Embarking on a quest for miniature marvels, we delve into the intricate world of diminutive yet powerful mechanisms. These diminutive wonders silently orchestrate a symphony of movement, enabling precise control in an array of applications. Within the realm of technical specifications lies a roadmap, a blueprint of capabilities waiting to be deciphered.

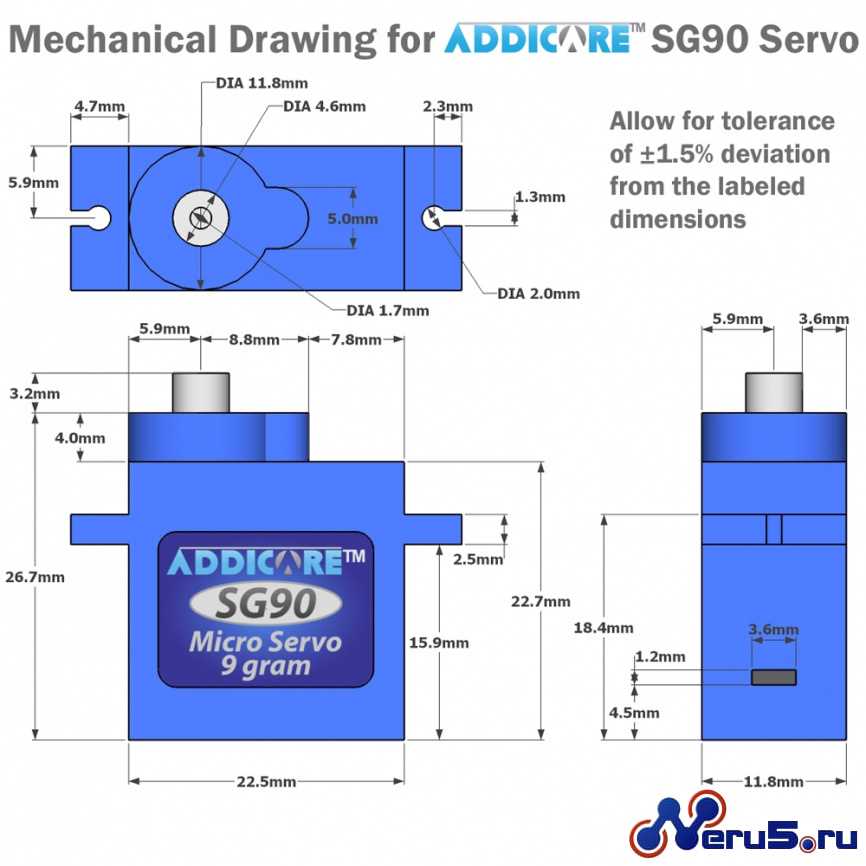

Unlocking the essence of these intricate artifacts demands a journey through labyrinthine documentation, where every curve and dimension holds significance. Absent the grandeur of larger counterparts, these scaled-down champions carry the weight of precision on their compact shoulders, each specification a testament to their potential.

Within these pages, we navigate through a lexicon of characteristics, each descriptor painting a portrait of functionality. From torque to voltage, every detail contributes to the grand narrative of performance. Embrace the challenge of understanding, for within these datasheets lie the blueprints of innovation.

Understanding Specifications of Miniature Actuator Documentation

When delving into the intricacies of miniature actuator documentation, it becomes paramount to grasp the nuances and subtleties embedded within these technical documents. Such documentation serves as a roadmap, offering insight into the capabilities, limitations, and operational parameters of these compact motion devices.

Within the realm of miniature actuator documentation, a thorough understanding of the provided specifications is indispensable. These specifications, akin to the DNA of the device, delineate its performance metrics, operational boundaries, and compatibility with diverse applications. They serve as a compass, guiding engineers and enthusiasts through the labyrinth of technical intricacies.

