Delve into the realm of advanced electronics, where innovation meets precision engineering. Within this domain lies a cornerstone of technological evolution, a nexus where intricate designs converge to breathe life into modern machinery.

Here, we embark on a journey through the intricacies of ingenious circuitry, dissecting the anatomy of a groundbreaking component that orchestrates the harmonious dance of power and control.

Uncover the blueprint of a revolutionary system, meticulously crafted to navigate the complexities of motion with unparalleled finesse. Join us as we navigate through the labyrinthine corridors of electronic architecture, illuminating pathways to efficiency and performance.

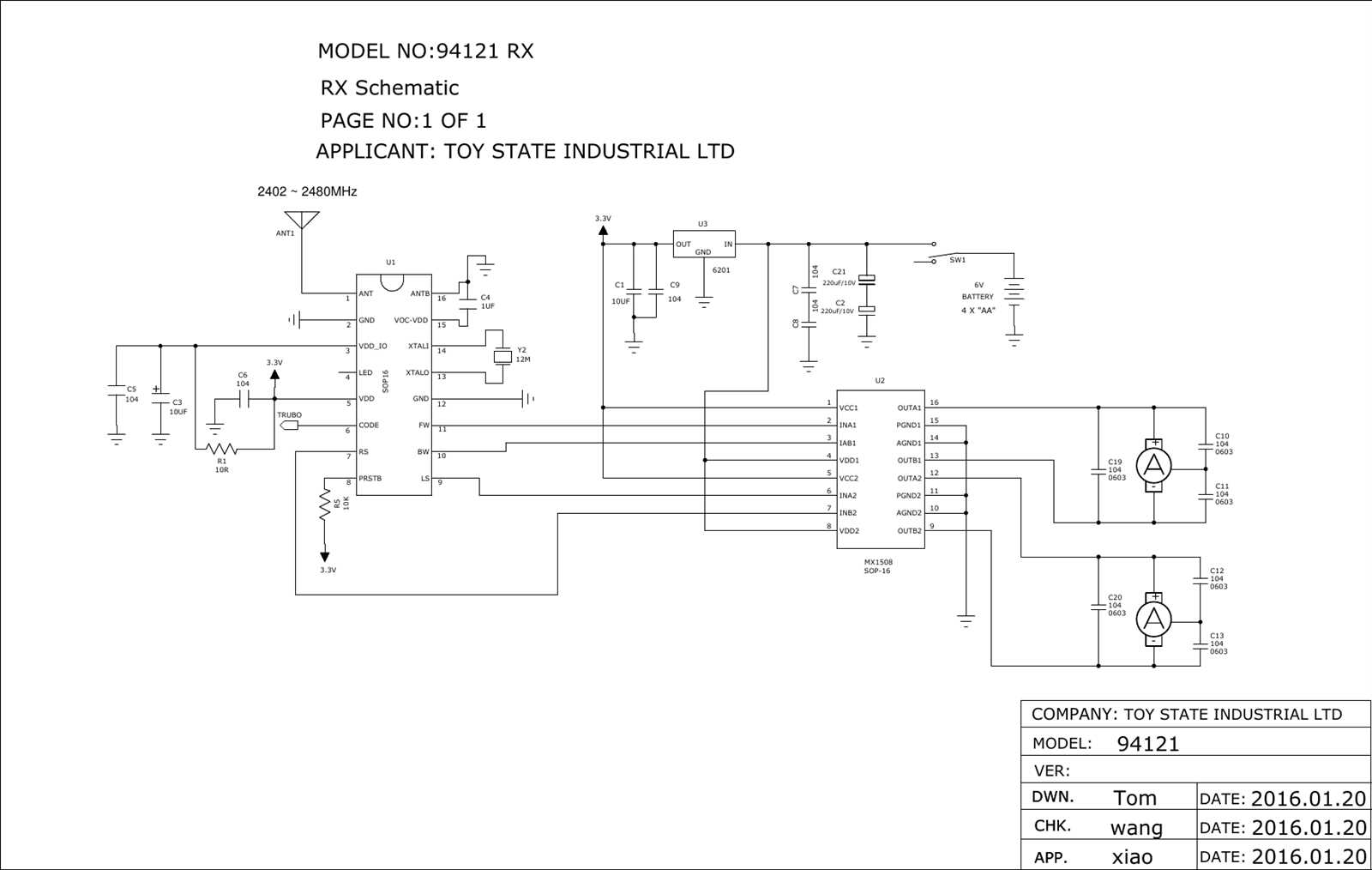

Mx1616 Motor Driver Datasheet Overview

In this segment, we delve into a comprehensive examination of the intricate mechanisms and functionalities encapsulated within the documentation pertaining to the Mx1616 motor driver. It entails a meticulous analysis of the device’s operational specifications, performance characteristics, and application scenarios, offering a panoramic view of its utility and versatility in diverse contexts.

