In the realm of electronic motor control, lies a crucial document that serves as the compass for engineers navigating the intricate seas of circuit design. This foundational manuscript, akin to a map of technological territories, unveils the inner workings of a pivotal component, guiding the hands of creators toward the realization of their electrifying visions.

Within its pages, one discovers the intricate dance of electrons, choreographed to propel machinery with precision and power. It reveals the secrets behind the orchestration of motion, elucidating the pathways through which commands translate into kinetic marvels. This document, a tapestry woven with symbols and schematics, holds the promise of unlocking the gates to a realm where innovation reigns supreme.

Delve deeper, and witness the symphony of signals orchestrated by this unseen conductor, shaping the very fabric of motion. Through the lens of this manuscript, the curious mind is invited to decipher the language of motors, decoding the whispers of current and voltage into a symphony of movement. Thus, armed with knowledge, the intrepid explorer embarks on a journey toward mastery, fueled by the insights gleaned from this sacred scroll.

The Functionality of Motor Control IC

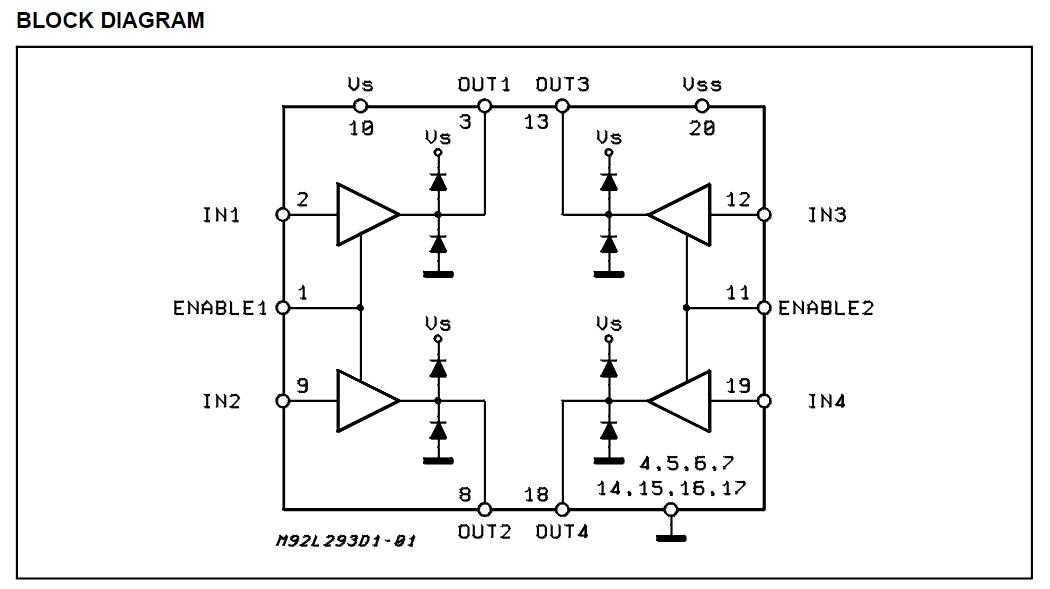

Within the realm of motor control technology lies a crucial component, often referred to as the backbone of motor control systems. This component facilitates the seamless interaction between digital circuits and motors, ensuring efficient power management and precise control over motor operations. Delving into the functionality of this integral device unveils its pivotal role in driving motors, regulating speed, and managing directionality.

The Essence of Motor Control

At the core of motor control lies the need for a reliable interface between electronic systems and mechanical motion. This interface dictates the manner in which power is delivered to motors, orchestrating the synchronized movement essential for various applications. By understanding the fundamental principles governing motor control, one can appreciate the significance of the intricate mechanisms embedded within.

Enabling Precision and Flexibility

Efficient motor control demands precision and flexibility, attributes seamlessly embodied within this essential component. Through sophisticated circuitry and intelligent design, it empowers engineers to tailor motor operations to specific requirements, whether it be speed modulation, direction reversal, or torque regulation. This level of customization ensures optimal performance across diverse applications, from robotics to automotive systems.

