Exploring the intricacies of an electrical powerhouse reveals a labyrinth of details that propel machines into motion. Delving into the enigmatic realm of specifications unveils a tapestry of intricately woven data, guiding the trajectory of innovation.

Unveiling the essence of this technological marvel requires deciphering the cryptic language that delineates its capabilities. Beyond mere numbers lie the blueprints of potential, encapsulating the essence of power and performance.

Embark on a journey through the labyrinth of descriptors, where each digit and symbol serves as a beacon illuminating the path towards efficiency and efficacy. These specifications, like pieces of a puzzle, interlock to form a comprehensive portrait of functionality and form.

The Fundamentals of RS550 Motor Documentation

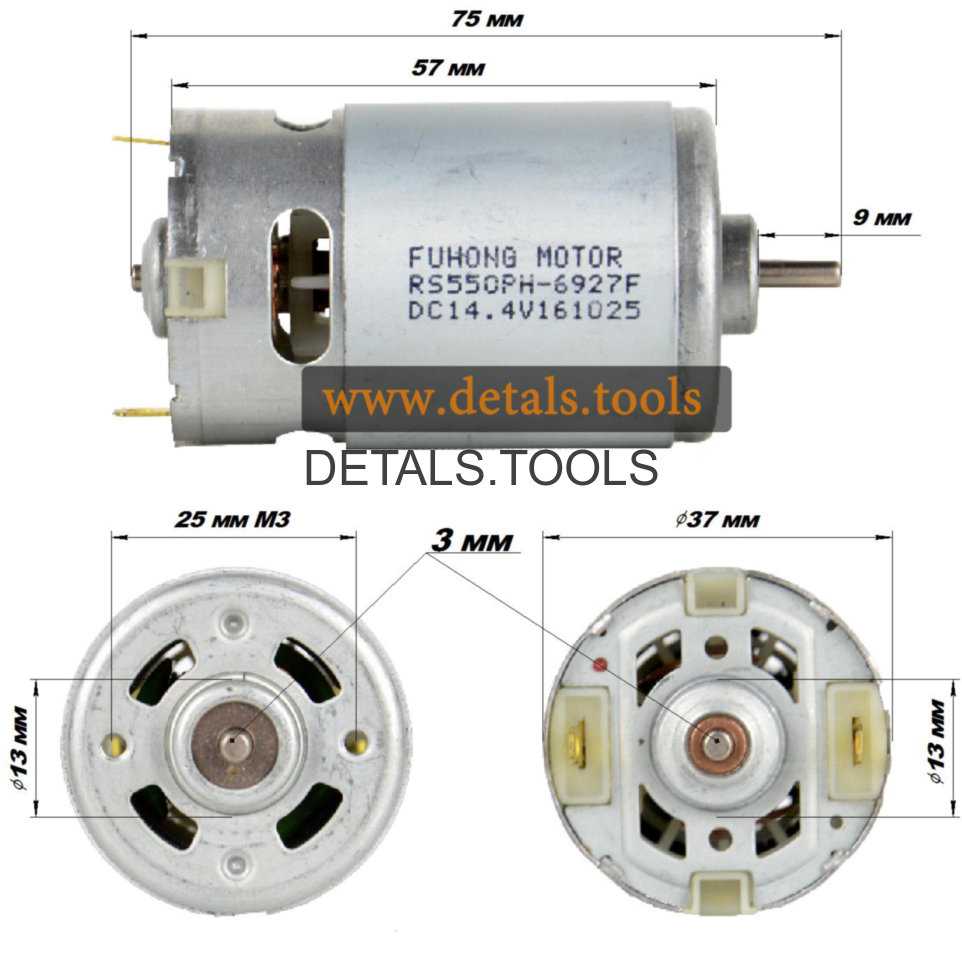

In this section, we delve into the foundational aspects of understanding the technical specifications provided in documentation pertaining to the powerful RS550 motor. Exploring the intricacies of this documentation is essential for comprehending the capabilities and limitations of this robust machinery.

