Imagine a cutting-edge technology that revolutionizes the way you approach thermal imaging. Presenting the ultimate solution for professionals in need of precise temperature measurements and enhanced visual inspection capabilities. This groundbreaking innovation offers an unparalleled combination of accuracy, versatility, and reliability, tailored to meet the demands of various industries and applications.

Get ready to embark on a journey into the realm of thermal imaging excellence, where every detail matters. Unleash the power of advanced features that enable you to capture and analyze data like never before. With its unrivaled performance and user-friendly interface, this state-of-the-art solution provides a seamless experience that allows you to focus on what truly matters – achieving perfection in thermal inspections.

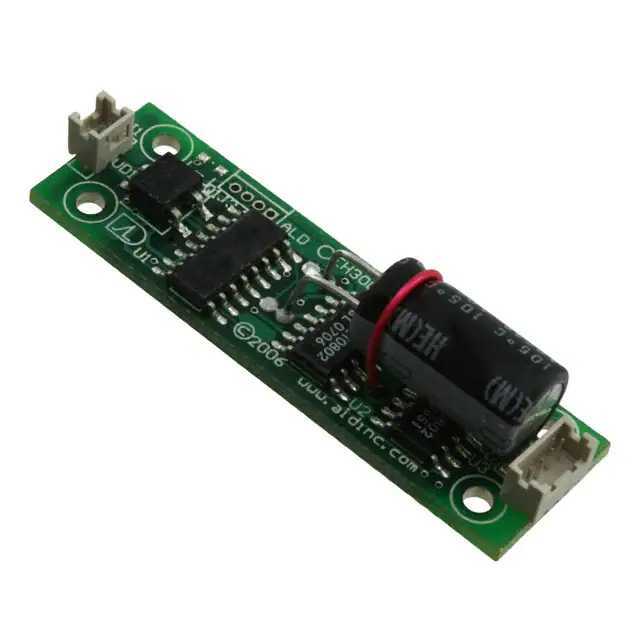

Experience the brilliance of cutting-edge technology packed into a sleek and compact design. This rugged and durable imaging device is ready to accompany you on any adventure, delivering accurate and dependable results every time. Its ergonomic design ensures comfortable handling, while its robust construction guarantees long-lasting performance in even the harshest environments.

Unlock a new world of possibilities with this remarkable thermal imaging solution. Whether you’re involved in building diagnostics, electrical inspections, or mechanical troubleshooting, this device is your ultimate companion, empowering you to make informed decisions with confidence. Don’t settle for anything less than the best in thermal imaging technology – embrace the future today.

Overview of the Flir a300 Datasheet

In this section, we will provide a comprehensive overview of the technical specifications and features found in the documentation for the Flir a300 thermal imaging camera. The datasheet offers a wealth of information regarding the capabilities and performance of this advanced imaging device. From the specifications to the operational details, this overview aims to provide a clear understanding of the Flir a300’s key attributes.

