When it comes to exploring the intricate details of circular vibrating components, a wealth of valuable information lies within their technical documentation. This comprehensive guide aims to present a thorough analysis of the specifications and characteristics of these remarkable devices, shedding light on their diverse range of applications.

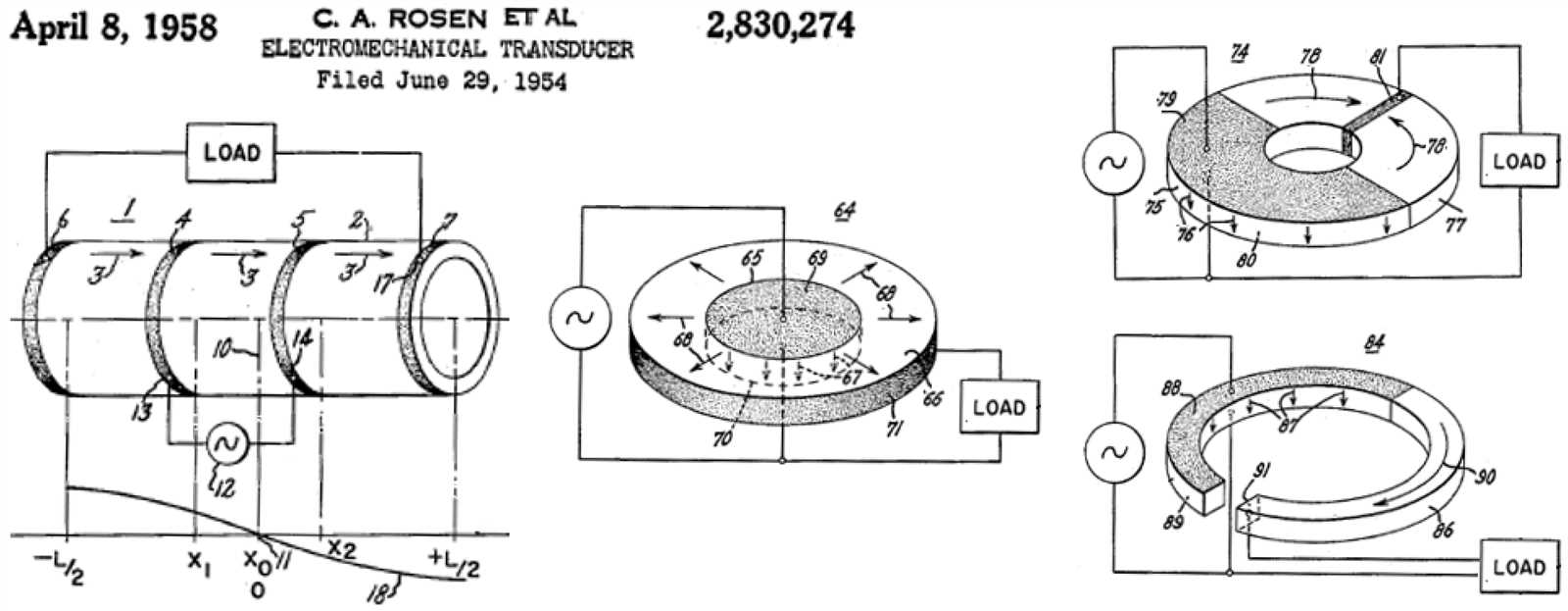

Through the aid of cutting-edge technology, these circular vibrating elements possess the ability to transform electrical energy into mechanical vibrations, enabling them to perform a wide array of functions across multiple industries. With their unique composition and intricate design, these components have become an indispensable asset in various fields, from aerospace and automotive engineering to medical and consumer electronics.

Understanding the technical intricacies of these circular vibrating elements is crucial for engineers and designers alike. This in-depth exploration will delve into the performance parameters, physical properties, and operational capacities of these remarkable devices, providing readers with an insight into the marvels of modern engineering. Through a combination of precise measurements, comprehensive data sheets, and intricate diagrams, an illuminating picture will be painted of the intricate workings of these circular vibrating components.

