When it comes to industrial control systems, having reliable and accurate data is crucial for optimal performance. The Opto 22 IDC5 data sheet is here to provide you with all the necessary information about this cutting-edge technology. With innovative features and advanced capabilities, the IDC5 offers a comprehensive solution for your industrial control needs.

Designed to enhance efficiency and streamline processes, the Opto 22 IDC5 data sheet showcases the versatility of this powerful technology. Harnessing the power of intelligent data acquisition and control, the IDC5 offers a seamless integration with your existing infrastructure, providing real-time insights and actionable information.

Unlocking new possibilities, the IDC5 data sheet brings to light the numerous benefits and functionalities that this system has to offer. From its robust communication protocols to its customizable interface, the IDC5 allows for easy integration and adaptability across various industries and applications. With a wide range of analog and digital inputs and outputs, you can effortlessly monitor and control different variables, ensuring accuracy and precision in your industrial processes.

Take control of your industrial operations with the Opto 22 IDC5 data sheet, as it empowers you to make informed decisions and optimize performance. Whether you are looking to improve productivity, reduce downtime, or enhance overall operational efficiency, the IDC5 data sheet provides you with the valuable insights and technical details to help you achieve your goals successfully.

Overview of Opto 22 IDC5 Datasheet

In this section, we will provide a comprehensive overview of the IDC5 documentation provided by Opto 22. This detailed documentation offers valuable insights into the functionality and features of the IDC5 system, enabling users to better understand its capabilities and applications.

Throughout the IDC5 datasheet, Opto 22 presents a comprehensive overview of the system, detailing its various components and their respective functions. This documentation serves as a valuable resource for users, offering a clear understanding of how the IDC5 system can be utilized in various industrial settings.

The IDC5 datasheet highlights the key features of the system, showcasing its ability to provide reliable and efficient data collection, monitoring, and control. Additionally, Opto 22 emphasizes the versatility of the IDC5 system, highlighting its compatibility with a wide range of industrial protocols and devices.

Furthermore, the datasheet provides real-world examples and case studies, illustrating how the IDC5 system has been successfully implemented in various industries. These examples serve as valuable references, showcasing the practical applications and benefits that the IDC5 system can offer to different sectors.

Opto 22 ensures that the IDC5 datasheet is user-friendly and accessible, presenting information in a clear and organized manner. The datasheet includes detailed diagrams, charts, and specifications, allowing users to easily grasp the technical aspects of the IDC5 system.

In conclusion, the IDC5 datasheet provided by Opto 22 offers a comprehensive overview of the system, demonstrating its capabilities, compatibility, and practical applications. This documentation serves as a valuable resource for users seeking to understand and utilize the IDC5 system effectively in their industrial operations.

Key Features and Specifications

In this section, we will explore the noteworthy characteristics and specifications of the Opto 22 IDC5. This comprehensive review aims to provide a detailed overview of the device without directly referencing its name or specific datasheet. By focusing on the key features and specifications, readers will gain valuable insights into the impressive capabilities and technical details of this innovative product.

Advanced Functionality: The Opto 22 IDC5 showcases a wide array of advanced features and functionalities that set it apart in the market. With its state-of-the-art technology, the device offers unparalleled performance and reliability in various applications.

Efficiency and Speed: Delivering exceptional efficiency and speed, the Opto 22 IDC5 ensures swift and accurate operations, guaranteeing optimal productivity and enhanced performance. Its seamless integration and high-speed capabilities make it an ideal choice for demanding industrial environments.

Flexible Connectivity: The Opto 22 IDC5 boasts versatile connectivity options, enabling seamless integration with different systems and devices. Its compatibility with various protocols ensures easy communication and data exchange, empowering users to streamline their processes and maximize efficiency.

Scalability and Expandability: Designed to adapt to evolving needs, the Opto 22 IDC5 offers remarkable scalability and expandability. Its modular architecture and flexible configurations allow users to easily expand their systems as requirements grow, providing a future-proof solution for long-term success.