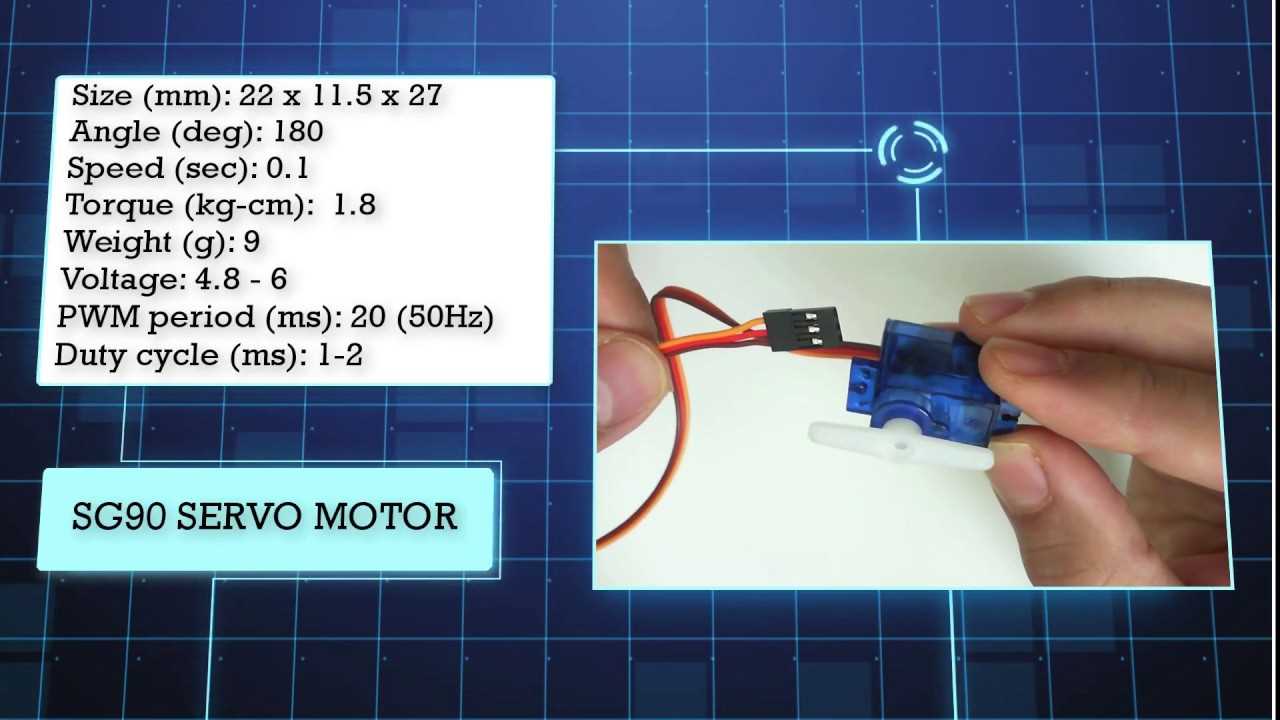

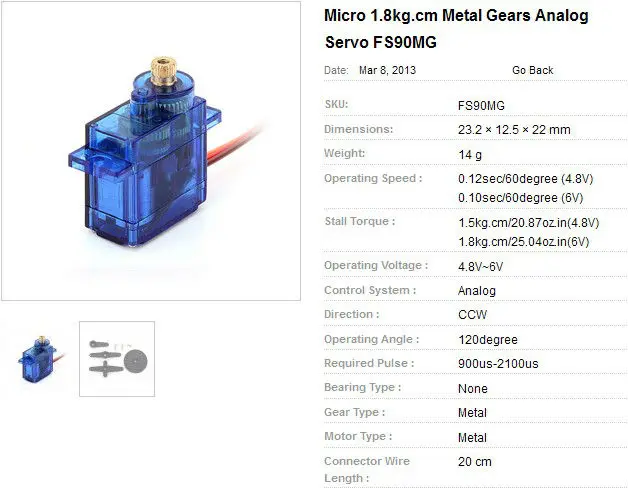

Amidst the plethora of specifications, certain key elements stand out as pillars, anchoring the comprehension of the device’s functionality. From torque ratings to speed characteristics, each specification contributes a unique piece to the puzzle, painting a comprehensive picture of the miniature actuator’s capabilities.

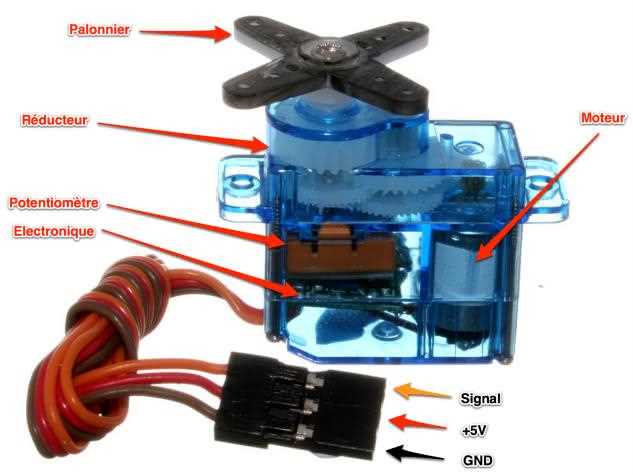

Furthermore, delving beyond the surface of specifications unveils a treasure trove of insights into the inner workings of the miniature actuator. Exploring factors such as operating voltage, pulse width modulation (PWM) frequency, and stall current sheds light on the nuances that dictate the device’s performance under varying conditions.