Piezoelectric Disc Datasheet: Overview and Technical Specifications

In this section, we will provide a detailed overview and technical specifications of the unique component known for its ability to convert mechanical energy into electrical energy, commonly referred to as a piezoelectric disc. This innovative device, featuring a circular shape and composed of specialized crystals, showcases exceptional properties that make it an indispensable element in various applications across industries.

Design and Construction

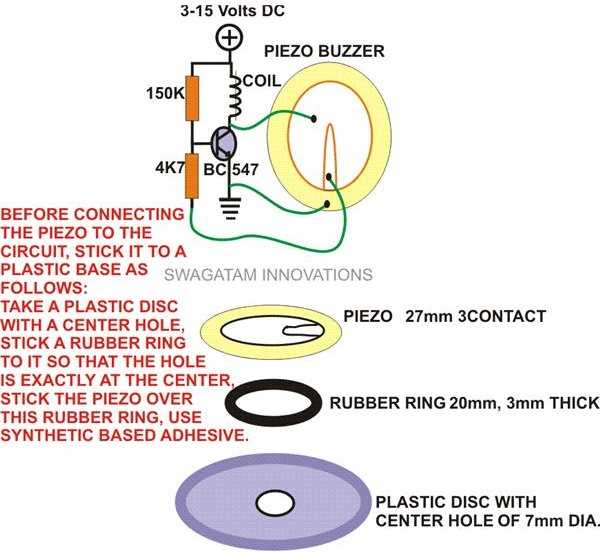

The design of the piezoelectric disc revolves around its circular shape combined with meticulous engineering, resulting in an efficient conversion mechanism. Crafted with precision, this component is made utilizing advanced manufacturing processes, incorporating specialized materials renowned for their piezoelectric properties. The intricate construction ensures optimal performance and durability throughout its lifespan.

Functionality and Applications

The piezoelectric disc operates based on the piezoelectric effect, which enables it to generate electricity when subjected to mechanical stress or vibrations. This unique functionality makes it a versatile component with a wide range of applications across diverse fields. It finds extensive use in industries such as automotive, aerospace, medical, and energy, where it contributes to sensing, actuation, and energy harvesting systems.

The applications of the piezoelectric disc vary from precision instrumentation, including level and pressure sensors, to ultrasonic imaging devices used in medical diagnostics. Additionally, its use extends to vibration monitoring systems, acoustic transducers, and energy harvesting modules, where it efficiently converts vibrations and mechanical energy into usable electrical power.

Technical Specifications

The technical specifications of the piezoelectric disc provide crucial details about its performance characteristics and operating parameters. These specifications include dimensions, resonance frequencies, capacitance, mechanical properties, and electrical parameters. By adhering to these specifications, manufacturers and engineers can optimize the integration of the piezoelectric disc into their respective systems, ensuring compatibility and achieving desired performance levels.

It is noteworthy that these technical specifications can vary based on the specific model or design of the piezoelectric disc. Therefore, it is essential to consult the corresponding datasheet for precise information to guarantee accurate and reliable application of this unique component.

In conclusion, the piezoelectric disc is an exceptional device possessing remarkable conversion capabilities and offering versatile applications across industries. With its precise design, functionality, and adherence to technical specifications, this component revolutionizes the field of electromechanical systems, enabling innovative solutions in various domains of technology and engineering.

Operating Principles and Applications

The use of piezoelectric materials in various industries has revolutionized the way mechanical energy is converted into electrical energy. This section explores the fundamental operating principles and diverse applications of these materials, offering insights into their immense potential.