Understanding the Key Features

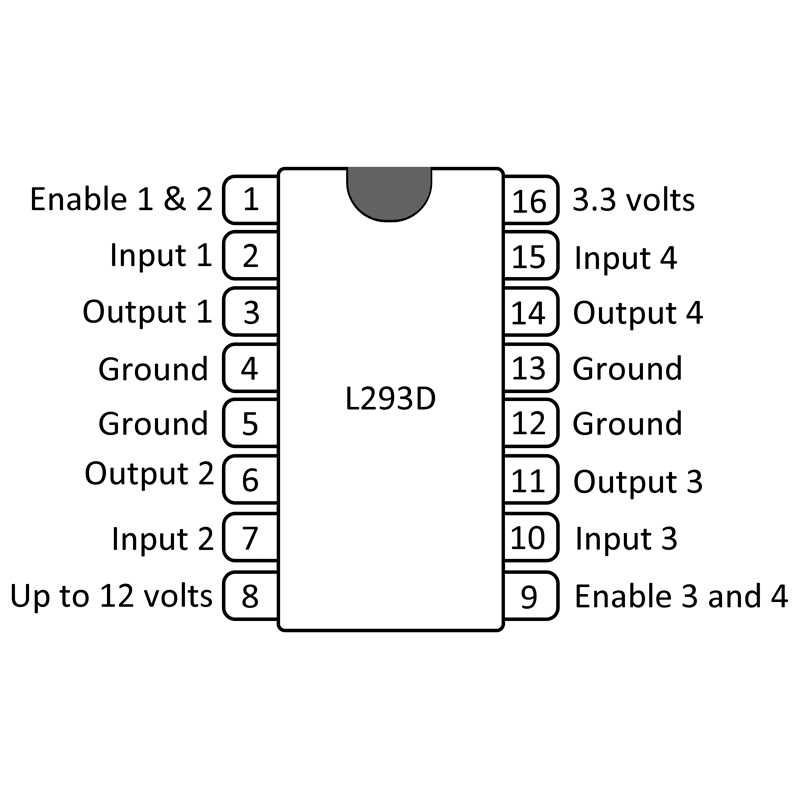

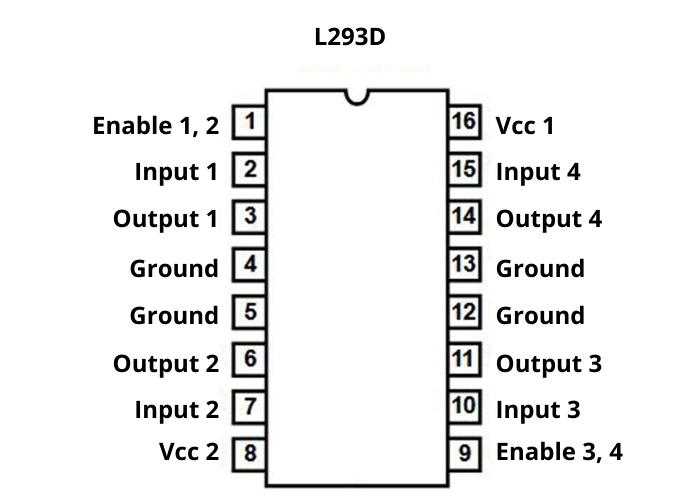

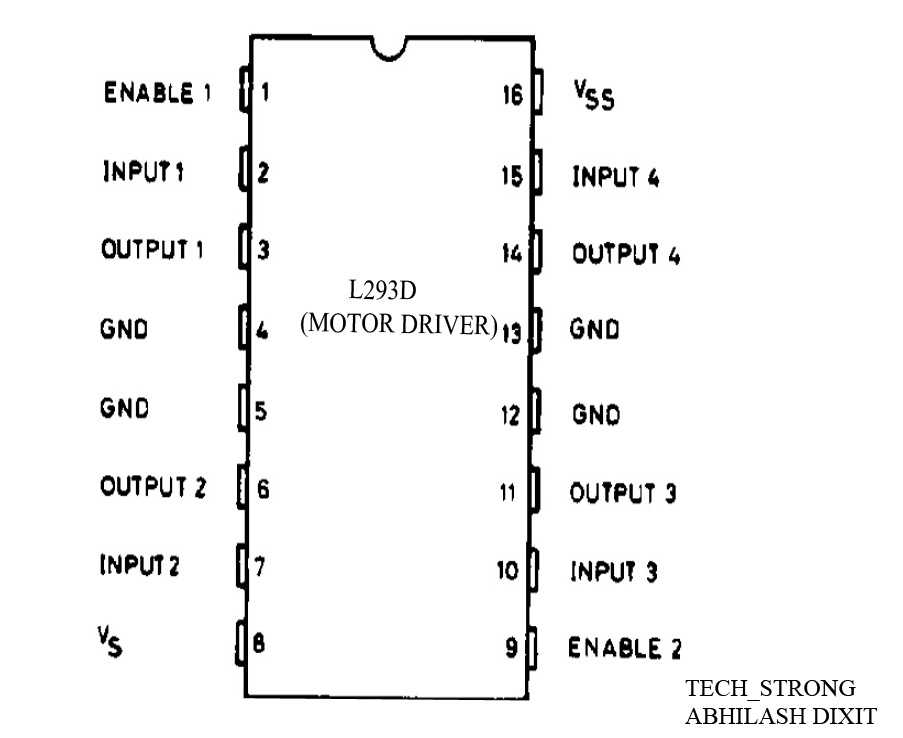

In delving into the intricacies of this component’s specifications, it’s imperative to grasp the fundamental elements that distinguish its functionality. This section elucidates the core characteristics, shedding light on its operational nuances and capabilities.

1. Performance Attributes

Within the realm of electronic control, discerning the performance benchmarks is paramount. Unveiling the nuances of its efficiency, reliability, and adaptability unveils a comprehensive understanding of its potential applications.

2. Functional Capacities

Beyond mere technical specifications lie the functional capacities that define its utility. Exploring its operational range, input-output configurations, and protective features elucidates its versatility and applicability across diverse scenarios.

Applications and Implementations of L293D

In this section, we explore the diverse array of applications and practical uses of the versatile L293D integrated circuit. From robotics to motor control systems, the L293D finds its utility in a multitude of electronic projects, owing to its ability to efficiently drive and control various loads.