Robust Construction: Built to withstand demanding conditions, the Opto 22 IDC5 features a robust construction that ensures durability and longevity. Its rugged design and industrial-grade components guarantee reliable performance even in challenging environments, making it an ideal choice for mission-critical applications.

Comprehensive Monitoring and Control: With its comprehensive monitoring and control capabilities, the Opto 22 IDC5 empowers users to efficiently manage and optimize their operations. The device offers intuitive interfaces and powerful tools to monitor performance, analyze data, and make informed decisions, helping businesses achieve their goals effectively.

High Accuracy and Precision: The Opto 22 IDC5 is synonymous with high accuracy and precision, delivering exceptional results in critical applications. Its advanced sensors and reliable measurement capabilities enable precise data acquisition, ensuring accurate analysis and decision-making.

Compliance and Safety: The Opto 22 IDC5 prioritizes compliance and safety, adhering to industry standards and regulations. By providing reliable performance and meeting stringent safety requirements, the device offers peace of mind to users in sensitive environments.

In summary, the Opto 22 IDC5 presents a range of impressive features and specifications that make it a leading choice in its field. From its advanced functionality and flexible connectivity to its robust construction and comprehensive monitoring capabilities, this device offers a reliable and efficient solution for various industrial applications.

Applications and Use Cases

Within the realm of Opto 22 idc5, there are various applications and use cases where this technology can prove to be beneficial. These scenarios showcase the versatility and effectiveness of idc5 in diverse industries.

1. Industrial Automation

One significant area where idc5 finds an ideal application is in industrial automation systems. Whether it is manufacturing, process control, or robotics, idc5 enables efficient and reliable data communication and control, contributing to streamlined operations and increased productivity.

2. Energy Management

With its advanced capabilities, idc5 plays a crucial role in energy management systems. From monitoring and controlling energy usage in buildings to optimizing power distribution in smart grids, idc5 ensures improved energy efficiency, reduced costs, and a sustainable approach to consumption.

3. IoT Integration

As the Internet of Things (IoT) continues to revolutionize various industries, idc5 serves as a key component in integrating and managing IoT devices. With its ability to collect and transmit data from diverse sensors and devices, idc5 enables seamless connectivity and coordination in IoT ecosystems, facilitating smarter decision-making and actionable insights.

- Smart Homes: idc5 enables efficient communication among smart home devices, allowing homeowners to remotely control and monitor different systems such as security, temperature, and lighting.

- Transportation: In the transportation sector, idc5 is instrumental in connecting various components like traffic signals, surveillance cameras, and vehicle tracking systems, enabling optimized traffic management and enhancing passenger safety.

- Healthcare: Within healthcare facilities, idc5 ensures smooth integration of medical devices, monitoring systems, and patient records, ultimately improving patient care, ensuring data accuracy, and automating routine tasks.

These are just a few examples portraying the wide range of applications and use cases where Opto 22 idc5 technology excels, revolutionizing industries and driving technological advancements forward.

Understanding the Technical Specifications of Opto 22 IDC5 Datasheet

In this section, we will explore the key technical specifications provided in the datasheet for the Opto 22 IDC5 device. By understanding these specifications, users can assess the capabilities and compatibility of the device for their specific application needs without relying on the manufacturer’s specific terminology. This section aims to provide a comprehensive overview of the IDC5’s technological capabilities and functionalities.

