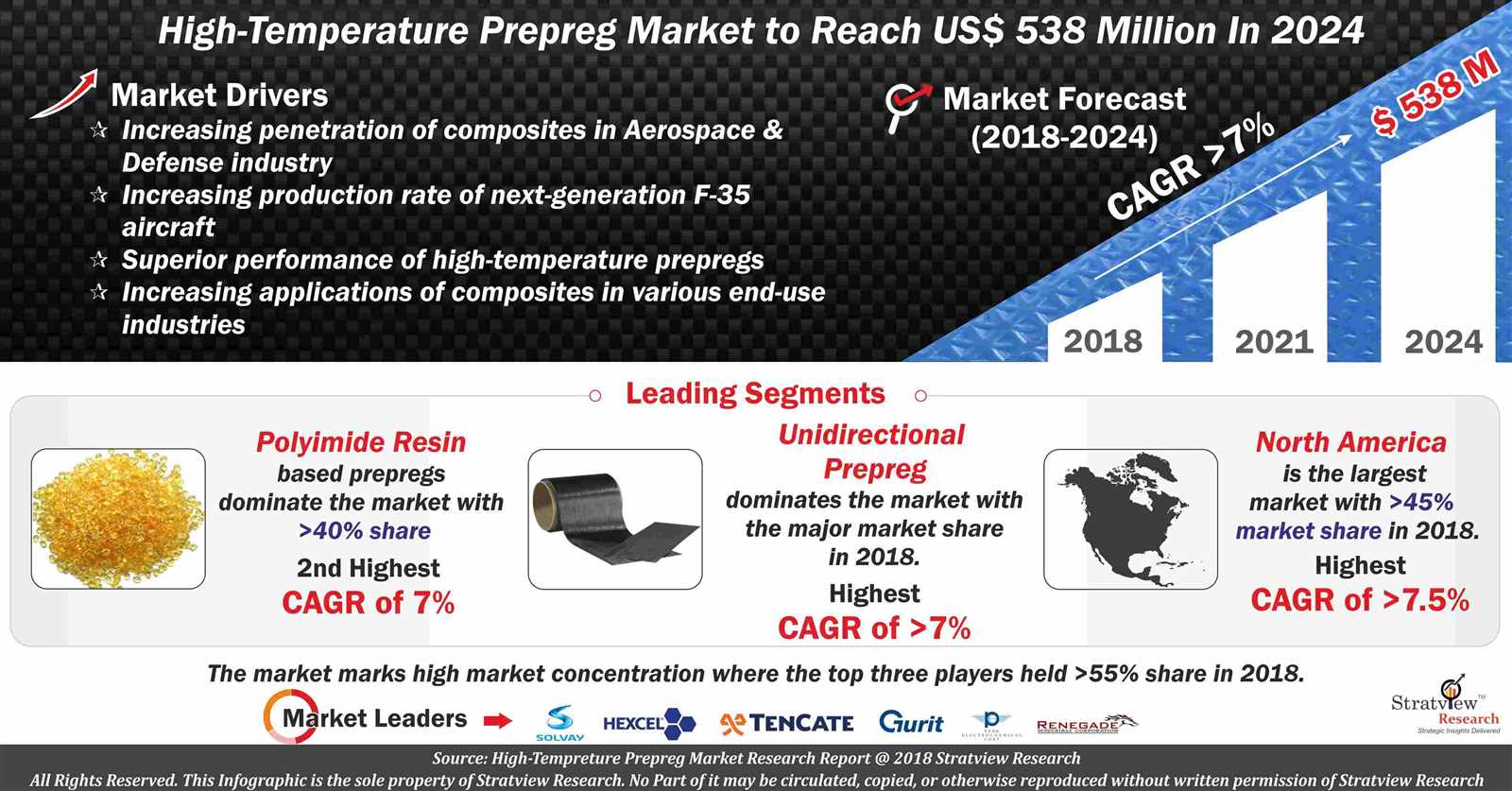

Discovering and staying up-to-date with the latest advancements in composite materials is crucial for engineers, designers, and manufacturers alike. It is through detailed technical information that groundbreaking innovations can be achieved. In this section, we will delve into the realm of Prepreg Datasheets – an essential resource for understanding the characteristics and performance capabilities of these revolutionary materials.

Unveiling the Science Behind Prepregs

The journey towards creating high-performance composites begins with a precise understanding of the intricate chemistry and manufacturing processes. Prepregs, the building blocks of composite materials, consist of reinforcement fibers impregnated with a matrix material, typically a thermoset resin. The combination of these elements provides the mechanical strength, durability, and versatility that make prepregs a sought-after solution across various industries.