Principles of Operation

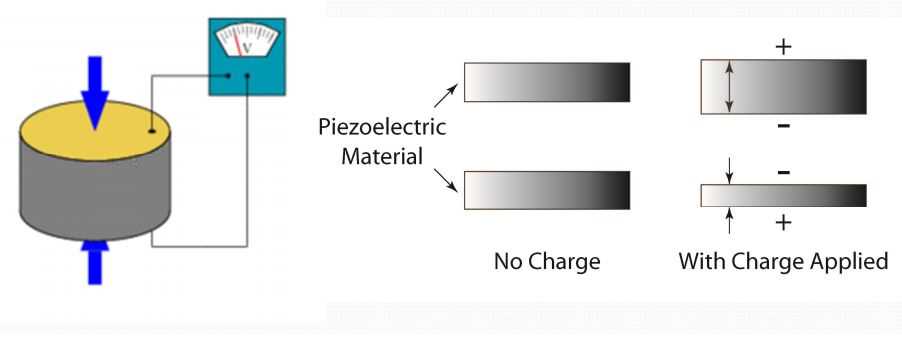

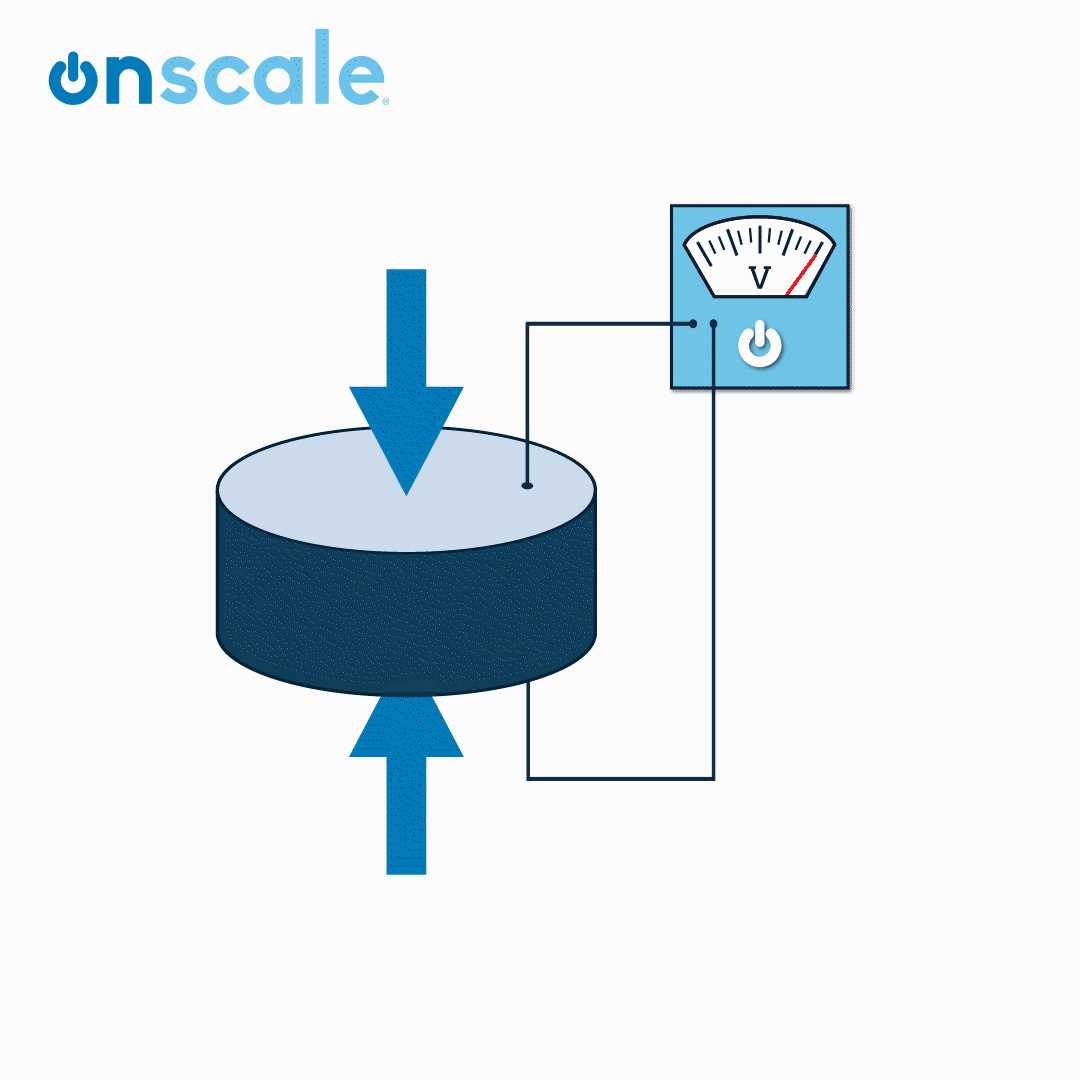

At the core of piezoelectric technology lies the ability of certain materials to generate an electric charge when subjected to mechanical stress or, conversely, deform under an applied electric field. These materials possess an inherent crystal structure or are engineered to exhibit the piezoelectric effect. When external forces or vibrations act upon the material, it undergoes molecular changes that result in the generation of electrical charges.

This unique property enables piezoelectric materials to be employed in various sensing, actuation, and energy harvesting applications. Understanding the underlying principles is crucial for grasping the full potential and customization possibilities of piezoelectric discs.

Applications

The versatility of piezoelectric discs has led to their adoption in numerous fields. One of their primary applications is in the realm of sensors. Piezoelectric discs can detect vibrations, pressure, and force, making them ideal for use in accelerometers, sonar devices, and touch sensors.

Moreover, the ability of piezoelectric materials to convert mechanical energy into electrical energy has found use in energy harvesting systems. These discs can capture ambient vibrations or mechanical strains and convert them into usable electrical power, offering potential solutions for self-powered wireless sensors, wearable devices, and remote monitoring systems.

Additionally, piezoelectric discs have proven invaluable in actuator applications. By applying an electric field, these materials deform and generate motion, making them suitable for use in precision positioning systems, loudspeakers, and ultrasonic devices.

The wide range of applications highlights the significance of understanding the operating principles of piezoelectric discs to harness their capabilities effectively. Through ongoing research and development, the potential applications of these materials are continuously expanding across industries such as aerospace, automotive, healthcare, and consumer electronics.

Technical Specifications and Performance Characteristics

