In the realm of industrial applications, where the integrity of connections is paramount, engineers seek out ingenious methods to ensure airtight and leak-free seals. Within this pursuit lie intricate profiles, meticulously designed to harmonize form and function, crafting a seamless union between components. In the realm of engineering lexicon, these profiles stand as silent guardians, shielding against the intrusion of foreign elements, preserving the sanctity of mechanical systems.

Unveiling the essence of these sealing marvels requires a journey into the realm of precision engineering and material science. Through the exploration of these meticulously crafted configurations, we delve into the artistry of joint sealing, where each contour and ridge serves as a testament to the pursuit of perfection. This odyssey embarks on a quest to unravel the intricacies of these sealing solutions, transcending the boundaries of conventional engineering paradigms.

Prepare to embark on a voyage through the labyrinthine corridors of industrial innovation, where the symphony of design and functionality orchestrates a ballet of resilience and reliability. Join us as we navigate through the landscape of joint sealing technologies, deciphering the language of efficiency and efficacy, and uncovering the blueprint of tomorrow’s industrial harmony.

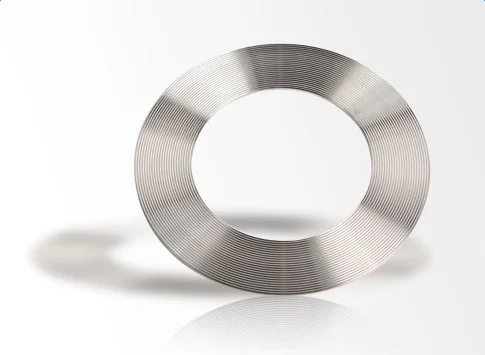

Kammprofile Gasket: An Overview

In the realm of industrial sealing solutions, there exists a specialized component that plays a pivotal role in ensuring leak-proof joints within machinery and piping systems. This component, characterized by its unique design and functionality, serves as a crucial interface between two mating surfaces, safeguarding against the escape or ingress of fluids and gases. Its significance extends beyond mere physical presence, contributing to the efficiency, reliability, and safety of diverse industrial processes.

Key Characteristics

Embedded within its structure are intricacies meticulously crafted to meet the demands of rigorous operational environments. Its profile, ingeniously engineered to accommodate variations in surface irregularities, ensures optimal contact and pressure distribution, thereby fortifying the seal against potential leak paths. The choice of materials, selected with precision to withstand extreme temperatures, pressures, and chemical exposures, underscores its resilience and longevity.

| Feature | Functionality |

|---|---|

| Interlocking Design | Enhances stability and prevents extrusion under high pressure conditions. |

| Soft Filler Material | Provides conformability and compensates for flange surface imperfections. |

| Integral Outer Ring | Facilitates accurate alignment and simplifies installation. |

Applications

Deployed across a spectrum of industries ranging from oil and gas to chemical processing, its versatility finds expression in myriad applications. Whether sealing connections within pipelines carrying volatile fluids or containing the intense pressures of hydraulic systems, it remains a cornerstone of operational integrity. Its adaptability to diverse sealing challenges positions it as an indispensable asset in the pursuit of efficiency, safety, and regulatory compliance.

Understanding the Fundamentals and Practical Applications

In this section, we delve into the fundamental principles and diverse applications of a specialized engineering component designed to enhance sealing efficiency and mechanical integrity in various industrial contexts. By exploring the underlying concepts and real-world implementations, we aim to provide a comprehensive understanding of this vital element’s role in modern engineering.

At its core, the technology we examine represents a sophisticated solution engineered to address the challenges of fluid containment and mechanical stability across diverse operational environments. Through innovative design and meticulous manufacturing, this component embodies the culmination of scientific principles and practical ingenuity.

- Exploring the role of this component in sealing systems

- Analyzing its applications across industries such as petrochemical, automotive, and aerospace

- Understanding the operational dynamics and performance metrics

- Examining the factors influencing material selection and design considerations

- Highlighting case studies showcasing real-world efficacy

By elucidating these fundamental concepts and practical applications, we aim to empower engineers, designers, and stakeholders with the knowledge necessary to leverage this innovative solution effectively. Through a nuanced understanding of its capabilities and limitations, professionals can optimize system performance, enhance operational efficiency, and ensure the integrity of critical infrastructure.