Embarking on a Technical Exploration

In order to harness the full potential of prepregs, it is crucial to explore the comprehensive technical information available in datasheets. Datasheets serve as a valuable repository of knowledge, encompassing a wide range of details including mechanical properties, curing processes, temperature resistance, and much more. By thoroughly analyzing these datasheets, engineers are armed with the necessary information to make informed decisions regarding material selection, design optimization, and manufacturing techniques.

Empowering Innovators

By offering a combination of strength, lightweight properties, and exceptional performance, prepregs have revolutionized industries such as aerospace, automotive, sports equipment, and renewable energy. Through the technical information provided in datasheets, engineers and innovators are empowered to bring their ideas to life, pushing the boundaries of what is possible in the world of composite materials.

What is a Prepreg Datasheet and Why is it Important?

Understanding the characteristics and properties of a material is crucial in any industry that involves the use of composite materials. For those working with prepreg materials, a prepreg datasheet serves as a valuable source of information to guide the design, production, and performance of various components and products.

Importance of Prepreg Datasheets

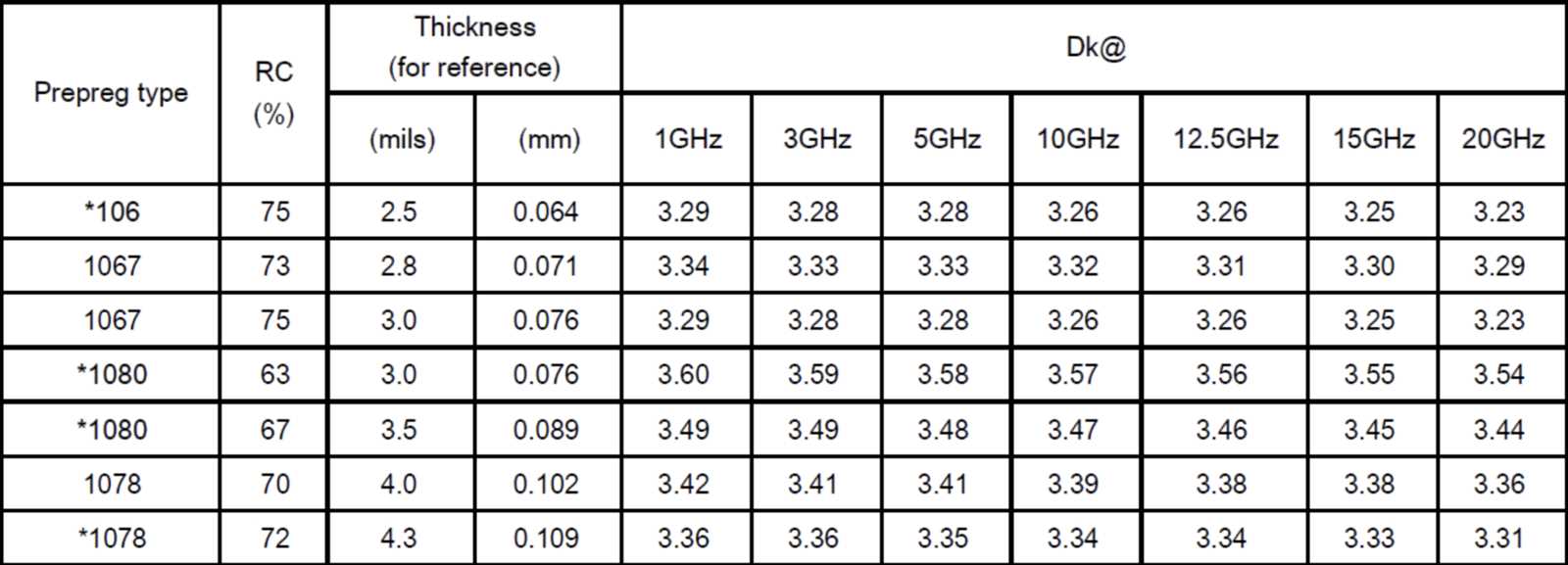

Prepreg datasheets provide essential data and specifications that help engineers, designers, and manufacturers make informed decisions regarding the selection and application of prepreg materials. These datasheets outline crucial information regarding the composite material’s mechanical, thermal, electrical, and physical properties, as well as processing guidelines and environmental considerations.

