Embark on a journey through the intricate labyrinth of technical intricacies, where every curve of data and every nuance of specification unveils a world of possibilities. Dive into the realm of precision and performance, where each parameter is a thread in the fabric of innovation.

In this exploration, we navigate through the blueprint of a transformative component, delving into its characteristics and capabilities without directly naming it. Uncover the essence of a document that serves as a gateway to understanding and harnessing the power of modern engineering.

Discover the keys to decoding a manuscript that encapsulates the essence of cutting-edge technology, offering insights into the inner workings of a revolutionary device. Join us as we decipher the language of innovation and glimpse into the future it promises.

Understanding the Mpx2200dp Datasheet: Key Specifications

Delving into the intricacies of the technical documentation for the Mpx2200dp entails unraveling its critical specifications, providing insight into its performance metrics and operational parameters. This section aims to dissect and elucidate the pivotal details encapsulated within the datasheet, shedding light on the essential characteristics that define the functionality and utility of this sensor.

Exploring the fabric of the Mpx2200dp documentation unveils a tapestry of fundamental attributes, delineating its operational boundaries, sensitivity thresholds, and accuracy benchmarks. Through a systematic analysis of the provided specifications, one can discern the device’s capacity to capture, process, and transmit data with precision and reliability, underpinning its suitability for diverse applications.

Examining the datasheet illuminates the nuanced nuances of the Mpx2200dp’s performance profile, elucidating aspects such as its measurement range, resolution, and response time. By deciphering these intricate details, users can gauge the sensor’s efficacy in capturing subtle variations in pressure, facilitating informed decision-making regarding its integration into various systems and projects.

Exploring Sensor Accuracy and Calibration

In this section, we delve into the intricacies of sensor precision and fine-tuning, aiming to elucidate the nuances of its performance and refinement. Understanding the reliability and precision of sensor measurements is paramount in various applications, where even slight deviations can lead to significant discrepancies in outcomes. We embark on a journey to unravel the factors influencing sensor accuracy and delve into the art of calibration to enhance its precision.

Accuracy, the cornerstone of sensor performance, encapsulates its ability to provide measurements that closely mirror the true values of the observed phenomenon. Calibration, on the other hand, serves as the meticulous process of aligning the sensor’s output with known standards, thereby rectifying any inherent biases or inaccuracies. Through meticulous calibration techniques, sensors can achieve optimal performance across a spectrum of conditions, ensuring dependable and consistent measurements.

