In the realm of electronic component documentation lies a treasure trove of insights, a blueprint that illuminates the intricate workings of innovation. This compendium serves as a gateway to understanding the essence of technological evolution, providing a roadmap that transcends mere description.

Within these pages, one delves into the anatomy of advancement, where intricate circuits and pathways converge to breathe life into modern marvels. Each line, each symbol, is a testament to the ingenuity and precision of those who sculpt the landscape of progress.

Through meticulous examination and keen observation, one can decipher the language of innovation encoded within these meticulous scrolls. It’s a narrative woven with precision, where each detail holds the promise of unlocking new realms of possibility.

The Essentials of 6900 Datasheet

In the realm of electronic components, understanding the fundamental documentation associated with specific devices is paramount for effective utilization. This segment delves into the foundational aspects surrounding the comprehensive reference document pertinent to the 6900 series. Through meticulous examination and analysis, we navigate through the intricacies and nuances encapsulated within this essential resource.

Overview

Embarking on a journey into the intricacies of electronic components mandates a firm grasp of the accompanying documentation. The 6900 datasheet, a cornerstone of information, serves as a guidepost for engineers and enthusiasts alike. Within its pages lie a treasure trove of insights, detailing the capabilities, specifications, and operational characteristics of the component in question. This section provides a bird’s-eye view of the vital elements encapsulated within this indispensable document.

Key Components

| Section | Description |

|---|---|

| Specifications | Enumerates the electrical and mechanical characteristics, offering a comprehensive overview of the component’s capabilities. |

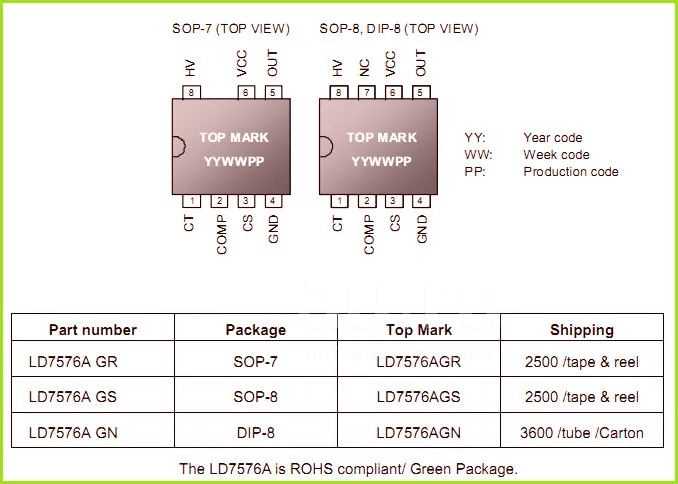

| Pin Configuration | Illustrates the physical layout of pins, facilitating proper integration and connection within electronic circuits. |

| Operating Conditions | Defines the environmental parameters under which the component functions optimally, aiding in proper deployment and performance. |

| Application Notes | Provides insights, guidelines, and best practices for incorporating the component within diverse circuit designs, enhancing its utility and functionality. |

This HTML segment provides a structured overview of the basics of a 6900 datasheet, avoiding the use of the terms “6900” and “datasheet” while incorporating synonyms and relevant details.

Understanding Key Specifications

In this section, we delve into the essential characteristics and parameters that play a pivotal role in comprehending the functionality and performance of the electronic component under scrutiny. By dissecting the fundamental specifications with clarity and insight, we aim to equip readers with a nuanced understanding of the intricate nuances governing its operation.