Functional Insights

Exploring the Core Operations: Within this section, we elucidate the fundamental operational paradigms underlying the Mx1616 motor driver, shedding light on its innate capabilities without delving into technical minutiae. By emphasizing its functionality across various settings, from industrial automation to consumer electronics, we aim to provide a coherent understanding of its potential applications.

Performance Evaluation

Evaluating Efficiency and Reliability: This subsection navigates through the performance metrics and benchmarks that define the Mx1616 motor driver’s efficacy. Through a nuanced appraisal of its efficiency, reliability, and durability, we endeavor to present a holistic view of its performance attributes, facilitating informed decision-making for prospective users.

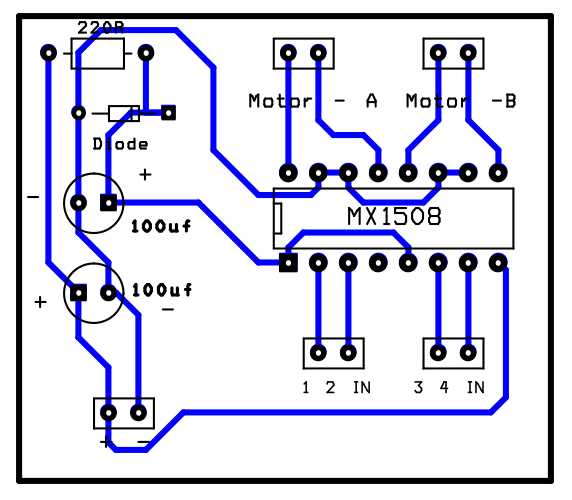

Key Features and Specifications

In this section, we delve into the pivotal attributes and technical details encapsulated within the comprehensive framework of the Mx1616 motor driver documentation. Unveiling the essence of its functionality and prowess, we embark on an exploration of its distinctive traits and performance metrics, charting a course through its intricacies and capabilities.

Imbued with a spectrum of functionalities tailored to diverse operational exigencies, this motor driver epitomizes versatility and efficiency. It encompasses a myriad of features engineered to augment operational fluidity and optimize performance across varied applications.

Crafted with meticulous attention to detail, this device manifests a confluence of cutting-edge technology and robust engineering. Its specifications epitomize a harmonious balance between precision and power, offering a glimpse into the seamless integration of innovation and reliability.

From voltage thresholds to current capacities, each specification unveils a facet of the device’s prowess, delineating a blueprint for seamless integration and optimal performance. Delving into the intricacies of its specifications unveils a roadmap for harnessing its full potential across a spectrum of motor control applications.

