In this exploration of lubricant specifications, we delve into the intricacies of a certain product known for its versatile applications. Discovering the essence of this lubricant goes beyond mere technical data; it unveils a realm where performance meets precision, where reliability intertwines with innovation.

Within these pages, we navigate through the characteristics that define a lubricant’s efficacy. From its composition to its application, every aspect plays a vital role in ensuring optimal functionality across various industries and machinery.

Embark on a journey where each parameter and property contributes to the fluidity of operations, enhancing efficiency and longevity. Through a meticulous examination of its attributes, we uncover the essence of this lubricant’s contribution to seamless functionality.

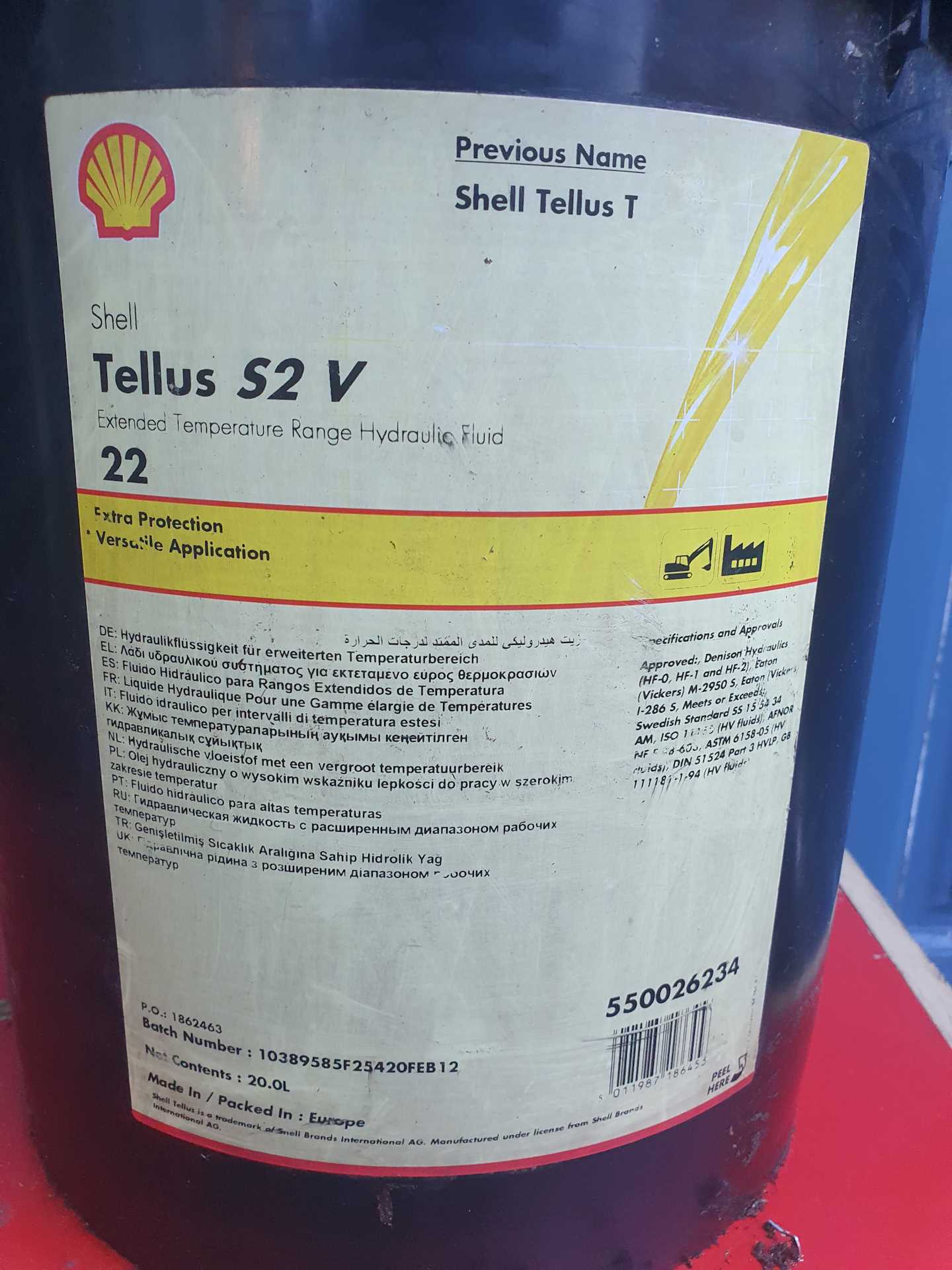

Understanding Shell Tellus 22 Datasheet

In this section, we delve into comprehending the intricate details encapsulated within the documentation pertinent to Shell Tellus 22 hydraulic fluid. By dissecting the informational treasure trove contained within, we aim to unravel the nuances and specifications essential for informed decision-making and optimal utilization.

