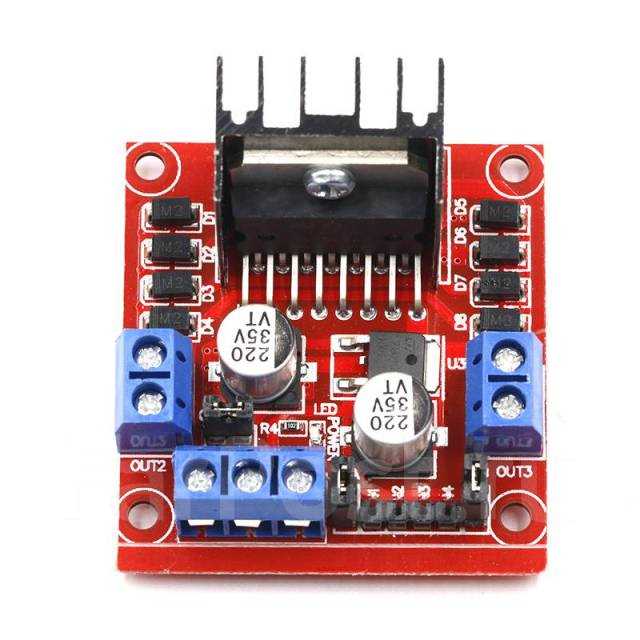

Unleash your creativity with a remarkable piece of engineering that opens up a world of possibilities. This electronic marvel, known as the L298n mini datasheet, is the perfect tool for any tech enthusiast or DIY tinkerer. With its compact size and powerful performance, it has become a favorite among hobbyists and professionals alike.

Imagine a small but mighty device that allows you to control and manipulate electrical currents with ease. Its cutting-edge technology enables you to build and create innovative projects, from simple motor controls to complex robotic systems. Whether you are a seasoned electronics enthusiast or just starting your journey, the L298n mini datasheet is an essential component that will revolutionize your creations.

Embrace the power of precision with this remarkable circuit board. Equipped with state-of-the-art features, the L298n mini datasheet guarantees optimal performance and functionality. Its robust design ensures stability and reliability, even in the most demanding applications. The incorporation of advanced technologies and components makes this mini datasheet a force to be reckoned with.

Unlock endless possibilities and let your imagination run wild. The L298n mini datasheet gives you the freedom to turn your wildest ideas into reality. From home automation to smart appliances, this versatile circuit board is the key to unlocking the potential of your electronic projects. Its flexibility and ease of use make it a must-have for anyone looking to push the boundaries of what is possible.

Understanding the key features and capabilities

In this section, we will explore the essential functionalities and characteristics of a compact electronic component that plays a vital role in various applications. By delving into its fundamental features and remarkable capabilities, we can gain a comprehensive understanding of its potential applications and advantages.

Through a careful analysis of its unique properties, we can unlock the immense potential that this electronic device offers. By exploring its expansive range of functions and capabilities, we will discover how it can enhance the performance and efficiency of a diverse array of electronic systems and projects.

By highlighting its impressive versatility and adaptability, we can grasp how this component can seamlessly integrate with other elements of a circuit, allowing for seamless control and regulation of electrical systems. Its ability to handle high currents and drive multiple motors makes it indispensable for robotics, automation, and other fields that require precise and efficient control over power and motion.

Moreover, its exceptional thermal protection mechanisms ensure its durability and reliability even under demanding conditions. The integration of advanced safety features guarantees the protection of both the component itself and the surrounding system, safeguarding against potential malfunctions and hazards.

Furthermore, its compact size and practical design facilitate easy installation and flexible usage in a wide range of electronic projects. This versatility makes it an ideal choice for hobbyists, engineers, and enthusiasts alike, allowing for creativity and innovation in the development of various electronic systems.

In conclusion, the exploration of the key features and capabilities of this electronic component unveils its immense potential and advantages in different applications. By understanding its functionalities and characteristics, we can harness its power to enhance the performance and efficiency of electronic systems, opening up a world of possibilities in various fields of technology.

