Unlocking the intricacies of electronic safety protocols entails delving into a realm where precision and reliability reign supreme. This journey of comprehension demands a meticulous scrutiny of foundational elements that underpin secure operations within volatile environments.

Within this realm, the essence of safeguarding vital processes pulsates through a symphony of components, each harmonizing to orchestrate a seamless defense against potential hazards.

Embark on an expedition through the labyrinthine corridors of shielding documentation, where the narrative unfolds in the intricate dance of data sheets and technical specifications.

Join us as we navigate through the blueprint of protection, unraveling the intricacies that fortify industrial landscapes against the unseen forces that lurk in the shadows.

Understanding Documentation for Electronic Safety Barriers

In this section, we delve into comprehending the informational resources provided for electronic safety barriers. These documents serve as crucial guides for users and technicians, offering insights into the operational characteristics, safety features, and installation requirements of the equipment.

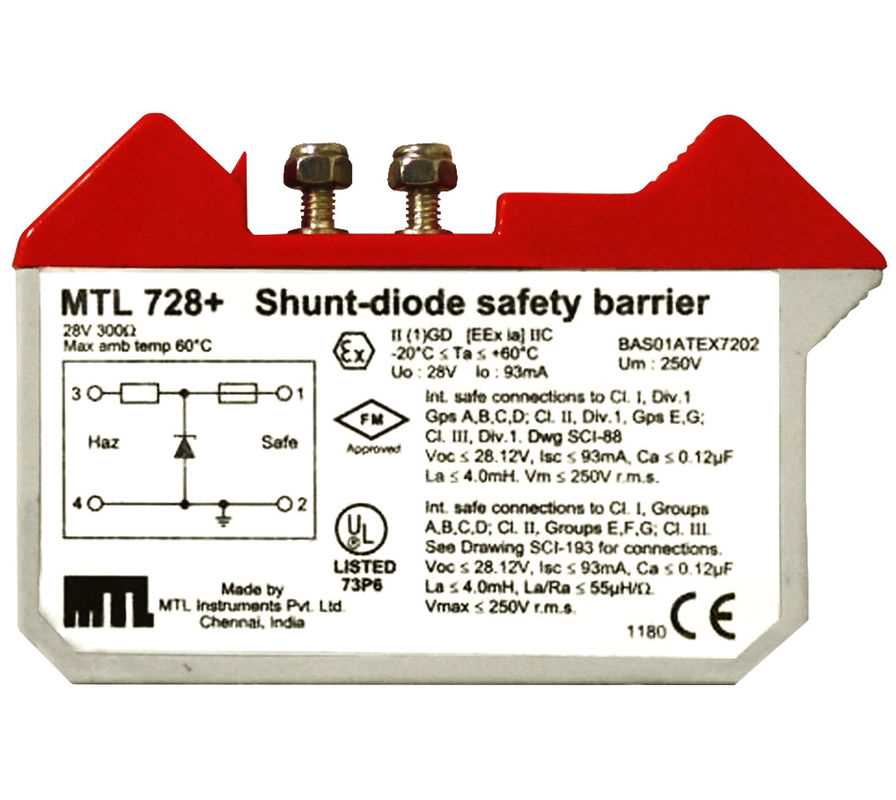

Deciphering Technical Specifications

Technical specifications serve as the cornerstone of comprehending the performance parameters and limitations of electronic safety barriers. By dissecting these details, users gain a nuanced understanding of the device’s capabilities, ensuring its optimal utilization within various industrial settings.

Interpreting Installation Guidelines

Installation guidelines elucidate the procedural steps and prerequisites for deploying electronic safety barriers effectively. By adhering to these instructions meticulously, technicians can ensure the seamless integration of the equipment into existing infrastructure, thereby enhancing workplace safety and operational efficiency.

| Section | Content |

|---|---|

| 1. Technical Specifications | Details on performance parameters and limitations |

| 2. Installation Guidelines | Procedural steps and prerequisites for deployment |

Exploring Key Specifications

In this section, we delve into the fundamental characteristics and performance metrics of the device, shedding light on its core attributes and operational capabilities. Understanding these pivotal specifications is essential for grasping the device’s functionality and assessing its suitability for diverse applications.