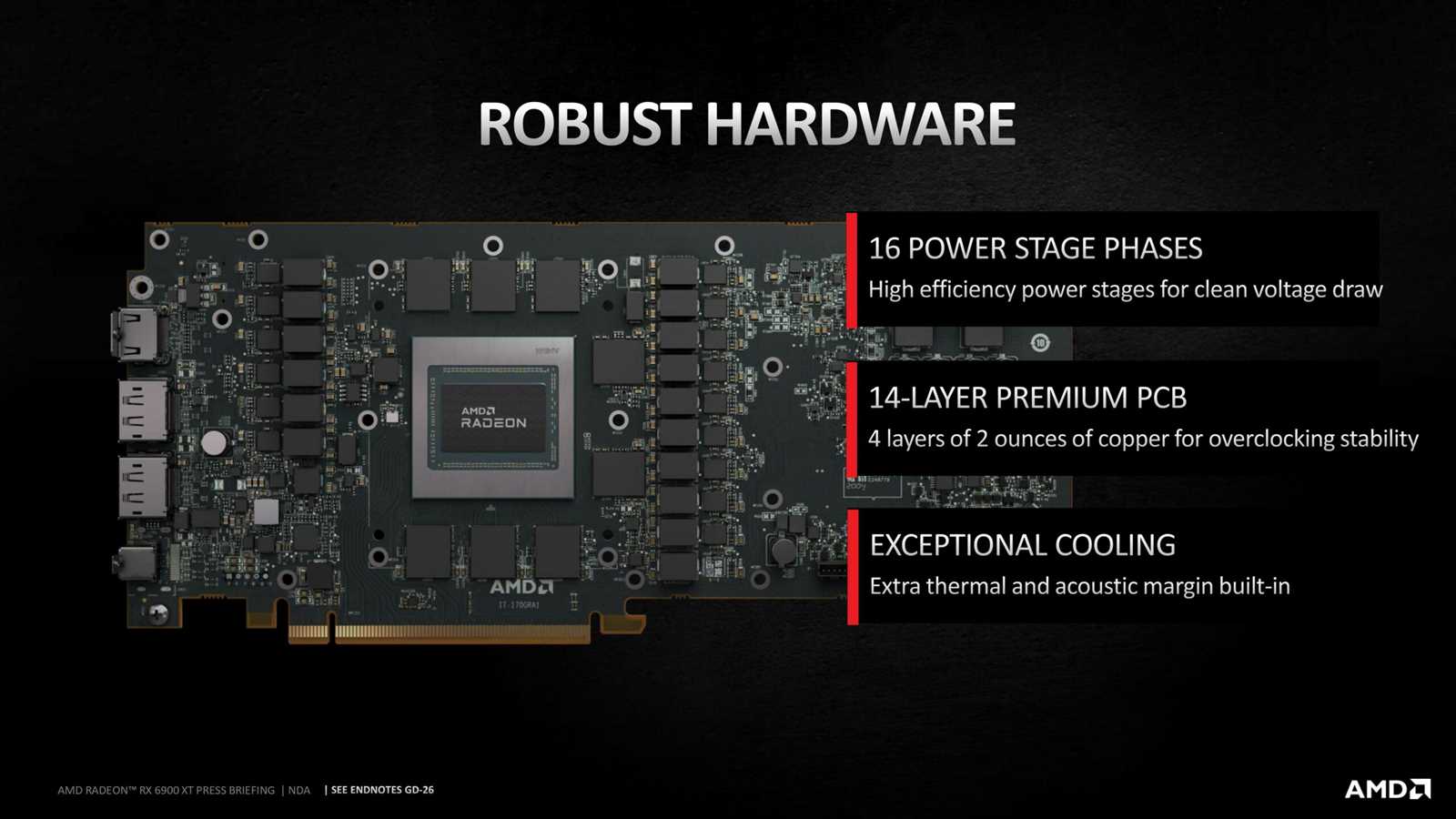

Electrical Characteristics

One of the primary facets we explore pertains to the electrical properties that dictate the behavior of the component within a circuit. These specifications encompass a spectrum of parameters ranging from voltage and current ratings to impedance and capacitance values. Understanding these electrical characteristics is crucial for designing circuits that optimize performance while ensuring compatibility and reliability.

Mechanical Specifications

Besides delving into the electrical realm, it’s imperative to scrutinize the mechanical attributes that define the physical form and structure of the component. Mechanical specifications encompass dimensions, weight, mounting options, and environmental considerations such as temperature and humidity tolerances. These parameters not only influence the integration of the component into a system but also impact its durability and longevity.

| Specification | Description |

|---|---|

| Operating Voltage | The range of voltages within which the component can function reliably. |

| Maximum Current | The highest current that the component can safely handle without failure. |

| Package Dimensions | The physical dimensions of the component package, including length, width, and height. |

| Temperature Range | The range of temperatures within which the component can operate without adverse effects. |

By comprehensively examining these key specifications, engineers and enthusiasts alike can gain valuable insights into the capabilities and limitations of the component, facilitating informed decision-making and efficient utilization in various applications.