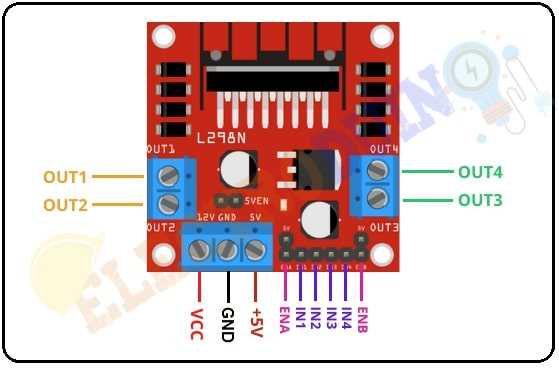

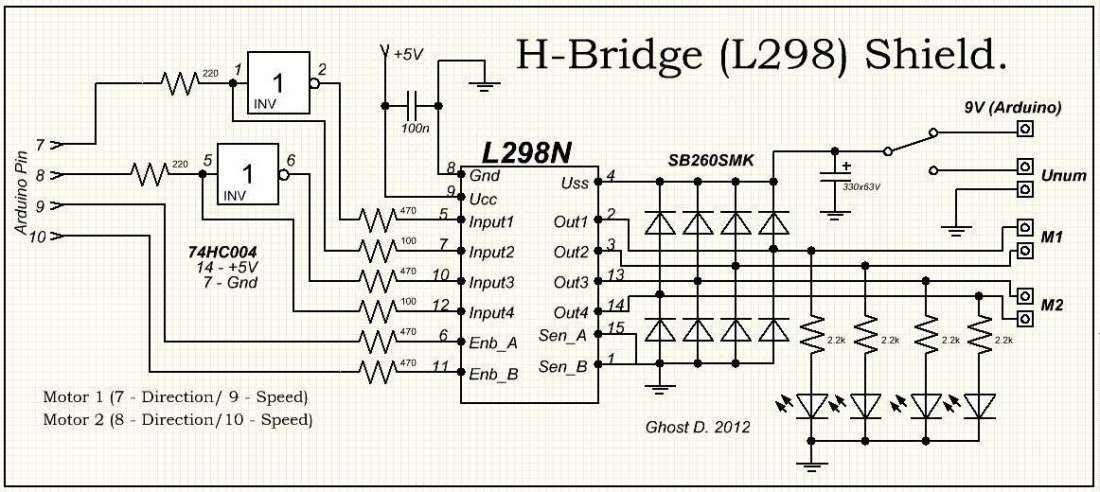

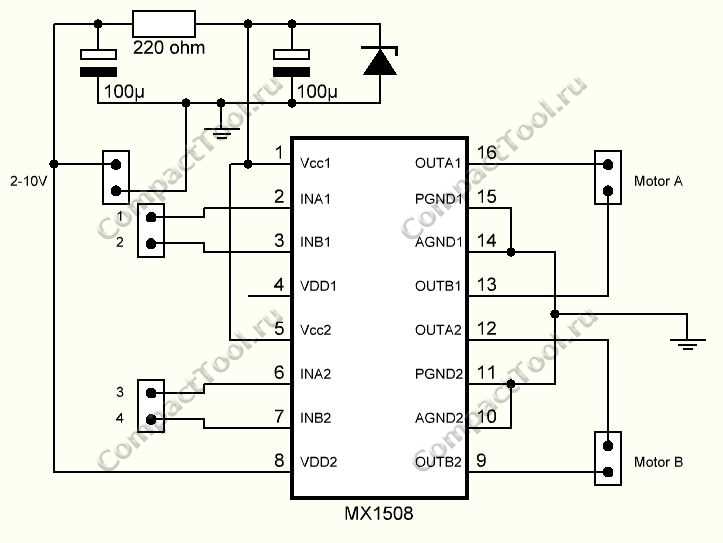

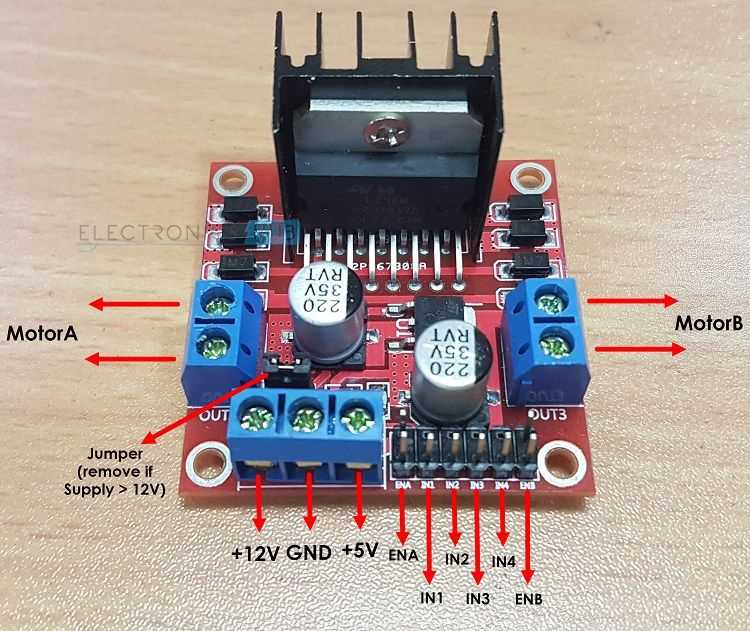

Wiring and Pinout Guide: A Complete Reference for Connecting the L298n Mini

When working with the L298n Mini motor driver, understanding its wiring and pinout configuration is crucial for successful projects. This guide provides a comprehensive overview of the necessary connections and their corresponding functions, empowering you to effortlessly integrate the L298n Mini into your robotics or automation systems.

Power Supply Connections

One of the crucial aspects of connecting the L298n Mini is establishing a reliable power supply. The driver requires two separate power sources – one for the logic circuits and the other for the motor(s) being controlled. This separation ensures optimal performance and prevents interference. The guide will clearly outline the necessary voltage and current requirements for both power sources, allowing you to choose the appropriate power supply for your specific needs.

Motor Connections

Another key aspect covered in this guide is the connection of motors to the L298n Mini. Multiple motors can be controlled simultaneously with this driver, offering enhanced flexibility for various applications. The guide provides detailed instructions on how to connect motors, ensuring proper alignment with the driver’s outputs. By following the step-by-step procedures, you can effortlessly integrate your motors and maximize their efficiency.

Overall, this Wiring and Pinout Guide serves as a comprehensive reference for connecting and utilizing the L298n Mini motor driver effectively. By providing clear instructions and guiding you through the necessary connections, this guide empowers you to unlock the full potential of the L298n Mini, enabling seamless integration into your projects.

