Unlocking the blueprint of cutting-edge electrical propulsion systems demands a meticulous dissection of the intricate specifications that propel modern innovation forward. Delving into the intricacies of this engineering marvel, one finds a trove of insights encapsulated within a compendium of technical particulars.

Within the labyrinth of specifications and performance metrics lies the roadmap to powerful propulsion solutions, offering a glimpse into the heart of electric motion mastery. As we embark on this journey through the labyrinthine corridors of technical documentation, we unearth the building blocks of electrifying revolutions, piecing together the puzzle of modern mobility.

Immersing ourselves in the cryptic lexicon of electrical propulsion, we navigate through a landscape adorned with statistical constellations and performance paradigms. Each figure and diagram serves as a beacon, illuminating the path toward enhanced efficiency, reliability, and performance. Join us as we unravel the enigmatic tapestry of technical literature, deciphering the language of innovation one specification at a time.

Navigating Technical Specifications: An Exhaustive Guide

In the realm of industrial machinery documentation, deciphering intricate technical blueprints can often feel akin to navigating a labyrinth without a map. In this comprehensive guide, we embark on a journey to demystify the intricacies of product specifications for cutting-edge electromechanical devices. Our aim is to equip you with the knowledge and understanding necessary to confidently navigate the dense forest of technical details inherent to these essential components.

Understanding Performance Metrics:

Before delving into the specifics, it’s paramount to grasp the fundamental performance metrics that underpin the functionality of these devices. From power ratings to efficiency measures, each metric serves as a vital cog in the machinery of comprehension, influencing performance, reliability, and compatibility.

Deciphering Mechanical Attributes:

Next on our expedition is the exploration of mechanical attributes, which encompass a spectrum of characteristics ranging from dimensions and mounting configurations to shaft specifications and enclosure types. Unraveling these intricacies provides invaluable insights into the physical form and operational requirements of the machinery.

Unlocking Electrical Characteristics:

The journey continues into the realm of electrical characteristics, where voltage, current, and frequency reign supreme. Understanding these parameters is essential for ensuring seamless integration within electrical systems, preventing compatibility issues and optimizing performance.

Interpreting Environmental Considerations:

As we traverse deeper into the datasheet terrain, we encounter vital information regarding environmental considerations. Temperature ratings, ingress protection levels, and ambient conditions shed light on the operational boundaries within which these devices thrive, safeguarding against premature failure and ensuring longevity.

Embracing Ancillary Information:

Beyond the core technical specifications lie a plethora of ancillary details that enrich our understanding of the product. From compliance certifications and agency approvals to application notes and recommended accessories, each nugget of information contributes to a holistic comprehension of the device and its intended usage.

Armed with this newfound knowledge, you’re well-equipped to embark on your own expedition through the labyrinthine corridors of technical documentation, confidently deciphering the nuances of electromechanical specifications with clarity and precision.

Understanding Key Specifications and Performance Metrics

In exploring the intricacies of technical documentation related to electric propulsion mechanisms, it becomes imperative to delve into the foundational elements governing their operation and efficacy. This section aims to dissect and elucidate the essential parameters and performance indicators integral to comprehending the operational prowess of such electromechanical systems.

- Electrical Characteristics: Unraveling the nuances of electrical properties is fundamental to grasp the intricacies of propulsion systems. These characteristics encompass parameters such as voltage requirements, current ratings, and power consumption, delineating the electrical demands for optimal functionality.

- Mechanical Attributes: Beyond the realm of electrical phenomena lie the mechanical traits pivotal in gauging performance. These include torque capabilities, rotational speed, and efficiency metrics, serving as barometers of mechanical prowess and operational efficiency.

- Environmental Considerations: A holistic understanding necessitates an appraisal of environmental factors influencing operational feasibility. Temperature tolerances, ingress protection ratings, and vibration resistance elucidate the adaptability of the propulsion mechanism to diverse operational contexts.

