Discovering the intricacies of electrical components often involves delving into detailed documents that provide essential insights into their functionality and capabilities. Within the realm of industrial equipment, there exists a vital component, enabling seamless control and management of electrical circuits, with a focus on safety and efficiency.

Exploring the intricacies of this essential element unveils a world of technical specifications and performance metrics, providing engineers and technicians with the necessary details to ensure optimal integration and operation. Understanding its characteristics goes beyond mere acquaintance; it ushers professionals into a realm of informed decision-making and precise application.

Unveiling the layers of this component’s documentation illuminates not just its physical attributes but also its potential impact on the broader system it serves. Through careful examination and analysis, the pathway to harnessing its full capabilities becomes clearer, promising enhanced operational efficiency and reliability.

Understanding Specifications of Electrical Contactors: A Comprehensive Guide

In this section, we delve into the intricate details encapsulated within the technical documentation of electrical contactors, aiming to provide a lucid comprehension of their specifications. Delving beyond mere terminology, we unravel the nuanced intricacies embedded within these documents, elucidating their significance in the realm of electrical engineering.

Deciphering Performance Parameters

Within the realm of electrical engineering, performance parameters serve as the cornerstone for evaluating the efficacy and suitability of contactors for diverse applications. These parameters encompass a spectrum of attributes, ranging from electrical ratings to operational characteristics, each bearing profound implications on the contactor’s functionality and performance.

Interpreting Dimensional and Mounting Information

Beyond the realm of electrical characteristics, the datasheet provides invaluable insights into the physical dimensions and mounting configurations of contactors. Understanding these specifications is pivotal in ensuring seamless integration within diverse electrical systems, facilitating optimal performance and operational efficiency.

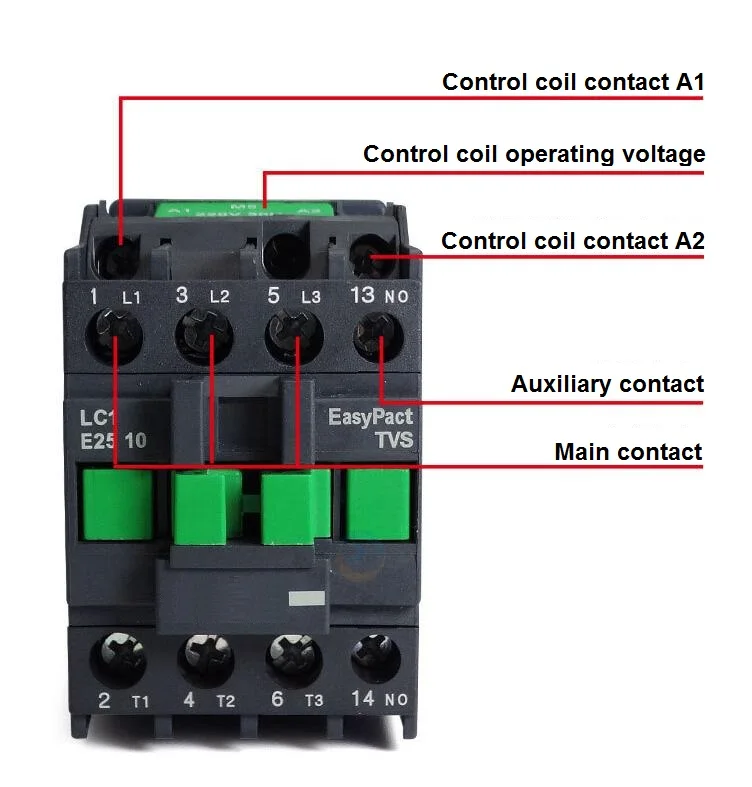

| Specification | Description |

|---|---|

| Electrical Ratings | Indicates the voltage and current capacities of the contactor, crucial for compatibility with specific electrical systems. |

| Coil Voltage | Specifies the voltage required to energize the contactor coil, influencing its compatibility with control circuits. |

| Operational Duty | Defines the duty cycle and operational lifespan of the contactor under varying load conditions, guiding its application suitability. |

| Auxiliary Contacts | Details the availability and configuration of auxiliary contacts, facilitating enhanced functionality and control capabilities. |

By comprehensively understanding the specifications delineated within the datasheet, engineers and practitioners can make informed decisions regarding the selection, deployment, and utilization of electrical contactors, thereby optimizing system performance and reliability.

Deciphering Electrical Ratings and Performance Metrics

In the realm of electrical components, understanding the intricate details of ratings and performance metrics is paramount. These specifications serve as the blueprint for assessing the capabilities and suitability of a given device for various applications. Delving into the nuances of electrical ratings unveils a world of crucial information that facilitates informed decision-making and ensures optimal performance.

