In the realm of miniature electronic components, a world of intricacies and innovation unfolds, offering a glimpse into the future of technology. Within this domain lies a particular type of electronic device, a diminutive yet potent entity, whose significance transcends its small stature. Delving into the intricacies of this component unveils a universe of possibilities, where precision engineering meets the boundless potential of modern electronics.

Embark on a journey to unravel the mysteries of these micro-scale wonders, as we navigate through their characteristics, applications, and underlying principles. Within the confines of their compact dimensions lies a wealth of functionality, serving as the building blocks of contemporary electronic systems. Through meticulous examination and analysis, we aim to shed light on the nuanced intricacies of these enigmatic components.

Join us as we embark on a quest to decode the language of electrons, exploring the intricate dance of signals and currents within the confines of these miniature marvels. Through careful scrutiny and thoughtful interpretation, we endeavor to unlock the secrets held within, paving the way for innovation and advancement in the realm of microelectronics.

The Evolution of Lnw SMD Transistors

In the realm of electronic components, the journey of Lnw Surface-Mount Device (SMD) transistors unveils a narrative rich in innovation and advancement. This section delves into the progressive trajectory of these miniature semiconductor devices, tracing their development from their nascent stages to their current state of sophistication.

| Epoch | Milestone Achievements |

|---|---|

| Emergence | Origins in early semiconductor technology |

| Miniaturization | Transition from bulky through-hole to compact surface-mount designs |

| Integration | Advancements in multi-functionality and system integration |

| Performance Enhancement | Improvements in speed, power efficiency, and reliability |

Throughout this evolutionary journey, Lnw SMD transistors have evolved from rudimentary components to indispensable elements in modern electronic circuits, contributing to the efficiency and functionality of various electronic devices across industries.

From Miniaturization to Enhanced Performance

In the realm of electronic components, the journey from compactness to superior functionality has been a hallmark of progress. This evolution, akin to refining a finely crafted instrument, has propelled innovation in the domain of semiconductor devices. Delving into the intricacies of size reduction and augmenting operational capabilities, this discourse explores the transformative trajectory from diminutive proportions towards heightened efficacy.

Shrinking Dimensions: The Pursuit of Miniaturization

Within the landscape of electronic components, the quest for miniaturization stands as a testament to human ingenuity. From the sprawling architectures of yesteryears to the present-day marvels of compactness, engineers have relentlessly pursued the condensation of form without compromising function. This endeavor, akin to sculpting intricate statuettes from blocks of silicon, has heralded an era where the once towering behemoths of technology now reside within the confines of diminutive packages.

Empowering Performance: The Paradigm Shift Towards Excellence

Beyond mere reduction in size lies the pivotal paradigm shift towards enhanced performance. The metamorphosis from modest capabilities to formidable prowess epitomizes the essence of technological advancement. Through meticulous design iterations and relentless optimization, semiconductor devices have transcended erstwhile limitations, emerging as veritable titans of efficiency and reliability. This evolution, reminiscent of refining raw ore into gleaming steel, underscores the relentless pursuit of excellence within the realm of electronics.

Understanding Specifications of Miniature Surface-Mount Device Semiconductors

In the realm of modern electronics, the thorough comprehension of miniature surface-mount device (SMD) semiconductor specifications stands as an imperative cornerstone. Delving into the intricacies of these components necessitates a nuanced grasp of their performance characteristics, operational parameters, and application-specific considerations.

