Delve into the intricacies of the latest technological marvel poised to revolutionize connectivity and control. In this comprehensive exploration, we embark on a journey to unravel the innovative functionalities and technical intricacies of a cutting-edge device designed to enhance efficiency and precision in industrial settings.

Step into the realm of advanced engineering as we dissect the components and capabilities of this state-of-the-art solution. Through a meticulous examination, we aim to shed light on the underlying mechanisms and operational nuances that distinguish this device as a formidable contender in the realm of industrial automation.

Prepare to be immersed in a world where efficiency meets innovation and precision merges with reliability. Join us as we navigate through the technical intricacies and functional possibilities that lie at the heart of this groundbreaking technology, setting new benchmarks for performance and versatility.

Understanding the Opto 22 OAC5 Datasheet

In this section, we delve into comprehending the intricacies encapsulated within the documentation of the Opto 22 OAC5. The discourse navigates through the nuanced details, elucidating the essence concealed within the comprehensive array of specifications, functionalities, and operational attributes.

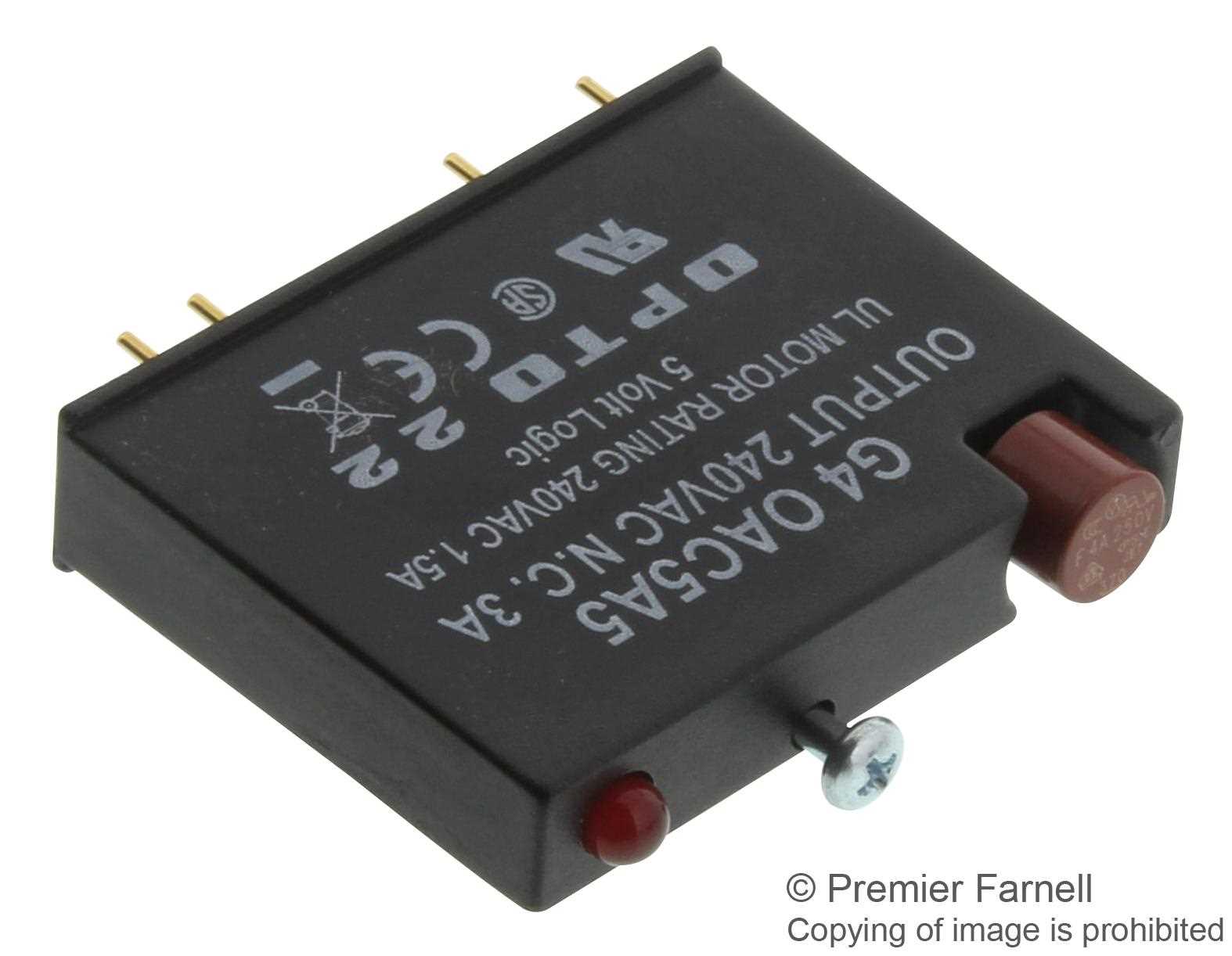

Deciphering Specifications: The dossier presents a compendium of technical particulars, delineating the operational parameters, performance metrics, and distinctive features pertinent to the Opto 22 OAC5 module. These specifications serve as the cornerstone for discerning its capabilities and compatibility within diverse applications.

Unveiling Functionality: Beyond the realm of mere specifications, the datasheet unfurls the functional prowess of the OAC5, elucidating its operational modalities, signal processing mechanisms, and integration methodologies. Through a discerning lens, it delineates the functionality matrix, elucidating the synergy between hardware components and software interfaces.