By referring to a prepreg datasheet, professionals gain insight into the material’s strength, stiffness, and durability. This information enables them to determine whether the material is suitable for specific applications and to predict its expected performance under various conditions. Additionally, the datasheet’s guidance on processing parameters ensures that manufacturers adhere to the recommended cure cycles, temperature ranges, and handling precautions. This helps achieve consistent product quality and reduces the risk of manufacturing defects.

Content of a Prepreg Datasheet

A typical prepreg datasheet includes specific sections highlighting various aspects of the material, such as:

| Section | Description |

|---|---|

| Composition | Details the types and percentages of fibers, resins, and other additives used in the prepreg material. |

| Mechanical Properties | Provides information on the material’s tensile strength, flexural strength, impact resistance, and other mechanical properties. |

| Thermal Properties | Outlines the material’s thermal conductivity, coefficient of thermal expansion, and temperature resistance. |

| Electrical Properties | Describes the material’s electrical conductivity, dielectric constant, and insulation properties. |

| Processing Guidelines | Offers recommendations for storage, handling, curing, and processing techniques to ensure optimal material performance. |

| Environmental Considerations | Highlights any specific precautions or guidelines for handling and disposing of the material in an environmentally responsible manner. |

Having access to a comprehensive prepreg datasheet empowers professionals in the composites industry to make well-informed decisions, optimize their manufacturing processes, and ultimately produce high-quality and reliable products.

Understanding the Basics of Prepreg Materials

In the realm of material engineering, there exists a class of composites that hold immense potential for various industries. These materials offer unparalleled strength, durability, and versatility, making them indispensable in fields such as aerospace, automotive, and electronics. This section aims to provide an in-depth understanding of the fundamentals of these remarkable materials.

Unveiling the Essence of Prepregs

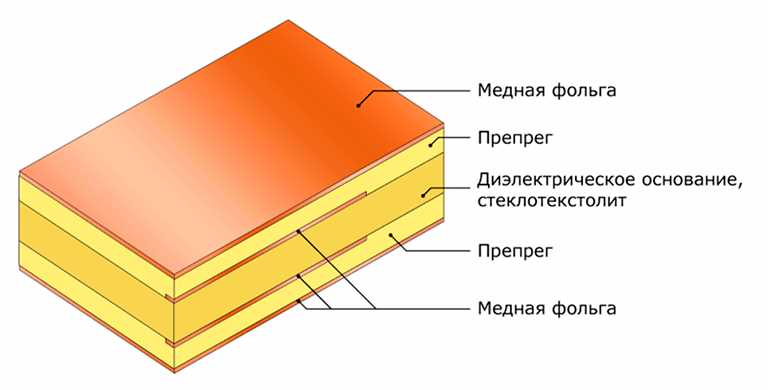

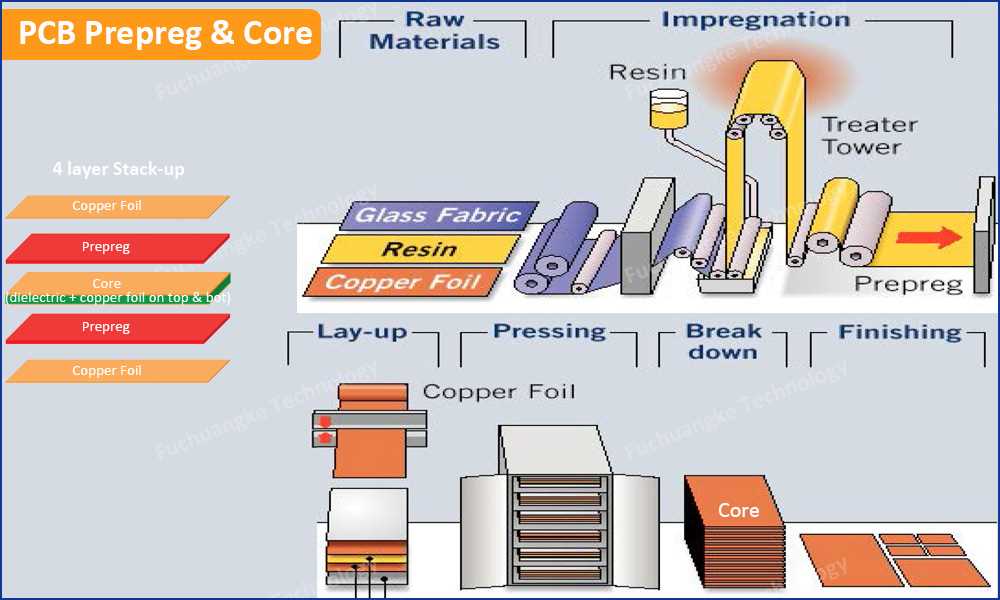

At the core of modern composite technology lie prepreg materials, which embody a unique combination of fibers and resin matrix. Unlike traditional composites, prepregs come pre-impregnated with a precise amount of resin, giving them a distinct advantage in terms of consistency and quality control. This advanced manufacturing method allows for optimal resin-to-fiber ratio, resulting in superior mechanical properties and exceptional performance characteristics.