Key Performance Metrics

- Electrical Characteristics

- Thermal Properties

- Mechanical Dimensions

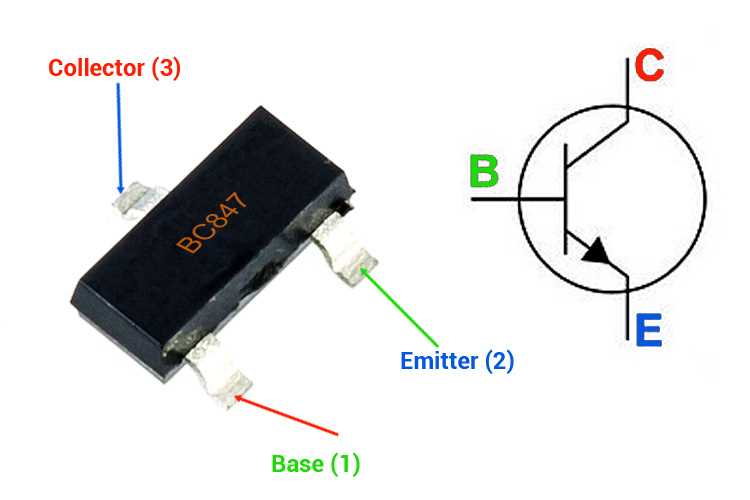

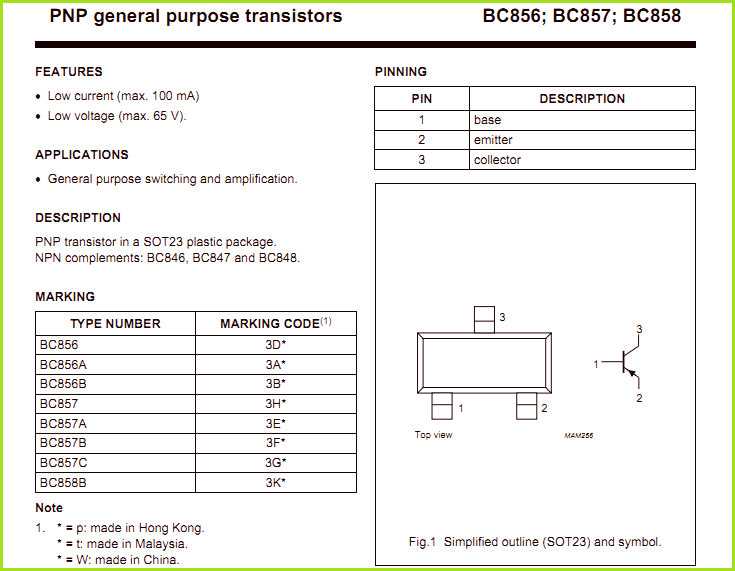

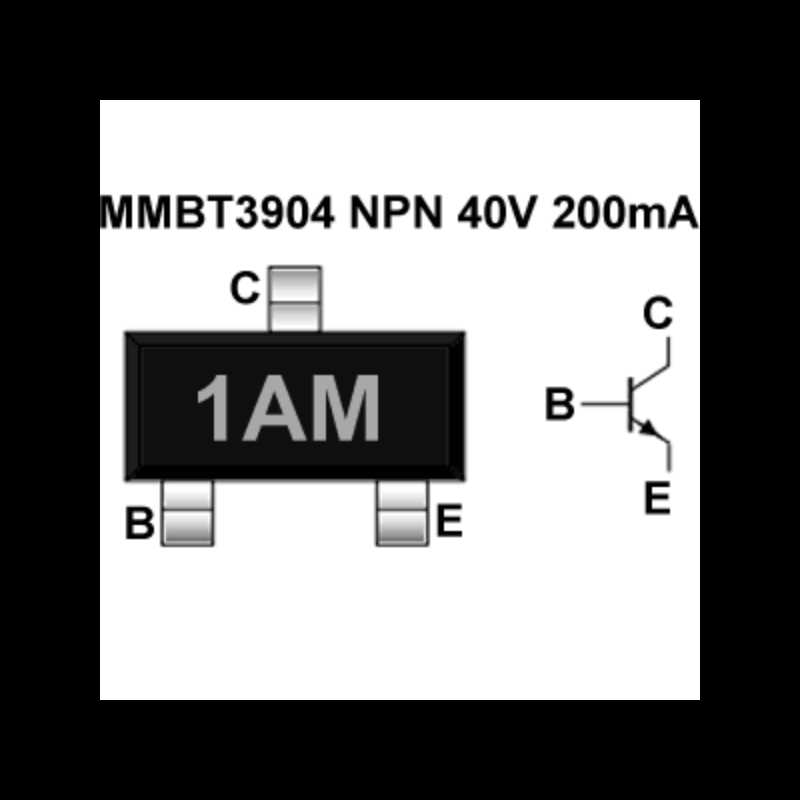

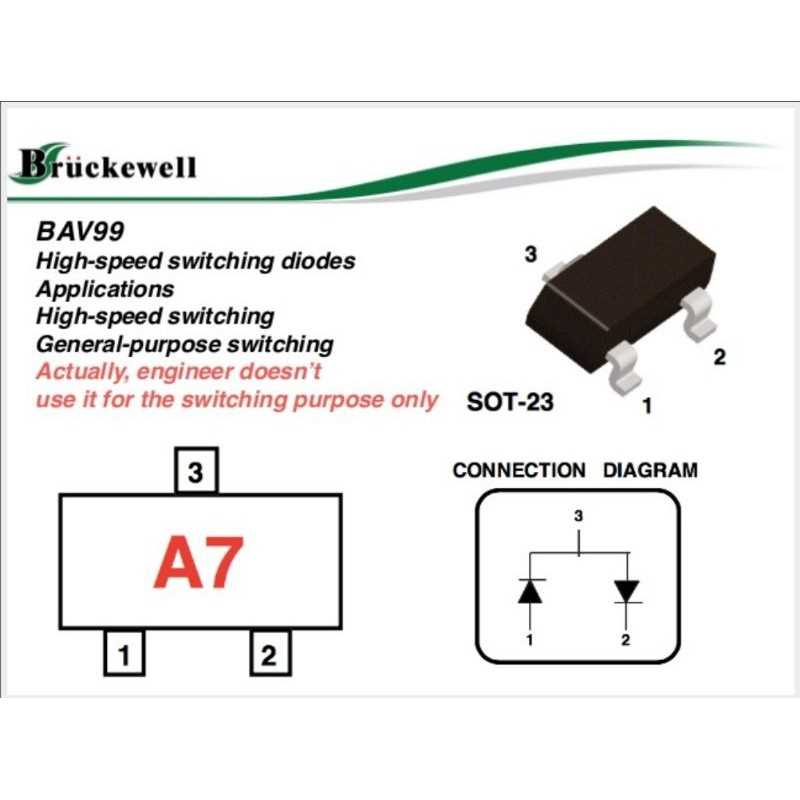

Exploring the nuances of these metrics unveils the intricate tapestry that defines the functionality and utility of SMD semiconductors. Electrical characteristics encompass a spectrum of parameters delineating operational voltage ranges, current-handling capacities, and frequency response, among others. Understanding thermal properties delves into the heat dissipation capabilities and temperature tolerances crucial for stable operation. Mechanical dimensions, comprising package type, footprint, and lead configuration, play a pivotal role in compatibility and integration within diverse electronic layouts.

Application-Specific Considerations

- Circuit Design Implications

- Environmental Constraints

- Reliability Standards

Beyond the realm of generic specifications, delving into application-specific considerations unveils a landscape where the efficacy of SMD semiconductors truly manifests. Circuit design implications entail optimizing component selection to align with desired performance criteria while adhering to space and cost constraints. Environmental constraints encompass factors such as operating temperature ranges, humidity levels, and exposure to vibration or shock, necessitating robust packaging and material selections. Reliability standards dictate the longevity and stability of SMD semiconductors under varied operating conditions, demanding meticulous attention to manufacturing processes and quality control measures.

Diving into Datasheets for Effective Component Selection

In this section, we embark on a journey through the intricate landscape of technical documents that serve as indispensable guides in the quest for optimal electronic components. These comprehensive references, akin to treasure maps, empower engineers and enthusiasts alike to navigate the vast realm of electronic components with precision and insight.

Understanding the intricacies of these documents requires a keen eye for detail and a thorough grasp of the terminology employed within. Delving beyond mere specifications, these datasheets unveil a wealth of information, ranging from performance metrics to operational parameters, all meticulously organized to facilitate informed decision-making.