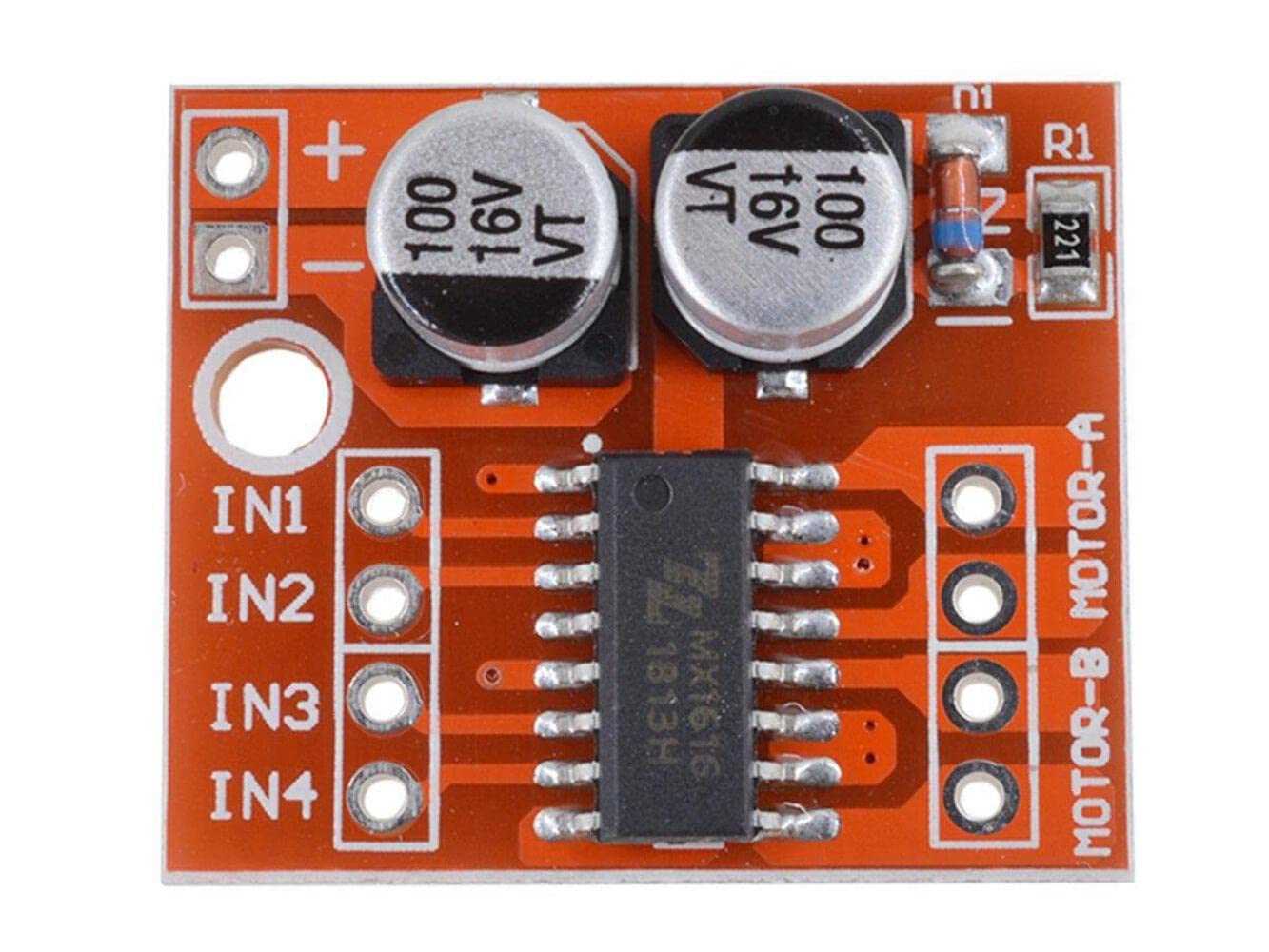

Understanding the Core Functions of Advanced Motor Control Hardware

In the realm of modern engineering, intricate electronic components empower the seamless orchestration of mechanical movements, embodying precision and efficiency. Delving into the intricate mechanisms of cutting-edge motor control hardware, we unravel the foundational functionalities that propel innovation in diverse applications.

The Essence of Control

- Mastering the orchestration of motion hinges upon sophisticated control mechanisms that dictate speed, direction, and torque with finesse.

- At the heart of motor control lies a symphony of algorithms and circuits that synchronize to execute nuanced commands, driving machinery with unparalleled accuracy.

Efficiency in Motion

Efficiency stands as the cornerstone of modern engineering endeavors, where every watt of power expended translates into tangible motion. Exploring the dynamics of motor control unveils a realm where optimization reigns supreme, balancing performance and energy conservation in harmonious equilibrium.

- Efficient utilization of resources is not merely a goal but a necessity, shaping the design philosophy of motor control hardware to minimize wastage and maximize output.

- From adaptive current regulation to dynamic feedback loops, each facet of motor control architecture converges to amplify efficiency, ensuring every rotation counts.