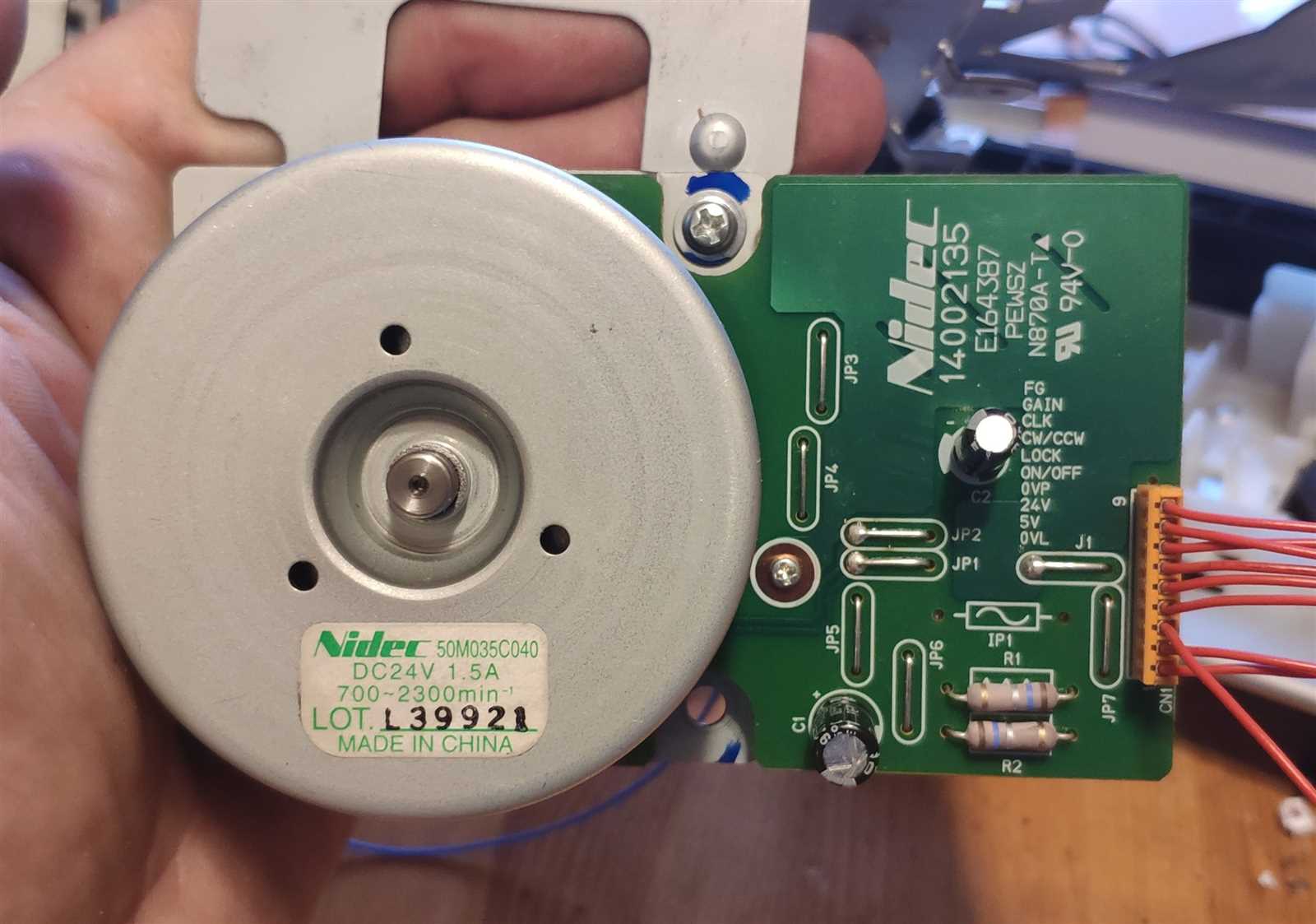

- Control and Feedback Mechanisms: The efficacy of propulsion systems hinges on sophisticated control and feedback mechanisms. Parameters such as feedback resolution, communication protocols, and control interfaces delineate the system’s responsiveness and adaptability to varying operational exigencies.

- Reliability and Durability: Assessing the reliability and durability of propulsion systems is imperative for ensuring sustained functionality. Metrics encompassing mean time between failures (MTBF), service life expectancy, and robustness against environmental stressors offer insights into the system’s longevity and operational resilience.

By unraveling these key specifications and performance metrics, stakeholders can glean invaluable insights into the operational prowess and applicability of electric propulsion systems, facilitating informed decision-making and fostering advancements in electromechanical engineering.