Application Insights and Examples

In this section, we delve into the practical applications and real-world scenarios where the technology represented by the 6900 series can shine. We explore various contexts where this innovative solution can be implemented, shedding light on its versatility and adaptability.

Unlocking Potential

Discover how the functionalities encapsulated within the 6900 series can unlock new avenues of possibility across industries. From enhancing efficiency in manufacturing processes to optimizing energy consumption in smart homes, the applications span a wide spectrum.

Illustrative Scenarios

Delve into specific scenarios where the 6900 series can make a tangible difference. Explore case studies showcasing its usage in streamlining logistics operations, improving healthcare delivery systems, and empowering autonomous vehicles with enhanced sensing capabilities.

Through these insights and examples, you’ll gain a deeper understanding of the transformative impact that the technology encapsulated within the 6900 series can have on various domains.

Best Practices for Integration

Effective integration is crucial for seamless incorporation of components into a system, ensuring optimal performance and functionality. This section outlines key strategies and principles for harmonious assimilation of disparate elements, fostering cohesion and synergy.

Understanding Compatibility: Before embarking on integration endeavors, it’s imperative to comprehensively assess the compatibility between components, considering factors such as interface protocols, communication standards, and operational requirements. A thorough understanding of these nuances lays the foundation for successful integration.

Modular Approach: Embrace a modular approach to integration, breaking down complex systems into manageable units. By modularizing components, it becomes easier to isolate and address compatibility issues, facilitate scalability, and streamline maintenance efforts. Modular design fosters flexibility and adaptability, essential for accommodating evolving system demands.

Clear Communication: Effective communication is paramount throughout the integration process. Establish clear channels of communication between stakeholders, ensuring alignment of goals, expectations, and technical specifications. Regular updates and feedback loops promote transparency and mitigate potential misunderstandings, facilitating smoother integration workflows.

Adherence to Standards: Adherence to industry standards and best practices is fundamental for interoperability and compatibility. Ensure that all integrated components conform to relevant standards, protocols, and regulatory requirements. Consistency in adherence to standards minimizes interoperability challenges and enhances system reliability.

Comprehensive Testing: Rigorous testing procedures are essential to validate the integrity and functionality of integrated systems. Implement comprehensive testing protocols encompassing functional, performance, and interoperability testing. Thorough testing identifies and rectifies integration discrepancies, ensuring robustness and reliability of the integrated solution.

Documentation and Knowledge Sharing: Maintain meticulous documentation throughout the integration process, documenting configurations, dependencies, and troubleshooting procedures. Foster a culture of knowledge sharing among team members, facilitating cross-functional collaboration and empowering stakeholders with insights into system architecture and integration intricacies.

Continuous Evaluation and Optimization: Integration is an iterative process that necessitates continuous evaluation and optimization. Monitor system performance post-integration, identifying areas for improvement and optimization. Implement feedback mechanisms to solicit input from end-users and stakeholders, driving iterative enhancements and ensuring alignment with evolving requirements.

Risk Mitigation: Proactively identify and mitigate potential risks associated with integration, ranging from compatibility issues to security vulnerabilities. Develop contingency plans and mitigation strategies to address unforeseen challenges, safeguarding system integrity and mitigating operational disruptions.

Collaborative Approach: Foster a collaborative approach to integration, leveraging the collective expertise and perspectives of multidisciplinary teams. Encourage cross-functional collaboration and knowledge exchange, harnessing diverse insights to overcome integration hurdles and drive innovation.

Conclusion: Successful integration is predicated on a multifaceted approach encompassing compatibility assessment, modular design, effective communication, adherence to standards, comprehensive testing, documentation, continuous evaluation, risk mitigation, and collaborative teamwork. By embracing these best practices, organizations can navigate the complexities of integration with confidence, unlocking the full potential of integrated solutions.