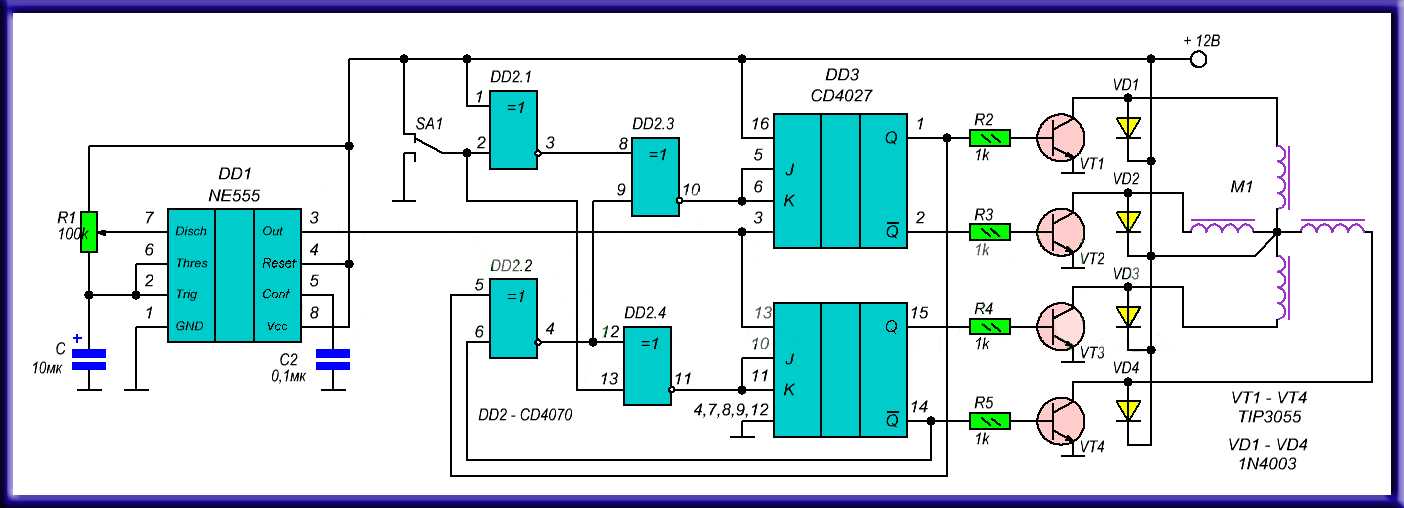

Motor Control Modes and Configurations

In this section, we explore various methods and setups for managing and adjusting the operation of motors, encompassing a spectrum of techniques to regulate their performance and behavior. Understanding these modes and configurations provides insight into optimizing motor functionality and achieving desired outcomes.

Operating Modes

1. Speed Control: This mode focuses on managing the velocity of motor rotations, allowing for precise adjustments to meet specific speed requirements. It involves regulating the rate of motor revolutions per minute (RPM) or angular velocity to ensure optimal performance in diverse applications.

2. Torque Control: Torque control emphasizes the manipulation of rotational force exerted by the motor shaft. By controlling torque levels, it becomes feasible to adjust the motor’s ability to overcome resistance or deliver power as needed, enhancing its versatility across different tasks.

Configurations

1. Open-Loop Control: In this configuration, the motor operates without feedback mechanisms to adjust its performance based on external factors. While simpler in design, it may lack precision and responsiveness compared to closed-loop systems.

2. Closed-Loop Control: Closed-loop configurations incorporate feedback mechanisms such as encoders or sensors to monitor motor performance and adjust parameters accordingly. This setup enables more accurate control and enhances stability, particularly in applications requiring precise positioning or dynamic response.

Exploring these motor control modes and configurations offers valuable insights into tailoring motor operation to meet specific application requirements, balancing factors such as speed, torque, and precision to achieve optimal performance.