A step-by-step tutorial for connecting and configuring the controller

In this section, we will guide you through the process of connecting and configuring the controller, allowing you to fully utilize its capabilities and enhance your project’s functionality.

Firstly, you will need to gather the necessary components. Ensure you have all the required cables, connectors, and power sources readily available.

- Start by identifying the appropriate ports on the controller. These ports will typically be labeled with corresponding symbols or letters.

- Next, connect the power source to the designated power port. Make sure to follow the polarity indications to avoid damaging the controller.

- Proceed by connecting the desired input devices or sensors to the appropriate input ports. This will vary depending on your project requirements, so refer to the controller’s documentation for specific guidelines and pin configurations.

- Once the inputs are connected, it’s time to establish the output connections. Determine the suitable output ports and connect your actuators or devices accordingly. Again, refer to the documentation for any pin or voltage restrictions.

- Now that all the connections are in place, it’s crucial to double-check the wiring to ensure everything is properly connected. Loose or incorrect connections can lead to malfunctions or damage.

- After verifying the connections, proceed with configuring the controller settings. This step may involve adjusting control parameters, setting up motor modes, or configuring sensor input thresholds. Refer to the documentation for specific instructions on accessing the controller’s configuration menu and making the necessary adjustments.

- Once the configuration is complete, test the controller’s functionality by applying different input signals or commands. Monitor the output response and verify if it aligns with your expectations and project requirements.

