Unlocking the potential of innovative engineering solutions, delving into the intricacies of machinery intricately designed to power industrial processes, lies at the heart of our exploration. In the realm of industrial automation, understanding the intricate specifications and capabilities of pivotal components fuels progress and efficiency. In this journey, we embark on deciphering the technical blueprint that drives modern industrial machinery forward, offering insights into the fundamental elements that propel manufacturing realms into the future.

Embarking on this odyssey, we navigate through the labyrinth of technical documentation, seeking to unravel the mysteries encapsulated within. With a keen eye for detail and an insatiable curiosity, we delve deep into the labyrinthine corridors of specifications, seeking not just data, but comprehension. Every line, every curve, whispers tales of precision engineering and meticulous design, beckoning us to decipher their secrets and harness their power.

Through this voyage of discovery, we aim to illuminate the pathways for engineers, enthusiasts, and innovators alike, offering clarity amidst the dense fog of technical jargon. Our quest is not merely to consume information, but to distill it into actionable insights, empowering those who dare to dream of a more efficient, more connected tomorrow.

Understanding Specifications in the Documentation of Electric Engine Components

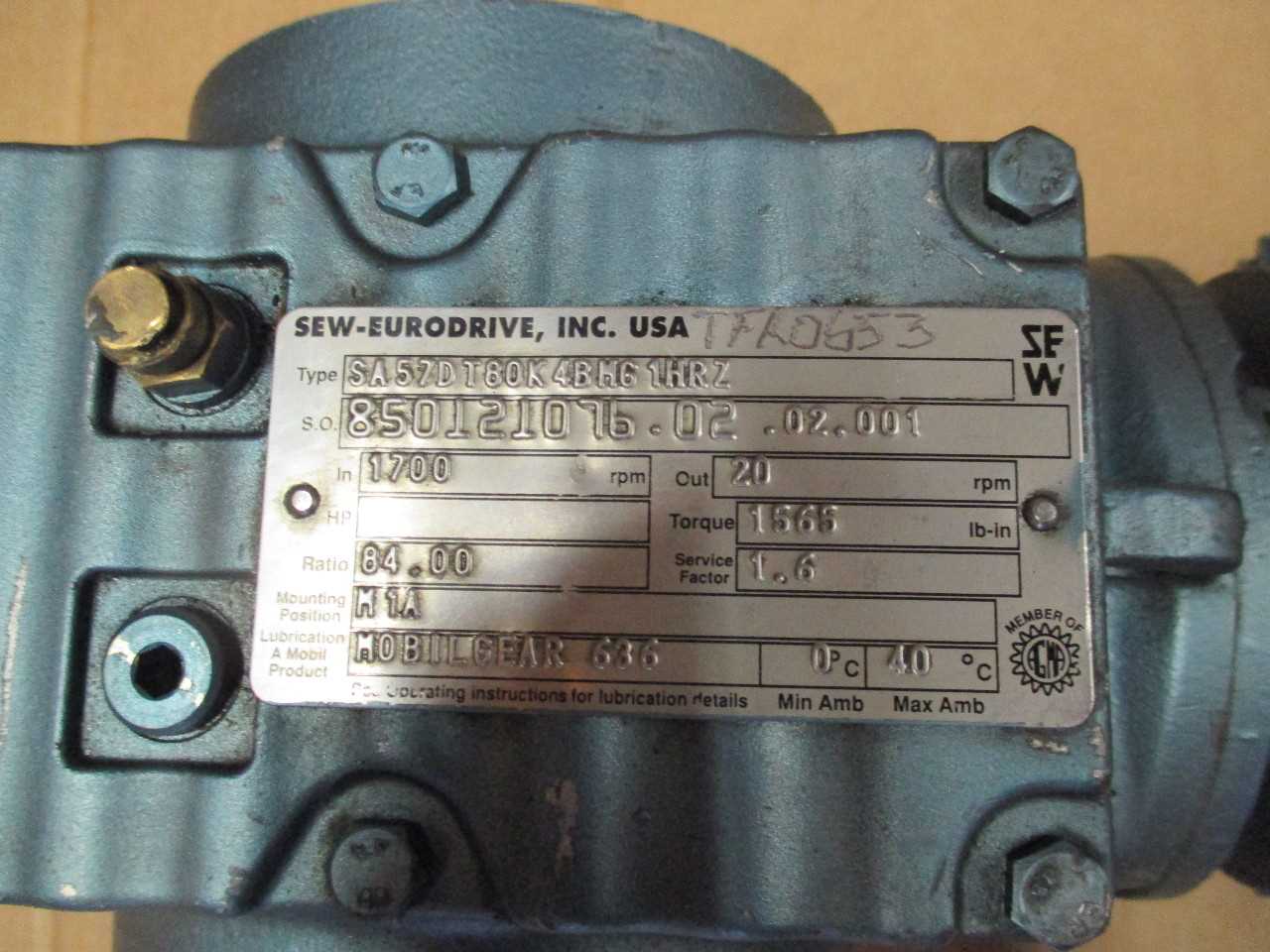

In the realm of industrial machinery, deciphering the intricacies of component specifications is paramount for informed decision-making and optimal performance. When delving into the technical documentation of electric engine components, a nuanced understanding of the provided specifications is indispensable.

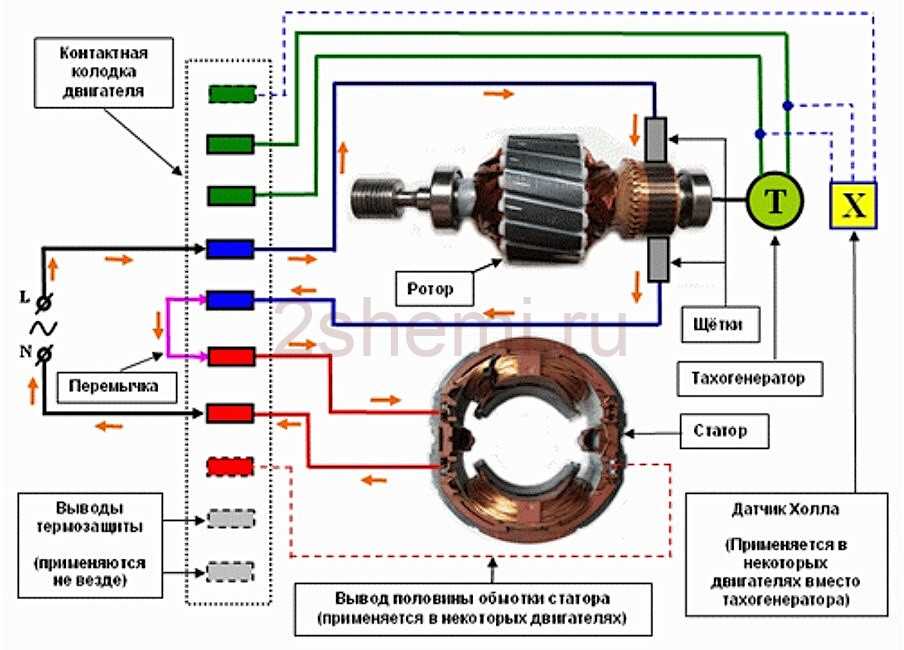

Deciphering Performance Metrics

- Unraveling the metrics that gauge operational efficiency.

- Interpreting parameters indicative of torque, speed, and power.

- Analyzing efficiency ratings and their implications on energy consumption.

Navigating Mechanical Characteristics

- Understanding dimensions, weights, and structural compositions.

- Evaluating thermal limits and environmental considerations.

- Assessing vibration levels and noise emissions for operational compatibility.

Grasping the nuances encapsulated within the specifications of electric engine components empowers engineers and operators to make informed choices, ensuring seamless integration and optimal performance within diverse industrial settings.