Unlocking the potential of datasheets entails deciphering complex graphs, interpreting tables laden with technical data, and discerning the implications of each specification on the overall system design. This process demands not only technical acumen but also the ability to discern subtleties and extrapolate implications beyond the surface level.

Navigating through the labyrinth of datasheets requires more than mere familiarity with technical jargon; it necessitates a structured approach to information extraction. By strategically prioritizing key parameters and cross-referencing various sections, one can streamline the selection process and unearth hidden insights that might elude the untrained eye.

Embracing the datasheet as an invaluable companion on the journey toward efficient component selection is not merely a matter of necessity but a testament to the symbiotic relationship between engineers and the wealth of knowledge encapsulated within these meticulously crafted documents.

Practical Tips for Maximizing the Efficiency of Surface Mount Device Semiconductor Components

In this section, we’ll explore effective strategies for optimizing the performance and longevity of surface mount device semiconductor components. By implementing these techniques, you can enhance the reliability and functionality of your electronic circuits without compromising on quality.

1. Handling and Storage

Proper handling and storage procedures are paramount to preserving the integrity of surface mount device semiconductor components. Ensure a static-free environment during handling and storage to prevent electrostatic discharge (ESD) damage. Utilize antistatic packaging and grounding straps to minimize the risk of component failure due to ESD.

2. Soldering Techniques

Mastering soldering techniques is essential for successful integration of surface mount device semiconductor components into electronic circuits. Employing the appropriate soldering iron temperature and soldering duration is crucial to prevent overheating and component damage. Additionally, adhere to recommended soldering profiles provided by manufacturers to achieve optimal solder joint quality and reliability.

| Parameter | Recommended Value |

|---|---|

| Soldering Iron Temperature | 260°C – 280°C |

| Soldering Duration | 3 – 5 seconds |

| Preheat Temperature | 150°C – 180°C |