realm of motion control, where tiny yet mighty devices propel progress with each calculated step. Explore the intricacies of a certain petite dynamo, whose silent revolutions underscore its significance in various applications. Discover the artistry in motion through the prism of precision engineering.

In the realm of mechanical mastery, certain diminutive marvels stand as silent sentinels of progress, orchestrating movements with surgical precision. Within the intricate dance of gears and coils lies a testament to human ingenuity, where each rotation heralds a symphony of functionality. This article embarks on a voyage to uncover the enigmatic allure of a particular compact contrivance, whose understated presence belies its profound impact.

Within the heartbeat of technological innovation lies a world where meticulous design meets relentless efficiency. Journey alongside as we unravel the mysteries of a diminutive dynamo, an unsung hero in the realm of precision mechanics. Witness the fusion of art and science as we dissect the anatomy of motion, offering insights into the nuanced workings of this unassuming yet indispensable component.

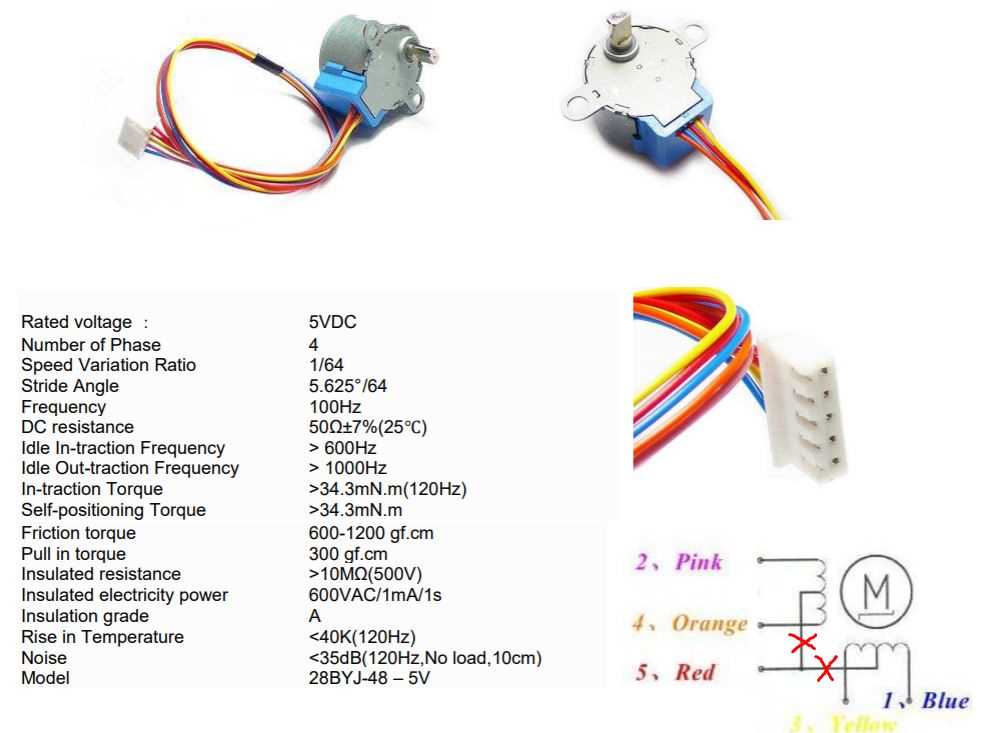

Understanding the 28BYJ-48 12V Stepper Motor Datasheet

In delving into the specifications of this particular electromechanical component, we embark on a journey to unravel the intricacies encapsulated within its documentation. Here, we explore the blueprint that guides our comprehension of its capabilities, characteristics, and operational parameters, providing a roadmap for its effective integration and utilization.

