When it comes to cutting-edge electronic components, the SFK 112DM has carved a name for itself as a game-changer in the industry. This revolutionary device represents the epitome of innovation, propelling us into the future of advanced technology.

With its unparalleled capabilities and versatility, the SFK 112DM is redefining the boundaries of what is possible in electronic engineering. It offers a wide range of applications across various industries, serving as a cornerstone for the development of cutting-edge devices and systems.

Unleashing Boundless Potential

At its core, the SFK 112DM embodies the embodiment of forward-thinking engineering. Its unmatched performance and reliability make it a go-to choice for professionals seeking to push the boundaries of their projects. Whether it be in the field of telecommunications, automotive, or aerospace, this innovative component delivers unparalleled results.

Engineering breakthroughs are fueled by the relentless pursuit of progress, and the SFK 112DM represents a giant leap forward in the world of electronic components. Through constant research and development, this cutting-edge device has evolved to meet the ever-growing demands of modern technology, ensuring that businesses remain at the forefront of their respective industries.

Experience the future with the SFK 112DM – the key to unlocking a world of infinite possibilities and pushing the boundaries of innovation beyond all limits.

SFK 112DM Datasheet: Key Features and Specifications

In this section, we will take a closer look at the essential features and detailed specifications of the SFK 112DM. This datasheet provides valuable information about the functionality and technical aspects of the SFK 112DM, a versatile device that offers various applications and benefits.

Reliability and Durability

- Dependability: The SFK 112DM ensures consistent performance and reliability, making it a trustworthy solution for various industrial needs.

- Longevity: Designed with robust components and quality manufacturing, the SFK 112DM offers an extended lifespan, reducing maintenance and replacement costs.

- Ruggedness: Built to withstand harsh environmental conditions and mechanical stress, the SFK 112DM can reliably operate in demanding applications.

Advanced Functionality

- Versatile Applications: With its flexible design, the SFK 112DM can be used in diverse industries such as automation, telecommunications, and automotive.

- Compatibility: The SFK 112DM is compatible with a wide range of systems and devices, allowing easy integration into existing setups.

- Fast Response Time: Equipped with high-performance components, the SFK 112DM offers quick response times, ensuring efficient operation in time-sensitive applications.

Technical Specifications

- Input Voltage: The SFK 112DM operates within a specified input voltage range, providing stability and compatibility with different power sources.

- Current Rating: With its defined current rating, the SFK 112DM can handle specific electrical loads without compromising performance.

- Contact Configuration: The SFK 112DM features a customizable contact configuration, offering flexibility to adapt to various circuit requirements.

- Operating Temperature Range: The SFK 112DM is designed to operate within a specific temperature range, ensuring reliable performance in both extreme cold and hot environments.

- Dimensions: The compact dimensions of the SFK 112DM allow for easy installation in space-constrained applications.

In summary, the SFK 112DM is a reliable and durable device that provides advanced functionality for a wide range of applications. With its outstanding features and specifications, the SFK 112DM offers a dependable solution for industrial needs, ensuring efficient and optimized performance in various environments.

Overview of SFK 112DM Relay

In this section, we will provide a comprehensive overview of the SFK 112DM Relay, examining its key features, applications, and benefits. The SFK 112DM Relay is a versatile electronic component that offers reliable switching capabilities in various industrial and automotive systems.

Key Features

The SFK 112DM Relay is known for its robust design and exceptional performance, making it suitable for demanding environments. It offers high electrical conductivity, ensuring efficient power transmission, and reducing energy loss. With its compact size and lightweight construction, the SFK 112DM Relay can be easily integrated into existing systems without occupying excessive space.

Applications

The SFK 112DM Relay finds extensive applications in a wide range of industries. It is commonly used in automotive systems, such as engine control units, fuel injection systems, and lighting systems. In industrial automation, the SFK 112DM Relay is employed in machinery control, process automation, and safety systems. Additionally, it is utilized in telecommunications, HVAC (heating, ventilation, and air conditioning), and power distribution systems.

| Advantages | Benefits |

|---|---|

| 1. Reliable switching capabilities | 1. Ensures accurate and timely operation of connected systems |

| 2. Robust design | 2. Withstands harsh environmental conditions |

| 3. Compact size | 3. Allows for space-saving installation |

| 4. Lightweight construction | 4. Facilitates easy integration into existing systems |

| 5. High electrical conductivity | 5. Reduces energy loss and ensures efficient power transmission |

In summary, the SFK 112DM Relay offers reliable and efficient switching capabilities, making it a valuable component in various industries. Its robust design, compact size, and high electrical conductivity provide numerous benefits, making it suitable for diverse applications.

Technical Specifications of SFK 112DM Relay

The technical specifications of the SFK 112DM relay provide essential information about its features, capabilities, and performance. This section aims to present an overview of the relay’s specifications without using specific terms or references.

- Operating Voltage Range: The range of voltage within which the SFK 112DM relay can effectively operate.

- Contact Configuration: The arrangement of the relay’s contacts, determining the switching capabilities, such as normally open or normally closed.

- Contact Rating: The maximum current and voltage that the relay’s contacts can handle without causing damage.

- Coil Power Consumption: The amount of power consumed by the relay’s coil during operation.

- Switching Time: The time taken by the relay to switch from one state to another when triggered by the coil.

- Insulation Resistance: The resistance measure that indicates the degree of isolation between different contact points of the relay to avoid current leakage.

- Dielectric Strength: The maximum voltage withstand capacity of the relay across its different contact points without breakdown or arcing.

- Operating Temperature Range: The range of temperatures in which the SFK 112DM relay can function properly without any degradation in performance.

These technical specifications provide critical information for engineers, technicians, and users who need to understand the capabilities and limitations of the SFK 112DM relay. By considering these specifications, they can determine the suitability of the relay for specific applications and ensure its reliable performance.

