In the realm of electronic components, there exists a realm of vital documents that serves as the guiding light for engineers, enthusiasts, and innovators alike. These documents, akin to blueprints in construction, offer a comprehensive insight into the functionality, capabilities, and intricacies of various electronic marvels.

Embarking on a journey through the labyrinth of technical specifications unveils a tapestry of information, rich in detail and significance. These documents, while seemingly mundane to the untrained eye, harbor a wealth of knowledge critical for understanding, designing, and implementing electronic systems with precision and finesse.

Delving into the heart of technical documentation transcends the mere perusal of numbers and diagrams; it embodies a quest for comprehension, an exploration of the inner workings of technology. Each line, each symbol, holds a story of innovation, a testament to the relentless pursuit of progress in the realm of electronics.

Understanding Key Information in LM2679 Documentation

Exploring the intricacies of the LM2679 documentation unveils crucial insights into its operational parameters and application guidelines. By delving into the essential details provided within the documentation, users can grasp the fundamental principles governing the functionality and performance of this component.

Key Parameters Overview

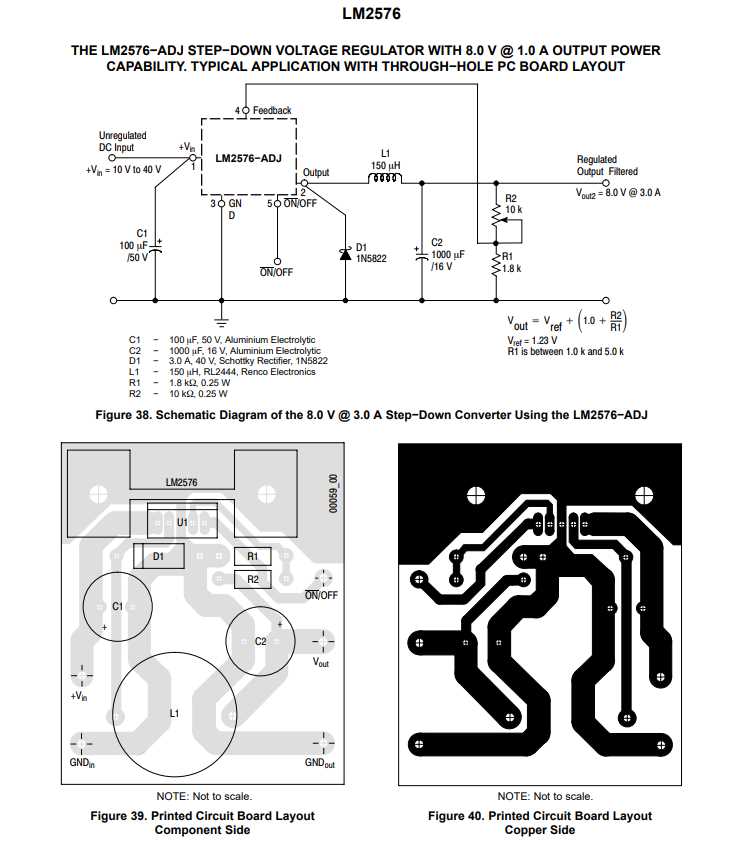

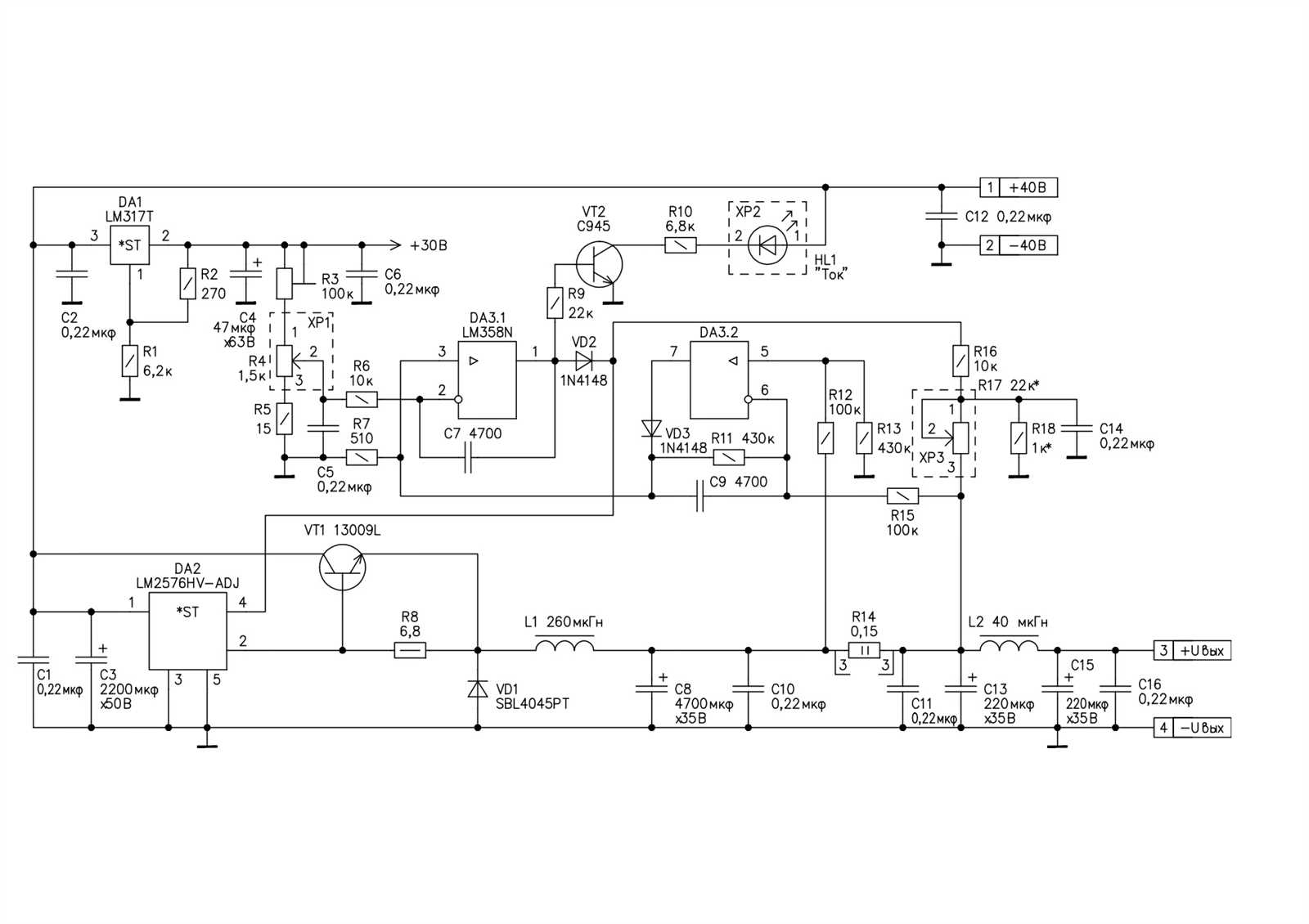

Operating Specifications: Within the documentation, you’ll encounter a comprehensive breakdown of the operating conditions, elucidating the range of voltages, currents, and temperatures within which the LM2679 operates optimally. Understanding these specifications is paramount for ensuring proper integration and reliable performance.