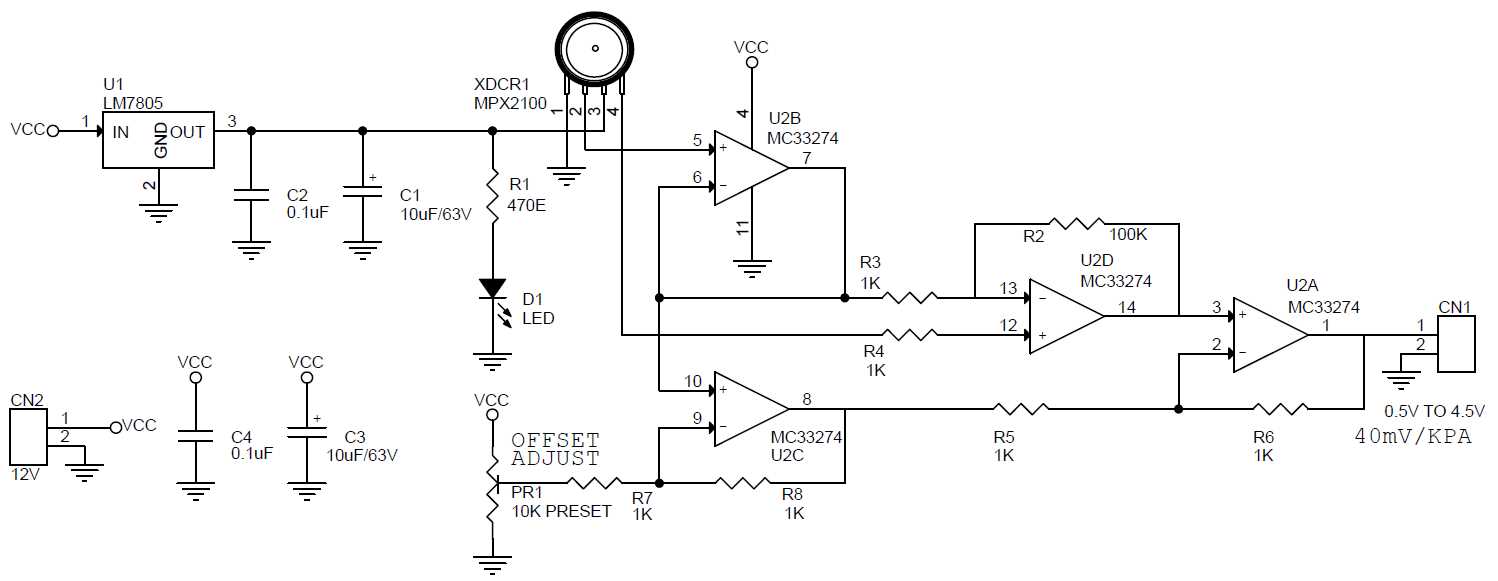

Our exploration extends beyond the theoretical realm into practical methodologies employed to assess and enhance sensor accuracy. We scrutinize various calibration techniques, ranging from simple offset adjustments to sophisticated multipoint calibrations, each tailored to suit the intricacies of the sensor’s behavior and the demands of its application.

Furthermore, we investigate the influence of environmental factors on sensor accuracy, acknowledging the role of temperature, humidity, and pressure in shaping its performance. By comprehensively understanding these variables, we equip ourselves with the knowledge to implement corrective measures, mitigating their impact on sensor readings.

Through this comprehensive analysis, we aim to empower practitioners with the insights and techniques necessary to navigate the complexities of sensor accuracy and calibration effectively. By fostering a deeper understanding of these fundamental principles, we pave the way for the development of robust and reliable sensing systems, poised to excel across diverse domains and applications.

Interpreting Output Signals and Voltage Ranges

Understanding the signals and voltage ranges produced by sensors is crucial for their effective utilization in various applications. In this section, we delve into the interpretation of output signals and voltage ranges provided by the sensor, shedding light on their significance and implications.

Signal Types

Output signals from sensors encompass a range of types, each conveying specific information about the measured parameter. These signals may include analog voltage, digital pulses, or other forms of output indicative of the sensor’s response to external stimuli.

Interpreting Voltage Ranges

Voltage ranges generated by the sensor correspond directly to the magnitude of the measured parameter. Understanding these voltage ranges enables users to accurately interpret the sensor’s readings and make informed decisions based on the acquired data. It is essential to discern the relationship between voltage variations and the corresponding changes in the physical quantity being measured.

| Voltage Range (Volts) | Measured Parameter |

|---|---|

| 0.5 – 2.5 | Temperature |

| 0 – 5 | Pressure |

| 1 – 10 | Force |

Application Insights: Leveraging the Mpx2200dp Sensor for Pressure Measurement

In this section, we delve into the practical applications and insights gained from employing the advanced sensing capabilities of the Mpx2200dp component for pressure measurement tasks. By harnessing the unique features and functionalities of this sensor, engineers and researchers can obtain valuable data crucial for various industries and applications.

Pressure measurement plays a pivotal role across diverse fields, ranging from automotive and aerospace industries to medical and environmental sectors. Understanding and accurately monitoring pressure levels are essential for ensuring safety, optimizing performance, and enhancing efficiency in numerous systems and processes.