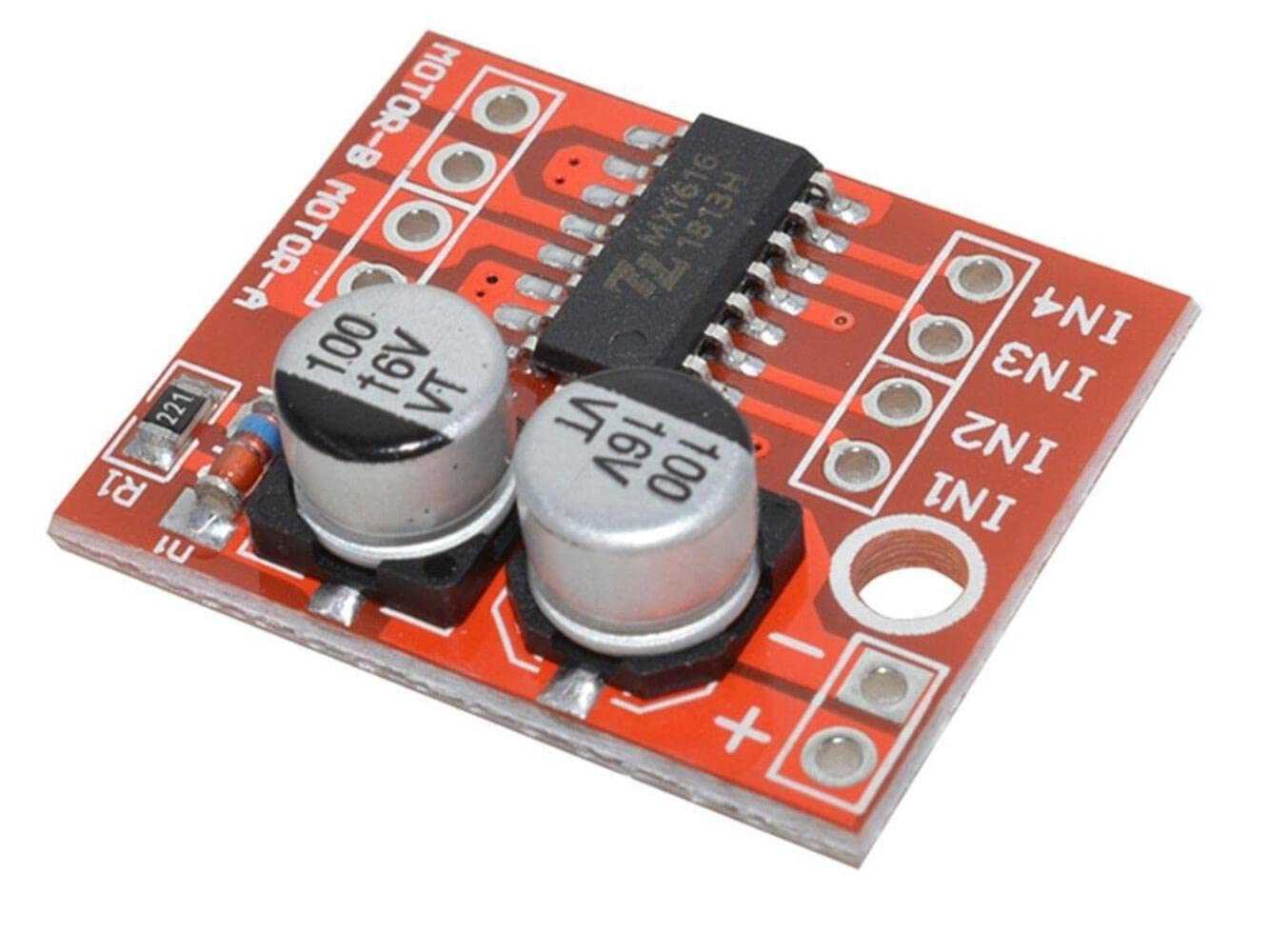

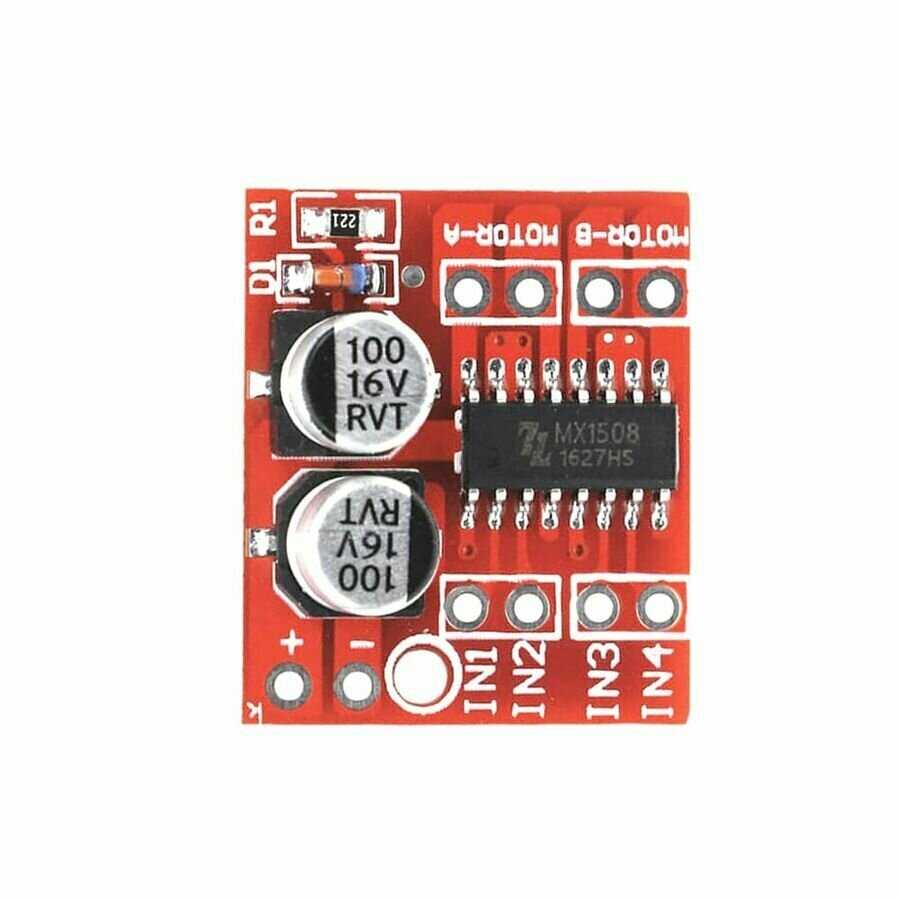

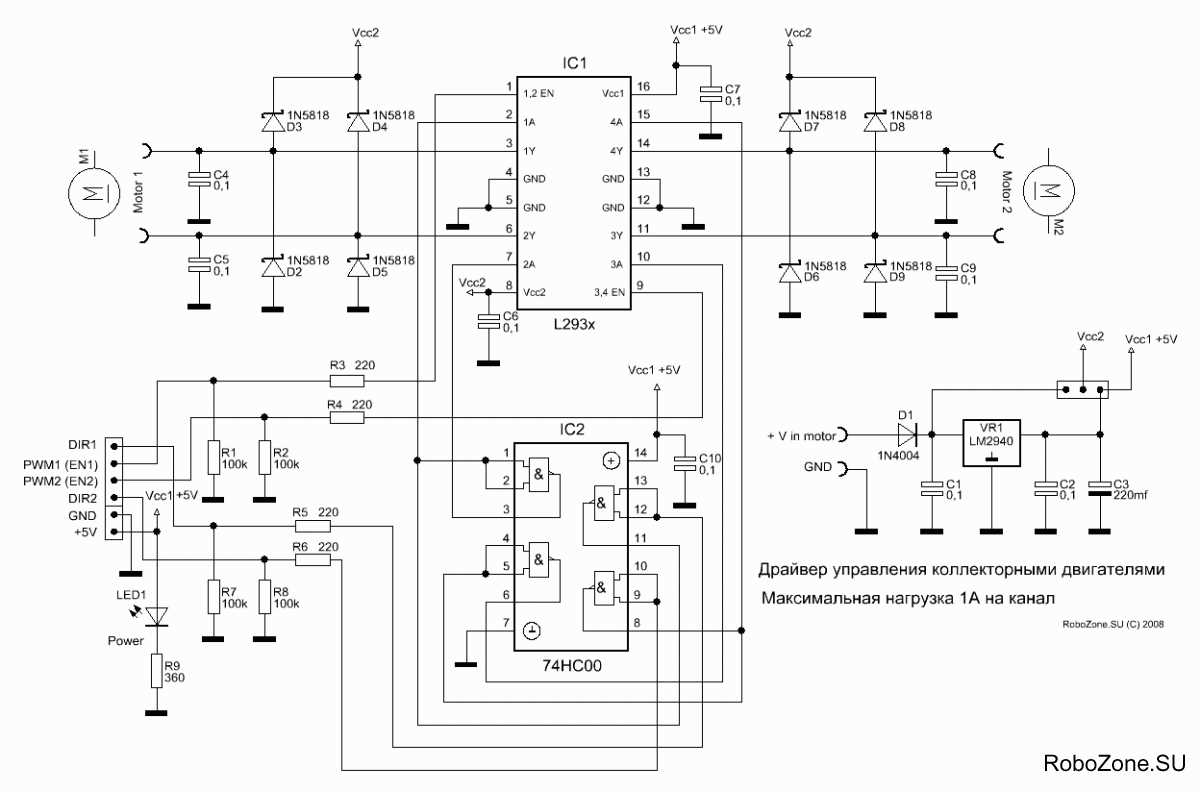

Interface and Compatibility

In this section, we delve into the connectivity aspects and interoperability features of the Mx1616 motor control solution. Understanding how this device integrates with various systems and interfaces is crucial for seamless operation and compatibility.

Connectivity Options

The Mx1616 offers versatile connectivity alternatives, facilitating communication between different components within a broader system architecture. Whether it’s through wired connections or wireless protocols, the interface possibilities are extensive.

Interoperability Considerations

Ensuring harmonious interaction between the Mx1616 and other system elements is paramount. Compatibility with diverse control systems, sensors, and actuators is a key aspect to address for optimal performance. Factors such as voltage levels, communication protocols, and signal processing methods play crucial roles in achieving interoperability.