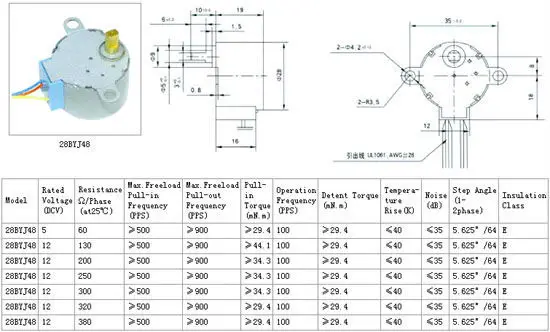

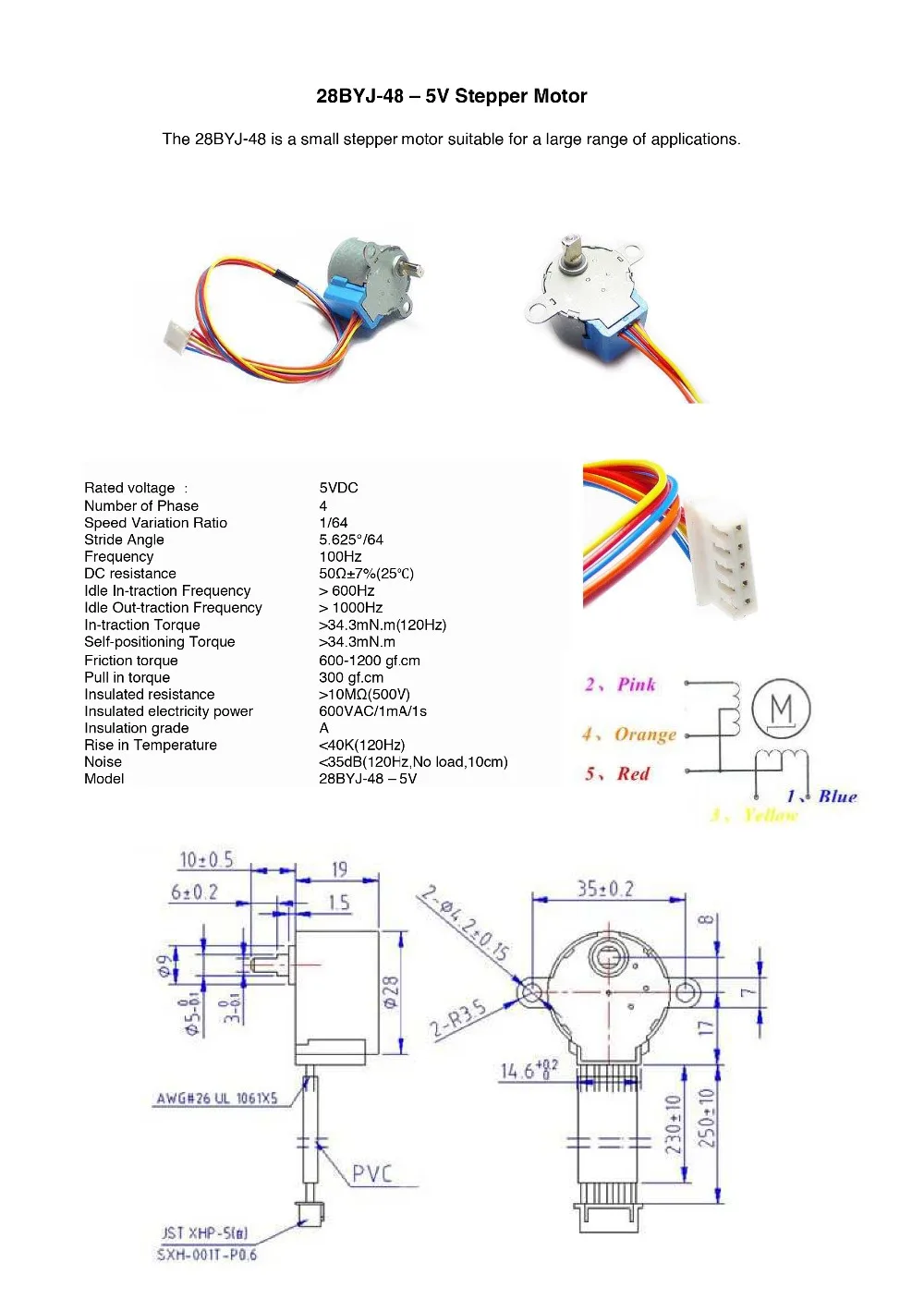

Key Specifications Overview

Embarking on our exploration, we first encounter a comprehensive overview of the fundamental specifications governing the performance of this device. Through an examination of its electrical, mechanical, and operational characteristics, we gain insight into its potential applications and limitations.

Interpreting Performance Metrics

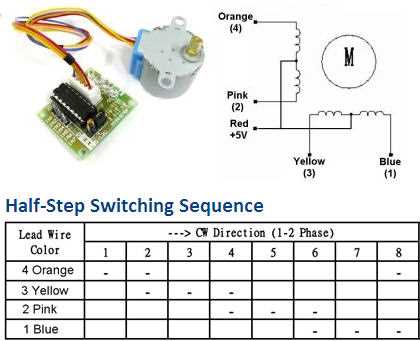

As we navigate through the labyrinth of technical data, we encounter an array of performance metrics delineating the motor’s efficacy in various scenarios. From torque curves to step resolution, each metric unveils a facet of its functionality, empowering us to optimize its performance within our projects.

