Imagine a world where leaks and seepages are a thing of the past. A world where sealing materials are not just efficient, but also durable and reliable. Well, that world is no longer a distant dream, thanks to a revolutionary new material known as Klingersil C4400.

With its exceptional properties and cutting-edge technology, Klingersil C4400 takes sealing applications to a whole new level. This innovative material is designed to withstand extreme temperatures, pressures, and aggressive media, ensuring a leak-free and long-lasting performance.

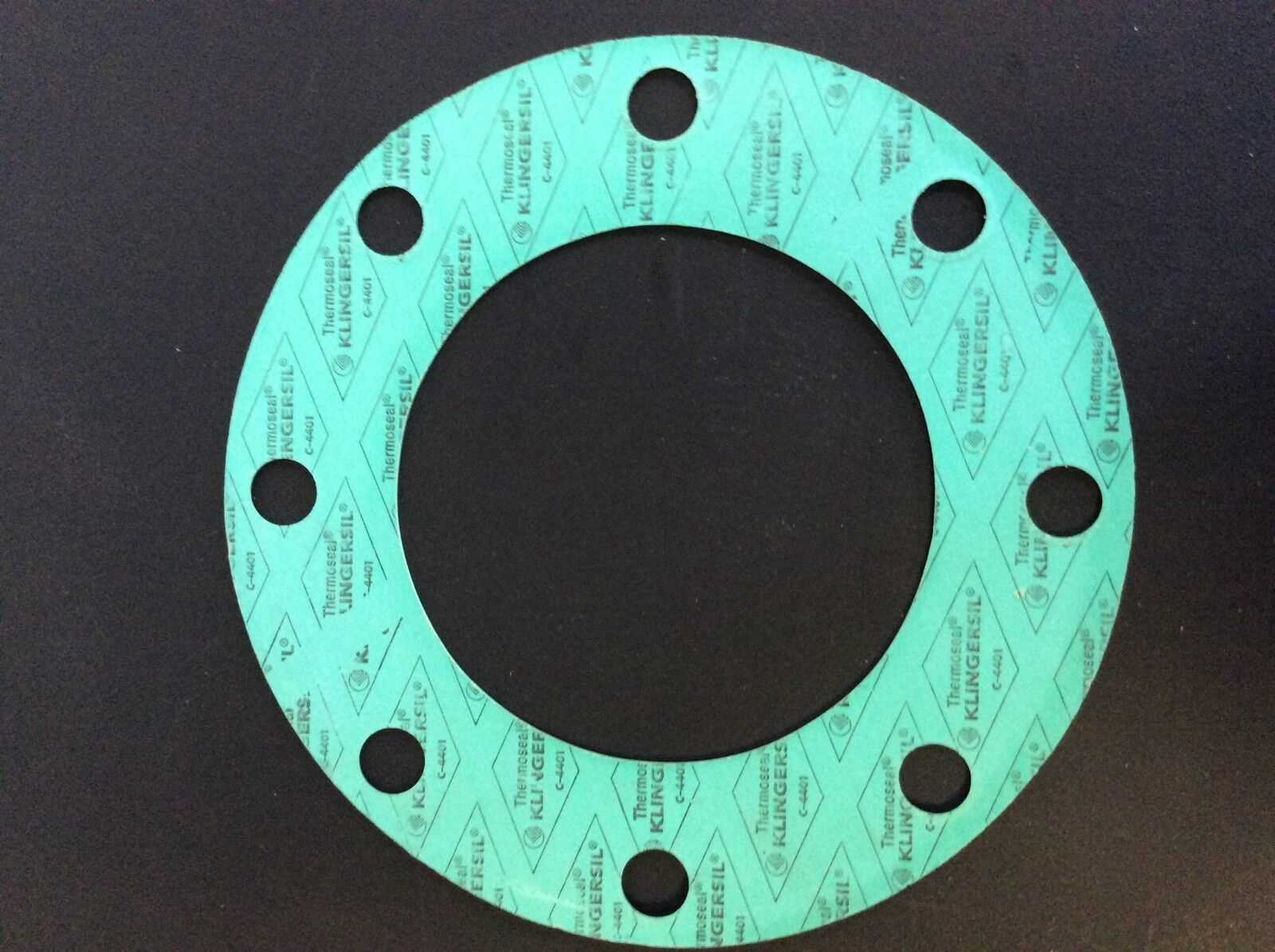

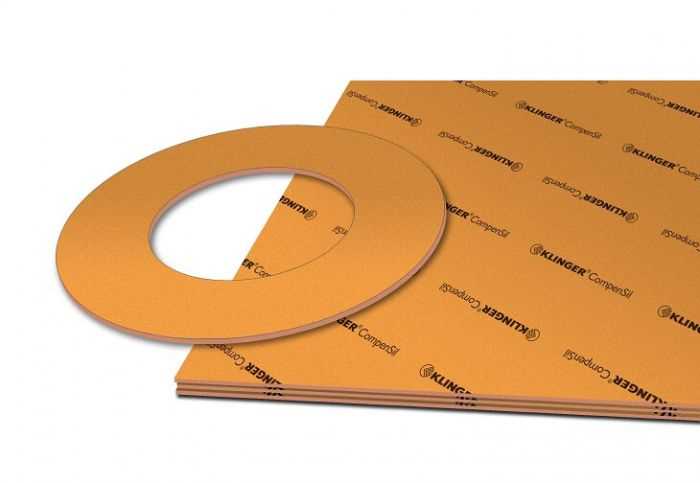

Unlike traditional gaskets, Klingersil C4400 is not simply a piece of rubber or cork. It is a high-performance composite material, meticulously engineered to provide superior sealing capabilities in even the most demanding environments. Its unique combination of strength, flexibility, and resilience makes it the ideal choice for a wide range of industrial applications.