Understanding Voltage Ratings: One of the fundamental aspects of electrical components is their voltage rating, which delineates the maximum voltage the device can safely handle. This metric serves as a safeguard against overloading and ensures the longevity and reliability of the equipment. Exploring the intricacies of voltage ratings unveils insights into the device’s compatibility with different power systems and environments.

Deciphering Current Ratings: Current ratings elucidate the maximum current that a component can carry without exceeding its operational limits. Mastery of current ratings empowers engineers to design circuits with precision, accounting for the demands placed on individual components and ensuring optimal performance under varying load conditions.

Exploring Thermal Performance: Thermal considerations play a pivotal role in the reliable operation of electrical components. Performance metrics related to temperature range, thermal resistance, and derating factors provide invaluable insights into the device’s ability to dissipate heat and maintain operational integrity under diverse environmental conditions.

Assessing Mechanical Durability: Beyond electrical parameters, mechanical durability stands as a testament to the robustness and resilience of a component. Metrics such as contact life, endurance ratings, and environmental certifications shed light on the device’s ability to withstand mechanical stressors, ensuring prolonged service life and enhanced reliability in demanding applications.

Interpreting Environmental Ratings: Environmental factors exert a significant influence on the performance and longevity of electrical components. Ratings pertaining to moisture resistance, ingress protection, and operating temperature range equip engineers with the knowledge to select components that can thrive in harsh industrial environments, outdoor settings, or other challenging conditions.

Evaluating Performance under Load: Comprehensive understanding of performance metrics under load conditions is indispensable for predicting the behavior of electrical components in real-world scenarios. Parameters such as voltage drop, power dissipation, and efficiency ratings enable engineers to assess the device’s performance under different operating conditions and optimize system efficiency.

Conclusion: Mastery of electrical ratings and performance metrics is not merely an exercise in deciphering technical specifications but a gateway to unlocking the full potential of electrical components. By delving into the intricacies of voltage, current, thermal, mechanical, and environmental ratings, engineers can make informed decisions, design robust systems, and ensure the seamless operation of electrical equipment across diverse applications.

Unlocking the Potential: Applications of Advanced Contactors

In this section, we explore the versatile applications and wide-ranging utility of cutting-edge contactor technology. These innovative devices serve as pivotal components across various industries, facilitating seamless electrical control and power management in diverse operational environments.

Enhancing Industrial Operations

Within industrial settings, these sophisticated contactors play a crucial role in streamlining processes, optimizing efficiency, and ensuring the smooth operation of machinery and equipment. From manufacturing plants to automated assembly lines, they enable precise control over electrical circuits, supporting uninterrupted production workflows.

Empowering Infrastructure Development

The deployment of advanced contactors extends beyond factory floors, contributing significantly to the development and maintenance of critical infrastructure. In applications ranging from transportation networks to energy distribution systems, these devices facilitate reliable power transmission, voltage regulation, and safeguarding against electrical faults.

- Automated Manufacturing Systems

- Renewable Energy Installations

- Building Automation Systems

- Commercial HVAC Systems

- Transportation Infrastructure

By harnessing the capabilities of modern contactor technology, industries can unlock new levels of operational efficiency, resilience, and safety, thereby driving progress and innovation across diverse sectors.

Exploring Industrial and Commercial Use Cases

Delving into the myriad applications of advanced electrical components unveils a diverse landscape of industrial and commercial possibilities. From powering heavy machinery to facilitating seamless operations in bustling commercial settings, the utilization of innovative technology reshapes the way businesses operate and industries thrive.

Let’s journey through the realms where these sophisticated systems play pivotal roles, powering intricate processes and optimizing efficiency. From manufacturing plants to commercial buildings, the integration of cutting-edge electrical components revolutionizes productivity and safety standards.

- Industrial Automation: Embracing automation in manufacturing processes streamlines production, enhances precision, and reduces operational costs.

- Energy Management: Implementing efficient energy management systems not only conserves resources but also contributes to sustainability goals, fostering a greener future.

- Building Infrastructure: In commercial spaces, modern electrical components ensure seamless operations of HVAC systems, lighting controls, and security mechanisms, elevating comfort and security standards.

- Transportation: From powering electric vehicles to optimizing traffic control systems, advanced electrical solutions play a crucial role in shaping the future of transportation, enhancing both efficiency and environmental sustainability.

- Telecommunications: In the digital age, robust electrical infrastructure supports the seamless flow of data, enabling reliable communication networks essential for businesses and individuals alike.

As we delve deeper into the intricate web of industrial and commercial landscapes, the significance of these advanced electrical components becomes increasingly evident. Beyond mere functionality, they represent the backbone of modern infrastructure, driving progress and innovation across diverse sectors.