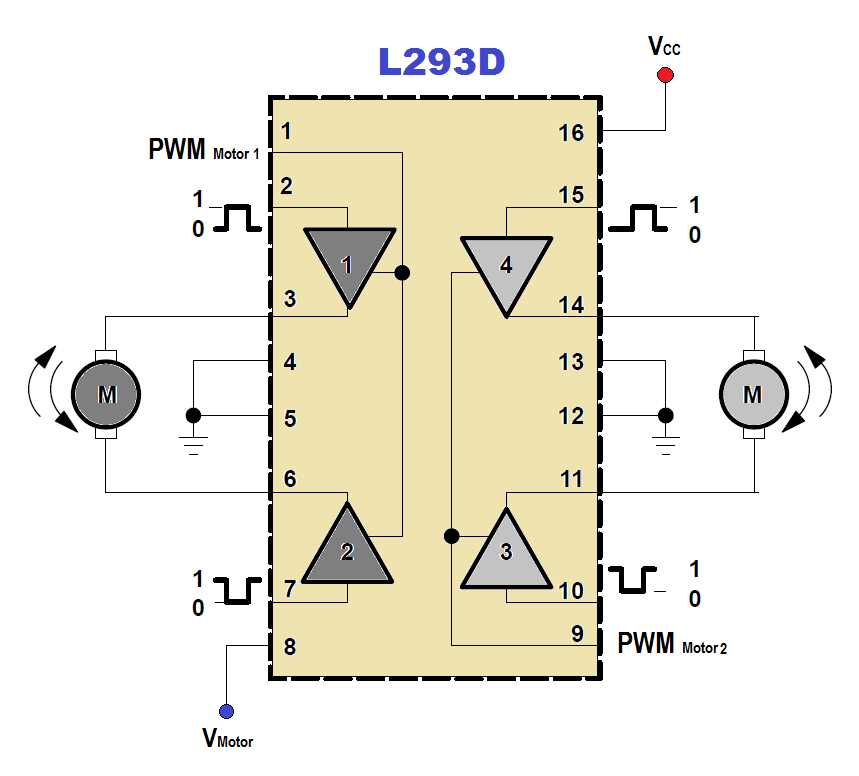

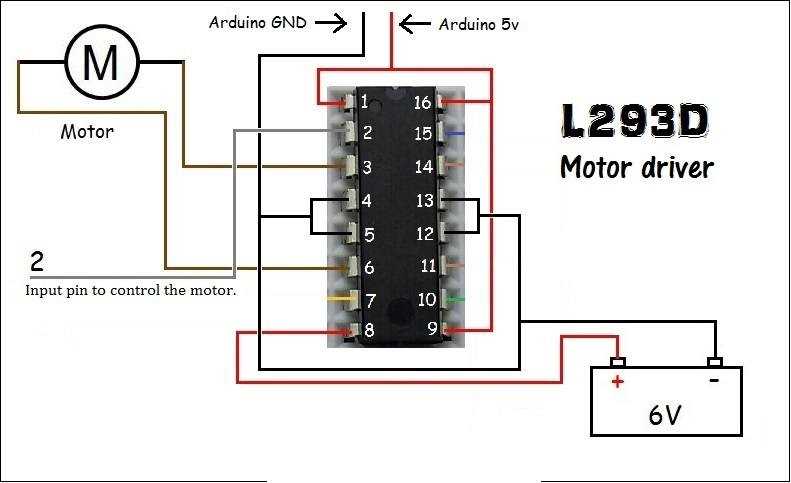

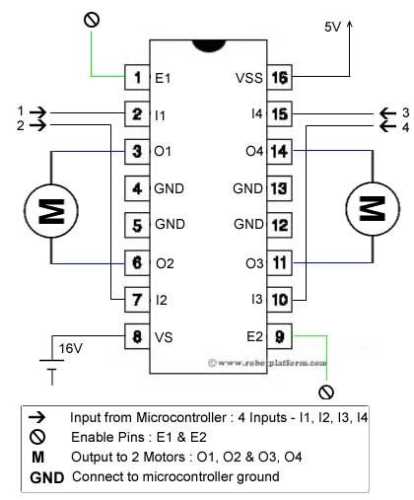

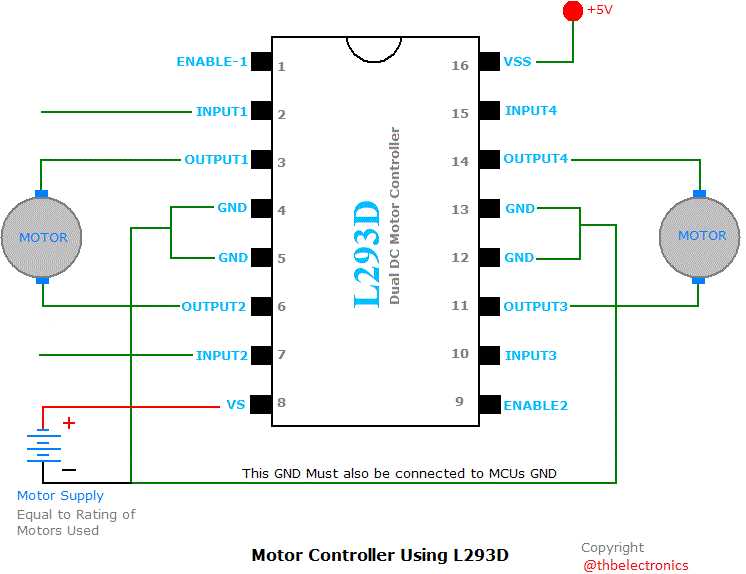

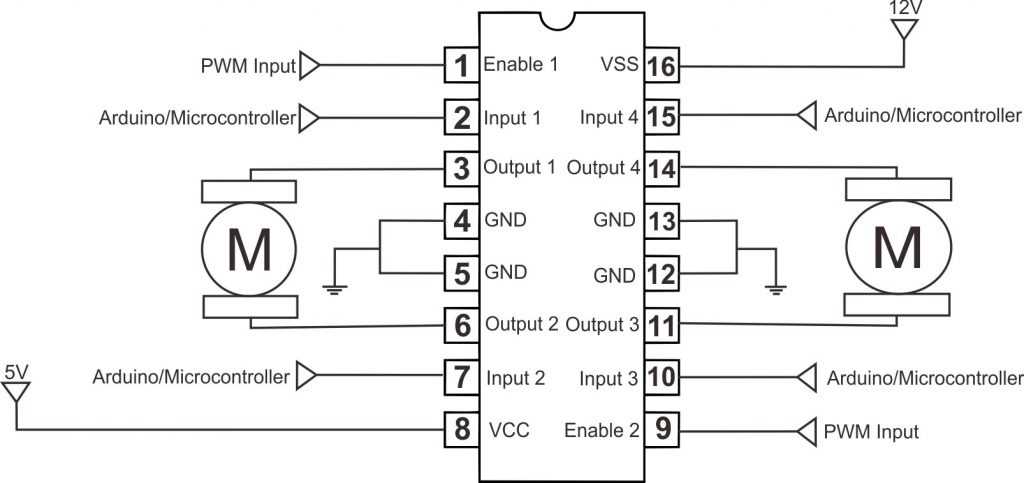

Motor Control Systems

One of the primary applications of the L293D lies in motor control systems, where it serves as a crucial component for driving and controlling DC motors. Whether in small-scale hobbyist projects or industrial applications, the L293D facilitates precise motor control, enabling smooth operation and maneuverability.

- Robotics: The L293D plays a pivotal role in robotics applications, powering the movement of robotic arms, wheels, and other mechanical components. Its dual H-bridge configuration allows for bi-directional control of motors, essential for precise navigation and manipulation tasks.

- Automotive Electronics: In automotive electronics, the L293D contributes to functions such as power window control, mirror adjustment, and motorized seat adjustments. Its robust design and ability to handle moderate current loads make it suitable for automotive applications requiring reliable motor control.

Embedded Systems

Beyond motor control, the versatility of the L293D extends to embedded systems, where it facilitates the integration of various electromechanical components into electronic projects.

- Home Automation: Incorporating the L293D into home automation systems enables the remote control of appliances such as curtains, blinds, and door locks. By interfacing with microcontrollers or other control units, the L293D empowers users to automate routine tasks and enhance convenience.

- Industrial Automation: In industrial settings, the L293D finds application in conveyor belt systems, robotic arms, and other automated machinery. Its ability to interface with microcontrollers and sensors enables precise control over industrial processes, improving efficiency and productivity.