Performance Metrics

First and foremost, we scrutinize the device’s performance metrics, which encompass a range of parameters indicative of its efficiency and reliability in diverse environments. These metrics serve as yardsticks for evaluating the device’s efficacy in facilitating seamless operations.

Functional Capabilities

Furthermore, we explore the functional capabilities of the device, elucidating its prowess in mitigating risks and ensuring the integrity of critical processes. By delineating its functional spectrum, we gain insight into the multifaceted roles it can fulfill within industrial settings, enhancing operational efficiency and safety.

Application Considerations and Recommendations

When implementing the technology outlined in the referenced documentation, it is imperative to consider a spectrum of factors influencing its deployment and operation. This section delves into the nuanced aspects vital for effective utilization, highlighting key insights and best practices.

Environmental Factors

Understanding the environmental conditions within which the system operates is paramount. Factors such as temperature fluctuations, humidity levels, and exposure to corrosive elements can significantly impact performance and longevity. Adequate measures must be taken to mitigate these influences, ensuring optimal functionality and durability.

Integration and Compatibility

Seamless integration of the technology into existing infrastructures necessitates careful consideration of compatibility and interface protocols. Interoperability with diverse systems, adherence to industry standards, and scalability for future expansions are pivotal aspects to address during the planning and implementation phases.

| Aspect | Considerations | Recommendations |

|---|---|---|

| Environmental Factors | Temperature, Humidity, Corrosive Elements | Implement protective measures, regular maintenance |

| Integration and Compatibility | Interoperability, Standards Compliance, Scalability | Thorough compatibility testing, adherence to industry standards |

By meticulously addressing these considerations and adhering to the outlined recommendations, stakeholders can optimize the performance, reliability, and longevity of the technology, thereby enhancing operational efficiency and mitigating risks.

Troubleshooting and Maintenance Tips

When encountering challenges with your equipment, it’s essential to have a comprehensive understanding of potential issues and how to address them effectively. This section provides valuable insights into troubleshooting and maintaining your device, ensuring optimal performance and longevity.

Identifying Common Concerns:

Understanding the symptoms of malfunction is the first step towards resolving any issues. Look out for irregularities in operation, such as inconsistent readings, unexpected shutdowns, or unusual sounds.

Diagnostic Procedures:

Implementing systematic diagnostic procedures can streamline the troubleshooting process. Utilize available tools and resources to pinpoint the root cause of the problem, whether it involves electrical components, connectivity issues, or environmental factors.

Preventive Maintenance:

Proactive maintenance plays a crucial role in preventing potential breakdowns and ensuring the reliability of your equipment. Regular inspections, cleaning, and calibration routines are indispensable for preserving functionality and accuracy.

Addressing Connectivity Challenges:

Issues related to connectivity can disrupt the seamless operation of your device. Check cables, connectors, and interface settings to ensure proper communication between components.

Environmental Considerations:

Environmental factors can significantly impact the performance of electronic equipment. Assess the operating conditions, including temperature, humidity, and exposure to contaminants, to mitigate potential risks and optimize reliability.

Collaborative Problem-Solving:

Engage with colleagues, technical support teams, and online communities to leverage collective expertise in troubleshooting complex issues. Sharing insights and experiences can lead to innovative solutions and faster resolution times.

Documentation and Record-Keeping:

Maintaining detailed records of maintenance activities, troubleshooting procedures, and equipment history facilitates efficient problem-solving and decision-making processes. Documenting observations and outcomes contributes to continuous improvement and knowledge sharing within your organization.

Continuous Learning and Adaptation:

Stay abreast of advancements in technology and best practices in equipment maintenance and troubleshooting. Embrace a mindset of continuous learning and adaptation to navigate evolving challenges and optimize the performance of your device over time.