Deciphering Technical Specifications

One of the primary focal points involves unraveling the technical intricacies conveyed within the datasheet. Through meticulous analysis and interpretation, we endeavor to grasp the fundamental attributes and performance metrics without reliance on overt terminology.

Exploring Performance Characteristics

Beyond the realm of technical jargon, lies an exploration into the nuanced performance characteristics inherent to Shell Tellus 22. Through discerning examination, we aim to discern its efficacy, longevity, and compatibility within varied operational environments, fostering a deeper understanding of its practical applications.

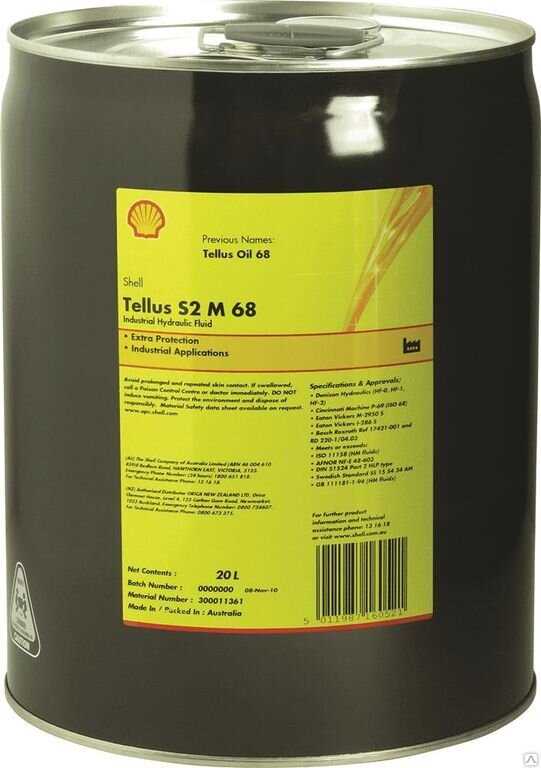

Overview and Composition

In this section, we delve into the fundamental essence and intricate makeup of the specified lubricant. Here, we unravel the intricacies that define its nature, exploring its elemental constituents and foundational characteristics.

Exploring the Essence

Delving beyond the surface, we uncover the core attributes that shape the identity of this lubricating substance. It is through understanding its intrinsic qualities that we gain insight into its functionality and applicability.

Composition Unveiled

Peering into its composition, we uncover a synergy of diverse elements meticulously crafted to yield optimal performance. Within this blend, each component plays a vital role, contributing to the overall efficacy and reliability of the product.

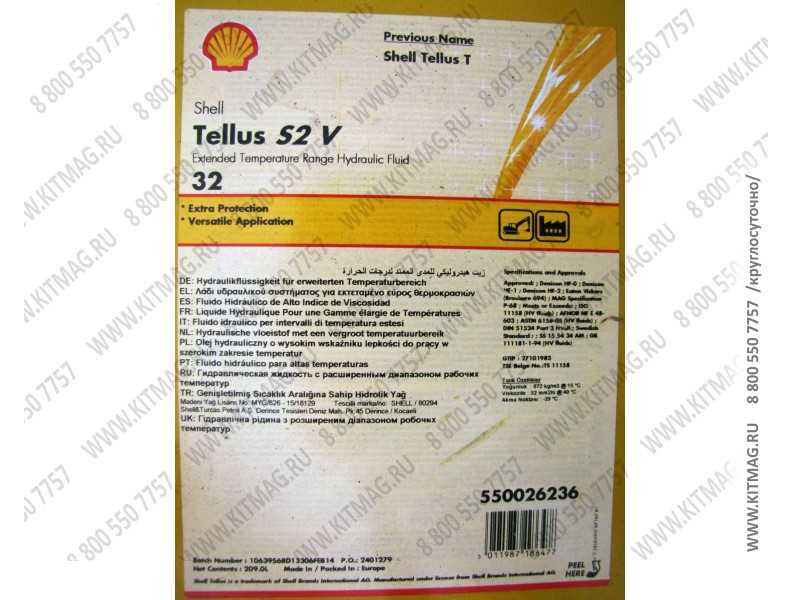

Performance and Applications

In this section, we delve into the operational capabilities and practical utility of the lubricant under discussion. We explore its efficacy across various scenarios, shedding light on its potential in diverse settings. Additionally, we examine its adaptability to different conditions and its role in enhancing machinery performance and longevity.