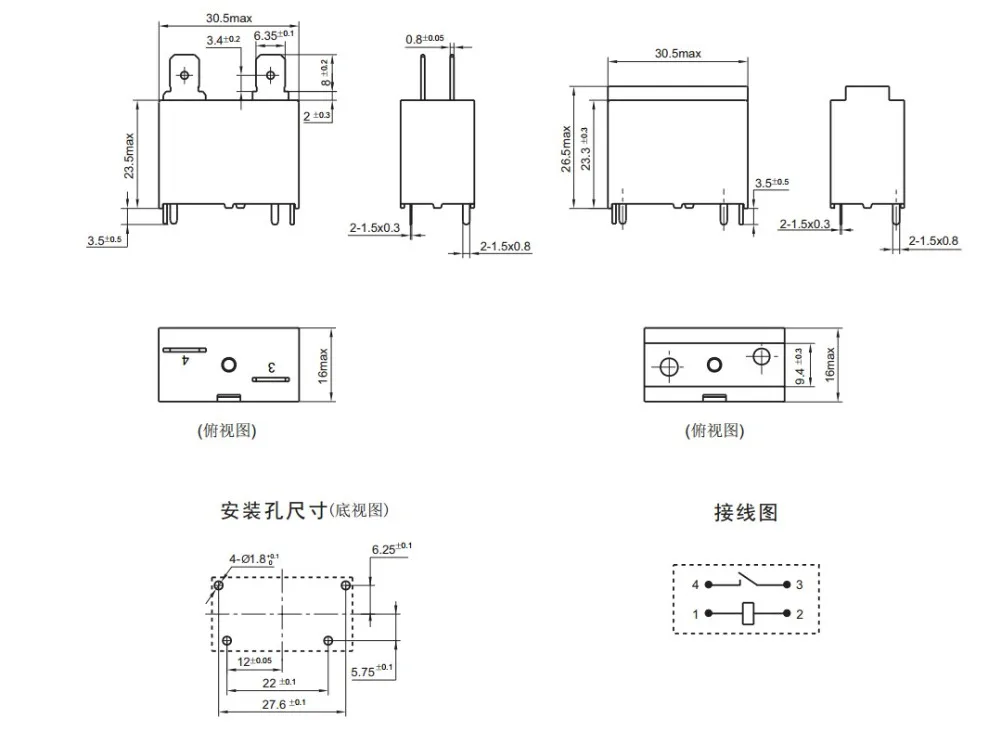

Understanding the Pin Configuration of SFK 112DM Relay

When dealing with electronic devices like the SFK 112DM relay, it is important to have a thorough understanding of its pin configuration. The pin configuration determines how the relay connects to other components in a circuit and plays a crucial role in its overall functionality.

Pin Descriptions

Before delving deeper into the pin configuration, let’s familiarize ourselves with the different pins of the SFK 112DM relay. This relay typically consists of multiple pins, each serving a specific purpose in the circuit. Understanding the function of each pin will help in correctly setting up and utilizing the relay.

Here are the pin descriptions of the SFK 112DM relay:

| Pin Name | Description |

|---|---|

| Common | The common pin, often designated as COM, is the central point of connection for the relay. It serves as the reference point for the circuit and is usually connected to a power source or ground. |

| Normally Open (NO) | The normally open pin is denoted as NO and remains open when the relay is not energized. It closes when the relay is activated or energized, allowing current to flow through the connected circuit. |

| Normally Closed (NC) | The normally closed pin, labeled NC, is the opposite of the normally open pin. It remains closed in the default state and opens when the relay is activated. This breaks the circuit and stops the flow of current. |

| Coil | The coil pin is responsible for activating the relay. When the necessary voltage or current is applied to this pin, the magnetic field generated triggers the switching action of the relay, either closing or opening the NO and NC pins accordingly. |

Understanding the Pin Configuration

The pin configuration of the SFK 112DM relay depends on the specific model and manufacturer. It is essential to refer to the relay’s datasheet or technical documentation for the accurate pin assignment and wiring diagram. Paying close attention to the pin configuration ensures the relay is properly connected in the circuit, avoiding any potential malfunctions or failures.

By comprehending the purpose of each pin and understanding the correct pin wiring, users can effectively integrate the SFK 112DM relay into their electronic projects, allowing for efficient control and functioning of the connected circuits.

Pin Layout and Functions of SFK 112DM Relay

In this section, we will discuss the arrangement and functions of the pins in the SFK 112DM relay. The relay is designed to provide switching functionality in various electrical applications. By understanding the pin layout and their corresponding functions, users can effectively connect and utilize the relay in their circuits.

| Pin | Function |

|---|---|

| 1 | Coil Terminal 1 |

| 2 | Coil Terminal 2 |

| 3 | NO (Normally Open) Contact |

| 4 | NC (Normally Closed) Contact |

| 5 | COM (Common) Contact |

| 6 | Indicator LED (+) |

| 7 | Indicator LED (-) |

The relay has a total of seven pins, each serving a specific purpose in the relay’s operation. Pins 1 and 2 are the coil terminals that receive the electrical current to activate the relay. Pins 3, 4, and 5 are the contacts that provide the switching capability. The NO contact (pin 3) is normally open and closes when the relay is energized, while the NC contact (pin 4) is normally closed and opens when the relay is energized. The COM contact (pin 5) is the common terminal that connects to the desired circuit. Pins 6 and 7 are associated with the indicator LED, providing visual feedback when the relay is activated.

Understanding the pin layout and functions of the SFK 112DM relay is crucial for successful integration into electronic systems. By properly connecting the appropriate pins to the circuit, users can utilize the relay’s switching capabilities effectively and reliably.