Exploring Operational Attributes: Delving deeper, the datasheet unveils the operational intricacies, encompassing aspects of input-output configurations, voltage ratings, and signal conditioning mechanisms. This exploration encapsulates the operational versatility and adaptability of the OAC5 module across a spectrum of industrial and automation environments.

Analyzing Performance Metrics: Embedded within the documentation are insights into performance benchmarks, reliability indices, and environmental tolerances, facilitating a comprehensive analysis of the OAC5’s efficacy under varied operational conditions. This analytical endeavor underscores its reliability, efficiency, and resilience in demanding industrial settings.

Interpreting Application Scenarios: Beyond the realm of technical elucidation, the datasheet provides vignettes of real-world application scenarios, illustrating the pragmatic utility and transformative potential of the OAC5 module within industrial automation, process control, and monitoring applications. These narratives imbue the technical discourse with practical relevance and contextual significance.

Conclusion: Through a meticulous examination of the Opto 22 OAC5 datasheet, one gains profound insights into its operational dynamics, functional attributes, and applicative versatility. This understanding serves as a catalyst for informed decision-making, empowering stakeholders to leverage the OAC5 module effectively within their respective domains of operation.

Exploring Key Features and Specifications

In this section, we delve into the essential characteristics and technical details that define the Opto 22 OAC5 module, shedding light on its functionality and capabilities. Through a comprehensive exploration, we uncover the intricacies and nuances of this innovative component, offering insights into its core attributes and performance metrics.

1. Performance Metrics

First and foremost, let’s examine the performance metrics of the Opto 22 OAC5 module. This entails an in-depth analysis of its operational efficiency, reliability, and responsiveness in various applications. By dissecting its key performance indicators, we gain a deeper understanding of its real-world effectiveness and potential.

- Reliability under varying load conditions

- Response time in signal processing

- Overall operational efficiency

2. Functional Capabilities

Next, we explore the functional capabilities inherent within the Opto 22 OAC5 module. This entails an exploration of its diverse features and functionalities, ranging from input/output compatibility to signal processing capabilities. By elucidating its functional scope, we elucidate its adaptability and versatility across different industrial and commercial scenarios.

- Input/output compatibility with diverse systems

- Signal processing capabilities for various applications

- Integration with existing infrastructure

Applications and Integration Possibilities

Exploring the diverse spectrum of applications and integration potentials unveils a myriad of innovative opportunities for leveraging the Opto 22 OAC5 module. From interfacing with various systems to enhancing operational efficiency, this section delves into the versatile applications and seamless integration pathways facilitated by this cutting-edge technology.

| Application | Integration Potential |

|---|---|

| Industrial Automation | Seamless integration with existing PLC systems for streamlined control and monitoring of industrial processes. |

| Building Management Systems | Integration capabilities allow for centralized management of building systems, enabling efficient energy utilization and facility optimization. |

| Environmental Monitoring | Facilitates integration with sensors and data acquisition systems, enabling real-time monitoring of environmental parameters for enhanced sustainability initiatives. |

| IoT Applications | Enables seamless incorporation into IoT ecosystems, facilitating data exchange and interoperability for connected devices and smart applications. |

| Remote Monitoring and Control | Allows for remote access and control of equipment and systems, enabling proactive maintenance and optimization from any location. |

Tips for Enhancing Implementation and Addressing Challenges

Embarking on the journey of utilizing cutting-edge electronic components necessitates a keen awareness of potential obstacles and the means to surmount them effectively. In this segment, we delve into strategies aimed at optimizing the integration process and tackling encountered issues with finesse.

1. Thorough Preliminary Assessment: Before initiating the deployment of advanced electronic systems, conduct a comprehensive evaluation of the intended application environment and operational requirements. This proactive measure aids in preemptively identifying potential compatibility issues and streamlining subsequent implementation phases.

2. Rigorous Component Testing: Prior to full-scale integration, subject the components to rigorous testing procedures to validate functionality and ascertain adherence to specified performance parameters. This meticulous approach not only mitigates the risk of unforeseen malfunctions but also instills confidence in the reliability of the deployed system.

3. Adherence to Manufacturer Guidelines: Abide by the guidelines outlined by component manufacturers, encompassing recommended operating conditions, installation protocols, and maintenance practices. Straying from these directives can compromise system integrity and impede optimal performance, warranting adherence as a paramount priority.

4. Continuous Monitoring and Calibration: Implement a regimen of continuous monitoring and periodic calibration to uphold the efficacy of integrated electronic systems over time. Regular assessments facilitate the early detection of deviations from desired performance benchmarks, enabling prompt corrective action to be taken.

5. Proactive Troubleshooting Strategies: Equip personnel involved in system deployment and maintenance with comprehensive troubleshooting protocols and resources. Fostering a proactive troubleshooting ethos empowers individuals to swiftly diagnose and rectify encountered issues, minimizing downtime and maximizing operational efficiency.

6. Collaborative Knowledge Exchange: Foster a culture of collaborative knowledge exchange among stakeholders involved in the implementation and upkeep of electronic systems. Encouraging open communication and information sharing cultivates a collective reservoir of expertise, enriching problem-solving capabilities and fostering innovation.

By adhering to these guiding principles and leveraging proactive strategies, stakeholders can navigate the complexities inherent in electronic system integration with confidence and proficiency.