Are you looking to delve into the world of brass alloys and explore the unique properties and applications they offer? Look no further! In this article, we will take a deep dive into the fascinating realm of H62 brass, a versatile alloy that finds its utility in various industries.

With its exceptional mechanical properties and excellent corrosion resistance, H62 brass has become a favored choice for engineers and designers alike. This alloy, also known as “yellow brass,” combines the desirable characteristics of both copper and zinc, delivering a material that is not only aesthetically pleasing but also highly functional.

From its stunning golden hue to its remarkable strength and malleability, H62 brass offers a plethora of possibilities in the manufacturing sector. With its remarkable electrical conductivity and thermal conductivity, this alloy is also widely used in electrical engineering applications.

H62 Brass: Overview and Composition

In this section, we will provide an overview of the characteristics and composition of a widely used brass alloy known as H62. Brass alloys have been utilized for various purposes throughout history due to their unique combination of properties, including excellent corrosion resistance, high conductivity, and ease of fabrication.

Characteristics

One notable characteristic of H62 brass is its impressive tensile strength, which makes it suitable for applications requiring durability and resilience. Additionally, this alloy exhibits good ductility, allowing it to be easily formed into different shapes and sizes. Its corrosion resistance properties make it highly resistant to oxidation, which is especially advantageous for applications in environments with high humidity or exposure to harsh chemicals.

Composition

H62 brass is primarily composed of copper (Cu) and zinc (Zn), with a nominal composition of approximately 60-63% copper and 37-40% zinc. The presence of small amounts of other elements, such as lead (Pb) and iron (Fe), further enhance its mechanical properties and facilitate its machinability. These additional elements contribute to improving the alloy’s performance in specific applications, such as plumbing fittings and electrical connectors.

In conclusion, H62 brass offers a versatile combination of strength, ductility, and corrosion resistance. Its composition, predominantly consisting of copper and zinc, ensures its suitability for various industrial and commercial applications. By understanding the characteristics and composition of this alloy, engineers and manufacturers can effectively utilize H62 brass to meet their specific requirements in diverse fields.

Composition of H62 Brass

In this section, we will explore the composition of H62 brass, a versatile alloy widely used in various industries. Understanding the chemical makeup of H62 brass is crucial for industries that rely on this material for its unique properties and applications.

Chemical Elements

H62 brass is primarily composed of copper (Cu) and zinc (Zn), with trace amounts of other elements. Copper is the main component of this alloy, providing both strength and conductivity. Zinc, on the other hand, is added to improve the alloy’s mechanical properties and corrosion resistance. It is the combination of these two elements that gives H62 brass its distinct characteristics.

Trace Elements

In addition to copper and zinc, H62 brass may contain small amounts of other elements, such as lead (Pb), iron (Fe), and manganese (Mn). These trace elements are often present due to the composition of the raw materials used in the manufacturing process. While their concentrations are minimal, they can still influence the alloy’s properties and performance in specific applications.

Lead is sometimes present in H62 brass to enhance machinability and formability. It allows the alloy to be easily shaped into various components without compromising its integrity. Iron can be found in H62 brass in small quantities, affecting its strength and electrical conductivity. Manganese is another trace element that can improve the workability and corrosion resistance of the alloy.

It is important for manufacturers and end-users to be aware of the specific composition of H62 brass, as it can dictate its suitability for certain applications. By understanding the chemical elements and trace elements present in H62 brass, industries can make informed decisions regarding the use of this alloy in their products and processes.

Properties and Applications of H62 Brass

In this section, we explore the various properties and applications of a material known for its versatility and durability. H62 brass, widely used in industries ranging from architecture to electronics, offers a myriad of benefits due to its unique composition and characteristics.

One of the notable properties of H62 brass is its excellent corrosion resistance, making it suitable for applications where durability in harsh environments is crucial. This property, combined with its high tensile strength and impressive ductility, allows for the fabrication of intricate and durable components.

The thermal conductivity of H62 brass also stands out, making it an ideal choice for heat exchange systems and other applications that require efficient heat transfer. Additionally, its electrical conductivity ensures its usefulness in electrical connectors, terminals, and various electronic components.

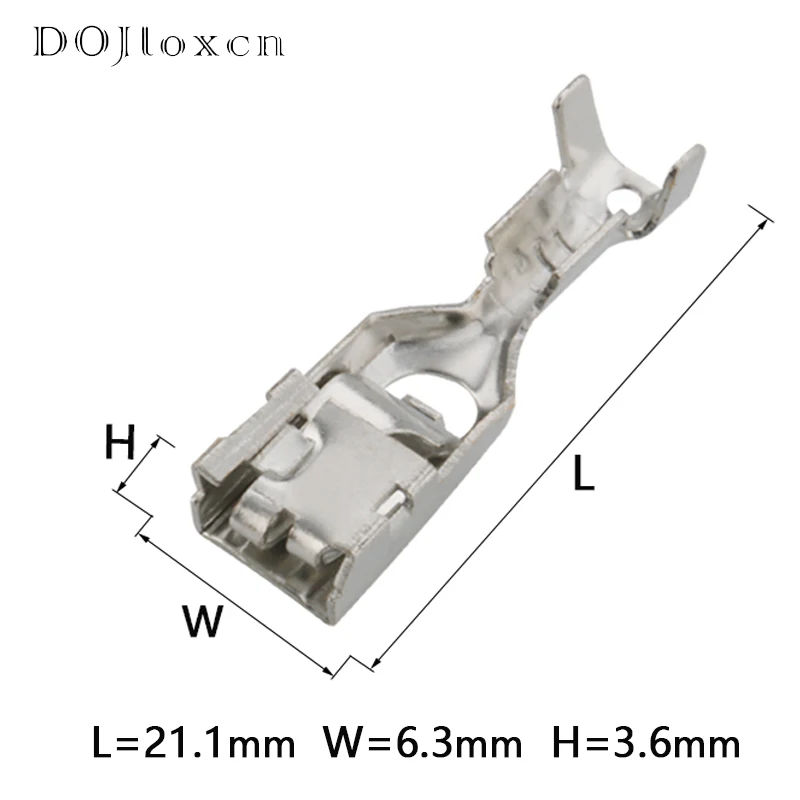

H62 brass exhibits exceptional formability, allowing it to be easily shaped into different forms, including sheets, rods, and tubes. This malleability, along with its attractive golden appearance, makes it a popular choice in architectural and decorative applications, such as ornamental fixtures, sculptures, and musical instruments.

In the industrial sector, H62 brass finds its applications in plumbing fittings, valves, and various mechanical components due to its excellent machinability. Its ease of cutting, drilling, and shaping further enhances its usability in the manufacturing processes, offering efficiency and cost-effectiveness.

Furthermore, H62 brass demonstrates excellent solderability and weldability, making it a preferred choice for joining operations in both industrial and amateur settings. This characteristic ensures ease of assembly and repair, allowing for efficient and reliable connections.

In summary, the unique combination of properties found in H62 brass, including corrosion resistance, high tensile strength, thermal and electrical conductivity, formability, and machinability, make it a versatile material suitable for a wide range of applications in industries such as architecture, electronics, plumbing, and manufacturing.

| Properties | Applications |

|---|---|

| Corrosion resistance | Harsh environment components |

| High tensile strength | Mechanical components |

| Thermal and electrical conductivity | Heat exchange systems, electronic components |

| Formability | Architecture, decorative applications |

| Machinability | Plumbing fittings, valves, manufacturing processes |

| Solderability and weldability | Joining operations |