Delve into the intricacies of the engineering marvel that lies within the technical documentation awaiting exploration. This comprehensive compendium is a treasure trove, revealing the inner workings and capabilities of a revolutionary instrument poised to redefine industry standards.

Embark on a journey through the labyrinthine corridors of innovation as we dissect the blueprint of cutting-edge technology. Within these pages, discover the myriad facets and functionalities that propel industrial operations towards unparalleled efficiency and precision.

Unravel the mysteries concealed within the cryptic diagrams and cryptic jargon, as we decode the language of measurement and control. Each line of text holds the promise of revelation, offering insights into the dynamic realm of instrumentation and process automation.

Rosemount 3051TG Datasheet Overview

In this section, we will delve into an insightful exploration of the comprehensive documentation encapsulating the essence of the esteemed Rosemount 3051TG device. The discourse herein aims to furnish a lucid comprehension of the intricacies inherent in this informational compendium, elucidating its pivotal role in facilitating a nuanced understanding of the device’s functionalities, specifications, and operational parameters.

Understanding Key Specifications and Features

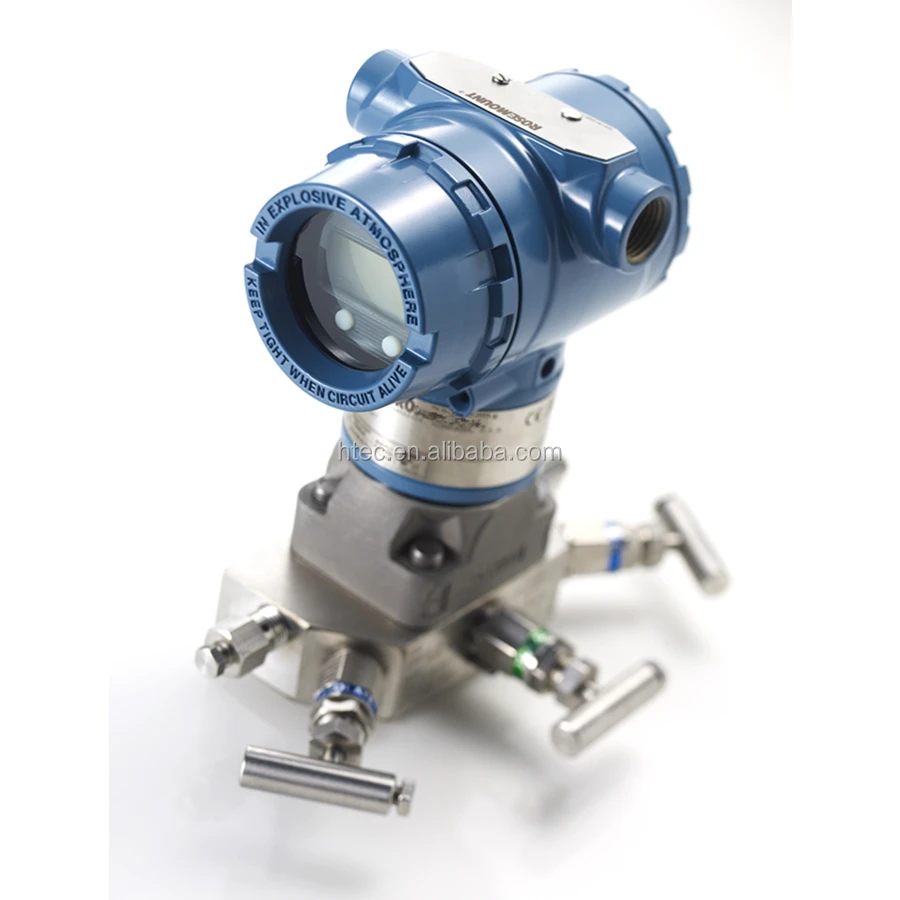

In this section, we delve into the essential aspects of the product’s specifications and functionalities, shedding light on its core attributes and capabilities. By comprehending these key specifications and features, users can gain a comprehensive understanding of the device’s performance and suitability for various applications.

Technical Specifications

The technical specifications provide vital information regarding the device’s operational parameters, including accuracy, range, resolution, and response time. By analyzing these specifications, users can assess the device’s precision, sensitivity, and overall performance under different conditions.