When evaluating the technical specifications and performance characteristics of a piezoelectric disc, it is essential to consider its inherent properties that contribute to its functionality. These features play a crucial role in determining the performance and efficiency of the disc in various applications.

Electrical Specifications:

One important aspect to examine is the electrical specifications of the piezoelectric disc. This includes aspects such as the voltage rating, capacitance, and impedance. The voltage rating indicates the maximum voltage that the disc can withstand without experiencing damage. Capacitance represents the ability of the disc to store an electrical charge, while impedance characterizes its opposition to the flow of alternating current.

Mechanical Specifications:

In addition to electrical specifications, mechanical characteristics of the disc are also crucial considerations. These include parameters such as size, weight, and resonance frequency. The size of the disc determines its overall dimensions, which can impact its compatibility with specific devices or systems. The weight of the disc can affect its portability and ease of installation. The resonance frequency indicates the natural frequency at which the disc vibrates, which is vital for proper operation and control.

Performance Characteristics:

Examining the performance characteristics of the piezoelectric disc is essential to understand its abilities and limitations. These characteristics encompass aspects such as sensitivity, linearity, and frequency response. Sensitivity refers to the disc’s responsiveness to external stimuli, such as changes in pressure or voltage. Linearity refers to how accurately the disc’s output reflects the input stimulus. Frequency response indicates the range of frequencies over which the disc can effectively operate.

Environmental Specifications:

Lastly, when evaluating a piezoelectric disc’s technical specifications, it is crucial to consider its environmental specifications, including temperature range, humidity, and operating conditions. These specifications determine the disc’s ability to function reliably in different environments, ensuring its suitability for various applications.