Deciphering Technical Jargon

In the realm of engineering documentation, navigating through the labyrinth of technical terminology can often feel like deciphering a complex code. Understanding the intricacies of technical jargon is paramount for engineers and enthusiasts alike to glean meaningful insights from technical documents.

Breaking Down Complexity

Technical jargon serves as the language of precision, encapsulating nuanced concepts and specifications essential for comprehending intricate systems. However, this dense lexicon can pose a formidable barrier to those unfamiliar with its intricacies. Hence, breaking down this complexity into digestible fragments is imperative for effective communication and comprehension.

Unveiling Key Terminologies

Unraveling the enigma of technical jargon entails unveiling key terminologies that constitute the foundation of the subject matter. By elucidating the meanings behind obscure terms and acronyms, individuals can unlock a deeper understanding of the intricacies inherent in technical documentation.

| Term | Definition |

|---|---|

| Specification | A detailed description of the design and performance parameters of a component or system. |

| Parameter | A measurable characteristic that defines the behavior or functionality of a component. |

| Rating | The maximum capacity or performance level of a component under specified conditions. |

| Efficiency | The ratio of useful output to input in a system, often expressed as a percentage. |

By dissecting technical jargon and elucidating its underlying meanings, individuals can navigate through complex documentation with confidence, unraveling the mysteries concealed within.