- Automotive Engineering: The automotive industry extensively utilizes pressure sensors for monitoring tire pressure, engine performance, and fuel injection systems. By integrating the Mpx2200dp sensor into automotive applications, engineers can enhance vehicle safety, fuel efficiency, and overall performance.

- Medical Devices: In medical settings, precise pressure measurements are critical for monitoring blood pressure, respiratory functions, and intracranial pressure. The Mpx2200dp sensor, with its high accuracy and reliability, can contribute significantly to the development of advanced medical devices for improved patient care and diagnostics.

- Industrial Automation: Industrial processes often require real-time monitoring of pressure levels to ensure optimal operation and prevent equipment failures. By leveraging the Mpx2200dp sensor in industrial automation systems, manufacturers can enhance productivity, minimize downtime, and streamline maintenance procedures.

- Environmental Monitoring: Environmental scientists rely on pressure sensors to assess atmospheric pressure changes, weather patterns, and altitude variations. With the integration of the Mpx2200dp sensor into environmental monitoring networks, researchers can gather valuable data for climate studies, forecasting, and disaster preparedness.

Overall, the versatile nature of the Mpx2200dp sensor enables its integration into a wide range of applications, facilitating precise and reliable pressure measurements across various industries. By exploring its capabilities and applications, engineers and researchers can unlock new possibilities for innovation and advancement in their respective fields.

Integration with Microcontroller Systems

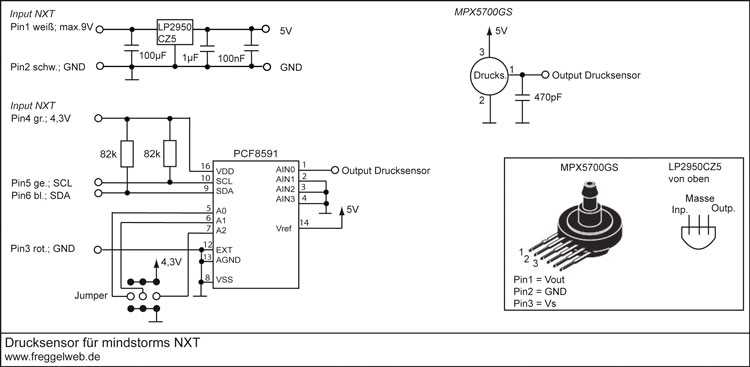

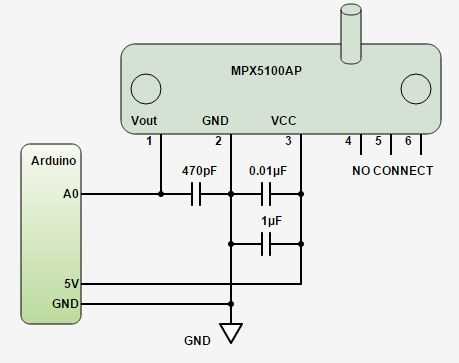

Incorporating the Mpx2200dp sensor into microcontroller systems enhances their functionality and versatility, allowing for seamless integration of pressure sensing capabilities. This section explores the integration aspects, highlighting the symbiotic relationship between the sensor and microcontrollers.

- Interfacing: Connecting the Mpx2200dp sensor with microcontrollers involves establishing communication protocols and ensuring compatibility for smooth data transmission.

- Data Processing: Microcontrollers play a pivotal role in processing the raw sensor data, performing necessary computations, and converting it into meaningful information for further analysis.

- Calibration: Calibration routines implemented within microcontroller systems ensure accurate sensor readings, compensating for environmental factors and inherent sensor variations.

- Control Logic: Utilizing microcontrollers enables the implementation of sophisticated control algorithms, allowing dynamic adjustment of parameters based on real-time sensor feedback.

By integrating the Mpx2200dp sensor with microcontroller systems, engineers can design intelligent sensing solutions for various applications, ranging from automotive and industrial automation to medical devices and consumer electronics.