- Electrical Parameters: Voltage, Current, and Resistance

- Mechanical Characteristics: Torque, Step Angle, and Holding Torque

- Operational Specifications: Speed, Duty Cycle, and Temperature Range

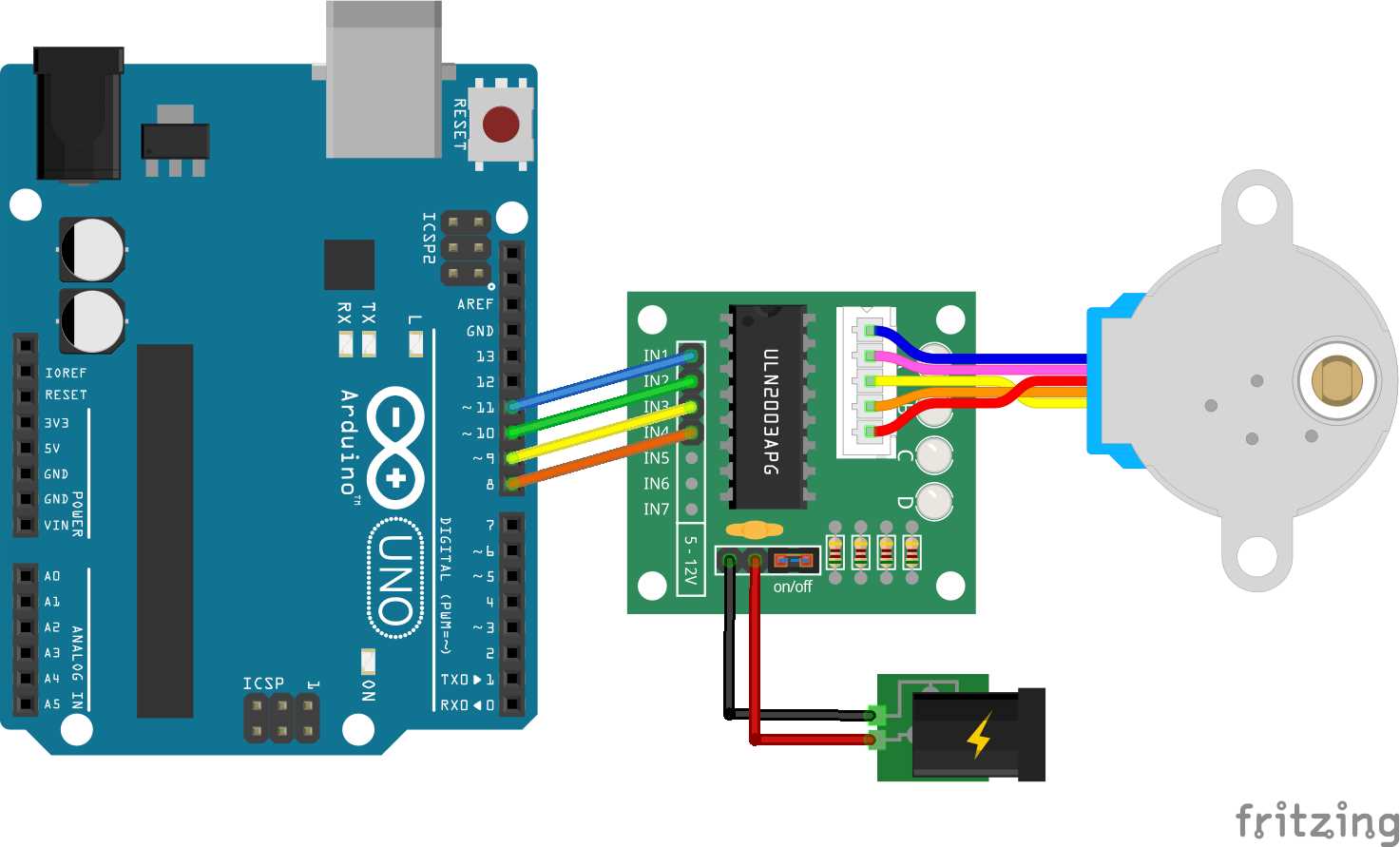

Exploring Technical Specifications and Pinout

In this section, we delve into the intricate details and pin configurations of the device under scrutiny, shedding light on its operational intricacies and connectivity. Through a meticulous examination of its technical specifications and pinout arrangement, we aim to unveil the underlying mechanisms and functional intricacies.

Technical Specifications Overview

Before delving into the specifics of pinout configurations, it is imperative to grasp the fundamental technical specifications governing the device’s performance. These specifications encompass a range of parameters, including electrical characteristics, operational limits, and performance metrics. By comprehensively understanding these specifications, one can gain insight into the device’s capabilities and limitations, facilitating informed decision-making in its utilization.