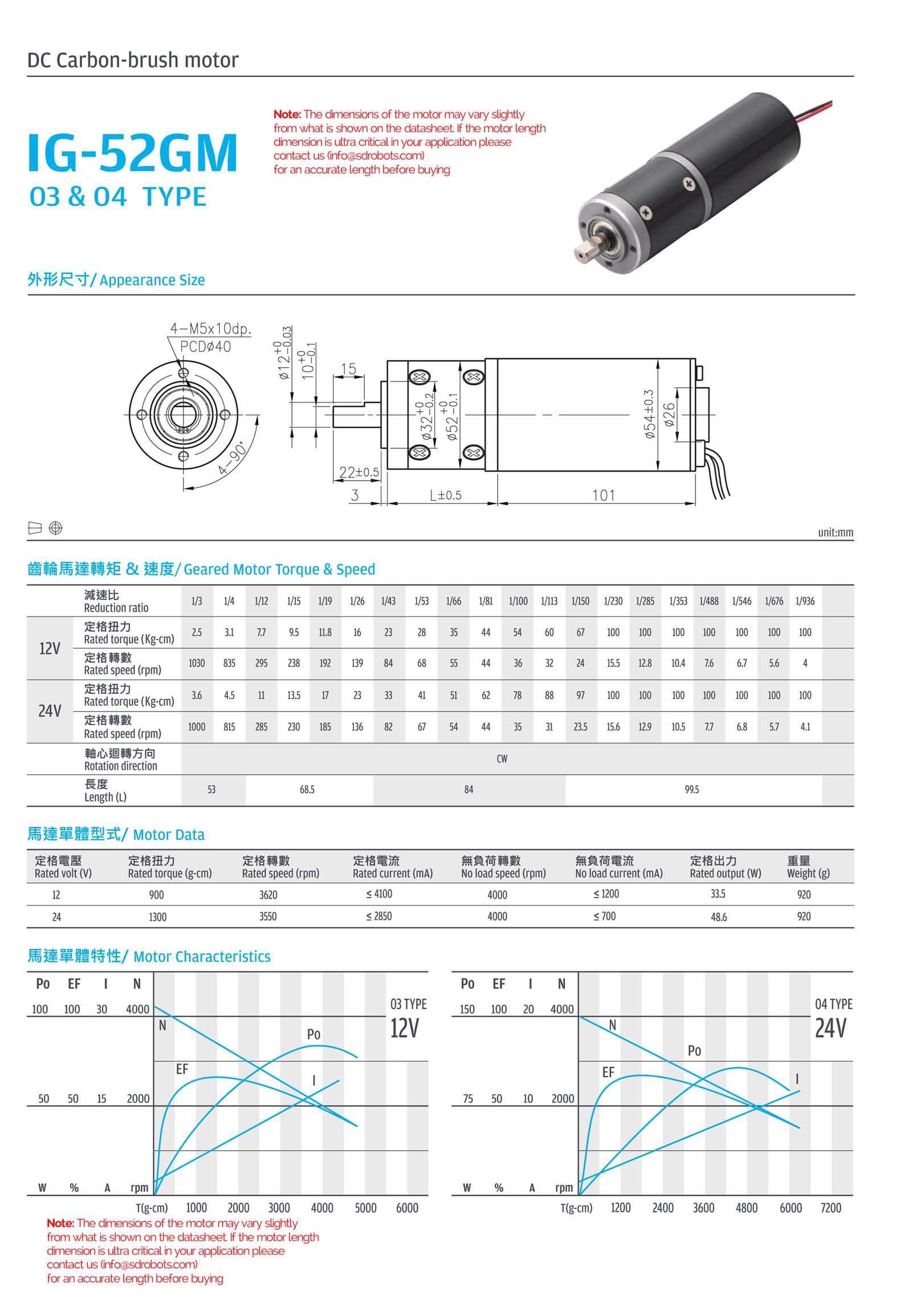

Interpreting Performance Metrics

Understanding the metrics provided in technical documentation is crucial for gaining insights into the functionality and capabilities of a particular machinery component. In this section, we delve into the significance of performance indicators, elucidating their implications on operational efficiency and overall system performance.

Deciphering Efficiency Parameters

Efficiency metrics offer invaluable insights into the effectiveness of a given component within a machinery system. By analyzing parameters such as energy utilization, power output, and operational efficacy, engineers can ascertain the resource utilization efficiency and potential areas for optimization.

Evaluating Operational Characteristics

Beyond efficiency, a comprehensive understanding of operational characteristics is imperative for optimizing system performance. Metrics pertaining to torque, speed, and responsiveness provide essential data for assessing the dynamic behavior of the component under varying operating conditions, enabling engineers to fine-tune control strategies and enhance overall system performance.