- Lastly, take note of any issues or challenges you encounter during the process. This information will be valuable for future troubleshooting or referencing purposes.

By following these step-by-step instructions, you can easily connect and configure your controller, allowing you to leverage its capabilities and integrate it seamlessly into your project.

Troubleshooting Common Issues with the L298n Mini

When working with the compact L298n Mini motor driver controller, it is not uncommon to encounter various issues that may hinder its performance. This section aims to address some frequently encountered problems and provide possible solutions without delving into technical details.

1. Motor not responding:

If the motor connected to the L298n Mini fails to respond or exhibit any movement, there could be several reasons for this issue. Firstly, ensure that the power supply is correctly connected and providing the appropriate voltage and current. Secondly, double-check the motor connections and make sure they are properly wired. Lastly, inspect the control signals sent to the L298n Mini from the microcontroller or motor driver board.

2. Overheating:

Overheating is a common problem with motor driver controllers, including the L298n Mini. Excessive heat generation may be caused by several factors such as an overload on the motors, using an inadequate power supply, or incorrect connections. It is crucial to check the power and current requirements of the motors being used and ensure that the power supply can handle the load. Additionally, confirm that the L298n Mini is adequately cooled with proper heatsinks or fans.

3. Voltage drops:

In some cases, voltage drops may occur when using the L298n Mini motor driver. This can lead to reduced motor performance or erratic behavior. To address this issue, check the power supply connections and wiring for any loose connections or high resistance points. It is also important to verify that the power supply can provide a stable voltage, especially under load.

4. Signal interference:

If the control signals sent to the L298n Mini are being interfered with, it can result in erratic motor movements or complete failure. To troubleshoot this issue, ensure that there are no loose or damaged wires in the signal path. Additionally, consider using shielded cables or separating the motor power and control signals to minimize interference.

5. Inconsistent motor speed:

When the motor speed fluctuates or is inconsistent, it can be frustrating when using the L298n Mini. This problem may arise due to several factors such as incorrect motor configurations, faulty speed control circuitry, or inadequate power supply capacity. Verify the motor wiring, control signal settings, and power supply specifications to eliminate potential causes of inconsistent speed.

In conclusion, troubleshooting issues with the L298n Mini motor driver controller requires attention to detail and careful examination of potential causes. By addressing common problems such as unresponsive motors, overheating, voltage drops, signal interference, and inconsistent motor speed, users can improve the performance and reliability of their motor control systems.

Tips and solutions for resolving problems and ensuring successful operation

In this section, we will explore various tips and solutions to help overcome common issues and ensure a smooth and successful operation of the L298n mini module. By understanding and implementing these strategies, users can optimize their application’s performance and minimize potential problems.

1. Troubleshooting common wiring issues

One common challenge when working with the L298n mini module is wiring it correctly. Incorrect wiring can lead to various issues such as motor not spinning, erratic behavior, or even module failure. To avoid these problems, carefully double-check the connections and ensure they are securely connected. Additionally, it is crucial to refer to the module’s pinout diagram to correctly identify and connect the necessary wires.

Moreover, using color-coded wires or labeling them can help in easily identifying and troubleshooting any wiring issues. Inspecting and tidying up the wiring before powering up the module can save valuable time and prevent potential damage.

2. Maximizing heat dissipation and preventing overheating

The L298n mini module can generate significant heat during operation, especially when driving high-current loads. Heat can degrade the performance and lifespan of the module, so it is essential to implement proper heat dissipation techniques.

One effective method is using heatsinks on the L298n ICs and ensuring a good thermal connection between the ICs and heatsinks. Thermal paste or adhesive can be applied to enhance heat transfer. Additionally, providing adequate ventilation by using a fan or placing the module in a well-ventilated area can help dissipate the heat efficiently.

Regularly monitoring the module’s temperature and taking appropriate measures to prevent overheating will contribute to its longevity and reliable operation.

By following these tips and implementing solutions for common issues, users can overcome challenges associated with the L298n mini module and ensure a successful and trouble-free operation in their applications.