Have you ever wondered about the capabilities of the revolutionary Kuka kr 30-3 robot? In this article, we will delve into the extensive range of features and functions offered by this powerful industrial robot arm. By understanding its specifications, we can gain a deeper insight into its potential applications in various industries.

The Kuka kr 30-3 robot boasts remarkable versatility, making it a valuable asset in an array of manufacturing and production settings. Equipped with cutting-edge technology, this advanced robotic arm combines precision, reliability, and speed to deliver top-notch performance. With its sleek design and state-of-the-art features, it is no wonder that the Kuka kr 30-3 is highly sought after in today’s ever-evolving industrial landscape.

One of the standout qualities of the Kuka kr 30-3 is its exceptional payload capacity. With the ability to handle heavy loads with ease, this robot arm proves to be a reliable partner in demanding tasks. Its robust construction ensures stability and accuracy, allowing for precise and efficient maneuvering of objects. Whether it’s lifting, manipulating, or assembling, the Kuka kr 30-3 excels in handling various materials and components, making it an invaluable asset in production lines.

Furthermore, the Kuka kr 30-3 is equipped with advanced control systems that enable seamless integration with existing manufacturing processes. Its user-friendly interface allows for straightforward programming, contributing to a streamlined workflow and enhanced productivity. The robot’s versatility is further enhanced by its compatibility with a range of end-of-arm tools, enabling it to perform a wide range of tasks with precision and efficiency.

KUKA KR 30-3: Overview and Features

In this section, we will provide an in-depth overview of the KUKA KR 30-3 robot and highlight its noteworthy features. This high-performance robotic system offers advanced capabilities and cutting-edge technology with its exceptional range of functionalities. By examining the various components and specifications, we will explore the vast potential and versatility of the KUKA KR 30-3.

With its state-of-the-art design and innovative engineering, the KUKA KR 30-3 demonstrates outstanding performance in industrial automation. Powered by advanced algorithms and intelligent control systems, this robot combines precision, efficiency, and reliability to meet the ever-evolving demands of modern manufacturing processes.

One of the notable features of the KUKA KR 30-3 is its impressive payload capacity, enabling it to handle heavy-duty tasks effortlessly. This ensures enhanced productivity, allowing the robot to seamlessly manipulate various objects and materials, exhibiting exceptional strength and stability.

Moreover, the KUKA KR 30-3 is equipped with advanced sensing technologies, enabling it to perceive its surroundings accurately. This enhances its ability to interact with the environment, making it suitable for intricate and complex operations. The robot’s precise sensing capabilities enable it to adapt to dynamic situations, ensuring optimal performance and safety.

Furthermore, the KUKA KR 30-3 boasts an intuitive user interface, facilitating easy programming and operation. Its user-friendly interface enables operators to quickly and efficiently command the robot, reducing setup time and increasing efficiency. This simplifies the integration of the KUKA KR 30-3 into existing manufacturing systems and allows for seamless collaboration between humans and robots.

In conclusion, the KUKA KR 30-3 is a powerful and versatile robotic system that offers exceptional performance, advanced sensing capabilities, and a user-friendly interface. With its remarkable features and capabilities, this robot is well-suited for a wide range of industrial applications, providing efficiency, precision, and reliability in every operation.