Interpreting Technical Diagrams and Graphs for Application Insights

Understanding the intricate visuals presented in technical documentation is paramount for extracting valuable insights into the functionality and applicability of various components. In this section, we delve into the art of deciphering technical diagrams and graphs to glean essential information relevant to specific applications. By scrutinizing these graphical representations with a discerning eye, engineers and enthusiasts alike can uncover crucial details that inform decisions and enhance comprehension.

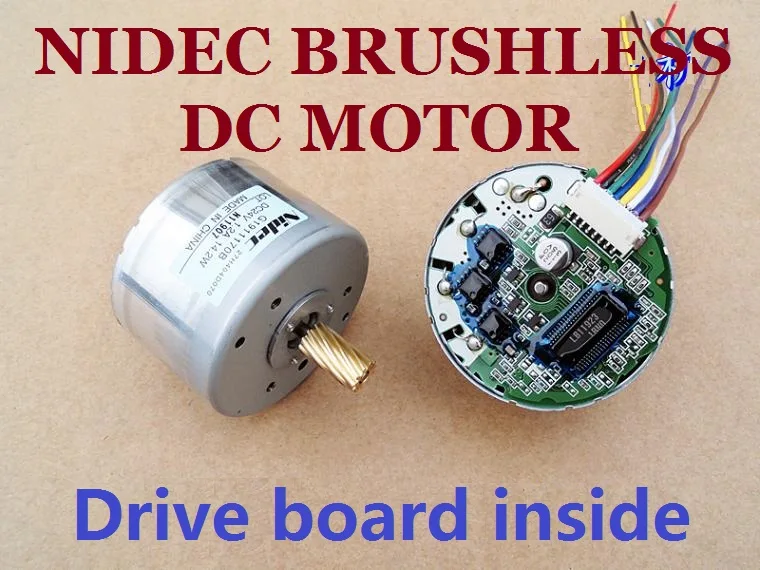

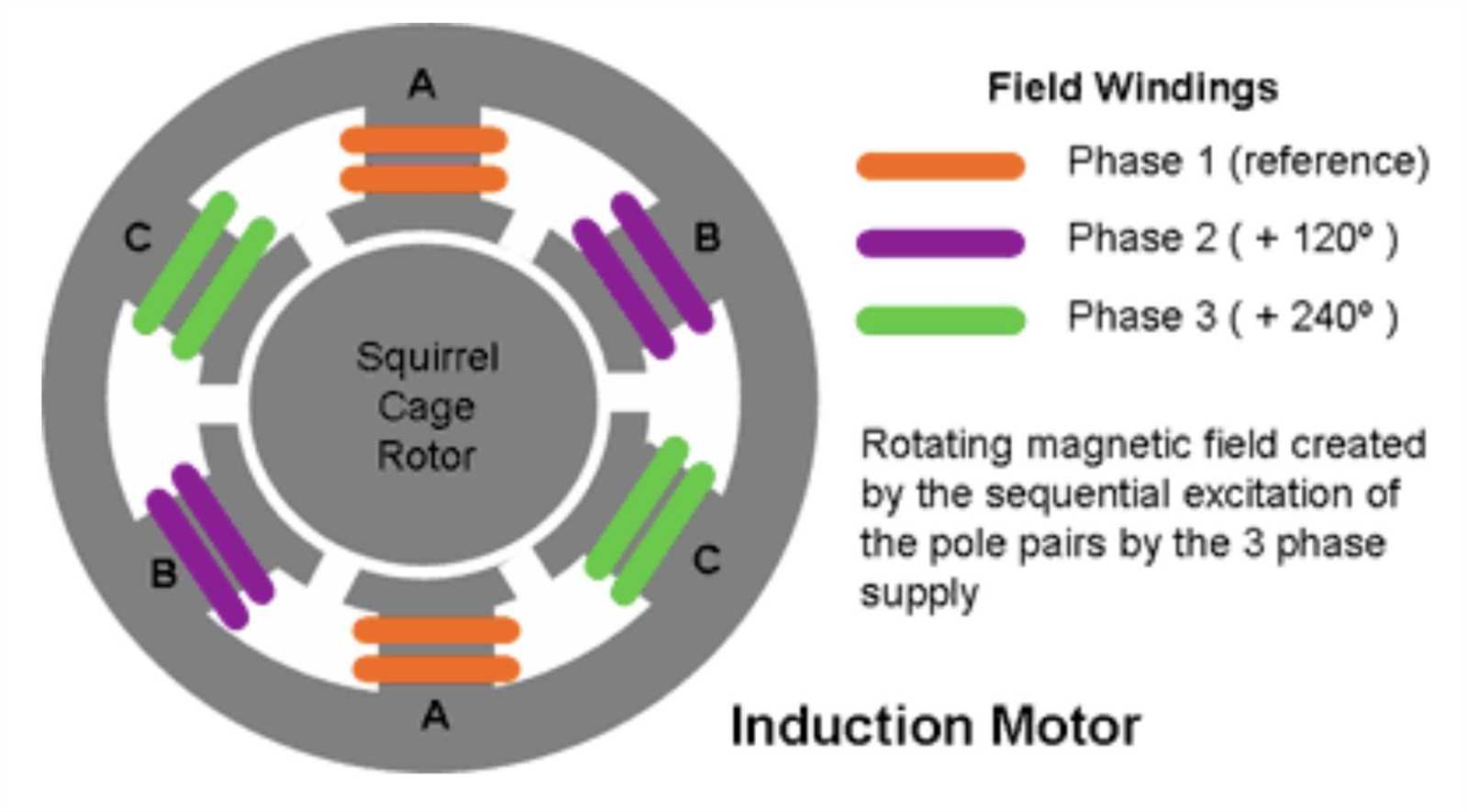

1. Identifying Key Components: Technical diagrams often depict the structural composition and interconnections of intricate systems. By scrutinizing these illustrations, one can discern the essential components comprising the system’s architecture. Recognizing these components lays the groundwork for understanding their individual functionalities and collective contributions to overall performance.

2. Analyzing Performance Graphs: Graphical representations of performance metrics provide invaluable insights into the behavior of a system under varying conditions. Whether it’s a torque-speed curve or an efficiency graph, careful analysis unveils the operational characteristics and limitations of the system. Engineers can extrapolate performance trends, identify optimal operating ranges, and anticipate potential challenges through thorough examination of these graphs.

3. Deciphering Schematics: Schematics serve as blueprints detailing the electrical or mechanical configurations of components within a system. Understanding these schematics involves interpreting symbols, connections, and component placements to grasp the underlying functionality and circuitry. Mastery of schematic interpretation empowers engineers to troubleshoot, modify, and optimize systems with precision and efficiency.