Understanding Technical Parameters

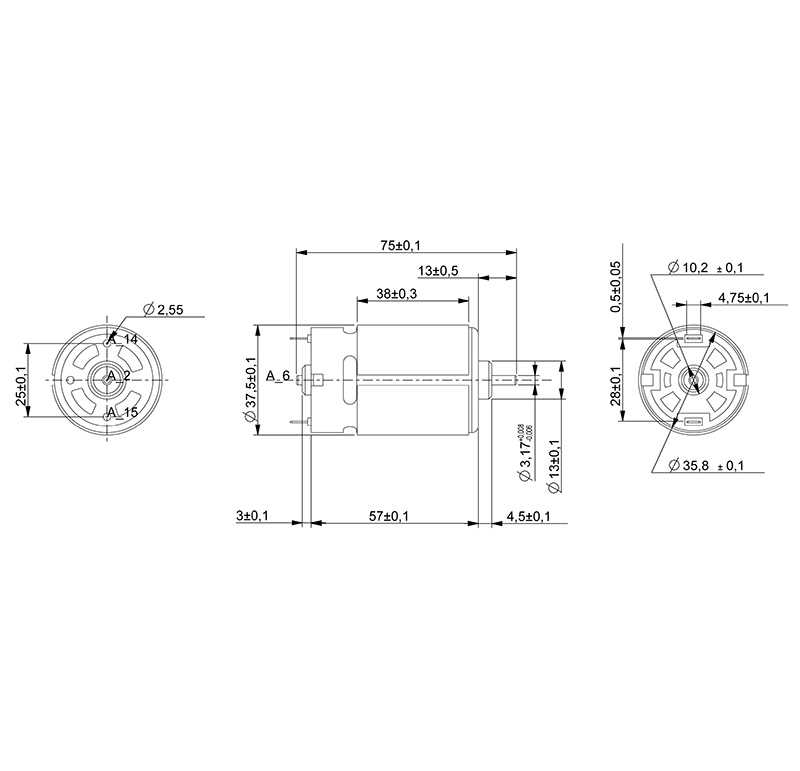

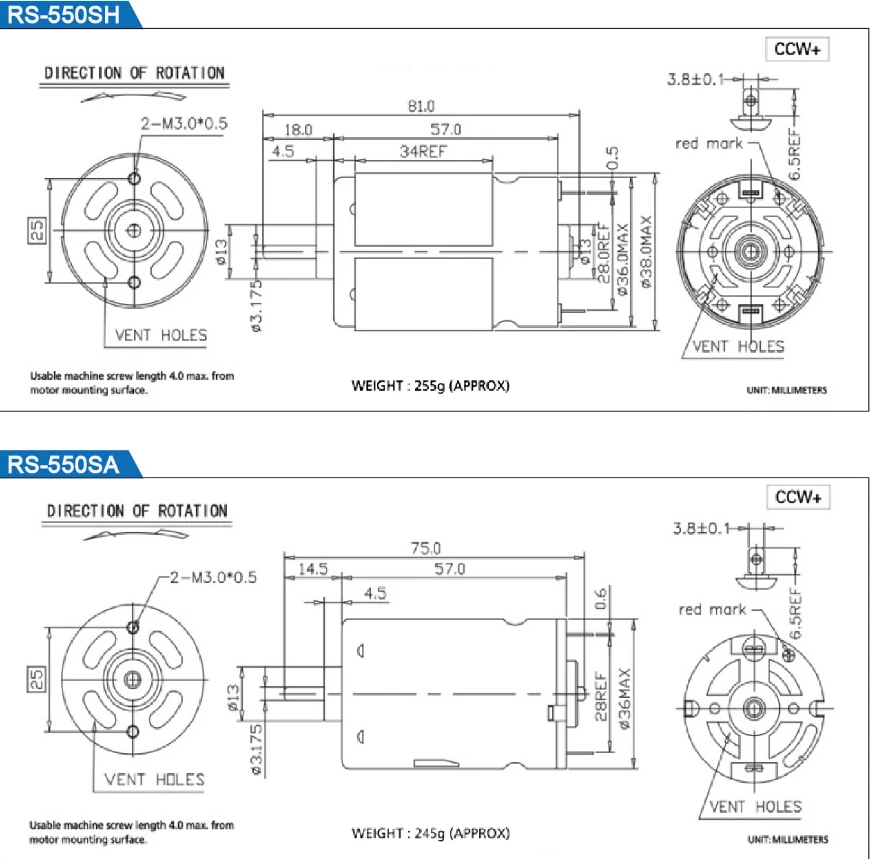

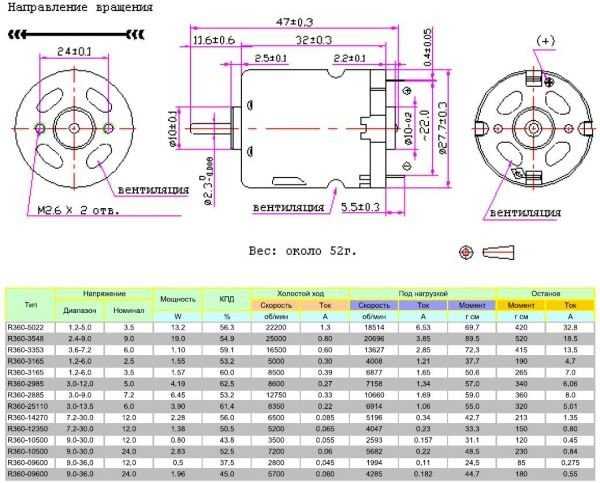

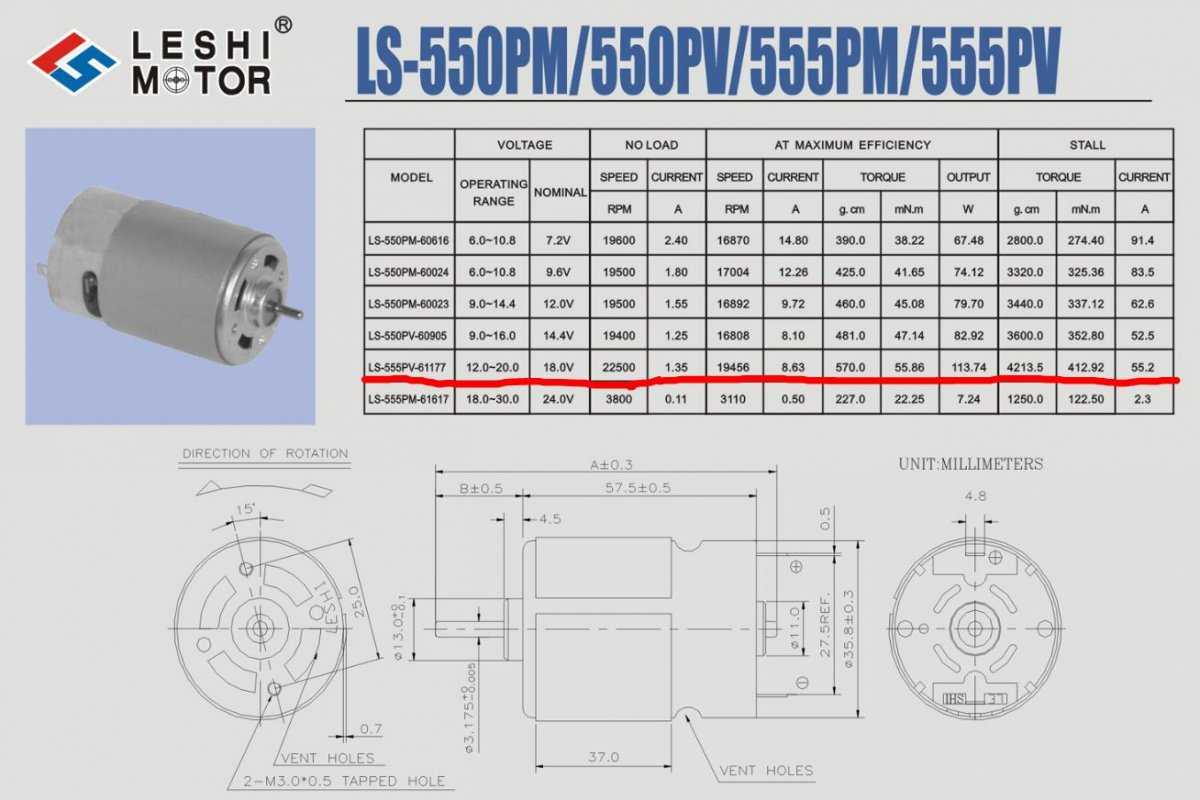

When dissecting the RS550 motor documentation, it is imperative to grasp the significance of the technical parameters outlined within. These parameters serve as the cornerstone for evaluating the performance and compatibility of the motor within various applications. From voltage ratings to current consumption, each parameter offers valuable insights into the operational characteristics of the motor.

Analyzing Performance Graphs

Another crucial aspect of RS550 motor documentation is the inclusion of performance graphs. These visual representations offer a comprehensive overview of the motor’s behavior under different operating conditions. By interpreting these graphs with precision, engineers can anticipate the motor’s response to varying loads and make informed decisions regarding its utilization.

Understanding Technical Specifications

In the realm of engineering and technology, deciphering technical specifications forms the bedrock of informed decision-making and effective implementation. These documents serve as comprehensive guides, delineating the intricacies and functionalities of various components and systems. Mastery over technical specifications fosters a deeper comprehension of product capabilities, enabling engineers and enthusiasts alike to harness the full potential of their creations.