As one navigates through the labyrinthine corridors of miniature actuator documentation, it becomes evident that each specification serves a distinct purpose, contributing to the holistic understanding of the device’s behavior. Mastery of these specifications empowers engineers and hobbyists alike to harness the full potential of miniature actuators, unlocking a realm of possibilities limited only by imagination.

Deciphering Specifications for Precision

In the realm of miniature electromechanical systems, understanding the intricacies of technical documentation is paramount for achieving optimal performance. Delving into the particulars of specifications entails navigating through a labyrinth of numerical values and performance metrics. This section endeavors to unravel the cryptic language of precision, shedding light on the essential parameters crucial for discerning the capabilities of these intricate mechanisms.

Key Performance Indicators

When scrutinizing the intricacies of technical documentation, several key performance indicators emerge as pivotal markers of functionality. These indicators encompass an array of quantitative measures that encapsulate the precision and efficiency of the apparatus. By dissecting these metrics, one can gain invaluable insights into the operational characteristics and limitations of the device.

| Parameter | Description |

|---|---|

| Accuracy | The degree of conformity between the actual and intended position or movement. |

| Resolution | The smallest increment of motion or position change detectable by the mechanism. |

| Torque | The rotational force exerted by the mechanism, typically measured in ounce-inches or Newton-meters. |

| Response Time | The duration required for the mechanism to react to a change in input signal. |

Interpreting Precision Metrics

Deciphering the significance of precision metrics necessitates a nuanced understanding of their implications on real-world applications. Each parameter serves as a critical determinant of the mechanism’s suitability for specific tasks and environments. By meticulously analyzing these metrics in conjunction with operational requirements, engineers can make informed decisions regarding the selection and optimization of miniature electromechanical systems.

Exploring Performance Metrics and Limits

In this section, we delve into the various indicators and thresholds that define the operational capabilities and constraints of this miniature actuation component. By dissecting the quantitative and qualitative parameters governing its functionality, we uncover a nuanced understanding of its potential and boundaries.

Understanding Operational Parameters: We embark on a journey to decipher the intricate nuances encapsulated within the operational spectrum of this diminutive actuator. Through meticulous analysis, we unravel the intricacies of its response dynamics, torque capabilities, and precision thresholds, shedding light on its capacity for seamless motion control.

Exploring Dynamic Performance: Venturing beyond static specifications, we scrutinize the dynamic performance metrics that delineate the responsiveness and agility of this compact motion enabler. From acceleration profiles to response times, we navigate through the dynamic landscape to discern the intricate interplay of speed, accuracy, and efficiency.

Unveiling Environmental Constraints: As we probe deeper, we confront the environmental factors that exert influence on the operational efficacy of this miniature marvel. From temperature fluctuations to mechanical stressors, we explore the extent to which external conditions shape its performance envelope, unraveling the delicate balance between resilience and vulnerability.

Challenging Performance Limits: Pushing the boundaries of conventional understanding, we confront the inherent limitations that delineate the upper echelons of performance achievable by this compact actuation unit. Through rigorous testing and analysis, we confront the thresholds of torque, speed, and precision, charting the course for future advancements and innovations.

Interpreting Application Guidelines and Recommendations

In this section, we delve into deciphering the practical directives and suggested approaches provided within the documentation. Understanding how to implement the outlined strategies effectively ensures optimized performance and longevity of the device in various contexts.

Deciphering Practical Directives

Exploring the directives entails grasping the nuanced instructions aimed at guiding the utilization of the technology in diverse scenarios. These directives encapsulate insights into the ideal operational parameters and environmental considerations.

- Analysing the environmental constraints: Assessing the ambient conditions and potential stressors aids in tailoring the application to mitigate risks and enhance resilience.

- Calibrating operational thresholds: Fine-tuning the operational thresholds aligns the device’s performance with the specific requirements of the application, optimizing its functionality.

- Integrating safety protocols: Incorporating recommended safety measures safeguards both the device and its surroundings, ensuring reliable operation while minimizing potential hazards.

Suggested Approaches for Optimal Performance

The recommended approaches serve as strategic pathways towards maximizing the efficiency and efficacy of the technology deployment. By embracing these approaches, users can unlock the full potential of the device while mitigating operational challenges.

- Embracing adaptive methodologies: Flexibility in approach allows for agile adjustments in response to evolving circumstances, fostering adaptability and resilience.

- Implementing proactive maintenance routines: Regular maintenance routines based on provided recommendations prevent premature wear and tear, prolonging the lifespan of the technology.

- Leveraging collaborative feedback: Engaging with user communities and leveraging collective insights fosters continuous improvement and innovation, enriching the overall user experience.