4. Extracting Application Insights: Ultimately, the ability to interpret technical diagrams and graphs facilitates the extraction of valuable insights pertinent to specific applications. By combining theoretical knowledge with practical analysis, stakeholders can make informed decisions regarding component selection, system design, and performance optimization. This comprehensive understanding fosters innovation and efficiency across various domains, from industrial automation to consumer electronics.

By honing the skill of interpreting technical diagrams and graphs, individuals can unlock a treasure trove of knowledge essential for advancing technology and solving real-world challenges.

Optimizing Motor Selection: Tips for Efficiency and Cost-Effectiveness

When considering the ideal electric propulsion component for your machinery, discerning the optimal choice involves a delicate balance of factors beyond mere brand recognition or technical specifications. Delving into the intricacies of motor selection unveils a realm where efficiency intertwines with cost-effectiveness, guiding you towards judicious decisions that harmonize performance with economy.

Understanding Application Requirements

Before diving into the vast array of available options, it’s imperative to embark on a journey of understanding your specific application’s demands. Each industrial context presents unique challenges, whether it be high torque requirements, precise speed control, or stringent energy efficiency targets. By scrutinizing these prerequisites with meticulous attention, you pave the way for tailored motor selection that aligns seamlessly with your operational needs.

Exploring Innovative Solutions

In the quest for optimal efficiency and cost-effectiveness, don’t confine yourself to conventional paradigms. Embrace the spirit of innovation by exploring emerging technologies and novel approaches to motor design. From advanced materials enhancing performance to cutting-edge control algorithms optimizing energy consumption, the landscape of electric propulsion is ripe with possibilities. By remaining open-minded and receptive to these innovations, you position yourself at the vanguard of efficiency, poised to reap the rewards of forward-thinking motor selection.