Overall, the L293D’s versatility and reliability make it an indispensable component in various electronic applications, ranging from hobbyist projects to industrial automation systems.

Exploring Real-world Usage Scenarios

In this section, we delve into various practical applications and contexts where the functionalities of the component in question prove indispensable. From automotive systems to robotics, the versatility of this device finds expression in a myriad of real-world scenarios.

Automotive Systems Integration

One prevalent application of this component lies in automotive systems integration, where it facilitates precise motor control for tasks ranging from power windows to windshield wipers. Its robust design ensures reliable performance even in demanding environments, making it a cornerstone in modern vehicle electronics.

Robotics and Automation

Furthermore, in the realm of robotics and automation, the utilization of this technology extends to intricate motion control mechanisms. Whether it’s steering mechanisms in unmanned aerial vehicles or articulation in robotic arms, the component offers seamless integration and precise control, enhancing the efficiency and accuracy of various automated processes.

- Industrial machinery control systems

- Home automation projects

- IoT device development

These are just a few examples of the diverse array of applications where the capabilities of this component are leveraged to achieve innovative solutions across different industries and domains.

Troubleshooting and Tips for Seamless Integration of the L293D Chip

When incorporating the venerable L293D integrated circuit into your projects, encountering challenges is not uncommon. However, with careful attention to certain key aspects, you can streamline the integration process and ensure optimal performance without frustration. This section aims to provide insightful troubleshooting tips and practical advice to enhance your experience with this versatile motor driver.

Understanding Power Requirements

1. Voltage Regulation: One of the primary issues often encountered relates to improper voltage regulation. Ensure that the input voltage remains within the specified range to prevent overheating and potential damage to the chip. Implementing voltage regulators or appropriate power management circuits can help maintain stability.

Addressing Heat Dissipation

2. Thermal Management: Heat dissipation poses a significant concern, particularly during prolonged use or when driving high-current loads. Integrating heat sinks or employing cooling fans can mitigate overheating issues and prolong the lifespan of the L293D chip. Additionally, optimizing PCB layout to facilitate efficient heat dissipation is paramount.

3. Current Limiting: Exceeding the maximum current ratings of the L293D chip can lead to thermal runaway and performance degradation. Implementing current-limiting measures, such as using external resistors or current-sensing circuits, can prevent excessive current flow and safeguard the integrity of the chip.

By adhering to these troubleshooting guidelines and leveraging the provided tips, you can overcome common challenges associated with integrating the L293D chip into your projects. Remember to prioritize proper power management, address heat dissipation concerns, and implement effective current-limiting measures to ensure seamless operation and optimal performance.