Application Guidelines and Considerations

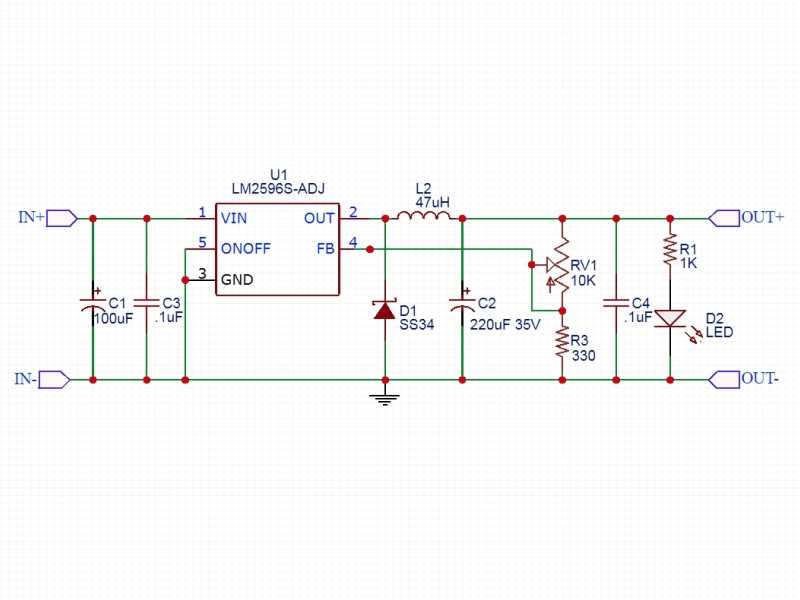

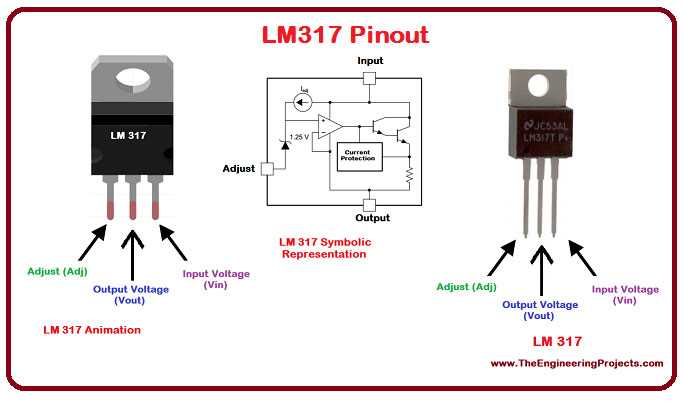

Component Interactions: The documentation also sheds light on the interaction of the LM2679 with other components within the circuit. By elucidating factors such as input/output capacitance requirements, feedback loop configuration, and thermal considerations, it equips users with the knowledge necessary to design robust and efficient power supply systems.

By familiarizing oneself with these critical aspects outlined in the LM2679 documentation, engineers and enthusiasts alike can harness the full potential of this component, unleashing its capabilities in diverse applications with confidence and precision.

Deciphering Key Specifications and Features

In dissecting the core essence of technical documentation, understanding the fundamental facets plays a pivotal role in navigating the intricacies of electronic components. Delving into the nuances of this realm unveils a tapestry woven with critical specifications and features, serving as the bedrock for informed decision-making and seamless integration within diverse applications.

At the heart of comprehending the intricacies lies a comprehensive grasp of the operational parameters, elucidating the operational boundaries and performance metrics essential for seamless integration. Unveiling the voltage regulation mechanisms, input and output voltage ranges, and efficiency profiles unravels the blueprint for optimal functionality.

- Input Voltage Range: The spectrum within which the module operates, delineating the permissible input voltages crucial for compatibility and stability.

- Output Voltage Range: Defining the range of output voltages attainable, encapsulating the flexibility and adaptability in diverse operational scenarios.

- Efficiency: An embodiment of power conservation, accentuating the efficacy of energy conversion and minimizing wastage, thereby enhancing operational efficiency.

- Load Regulation: A cornerstone in maintaining stability amidst varying loads, ensuring consistent performance across a myriad of operating conditions.

- Protection Mechanisms: Safeguards woven into the fabric of the component, shielding against overvoltage, overcurrent, and thermal aberrations, fortifying longevity and reliability.

Scrutinizing the thermal characteristics unveils insights into dissipative mechanisms and thermal management strategies, delineating the operational thresholds and optimizing performance under diverse environmental conditions. Moreover, delving into the form factor and packaging aspects delineates the spatial constraints and compatibility considerations, fostering seamless integration within compact layouts and diverse configurations.

Embracing a holistic perspective in deciphering these key specifications and features empowers stakeholders with the requisite knowledge to navigate the labyrinthine landscape of electronic components, fostering innovation and efficacy in design paradigms.

Optimizing LM2679 Performance: Practical Tips

Enhancing the Efficiency of Your Power Converter:

Unlocking the full potential of your power converter requires a keen understanding of its intricacies beyond the technical specifications. This section delves into practical strategies for optimizing the performance of your power converter, ensuring maximum efficiency and reliability without compromising on functionality.

Maximizing Efficiency through Component Selection:

One of the critical factors influencing the performance of your power converter lies in the selection of components. By carefully choosing components that align with your system requirements and performance goals, you can enhance efficiency and minimize losses.

Fine-Tuning Operating Parameters:

Delving into the operational parameters of your power converter opens avenues for optimization. Adjusting input and output voltages, current limits, and switching frequencies can significantly impact efficiency and overall performance, tailoring the converter to specific application demands.

Optimizing Layout and Thermal Management:

Efficient layout design and effective thermal management play pivotal roles in the performance of your power converter. By optimizing component placement, minimizing parasitic elements, and implementing robust thermal dissipation techniques, you can mitigate losses and ensure stable operation under varying conditions.

Implementing Advanced Control Strategies:

Beyond conventional techniques, implementing advanced control strategies can further enhance the performance of your power converter. Techniques such as pulse skipping, frequency modulation, and adaptive control algorithms offer avenues for improving efficiency and response to dynamic load variations.