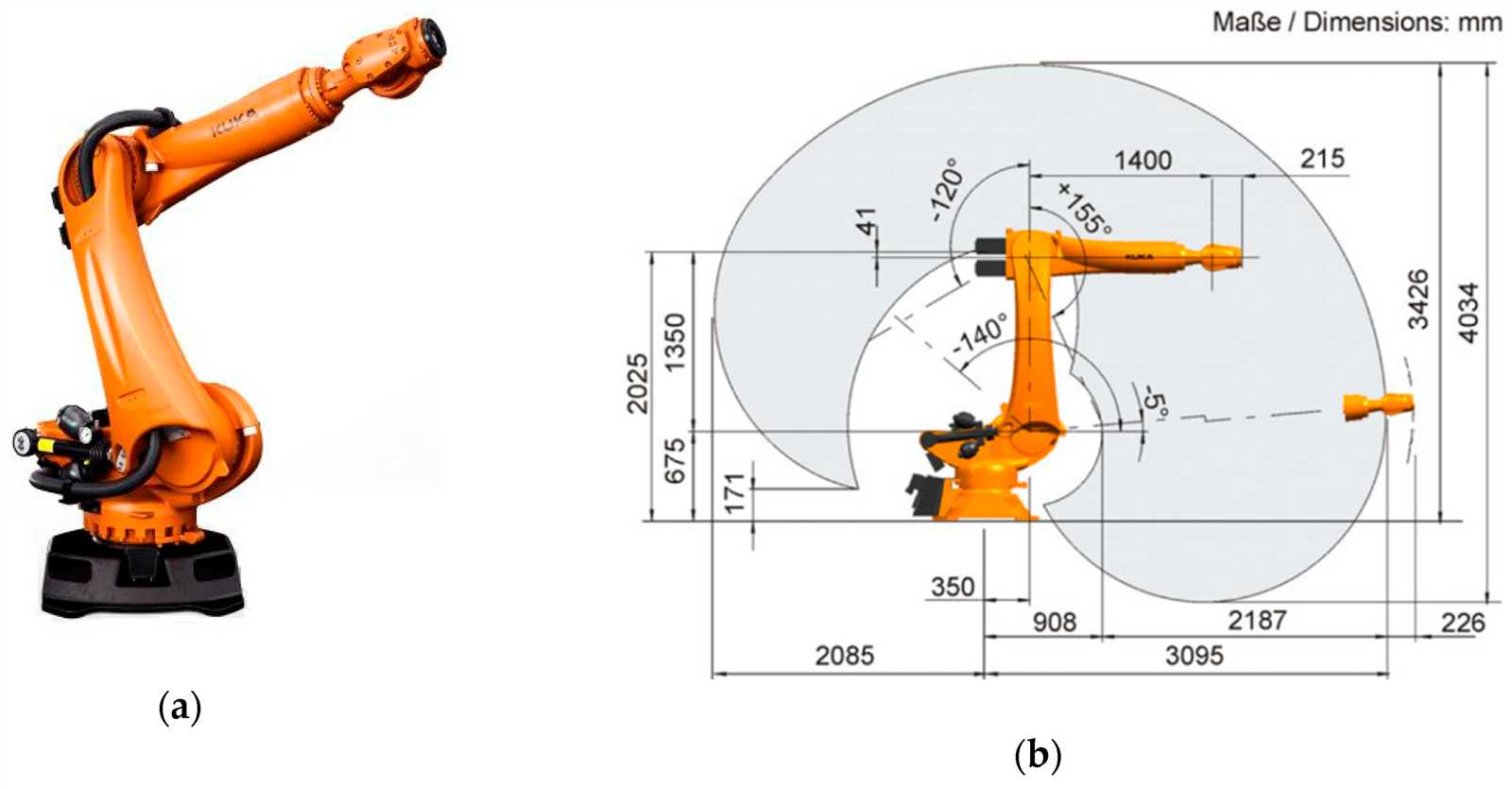

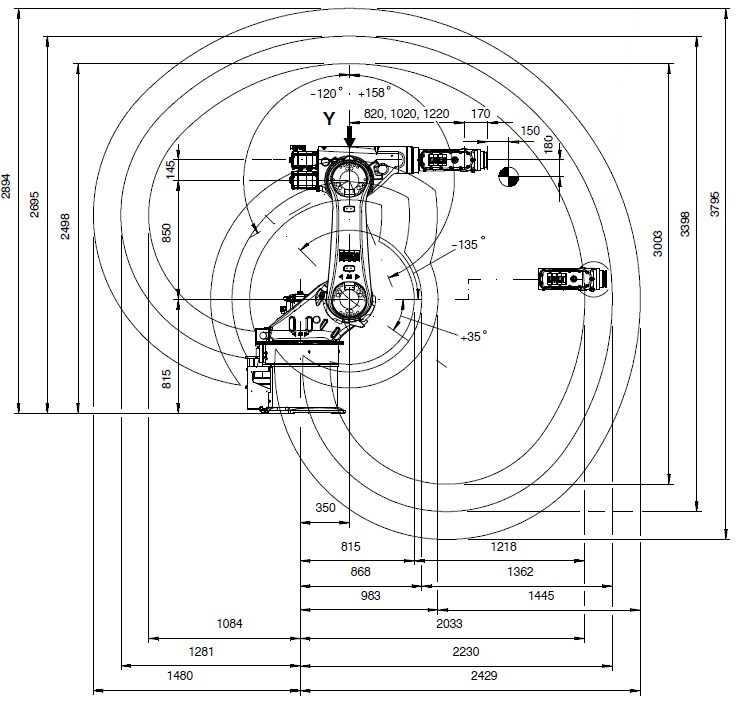

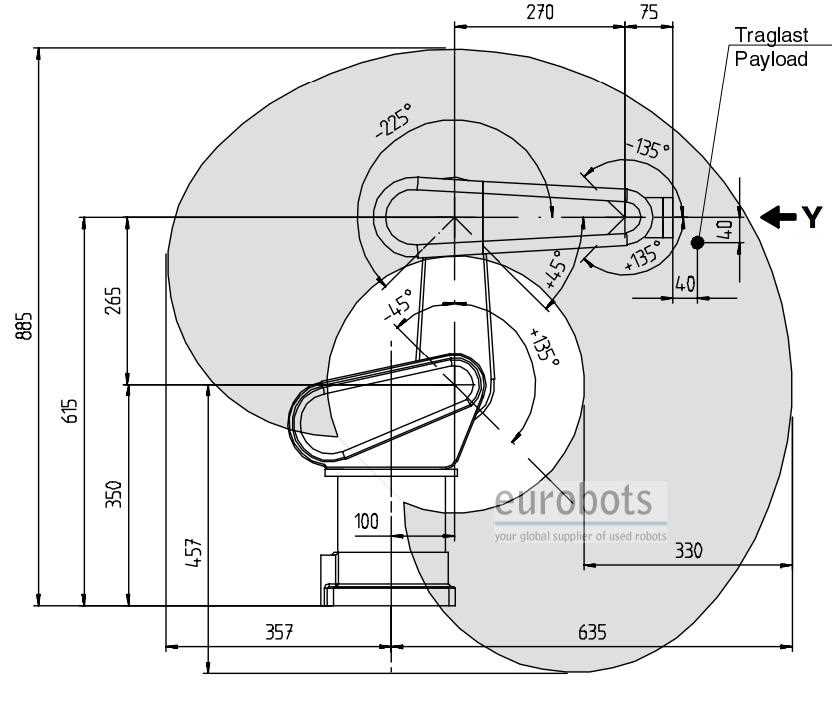

Exploring the Key Specifications of KUKA KR 30-3

In this section, we will delve into the important technical details of the KUKA KR 30-3 industrial robot, showcasing its remarkable capabilities and features. Through an extensive exploration of its key specifications, we aim to provide a comprehensive understanding of the robot’s performance and functionality, offering valuable insights for potential users and enthusiasts.

1. Precision and Accuracy

One of the notable aspects of the KUKA KR 30-3 is its exceptional precision and accuracy. The robot’s advanced sensors and calibration systems enable it to perform highly precise movements and execute tasks with utmost accuracy. With its precise repeatability and minimal deviation, the KR 30-3 ensures consistent and reliable results, making it an ideal solution for various industrial applications.

2. Payload Capacity and Reach

Another key specification of the KUKA KR 30-3 is its impressive payload capacity and reach. With a maximum payload of [insert specific weight] and a reach of [insert specific distance], this robot offers substantial flexibility and efficiency in handling various objects and materials. Whether it is lifting, stacking, or manipulating heavy loads, the KR 30-3 provides exceptional performance and versatility, enabling seamless integration into industrial production lines.

Benefits and Applications of KUKA KR 30-3

The KUKA KR 30-3 robot offers a wide range of advantages and applications in various industries. This versatile robotic solution combines efficiency, precision, and flexibility, making it suitable for diverse tasks across sectors.

Precision and Accuracy