Delving into the Composition

Fiber Reinforcement: The backbone of any prepreg material is its fiber reinforcement. These fibers, commonly made of materials like carbon, glass, or aramid, provide the composite with exceptional strength and stiffness. They are carefully arranged in a specific orientation to maximize the desired mechanical properties of the final product.

Resin Matrix: Serving as the glue that binds the fiber reinforcement together, the resin matrix plays a critical role in determining the overall characteristics of the prepreg material. Resins act as a medium for load transfer, providing protection against moisture, chemicals, and external impacts. Different types of resins can be used, each offering unique benefits such as elevated temperature resistance or electrical insulation.

Modifiers and Additives: To further enhance the properties of prepreg materials, various modifiers and additives can be incorporated into the resin matrix. These can include toughening agents, flame retardants, and fillers, among others. Such additives can significantly enhance the composite’s resistance to impact, fire, or other specialized requirements.

By grasping the fundamental principles behind prepregs, one gains a deeper appreciation for the widespread application of these materials across industries. Whether it’s for lightweight aircraft components, high-performance racing cars, or cutting-edge electronic devices, prepregs truly offer the foundation for innovation and advancement.

An Overview of Prepreg Datasheets and their Role in Manufacturing

Datasheets play a crucial role in the manufacturing industry as they provide a comprehensive overview of various materials used in the production process. This section aims to provide an overview of the significance of prepreg datasheets and how they contribute to the successful completion of manufacturing projects.