Key Features of Kammprofile Gaskets

Exploring the distinguishing attributes of these specialized sealing solutions unveils a realm of functionalities tailored for robust performance in industrial environments. These gaskets embody a fusion of innovative design elements, meticulously engineered to optimize sealing efficacy while ensuring operational resilience.

1. Enhanced Conformability and Resilience

Delivering adaptability akin to a chameleon, these gaskets effortlessly conform to irregular surfaces, establishing a uniform seal that withstands fluctuations in pressure and temperature. Their inherent resilience ensures sustained performance under challenging operating conditions, safeguarding against leaks and maintaining operational integrity.

2. Superior Load Distribution and Seal Integrity

Operating as guardians of containment, these gaskets excel in distributing load uniformly across mating flange surfaces, mitigating stress concentrations that could compromise seal integrity. Their intricate profile facilitates optimal compression, fostering a secure seal that endures over time, even in demanding industrial settings.

An Exploration of Form and Function

Delving into the intricacies of engineering marvels often unveils a tapestry of design intricacies and functional brilliance. In this segment, we embark on an insightful journey into the heart of innovation, unraveling the essence of form and function.

Design Ingenuity: At the core of every engineering marvel lies a testament to human ingenuity. Through meticulous craftsmanship and thoughtful planning, designs emerge that seamlessly blend efficiency with elegance. Each contour, curve, and facet serves a purpose, intricately woven into a symphony of functionality.

Functionality Unveiled: Beyond the aesthetics lies the true essence of functionality. Every component, every mechanism, has a role to play in the grand scheme of operation. From enhancing performance to ensuring reliability, the functionality of a system is a culmination of countless design decisions and engineering prowess.

The Interplay of Form and Function: It is in the harmonious interplay of form and function that true innovation thrives. Design elements are not merely aesthetic choices but serve as integral components in the functionality of a system. Conversely, functionality drives design, shaping it to meet the demands of practicality and efficiency.

Unveiling the Nexus: As we delve deeper, we uncover the intricate nexus where design and functionality converge. Here, every line, every feature, embodies a purpose-driven approach aimed at optimizing performance and enhancing user experience. It is this symbiotic relationship that propels engineering marvels to new heights of excellence.

Conclusion: In our exploration of design and functionality, we witness the artistry of human innovation at its finest. From the inception of an idea to the realization of a fully functional system, the journey is fraught with challenges and triumphs. Yet, through it all, the relentless pursuit of excellence drives us forward, shaping a world where form and function coalesce in perfect harmony.

Choosing the Right Sealing Solution

When it comes to finding the ideal sealing solution for your specific application, several key factors must be carefully considered to ensure optimal performance and reliability. This section aims to guide you through the process of selecting the most suitable gasket profile for your unique needs, taking into account various critical parameters and environmental conditions.

| Criteria | Considerations |

|---|---|

| Operating Pressure | Determine the maximum and minimum pressure levels your gasket will be subjected to during operation. |

| Temperature Range | Evaluate the temperature extremes your gasket must endure, considering both high and low temperature environments. |

| Fluid Compatibility | Assess the compatibility of the gasket material with the fluids it will come into contact with, including corrosive chemicals or abrasive substances. |

| Surface Finish | Consider the roughness and flatness of the sealing surfaces to ensure proper gasket compression and sealing performance. |

| Installation Method | Choose a gasket profile that aligns with your preferred installation method, whether it’s bolted or welded, and consider ease of installation. |

| Flange Conditions | Take into account the type and condition of the flange faces, such as raised face, flat face, or ring-type joint, to select the appropriate gasket style. |

By carefully evaluating these critical criteria and selecting the right gasket profile based on your specific application requirements, you can ensure a reliable sealing solution that delivers superior performance and longevity.