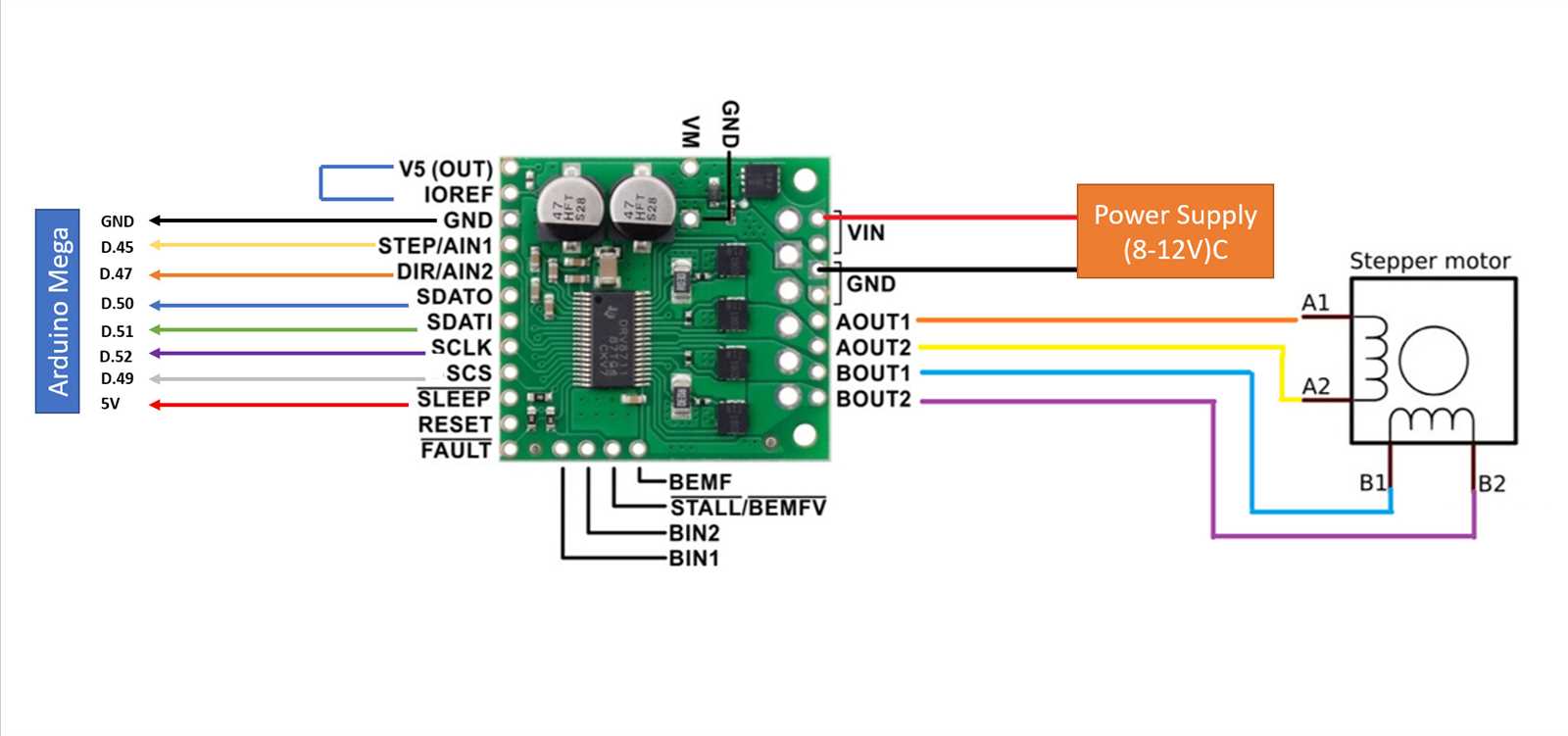

Insights into Applying Technical Specifications: A Deep Dive

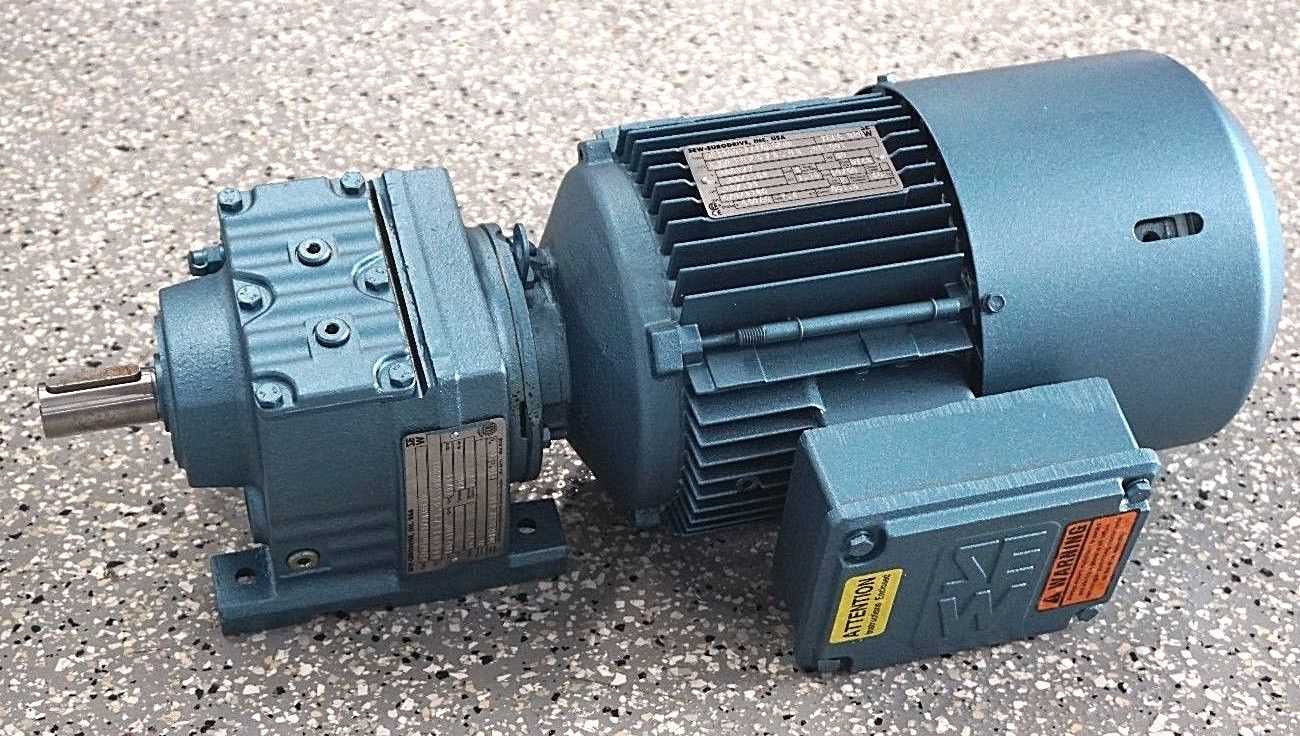

In this section, we delve into the practical applications and implications of the technical specifications provided in the document. Understanding how these specifications translate into real-world scenarios is crucial for optimizing the performance and efficiency of your machinery.

Optimizing Performance

Maximizing efficiency: Explore strategies for leveraging the motor’s capabilities to enhance overall system efficiency. This involves aligning load requirements with the motor’s torque and speed characteristics to operate within optimal ranges.

Ensuring Reliability

Temperature management: Delve into methods for effectively managing temperature rise within the motor to maintain reliability and prolong its operational lifespan. Understanding thermal limits and implementing appropriate cooling mechanisms is essential for preventing overheating and component degradation.

Vibration mitigation: Learn how to mitigate vibration effects on the motor and surrounding equipment through proper installation techniques and vibration-dampening measures. Minimizing vibration not only enhances performance but also reduces wear and tear, ultimately extending the motor’s longevity.