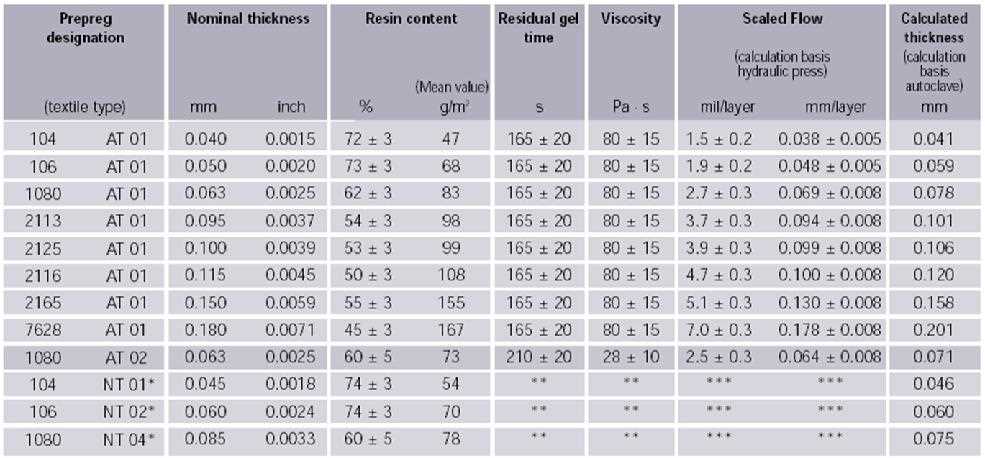

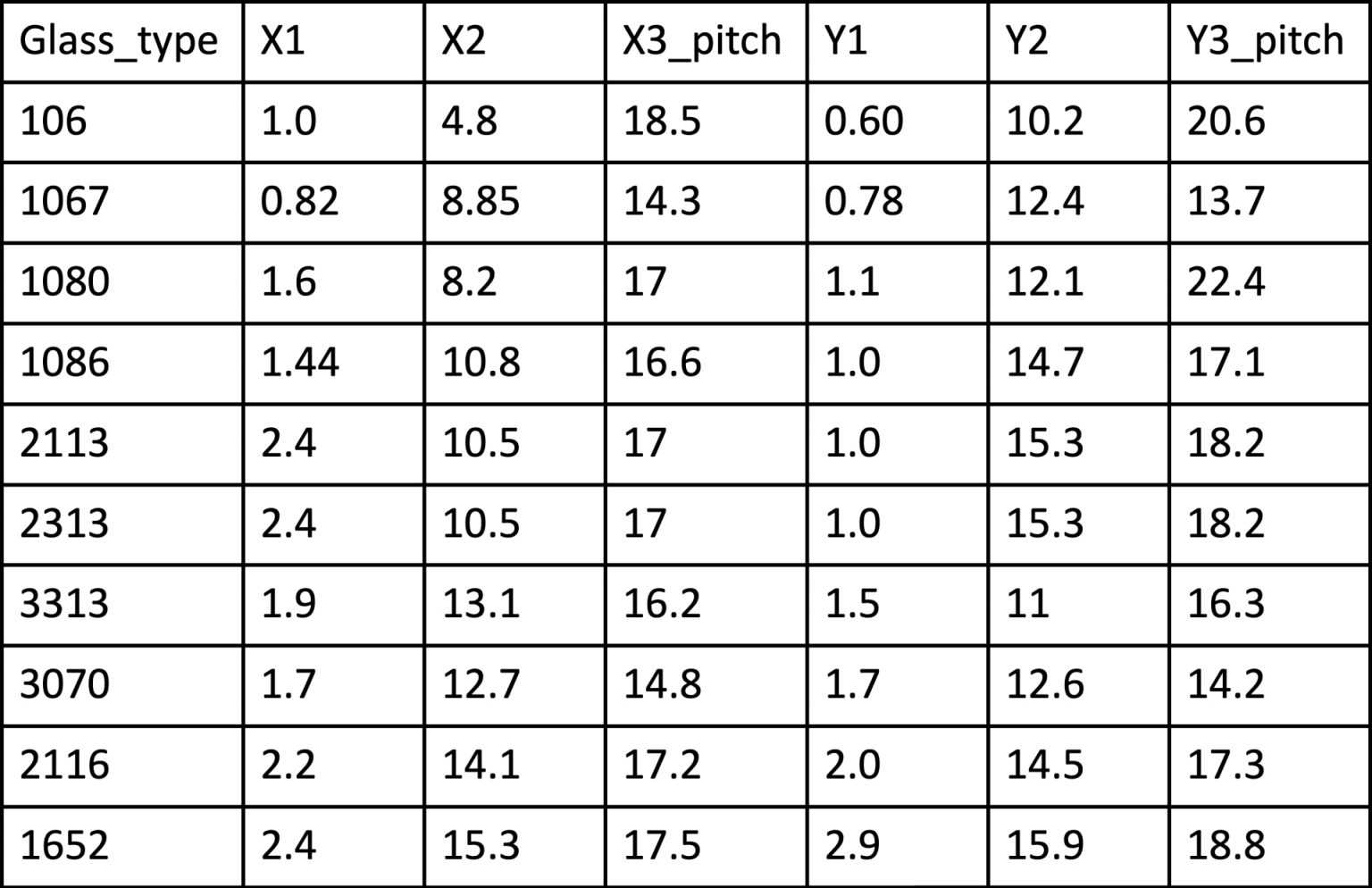

Understanding Key Specifications

When evaluating prepreg materials for manufacturing purposes, it is essential to have a clear understanding of the key specifications outlined in the datasheet. These specifications provide vital information about the material’s composition, mechanical properties, and performance characteristics. By examining these details, manufacturers can make informed decisions about selecting the most suitable prepreg for their specific application.

Within the datasheet, key specifications may include details on the resin content, fiber type, fiber orientation, thickness, and curing parameters. These specifications enable manufacturers to assess the material’s strength, flexibility, and overall suitability for their intended use. By paying attention to these factors, manufacturers can ensure that the selected prepreg meets their quality requirements and contributes to the overall success of the manufacturing process.

Ensuring Compliance with Industry Standards

In addition to providing key specifications, prepreg datasheets also play a vital role in ensuring compliance with industry standards and regulations. Manufacturers must adhere to specific guidelines and standards set forth by regulatory bodies to guarantee the safety and reliability of their products.

The datasheet acts as a reference point for manufacturers to verify that the prepreg materials they are using meet the necessary industry standards. It provides information on certifications, such as ISO standards and fire resistance ratings, which are essential for certain applications. By carefully reviewing the datasheet, manufacturers can ensure that their products meet the required compliance standards, preventing potential issues and ensuring customer satisfaction.

In conclusion, prepreg datasheets offer a comprehensive overview of key specifications and compliance standards for manufacturing purposes. By carefully examining these documents, manufacturers can make informed decisions about selecting the most suitable prepreg materials and ensure that their products meet the necessary quality and safety requirements.