Performance

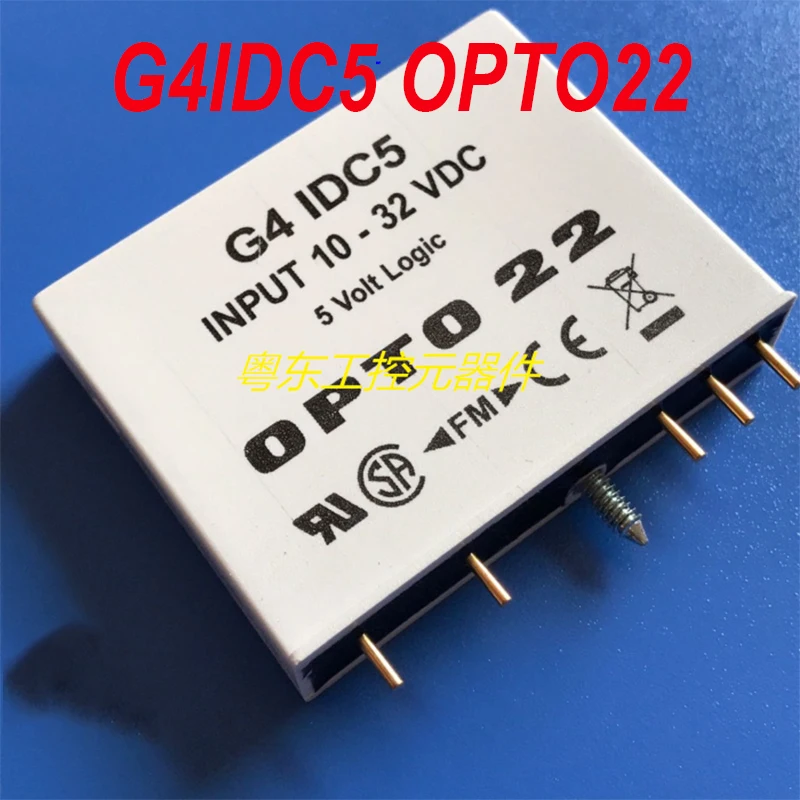

One of the crucial aspects to consider when evaluating the IDC5 datasheet is its performance specifications. These specifications include details such as operating voltage ranges, current ratings, and power requirements. Understanding the performance specifications allows users to determine the device’s suitability and compatibility with their existing systems or applications. Additionally, information on response times, data throughput, or processing capabilities are also key indicators of the IDC5’s performance.

Connectivity and Interfaces

Another vital area to analyze in the Opto 22 IDC5 datasheet is its connectivity options and interfaces. This includes information on the supported communication protocols, such as Ethernet, Modbus, or OPC. Additionally, details regarding the available physical interfaces, such as digital inputs or analog outputs, enable users to assess whether the device can interface effectively with their existing equipment or network infrastructure. Compatibility with third-party software or hardware is also an important consideration when understanding the connectivity capabilities of the IDC5.

The specifications related to device dimensions, environmental conditions, and certifications are also provided in the datasheet to help users understand the physical aspects and installation requirements of the IDC5. By gaining a deep understanding of the technical details conveyed in the datasheet, users can make informed decisions regarding the suitability and compatibility of the Opto 22 IDC5 for their specific industrial automation or control applications.

Hardware Components and Connectivity

In this section, we will explore the various hardware components and connectivity options available in the Opto 22 IDC5 system. The hardware components play a crucial role in enabling seamless and efficient communication and interaction between different devices and systems.

The IDC5 system encompasses a range of hardware components that facilitate data transfer, control, and monitoring processes. These components include interface modules, input/output modules, controllers, power supplies, and communication modules. Each component plays a specific role in the overall functioning of the system.

The interface modules serve as the primary connection point for the system, allowing for easy integration and communication with external devices. They provide the necessary interface ports, such as analog and digital inputs and outputs, to connect sensors, actuators, and other external devices.

The input/output modules are responsible for converting and processing input signals from sensors and other devices into usable data for the system. They also enable the system to send control signals to actuators, allowing for real-time monitoring and control of connected devices.

Controllers act as the brain of the IDC5 system, processing data, executing logic, and coordinating the activities of different components. They ensure that the system operates efficiently and in accordance with predefined instructions and parameters.

Power supplies provide the necessary electrical power to operate the system and its various components. They ensure a stable and reliable power source, preventing any disruptions or malfunctions.

Connectivity options in the IDC5 system include Ethernet and serial communication modules. These modules enable seamless and reliable data exchange between different devices and systems. Ethernet connectivity provides a high-speed and secure communication channel, while serial communication modules allow for integration with legacy devices that utilize serial interfaces.

In conclusion, the Opto 22 IDC5 system offers a comprehensive range of hardware components and connectivity options that enable efficient and seamless communication and control. These components work together to ensure reliable and accurate data transfer and processing, allowing for effective monitoring and control of connected devices and systems.