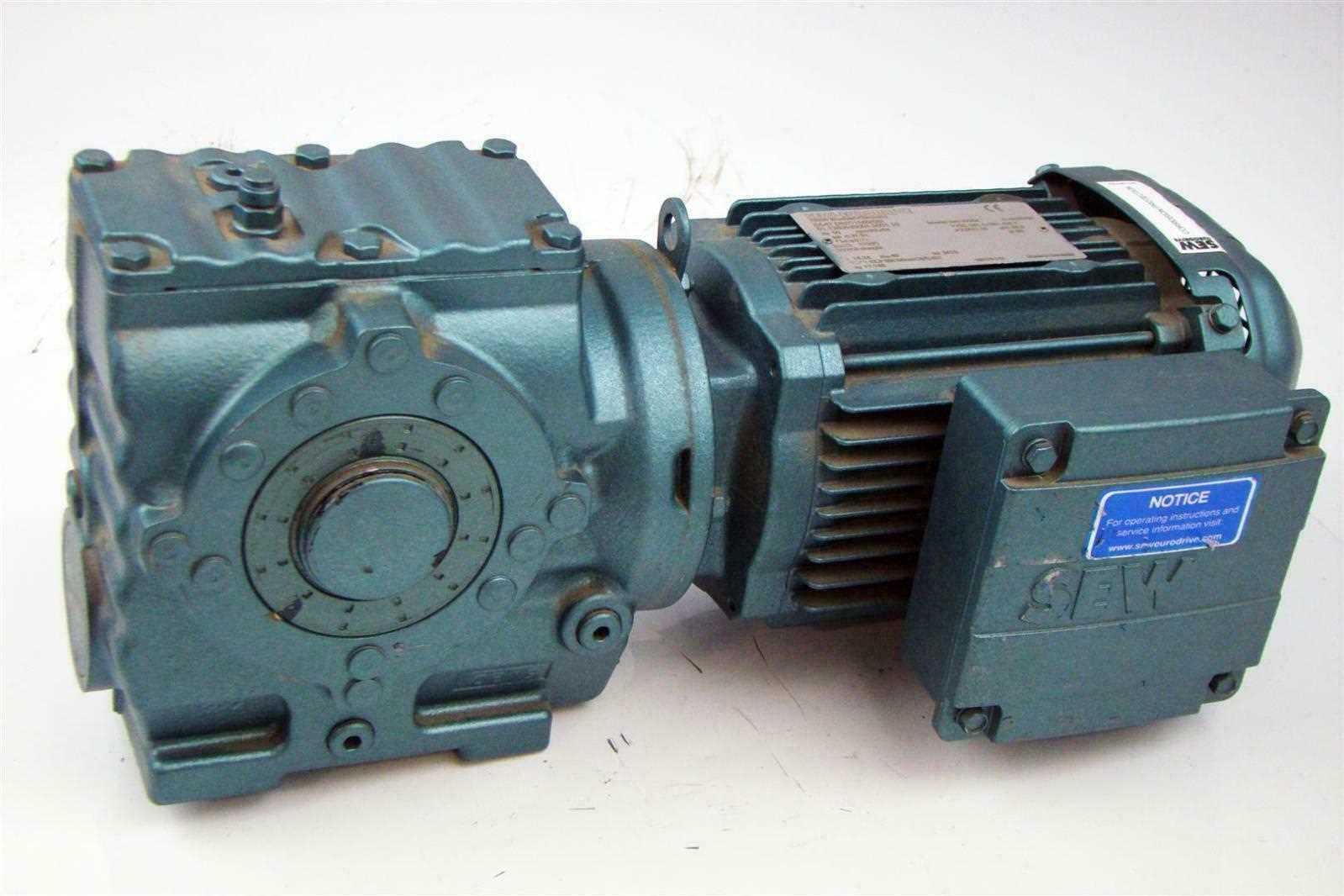

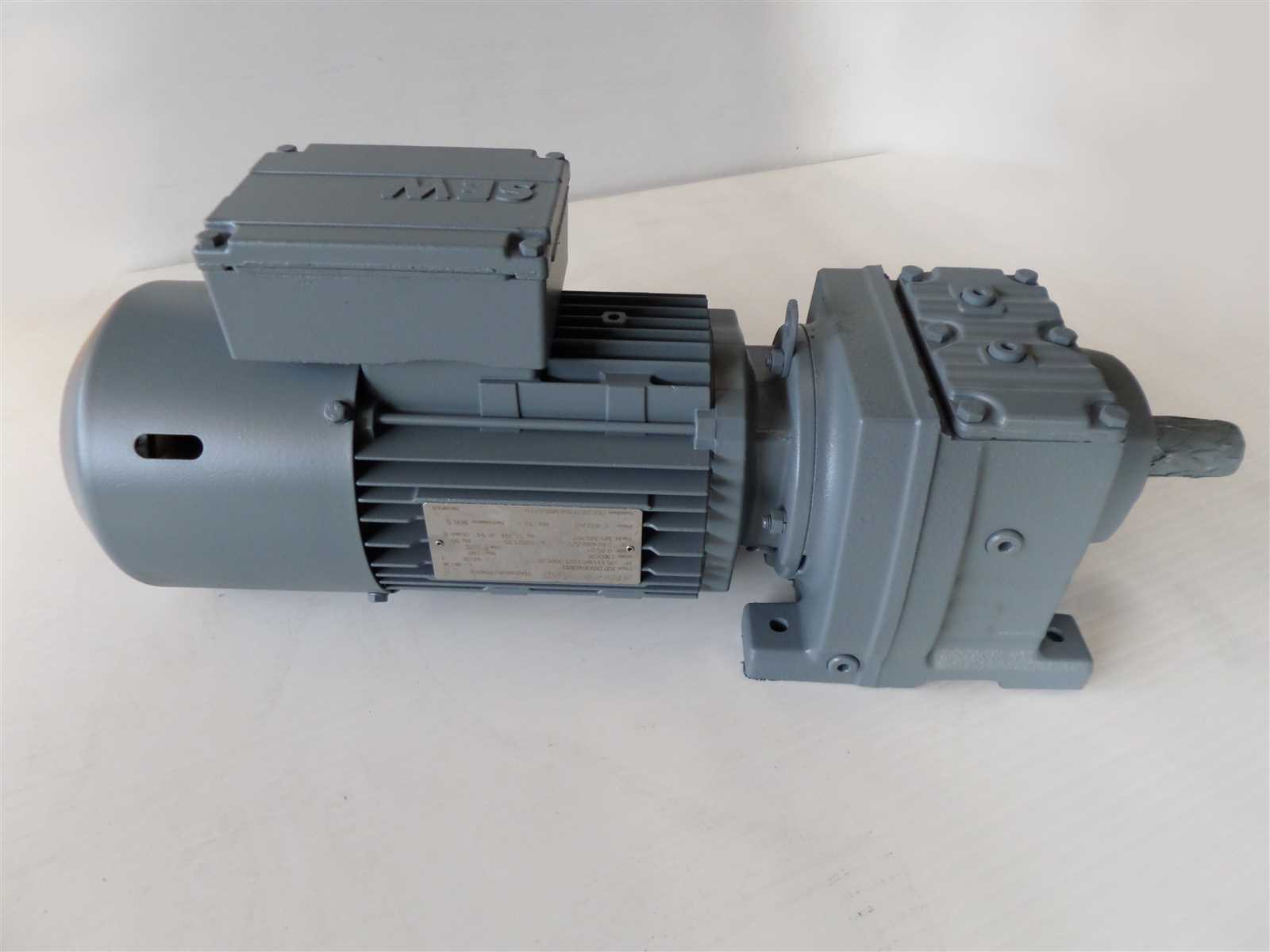

Optimizing Motor Selection

When delving into the realm of selecting the ideal propulsion component for your machinery, a meticulous approach is paramount. This segment navigates the intricate terrain of refining the choice of kinetic drivers to harmonize seamlessly with your application’s requisites. Embracing a comprehensive strategy entails a judicious examination of various parameters, encompassing torque specifications, efficiency metrics, and operational dynamics.

Embarking on the journey to optimize motor selection entails a multifaceted analysis of diverse factors interplaying within the operational ecosystem. Beyond mere numerical specifications lie nuanced considerations such as environmental constraints, thermal thresholds, and structural compatibility. Crafting a synergistic alignment between the envisioned functionality and the intrinsic characteristics of the chosen propulsion unit emerges as the cornerstone of this endeavor.

Scrutinizing the intricacies of motor selection involves an iterative process, underscored by the pursuit of equilibrium between performance prowess and resource allocation. Striking the delicate balance between power output, size constraints, and cost-effectiveness heralds the advent of a meticulously tailored solution. In navigating this labyrinthine landscape, cognizance of emerging technologies and industry trends serves as a guiding compass, facilitating informed decisions poised for future scalability.

Furthermore, a holistic approach to motor optimization extends beyond the realms of technical prowess, encompassing considerations of sustainability and ecological impact. Embracing energy-efficient designs and renewable energy sources underscores a commitment to environmental stewardship, fostering a symbiotic relationship between technological innovation and ecological harmony.