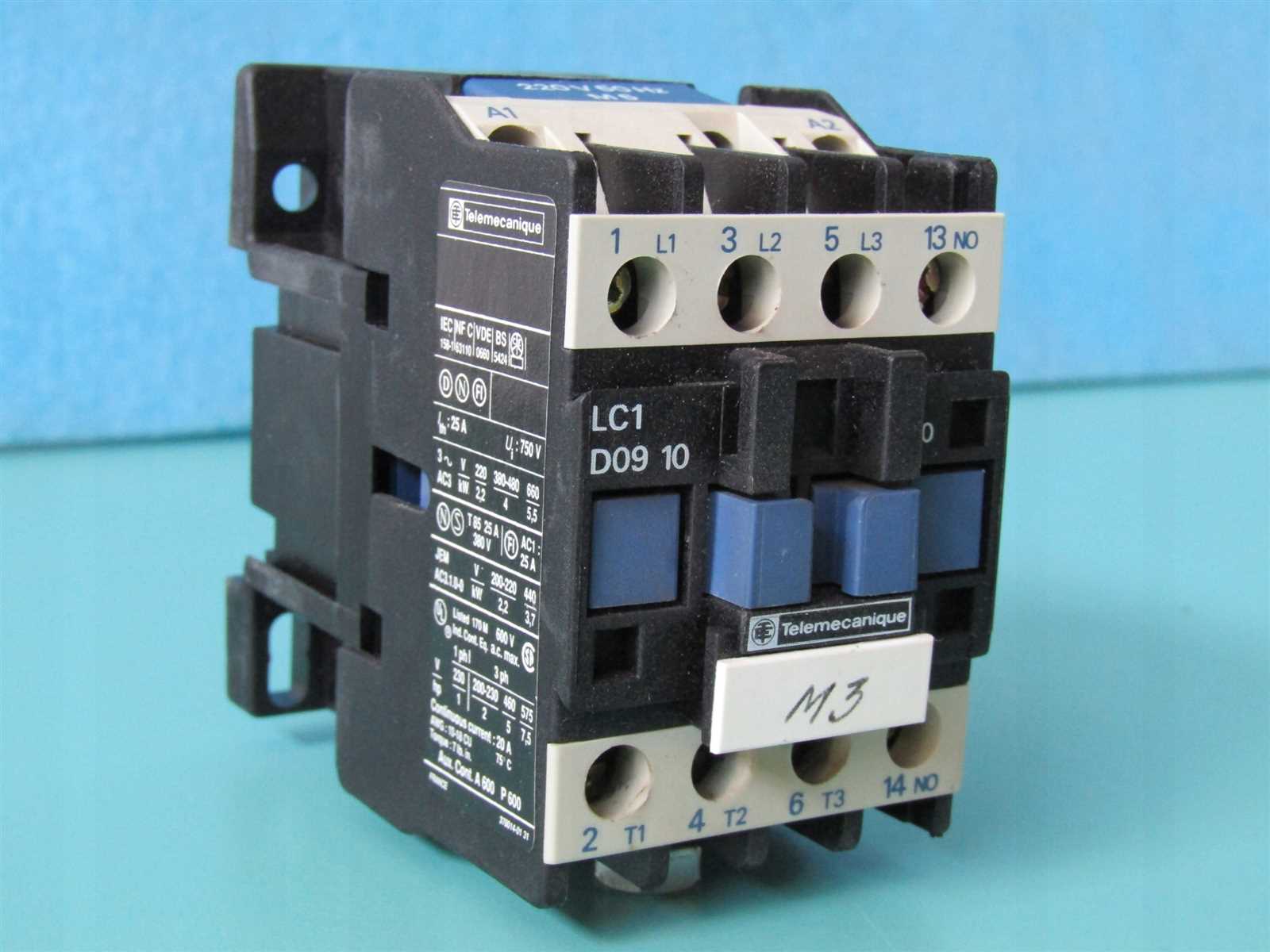

Installation and Maintenance Guide for Lc1d Contactors

In this section, we’ll delve into the essential aspects of setting up and ensuring the continued functionality of your electrical switching devices. From initial placement to routine care, this guide will provide comprehensive insights into optimizing the performance and longevity of your contactors.

Placement and Setup

When integrating your contactors into an electrical system, meticulous attention to placement and configuration is paramount. Begin by identifying suitable locations within your setup, considering factors such as proximity to power sources, load requirements, and accessibility for maintenance. Ensure that connections are made securely and according to manufacturer specifications, avoiding excessive stress on wiring and terminals.

Maintenance Practices

To uphold optimal performance, regular maintenance of contactors is indispensable. Implement a schedule for inspection and cleaning, addressing issues such as dust accumulation, corrosion, and mechanical wear. Verify the integrity of connections, tightening loose terminals as necessary. Additionally, monitor for signs of overheating or abnormal operation, promptly addressing any anomalies to prevent potential damage or downtime.

By adhering to these guidelines, you can safeguard the reliability and efficiency of your electrical systems, maximizing the functionality of your contactors without compromising safety or performance.