Technical Specifications

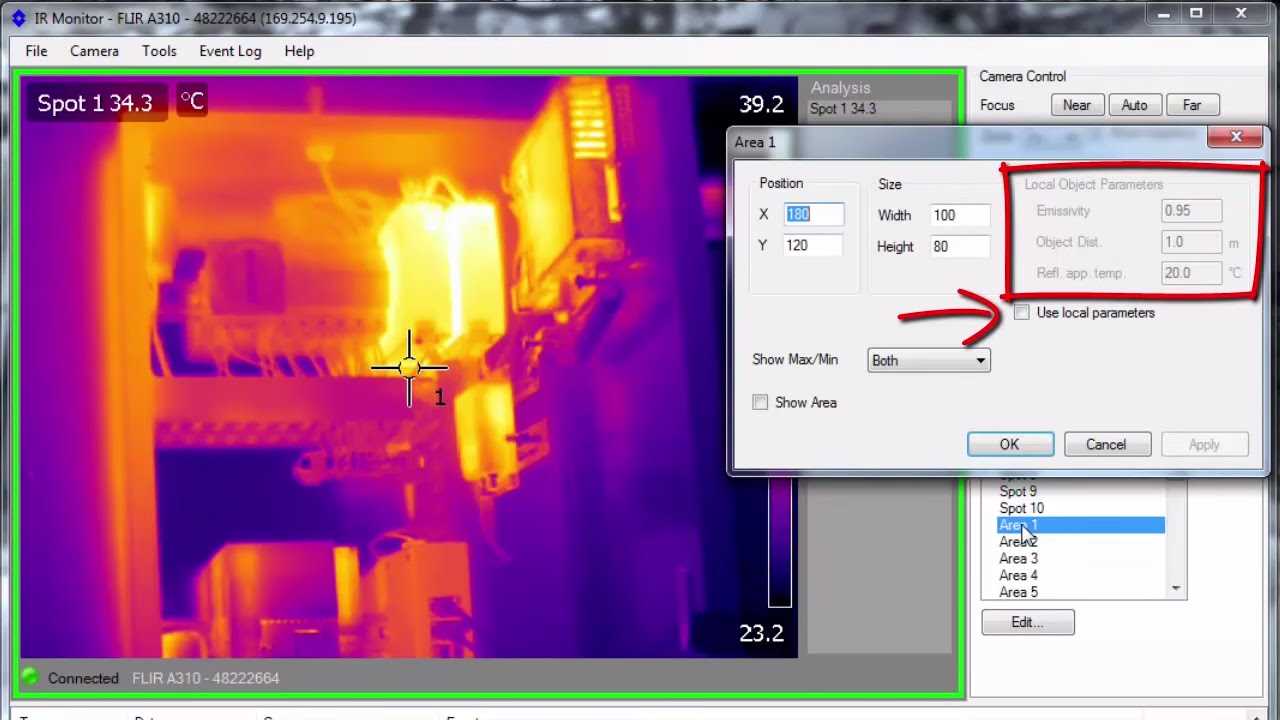

The Flir a300 datasheet begins with a detailed list of technical specifications. These specifications highlight the camera’s resolution, temperature measurement range, and accuracy, among other important parameters. In addition, the datasheet also provides information on aspects such as the camera’s frame rate, thermal sensitivity, and spectral range. By examining these specifications, users can determine if the Flir a300 is suited to their specific application requirements.