The secret behind Klingersil C4400 lies in its chemical composition. This state-of-the-art material is composed of a blend of synthetic fibers and high-quality elastomers, bonded together using advanced manufacturing techniques. The result is a gasket that boasts exceptional sealing efficiency, excellent resistance to wear and tear, and unmatched durability.

Whether you’re dealing with high temperatures in a power plant, aggressive chemicals in a chemical processing plant, or high pressures in an oil rig, Klingersil C4400 is the ultimate solution. Its outstanding performance and versatility make it the go-to choice for engineers and technicians worldwide.

So, if you’re tired of dealing with leaks, failures, and costly downtime, it’s time to make the switch to Klingersil C4400. Experience the future of sealing technology and say goodbye to your sealing worries once and for all.

Understanding the Importance of Gasket Selection

A key factor in ensuring the efficiency and reliability of industrial equipment lies in the careful selection of gaskets. These often-overlooked components play a crucial role in forming a reliable seal, preventing leakage, and providing necessary insulation in various applications. The careful evaluation and understanding of different gasket options are essential to avoid potential issues such as loss of efficiency, system failure, and costly repairs.

Choosing the appropriate gasket involves considering factors such as the operating conditions, the specific application requirements, and the type of media or fluid being sealed. Each gasket material possesses unique properties and capabilities, and selecting the right one can significantly impact the performance and longevity of the sealing solution.

Efficient gasket selection not only ensures leak-free operation but also contributes to the reduction of equipment downtime, maintenance costs, and energy consumption. Proper selection can enhance the overall performance and reliability of the system, leading to improved productivity and customer satisfaction.

In addition to function, gasket selection must also take into account factors such as compatibility with the mating flanges or surfaces, resistance to temperature, pressure, and chemicals, as well as compliance with industry standards and regulations. Consulting technical datasheets and seeking expert advice can provide valuable guidance in the selection process.

By investing time and effort in understanding the importance of gasket selection, businesses can proactively avoid potential issues caused by inappropriate sealing solutions. It not only ensures optimal equipment performance but also contributes to cost savings, increased operational efficiency, and a safer working environment.

Key Features and Technical Specifications of Klingersil c4400 Gasket

When it comes to selecting the right sealing material, the Klingersil c4400 gasket stands out from the rest with its exceptional features and technical specifications. This gasket offers a range of benefits that ensure reliable and effective sealing in various applications.

Superior Resilience: The Klingersil c4400 gasket exhibits outstanding resilience, allowing it to withstand high pressure and temperature conditions without losing its sealing properties. With its excellent compression and recovery properties, this gasket ensures a tight and leak-free seal.

Chemical Resistance: Thanks to its composition, the Klingersil c4400 gasket provides excellent resistance to a wide range of chemicals, including acids, alkalis, and solvents. This feature makes it suitable for use in demanding industrial environments where exposure to harsh chemicals is common.

Temperature Resistance: The Klingersil c4400 gasket is designed to perform reliably in extreme temperature conditions. Whether it is low or high temperatures, this gasket maintains its sealing integrity, making it an ideal choice for applications that involve temperature fluctuations.

Sealing Efficiency: With its optimal surface finish and uniform density, the Klingersil c4400 gasket ensures a tight and secure seal, minimizing the risk of leaks and fluid loss. Its low gas permeability also contributes to its sealing efficiency, making it a reliable choice for critical sealing applications.

Longevity: The Klingersil c4400 gasket offers excellent resistance to wear, tear, and aging, ensuring a longer lifespan compared to other sealing materials. This translates into cost savings and reduced downtime, making it a cost-effective solution for various industries.

Whether in the oil and gas, chemical, or automotive industry, the Klingersil c4400 gasket delivers exceptional performance and reliability. With its unique combination of key features and technical specifications, this gasket provides an effective sealing solution for even the most demanding applications.

Application Areas and Advantages of Klingersil c4400 Gasket

When it comes to ensuring reliable and efficient sealing in various industrial applications, the Klingersil c4400 gasket proves to be an exceptional choice. This versatile sealing solution offers a wide range of application areas and significant advantages, making it a preferred option for many industries.

Superior Performance in High-Pressure Environments

The Klingersil c4400 gasket is specially designed to excel in high-pressure environments, providing robust sealing performance even under extreme conditions. Whether it is in oil and gas pipelines, chemical processing plants, or power generation facilities, this gasket reliably prevents leaks and maintains the integrity of the systems.

Chemical Resistance and Stability

One of the key advantages of the Klingersil c4400 gasket is its exceptional resistance to a wide range of chemicals and corrosive substances. It remains stable and reliable even when exposed to aggressive media, making it a valuable sealing solution in industries such as petrochemical, pharmaceutical, and food processing.

Moreover, this gasket demonstrates excellent resistance to temperature variations, ensuring its performance remains consistent even in environments with fluctuating heat levels.

Additionally, the Klingersil c4400 gasket is highly resistant to aging, offering prolonged service life and reducing the need for frequent replacements.

Furthermore, this gasket is compliant with various industry standards and certifications, providing assurance of its quality and reliability in critical applications.

Overall, the application areas and advantages of the Klingersil c4400 gasket make it an ideal choice for sealing requirements in demanding industrial environments. Its superior performance, chemical resistance, stability, and compliance with industry standards contribute to enhanced efficiency, reduced downtime, and increased safety in various sectors.