Unlocking the potential of innovative adhesives opens doors to a world of boundless applications and solutions. Within the realm of industrial adhesives lies a product, known for its robustness and adaptability, reshaping the landscape of assembly and bonding.

Exploring the intricacies of this adhesive substance reveals a plethora of properties and characteristics, each tailored to address specific challenges across industries. Its formulation embodies resilience, reliability, and a commitment to durability, offering a steadfast bond in the face of diverse environmental conditions.

Delving deeper into its composition unravels a tapestry of chemical bonds meticulously engineered to foster cohesion and strength. This adhesive marvel transcends conventional boundaries, seamlessly uniting disparate materials with unmatched precision and efficacy.

Embark on a journey to unveil the myriad applications and benefits of this adhesive masterpiece, as we navigate through its distinctive features and performance attributes. Join us in exploring the realm of adhesive excellence, where innovation meets reliability, and possibilities abound.

Understanding the Composition of Adhesive e-30cl

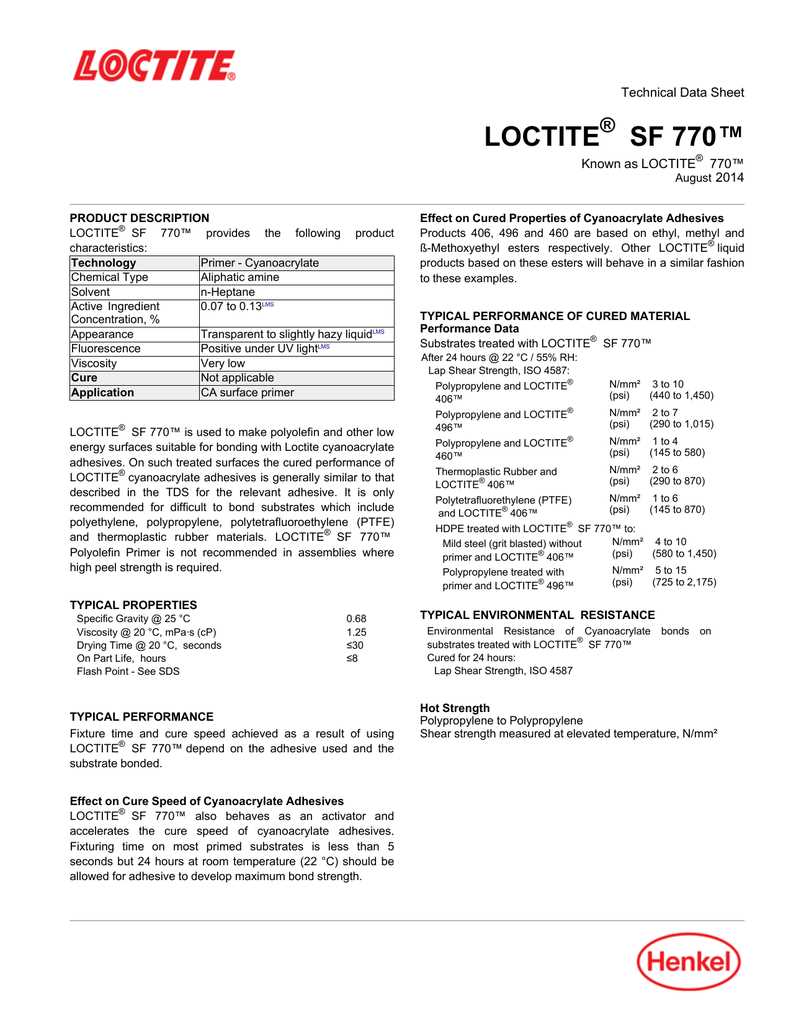

Delving into the intricate makeup of this adhesive compound unveils a wealth of insights into its chemical formulation and functional attributes. By dissecting its components and molecular architecture, we gain a comprehensive understanding of its adhesive properties and industrial applications.

At its core, this adhesive amalgamates a diverse array of chemical constituents meticulously crafted to achieve optimal bonding efficacy. Through a nuanced blend of organic and synthetic elements, it navigates the delicate balance between adhesion strength, durability, and versatility.

Exploring its chemical profile reveals a symphony of polymers, resins, and curing agents orchestrated to foster robust bonding across various substrates. Each component synergizes with others to engender a cohesive matrix capable of withstanding diverse environmental stresses and mechanical forces.

Furthermore, the composition embodies a strategic fusion of additives and modifiers, fine-tuned to enhance specific performance metrics such as viscosity, curing time, and thermal stability. This orchestrated integration of supplementary agents augments the adhesive’s adaptability to a spectrum of operational conditions and application requirements.

Through meticulous analysis and comprehension of its composition, we unravel the intricate tapestry of molecular interactions underpinning its adhesive prowess. Such insight not only fosters a deeper appreciation for its functionality but also serves as a foundation for optimizing its utilization across myriad industrial contexts.