Features and Functionality

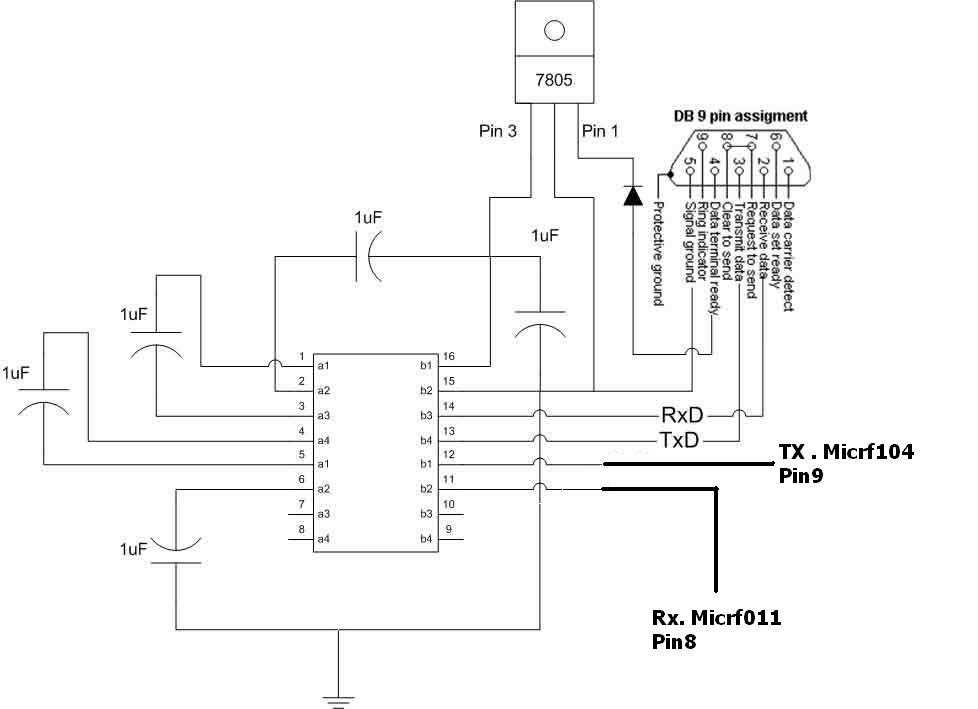

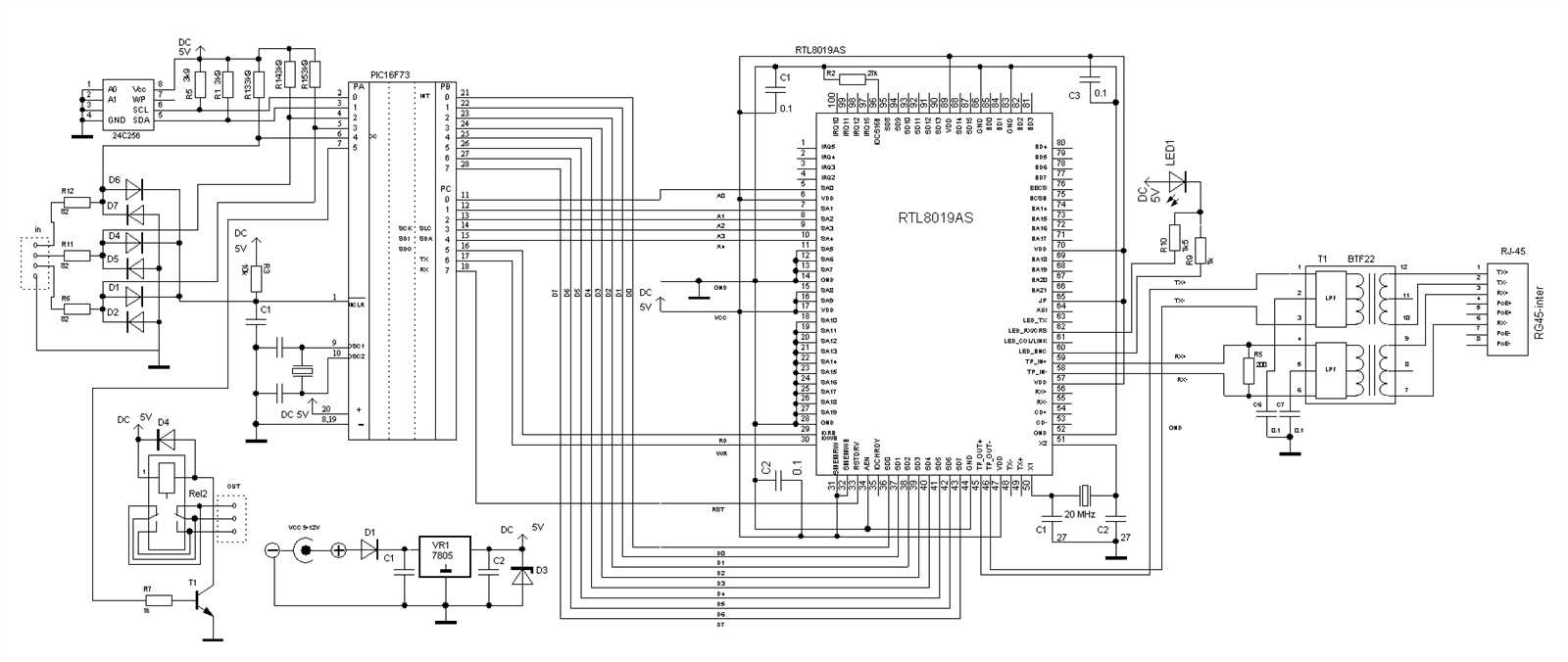

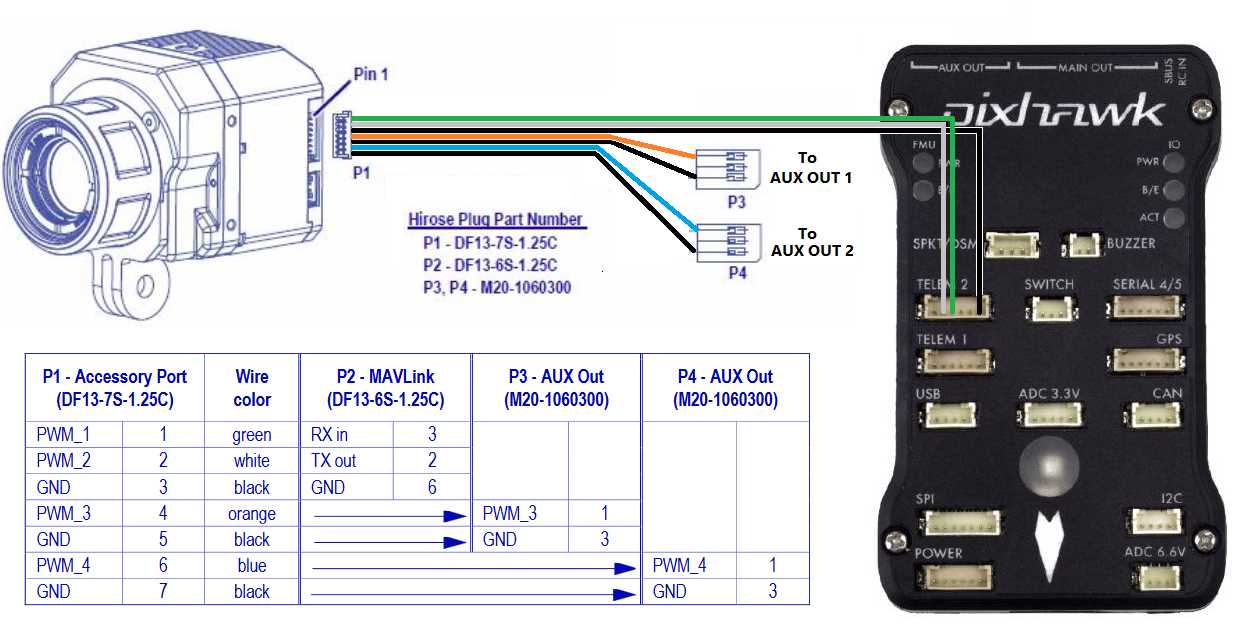

Aside from the technical specifications, the Flir a300 datasheet also presents an overview of the camera’s features and functionality. This section delves into the camera’s built-in analysis tools, such as spot meters and area measurement functions, which enable users to accurately assess temperature variations and identify potential issues. Furthermore, the datasheet explores the camera’s connectivity options and compatibility with external devices, providing insights into the seamless integration of the Flir a300 within existing systems.

| Table of Contents |

|---|

| 1. Introduction |

| 2. Technical Specifications |

| 3. Features and Functionality |

| 4. Sample Images |

| 5. Applications |

| 6. Conclusion |

Overall, the Flir a300 datasheet provides a comprehensive overview of the camera’s capabilities, allowing users to make informed decisions about its potential usage. By understanding the technical specifications, features, and functionality, individuals can determine whether the Flir a300 is the right thermal imaging camera for their specific needs.

Main Features

The Flir A300 datasheet showcases a range of distinctive features that make it a standout choice in the field of thermal imaging.

With its advanced technology and precision imaging capabilities, the Flir A300 offers unparalleled performance in capturing and analyzing thermal data. Its innovative design, combined with user-friendly features, ensures accurate and reliable results for a wide range of applications.

Efficiency is at the forefront of the Flir A300, allowing users to optimize their workflow and minimize downtime. Its high-resolution thermal camera produces clear and detailed images, enabling easy identification of potential issues or anomalies.