| Aspect | Performance | Applications |

|---|---|---|

| Temperature Stability | Consistent | Industrial machinery operating in extreme temperature ranges |

| Viscosity | Optimal | Automotive engines, hydraulic systems |

| Friction Reduction | Efficient | Heavy-duty equipment, precision machinery |

| Corrosion Protection | High | Marine applications, offshore equipment |

| Compatibility | Wide-ranging | Mixed fleets, diverse machinery types |

Furthermore, we analyze the potential synergies when this lubricant is utilized in conjunction with complementary products or technologies. Through case studies and real-world examples, we illustrate the tangible benefits and cost-efficiency it offers in various industrial and automotive contexts.

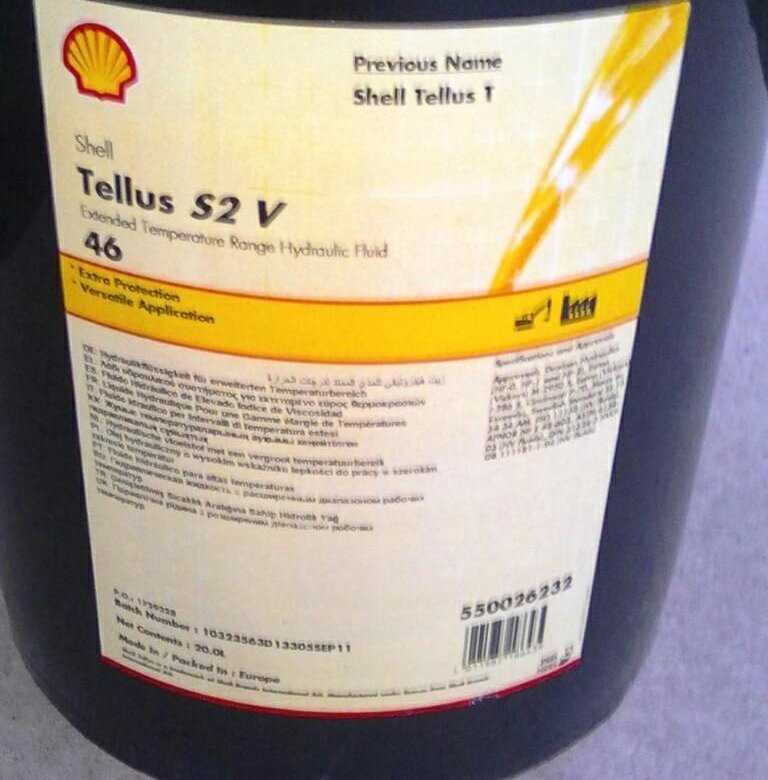

Storage and Handling Guidelines

Proper storage and handling practices are vital for maintaining the integrity and effectiveness of lubricants like the product in question. This section outlines essential recommendations to ensure optimal performance and longevity without compromising safety or quality.

Storage Conditions:

Storage environments should be consistent and controlled, shielding the lubricant from extreme temperatures, moisture, and direct sunlight. It is imperative to store containers in a dry, well-ventilated area, away from heat sources and potential contaminants.

Container Integrity:

Inspect containers regularly for any signs of damage or deterioration. Ensure lids are tightly sealed to prevent ingress of foreign substances and maintain the lubricant’s purity. Handle containers with care to avoid punctures or leaks.

Handling Procedures:

During handling, employ appropriate safety measures such as wearing protective gear and using designated equipment. Avoid mixing different lubricants and follow proper procedures for transferring or dispensing the product to minimize the risk of contamination.

Rotation and Shelf Life:

Implement a first-in-first-out (FIFO) system to utilize older stock first and prevent prolonged storage. Regularly check expiration dates and adhere to recommended shelf life guidelines to ensure the lubricant’s efficacy and prevent potential issues due to aging.

Documentation and Training:

Maintain accurate records of storage conditions, handling procedures, and usage to facilitate traceability and accountability. Provide comprehensive training to personnel involved in storage and handling to promote awareness and adherence to established guidelines.

Emergency Preparedness:

Develop and communicate emergency response protocols to address potential incidents such as spills or leaks promptly and effectively. Ensure availability of appropriate containment and cleanup materials, as well as training for personnel on emergency procedures.

By diligently following these storage and handling guidelines, users can uphold the quality and performance of lubricants, contributing to the smooth operation and longevity of equipment and machinery.