One of the key benefits of the KUKA KR 30-3 is its exceptional precision and accuracy. With advanced motion control systems and high-resolution sensors, this robot ensures precise movements even in complex tasks. It allows for precise positioning, repetitive actions, and delicate operations, making it ideal for applications that demand accuracy, such as assembly, welding, and quality control.

Increased Productivity and Efficiency

The KUKA KR 30-3 robot provides a significant boost in productivity and efficiency for industrial operations. Equipped with advanced automation features and intelligent control systems, it can streamline production processes, reduce cycle times, and minimize errors. With its fast and reliable performance, this robot optimizes workflows, enhances output rates, and enables businesses to achieve higher levels of productivity.

- Assembly: The KUKA KR 30-3 can efficiently handle assembly tasks, whether it’s in the automotive industry for installing components or in electronics manufacturing for precise soldering and delicate part handling.

- Welding: With its high precision and stability, this robot is widely used for various welding applications, including spot welding, arc welding, and laser welding. Its flexibility allows for easy adaptation to different workpieces and welding processes.

- Packaging and Palletizing: The KUKA KR 30-3 excels in handling packaging tasks, such as picking, placing, and palletizing products. It ensures reliable and efficient operation, making it suitable for industries such as food and beverage, logistics, and pharmaceuticals.

- Quality Control: The robot’s precise movements and advanced sensing capabilities enable it to perform accurate quality control inspections. It can quickly detect defects or variations, ensuring products meet the highest standards.

In conclusion, the KUKA KR 30-3 robot offers numerous benefits and applications across industries. Its precision, productivity enhancement, and versatility make it an invaluable asset for manufacturers looking to optimize their processes and improve overall efficiency.