Continuous Monitoring and Optimization:

Optimization is an iterative process that extends beyond initial setup. Continuous monitoring of system parameters coupled with periodic optimization ensures sustained performance and reliability over the operational lifespan of your power converter.

Conclusion:

Optimizing the performance of your power converter demands a holistic approach encompassing component selection, parameter optimization, layout design, and control strategies. By employing practical tips and techniques outlined in this section, you can unleash the full potential of your power converter, achieving superior efficiency and reliability in your applications.

Efficient Design Techniques and Application Insights

In this segment, we delve into innovative methods and strategic insights for enhancing the efficiency of circuit design and the practical application thereof. Through a nuanced exploration, we uncover valuable strategies and profound understandings to optimize performance and utility, all without explicitly referencing specific components or technical documents.

Maximizing Efficiency through Design: Efficient circuit design entails a multifaceted approach, encompassing considerations such as power management, component selection, and layout optimization. By integrating principles of energy conservation and leveraging synergistic component interactions, designers can achieve remarkable efficiency gains.

Application Insights: Beyond theoretical constructs, practical application insights are indispensable for realizing the full potential of a design. Through empirical observations and real-world case studies, we illuminate the intricacies of applying efficient design techniques across diverse contexts, empowering practitioners to navigate challenges and capitalize on opportunities.

Optimizing Performance: The pursuit of efficiency extends beyond mere power conservation; it encompasses overall performance optimization. Through strategic trade-offs and meticulous fine-tuning, designers can strike a delicate balance between conflicting design objectives, ultimately yielding solutions that excel in both efficiency and performance metrics.

Integration of Advanced Technologies: As technology continues to evolve, embracing cutting-edge advancements becomes imperative for maintaining a competitive edge. By harnessing emerging technologies such as advanced semiconductor materials, novel packaging techniques, and intelligent control algorithms, designers can unlock new frontiers in efficiency and performance.

Conclusion: In this exploration of efficient design techniques and application insights, we’ve traversed the intricate landscape of circuit optimization without explicitly referencing specific components. Armed with a deeper understanding of the underlying principles and strategic considerations, designers are empowered to push the boundaries of efficiency and innovation, driving transformative advancements in the field.

Troubleshooting the LM2679: Addressing Common Challenges and Solutions

In this section, we delve into the practical aspects of navigating through potential hurdles that might arise while working with the LM2679 voltage regulator. Understanding and resolving these challenges is crucial for ensuring optimal performance and reliability in your circuit designs.

Let’s explore some common issues that engineers encounter when integrating the LM2679 into their systems, along with effective strategies for troubleshooting and rectifying them:

- Output Voltage Fluctuations: One of the prevalent issues users may face involves fluctuations in the output voltage. This phenomenon could stem from various factors, such as input voltage variations, load fluctuations, or inadequate output capacitor sizing. To mitigate this, thorough examination of the input and output conditions is necessary, along with ensuring proper component selection and placement.

- Overheating: Excessive heat generation within the LM2679 can pose a significant challenge, leading to performance degradation and potential device failure. Overheating may result from inadequate thermal management, excessive current draw, or improper PCB layout. Implementing proper heat sinking techniques, optimizing the layout for efficient heat dissipation, and adhering to recommended operating conditions can help alleviate this issue.

- Stability Issues: Achieving stability in voltage regulation is paramount for the reliable operation of the LM2679. Instabilities such as oscillations or overshoots can compromise system performance and introduce reliability concerns. Analyzing the feedback loop, selecting appropriate compensation components, and ensuring proper grounding and decoupling are essential steps in addressing stability issues.

- Input Voltage Transients: The LM2679 may be susceptible to input voltage transients caused by external disturbances or switching events. These transients can propagate through the regulator and affect output stability. Implementing robust input filtering techniques, such as using transient voltage suppressors or additional capacitance, can help mitigate the impact of transient disturbances on the LM2679.

- Component Failures: Component failures, including those related to the LM2679 itself or surrounding circuitry, can occur due to various reasons such as overvoltage conditions, overcurrent events, or component aging. Conducting thorough reliability assessments, including stress testing and component qualification, can aid in identifying potential failure modes and implementing preventive measures to enhance system robustness.

By addressing these common challenges through systematic troubleshooting approaches and employing appropriate solutions, engineers can maximize the performance, reliability, and longevity of systems utilizing the LM2679 voltage regulator.