Equipped with state-of-the-art thermal sensors, the Flir A300 delivers exceptional thermal sensitivity and accuracy, ensuring precise temperature measurements in various environments. Its wide temperature range and adjustable emissivity offer flexibility in capturing thermal data across different materials and surfaces.

The Flir A300 also features a robust and durable construction, making it suitable for challenging working conditions. Its compact size and lightweight design enhance portability, allowing users to easily carry and operate the device in the field.

The Flir A300 datasheet showcases a range of distinctive features that make it a reliable and efficient tool for thermal imaging applications. From its high-resolution thermal camera to its advanced temperature measurement capabilities, the Flir A300 is a valuable asset for professionals in various industries.

High-Resolution Thermal Imaging

Thermal imaging technology has revolutionized various industries with its ability to detect and visualize heat signatures. In this section, we explore the concept of high-resolution thermal imaging and its applications in diverse fields.

Advancing Detection and Analysis

High-resolution thermal imaging leverages state-of-the-art sensors to capture infrared radiation emitted by objects. This technology allows for precise temperature measurements and the creation of detailed thermal images. By providing a clear view of thermal patterns, high-resolution thermal imaging enables accurate detection of anomalies or potential issues that may not be visible to the naked eye.

Applications Across Industries

The benefits of high-resolution thermal imaging extend to a wide range of industries. In the fields of electrical maintenance and inspection, it aids in identifying overheating components and potential electrical faults. In building inspections, it assists in detecting energy inefficiencies, water leaks, and insulation problems. High-resolution thermal imaging also finds applications in mechanical engineering, veterinary medicine, research, and development, enabling accurate temperature measurements and analysis.