Deciphering Terminology: Technical specifications are often laden with specialized jargon and terminology unique to the field. Mastery over this lexicon is paramount for accurate interpretation and utilization of the information provided. Understanding the nuances between terms ensures precise comprehension, facilitating seamless integration into projects and applications.

Clarity in Performance Metrics: Embedded within technical specifications are performance metrics that serve as benchmarks for evaluating the efficacy of a given component or system. Grasping the significance and implications of these metrics empowers engineers to make informed comparisons and selections based on their project requirements and performance expectations.

Analyzing Operational Parameters: Beyond performance metrics, technical specifications elucidate the operational parameters governing the functionality and limitations of a component or system. Delving into these parameters unveils crucial insights into operational boundaries, ensuring optimal performance and longevity while mitigating the risk of operational failures.

Interpreting Environmental Considerations: Technical specifications often encapsulate environmental considerations that dictate the suitability of a component or system for specific applications and operating conditions. Discerning these considerations is pivotal in ensuring compatibility and resilience in diverse environmental settings.

Embracing Standards and Certifications: Compliance with industry standards and certifications is a hallmark of reliability and quality assurance. Technical specifications elucidate adherence to these standards, offering assurances of performance consistency and regulatory compliance, thus instilling confidence in the reliability and integrity of the product.

Forecasting Future Adaptability: Anticipating future adaptability and scalability is integral to long-term project planning and sustainability. Technical specifications provide insights into the adaptability of components and systems to evolving technological landscapes, empowering engineers to future-proof their designs and investments.

Mastering the art of understanding technical specifications is not merely a skill but a strategic imperative in the pursuit of engineering excellence and innovation.

Applications and Implementations

In this section, we explore the diverse array of practical uses and real-world scenarios where the versatile capabilities of the Rs550 motor find relevance. From powering small-scale mechanical systems to driving intricate machinery, the applications span across various industries and fields. Let’s delve into the myriad implementations that leverage the intrinsic characteristics of this dynamic motor.

| Automotive Sector: | Within the automotive industry, the Rs550 motor plays a pivotal role in powering electric vehicles, hybrid cars, and auxiliary systems such as power windows, mirrors, and seat adjustments. Its compact size and efficient performance make it an ideal choice for enhancing vehicle functionality. |

| Robotics and Automation: | Robotics enthusiasts and industrial automation engineers often integrate the Rs550 motor into robotic arms, automated assembly lines, and unmanned aerial vehicles (UAVs). Its precise control and high torque output contribute to the smooth operation of these sophisticated systems. |

| Consumer Electronics: | From household appliances like vacuum cleaners and electric shavers to entertainment devices such as drones and remote-controlled toys, the Rs550 motor powers a myriad of consumer electronics. Its reliability and energy efficiency make it a preferred choice for manufacturers seeking to enhance product performance. |

| Industrial Machinery: | In industrial settings, the Rs550 motor finds applications in conveyor systems, packaging machines, and CNC (Computer Numerical Control) equipment. Its robust construction and adaptable nature enable seamless integration into diverse manufacturing processes, optimizing efficiency and productivity. |

| Renewable Energy: | Renewable energy initiatives harness the Rs550 motor for wind turbines, solar tracking systems, and hydroelectric generators. Its ability to convert renewable energy sources into usable electrical power contributes to sustainable energy solutions, promoting environmental conservation. |

These examples merely scratch the surface of the extensive applications and implementations of the Rs550 motor across various domains. Its versatility, reliability, and performance make it a cornerstone of modern technological advancements, driving innovation and progress in diverse fields.

Tips for Efficient Utilization

Maximizing the Performance: Enhancing the output of the propulsion mechanism requires a meticulous understanding of its operational dynamics. By optimizing operational parameters and fine-tuning performance settings, users can unlock the full potential of the propulsion system.

Optimal Power Management: Achieving peak efficiency necessitates judicious power allocation strategies. Implementing intelligent power management techniques ensures balanced distribution of resources, thereby minimizing wastage and enhancing overall system efficacy.

Enhancing Operational Efficiency: Streamlining operational procedures plays a pivotal role in augmenting efficiency levels. Leveraging advanced control algorithms and integrating cutting-edge technologies enables smoother operation and reduces energy expenditure, thereby maximizing resource utilization.

Strategic Resource Allocation: Efficient utilization entails strategic allocation of available resources. By prioritizing tasks and allocating resources based on priority and demand, users can ensure optimal utilization of available resources while minimizing idle time and energy consumption.

Continuous Monitoring and Optimization: Sustaining peak performance requires constant vigilance and proactive optimization efforts. Regular monitoring of system metrics coupled with iterative optimization ensures sustained efficiency gains and prolonged operational longevity.