Exploring the Chemical Ingredients

In this section, we delve into the intricate blend of compounds constituting the formulation of the product under scrutiny. Through meticulous examination, we uncover the diverse array of chemical constituents that synergistically contribute to its functionality and performance.

Composition Overview

Before delving into the specifics, it’s crucial to grasp the overarching composition of the solution. The intricate amalgamation of various chemical elements and compounds forms the backbone of its effectiveness.

Key Components

Within the formulation lie several key components, each playing a distinct role in shaping the product’s properties and characteristics. Through meticulous analysis, we unveil the significance of these elements in facilitating the desired outcomes.

| Chemical Component | Function |

|---|---|

| Resin | Provides adhesion and bonding capabilities. |

| Solvents | Aids in viscosity control and application. |

| Initiators | Facilitates the curing process. |

| Modifiers | Enhances specific properties such as flexibility or strength. |

Analyzing the Material Properties

In this section, we delve into a comprehensive examination of the intrinsic characteristics and performance attributes of the specified compound. By scrutinizing its physical, chemical, and mechanical traits, we aim to elucidate a profound understanding of its behavior and suitability for varied applications.

Physical Attributes

Firstly, we explore the tangible aspects of the substance, encompassing its appearance, texture, and consistency. Through meticulous observation and measurement, we assess parameters such as color, viscosity, and homogeneity, providing insights into its visual and tactile properties.

Chemical Composition

Subsequently, we analyze the elemental composition and molecular structure of the material, deciphering its chemical constituents and bonding configurations. This entails techniques ranging from spectroscopic analysis to chromatographic methods, facilitating a nuanced comprehension of its chemical identity and reactivity.

| Property | Measurement Method | Significance |

|---|---|---|

| Mechanical Strength | Tensile Testing | Determines load-bearing capacity and structural integrity. |

| Thermal Conductivity | Thermal Conductivity Analyzer | Indicates heat transfer efficiency and temperature stability. |

| Electrical Resistivity | Four-Point Probe Method | Evaluates insulating properties and electrical conductivity. |

| Chemical Stability | Accelerated Aging Tests | Assesses resistance to degradation and environmental factors. |

Furthermore, we examine its mechanical, thermal, and electrical characteristics through rigorous testing methodologies, elucidating its performance under diverse operational conditions. By correlating these findings with real-world applications, we ascertain its efficacy and suitability across a spectrum of industries.

Application Guide for Advanced Bonding Solution

Enhance your bonding expertise with this comprehensive application guide tailored for our cutting-edge adhesive, known for its remarkable versatility and reliability in various bonding tasks. Explore an array of practical techniques, tips, and recommendations to optimize your adhesive application process and achieve outstanding results.

Discover the optimal conditions and surfaces for application, explore the range of substrates this advanced adhesive effectively bonds, and learn how to prepare surfaces to ensure maximum adhesion strength. From industrial settings to DIY projects, this guide offers invaluable insights to empower your bonding endeavors.

Master the art of adhesive application as you delve into detailed instructions on proper mixing, dispensing, and curing procedures. Unlock the potential of our innovative bonding solution by understanding its compatibility with different materials and environments.

Equip yourself with troubleshooting strategies to address common challenges and optimize your bonding process for efficiency and effectiveness. With this application guide as your companion, you’ll forge bonds that withstand the test of time and meet the demands of diverse applications with confidence and precision.

Best Practices for Achieving Strong Adhesive Bonds

In the realm of adhesive bonding, achieving durable and reliable bonds is paramount for the success of various applications. This section elucidates fundamental practices to optimize the bonding process, fostering cohesion and longevity in bonded structures.

Surface Preparation

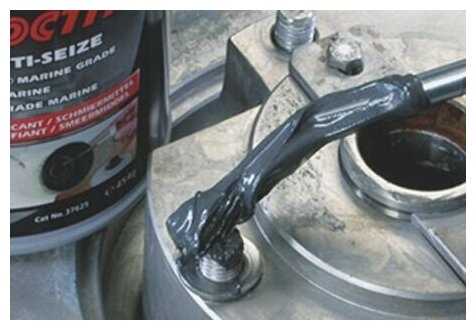

- Thoroughly clean and degrease bonding surfaces to eliminate contaminants that may impede adhesion.

- Utilize appropriate surface treatment methods such as abrasion, solvent wiping, or chemical priming to enhance surface energy and promote adhesion.

- Ensure uniformity in surface preparation across bonded substrates to mitigate disparities in adhesion strength.

Adhesive Application

- Apply adhesive evenly and in the recommended quantity to prevent excess adhesive buildup, which can compromise bond strength.

- Employ precise application techniques to minimize voids and air entrapment within the adhesive layer, optimizing bond integrity.

- Adhere strictly to recommended curing conditions, including temperature, humidity, and curing time, to facilitate proper adhesive polymerization and bond formation.

By adhering to these best practices, adhesive bonding processes can yield robust bonds capable of withstanding diverse mechanical and environmental stresses, ensuring the efficacy and longevity of bonded assemblies.