With its ability to capture minute temperature variations, high-resolution thermal imaging offers a non-destructive and non-contact method for analyzing thermal patterns. Industries can harness this technology to enhance safety, improve efficiency, and prevent costly damages. By maximizing the potential of high-resolution thermal imaging, professionals can make informed decisions based on accurate thermal data, leading to optimized operations and enhanced performance.

As technology continues to advance, the use of high-resolution thermal imaging is becoming increasingly vital across various sectors. From predictive maintenance to quality control, this powerful tool equips professionals with the ability to identify potential issues and take proactive measures to minimize risks. In the next sections, we will delve deeper into specific applications of high-resolution thermal imaging and explore its impact in different industries.

Applications and Benefits

The Applications and Benefits section discusses the various practical uses and advantages of the Flir a300 thermal imaging camera. This powerful device offers a range of applications across multiple industries, proving to be an invaluable tool for enhancing efficiency, improving safety, and reducing operational costs.

Industrial Maintenance

The Flir a300 camera is widely utilized in the field of industrial maintenance. It enables professionals to detect and identify potential equipment malfunctions, electrical faults, and abnormal thermal patterns. By capturing accurate temperature measurements and detailed thermal images, it can assist in preventive maintenance, thereby reducing downtime and enhancing productivity.

Building Inspections

With its ability to quickly identify insulation gaps, moisture intrusion, and energy inefficiencies, the Flir a300 camera has become an essential tool for building inspections. It allows inspectors to identify hidden problems and prioritize repairs or renovations, leading to improved energy efficiency, reduced utility bills, and enhanced occupant comfort.

The benefits of using the Flir a300 thermal imaging camera are plentiful. Its non-contact and non-destructive nature make it a safe and efficient tool for capturing data in various scenarios. The device’s high-resolution imaging capabilities provide clear and detailed visuals, allowing users to accurately assess real-time conditions and make informed decisions.

The Flir a300 helps to minimize the risk of accidents and failures by detecting potential issues before they become major problems. By facilitating proactive maintenance, it contributes to increased equipment reliability and extended lifespan. Furthermore, its comprehensive reporting features enable easy documentation and sharing of findings, supporting effective communication and collaboration among stakeholders.

| Key Applications | Key Benefits |

|---|---|

| Industrial maintenance | Enhanced efficiency and reduced downtime |

| Building inspections | Improved energy efficiency and occupant comfort |

Industrial Monitoring and Preventive Maintenance

In the world of manufacturing and industrial operations, the importance of effective monitoring and preventive maintenance cannot be overstated. By implementing robust monitoring systems and proactive maintenance strategies, organizations can ensure the smooth operation of their equipment and prevent costly unplanned downtime.

Enhancing Efficiency with Industrial Monitoring

Industrial monitoring enables organizations to gain real-time insights into the performance and condition of their critical machinery and processes. By utilizing advanced sensors and data collection technologies, operators can monitor various parameters such as temperature, pressure, vibration, and energy consumption, among others. This wealth of data allows for the early detection of anomalies or deviations from normal operating conditions, enabling prompt interventions before major failures occur.

Effective industrial monitoring provides organizations with the ability to optimize their operations and maximize efficiency. By continuously monitoring and analyzing data, organizations can identify areas for improvement, streamline workflows, and optimize resource allocation. This proactive approach helps prevent costly breakdowns, reduces maintenance costs, and extends the lifespan of equipment.

The Power of Preventive Maintenance

Preventive maintenance is a proactive approach to equipment maintenance that involves routine inspections, servicing, and repairs to prevent failures and breakdowns. By adhering to a well-defined preventive maintenance schedule, organizations can avoid the costly repercussions of unplanned downtime, which can result in lost production, decreased customer satisfaction, and increased repair costs.

Implementing a preventive maintenance strategy requires a comprehensive understanding of equipment performance, lifecycle data, and historical failure patterns. By utilizing data from industrial monitoring systems, organizations can establish predictive maintenance models that leverage advanced analytics and machine learning algorithms. These models can identify potential failure modes and recommend maintenance interventions at optimal times, ensuring proactive maintenance that minimizes disruption and maximizes productivity.

In conclusion, industrial monitoring and preventive maintenance are vital components of modern manufacturing and industrial operations. By harnessing the power of data and implementing proactive maintenance practices, organizations can optimize their efficiency, reduce downtime, and extend the lifespan of their equipment.