Notable Features

Aside from technical specifications, the product incorporates several notable features that enhance its functionality and usability. These features may include advanced signal processing algorithms, communication protocols, diagnostic capabilities, and environmental adaptability. Understanding these features enables users to harness the full potential of the device for their specific needs.

| Specification | Description |

|---|---|

| Accuracy | The degree of conformity between the measured value and the true value. |

| Range | The span of values within which the device can accurately measure. |

| Resolution | The smallest incremental change in the measured quantity that the device can detect. |

| Response Time | The time taken by the device to register a change in the measured parameter. |

Applications of 3051TG Transmitter

In various industrial settings, the versatile 3051TG transmitter finds diverse applications, leveraging its robust design and precise measurement capabilities. It serves as a cornerstone in processes requiring accurate monitoring and control of pressure, ensuring optimal performance and safety across different sectors.

Process Industries

Within process industries such as chemical manufacturing, petrochemical refining, and pharmaceutical production, the 3051TG transmitter plays a pivotal role. It facilitates real-time pressure measurement in reactors, pipelines, and storage vessels, enabling operators to maintain optimal operating conditions, enhance efficiency, and ensure product quality.

Utilities Sector

Across utilities sectors encompassing water treatment plants, power generation facilities, and HVAC systems, the 3051TG transmitter contributes significantly. It aids in monitoring and regulating pressure levels in pipelines, boilers, and cooling towers, thereby optimizing energy consumption, minimizing downtime, and ensuring the reliability of critical infrastructure.

| Industry | Application |

|---|---|

| Chemical Manufacturing | Pressure monitoring in reactors |

| Petrochemical Refining | Pressure measurement in pipelines |

| Pharmaceutical Production | Pressure control in sterile environments |

| Water Treatment Plants | Pressure regulation in filtration systems |

| Power Generation | Pressure monitoring in boilers |

| HVAC Systems | Pressure management in air handling units |

Exploring Industry-Specific Implementations

In this section, we delve into the diverse applications and tailored solutions that cater to specific industrial needs. From precision engineering to streamlined processes, industries worldwide harness cutting-edge technology to optimize performance and enhance reliability. By examining industry-specific adaptations, we uncover how innovative strategies align with unique operational demands, driving efficiency and fostering growth.

Oil and Gas Sector

The oil and gas sector presents a complex landscape where stringent regulations, remote environments, and high-pressure conditions converge. Here, specialized implementations of sensor technology, akin to the Rosemount 3051TG series, play a pivotal role in ensuring operational integrity and safety. Through robust instrumentation tailored to withstand harsh environments, oil and gas companies optimize resource extraction, monitor pipeline integrity, and mitigate risks associated with volatile substances.

Manufacturing Industry

In the realm of manufacturing, precision and efficiency are paramount. Industry-specific implementations of sensor technology empower manufacturers to maintain stringent quality control standards while maximizing production throughput. By integrating advanced sensors like those found in the Rosemount 3051TG datasheet, manufacturers achieve real-time monitoring of critical parameters such as pressure, temperature, and flow rates. This data-driven approach enables proactive maintenance, minimizes downtime, and ultimately enhances product quality, ensuring competitiveness in a rapidly evolving market.

| Industry | Key Challenges | Specialized Solutions |

|---|---|---|

| Oil and Gas | Harsh environments, regulatory compliance, safety concerns | Robust sensor technology, remote monitoring, compliance management systems |

| Manufacturing | Precision engineering, quality control, production efficiency | Advanced sensor integration, real-time monitoring, predictive maintenance |

Installation and Maintenance Guidelines

In this section, we provide comprehensive guidance on the proper procedures for installing and maintaining your equipment. Ensuring the optimal performance and longevity of your device necessitates adherence to these protocols. Below, we outline essential steps and considerations for both installation and ongoing maintenance.

| Topic | Description |

|---|---|

| Pre-Installation Checks | Before commencing the installation process, conduct thorough checks to confirm the suitability of the environment and the availability of necessary tools. |

| Installation Procedures | Follow the step-by-step instructions provided in this section to correctly install the equipment, ensuring proper alignment and connection. |

| Calibration | Calibrate the device according to the specified parameters to guarantee accurate readings and performance. |

| Testing and Validation | After installation and calibration, perform testing procedures to validate the functionality and accuracy of the equipment. |

| Maintenance Schedule | Establish a regular maintenance schedule, including routine inspections, cleaning, and any necessary adjustments or replacements. |

| Troubleshooting | Refer to this section for guidance on troubleshooting common issues that may arise during operation, along with recommended solutions. |

| Documentation and Record-Keeping | Maintain detailed documentation of all installation and maintenance activities, including records of calibration, testing, and any repairs or modifications. |

By adhering to the installation and maintenance guidelines outlined herein, you can ensure the optimal performance, reliability, and longevity of your equipment, thereby maximizing its value and functionality in your application.