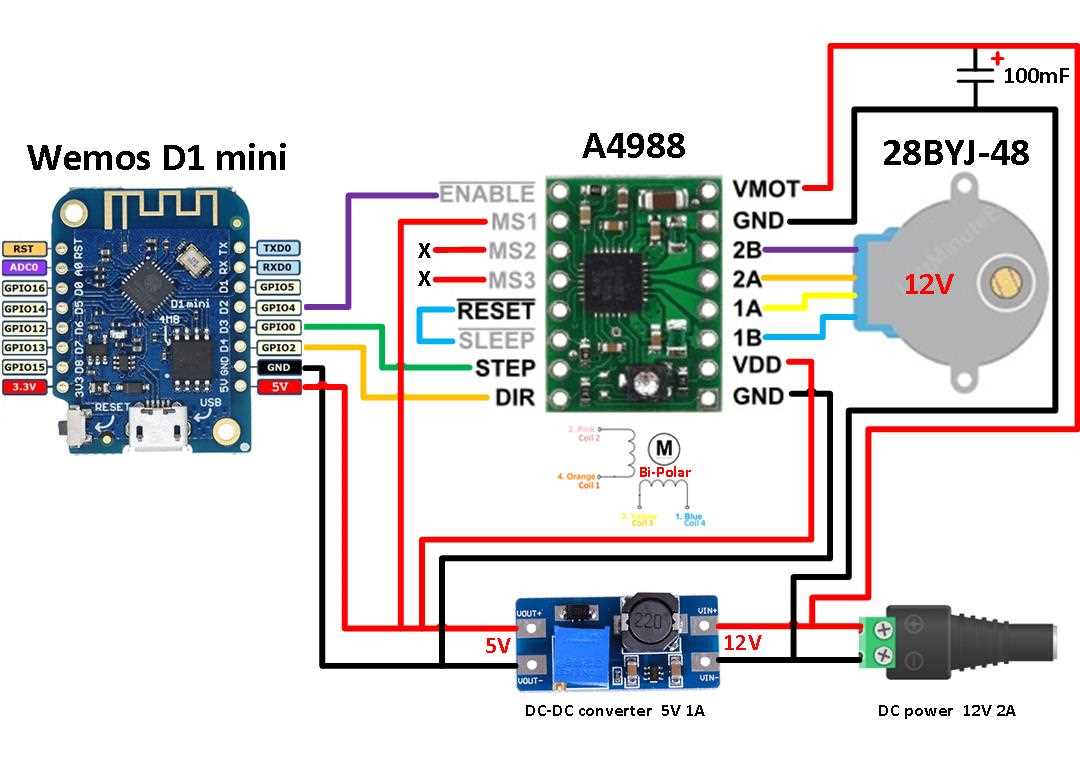

Pinout Configuration

The pinout configuration of the device delineates the arrangement and functionality of its various pins, elucidating how external components interface with it. Each pin serves a distinct purpose, ranging from power supply input to signal output and control functionalities. Understanding the pinout configuration is paramount for integrating the device into larger systems effectively and ensuring seamless interoperability.

Applications and Integration in DIY Projects

Exploring the versatility and adaptability of this miniature electromechanical component opens up a realm of possibilities for DIY enthusiasts and hobbyists. Its integration in various creative projects showcases its potential beyond conventional applications.

| Application | Integration |

|---|---|

| Robotics | Integrating the component into robotic arms and platforms enables precise movement control, enhancing functionality in tasks ranging from simple automation to complex maneuvers. |

| 3D Printing | Utilizing the motor in the mechanism for extruder and bed movement facilitates the precise positioning required for accurate layer deposition, improving print quality. |

| CNC Machining | Incorporating the motor into CNC machines allows for controlled movement of cutting tools and workpieces, enhancing accuracy and repeatability in machining operations. |

| Camera Slider | Implementing the motor in a camera slider setup enables smooth and programmable camera movements, adding cinematic effects to video footage and time-lapse photography. |

| Automated Gardening | Integrating the motor into irrigation systems and plant monitoring devices facilitates automated watering and maintenance routines, optimizing plant health and growth. |

These examples merely scratch the surface of the myriad applications and integration possibilities of this versatile component. Its affordability, compact size, and compatibility with various control systems make it a valuable asset in the toolkit of DIY enthusiasts, fostering innovation and creativity in projects across diverse domains.

Tips for Optimizing Control and Operation

Enhancing the management and performance of your motor system involves a series of strategic approaches. By refining your control techniques and operational methods, you can unlock the full potential of your equipment.

- Utilize Precision Techniques: Employ precise methodologies to streamline control mechanisms and operational procedures.

- Maximize Efficiency: Strive to achieve optimal efficiency levels by fine-tuning control algorithms and operational parameters.

- Implement Smart Strategies: Integrate intelligent strategies to enhance the responsiveness and accuracy of motor control.

- Focus on Seamless Integration: Ensure seamless integration of control systems with the broader operational framework to facilitate smooth functionality.

- Embrace Agile Practices: Embrace agile practices to adapt swiftly to changing operational requirements and optimize motor performance accordingly.

By adhering to these principles and refining your approach to control and operation, you can elevate the efficiency and effectiveness of your motor system, contributing to enhanced overall performance.