In the realm of electronic components, there exists a cornerstone of innovation, a nexus where the currents of technology converge to power our modern world. Within this domain lies a pivotal apparatus, whose intricate details illuminate the path towards electrifying advancements. Delving into the intricacies of this enigmatic document, we embark on a journey through the labyrinthine corridors of specifications and performance metrics.

Unlocking the encrypted language of technical documentation, we navigate through a sea of symbols and parameters, each holding a key to understanding the capabilities of the device in question. These cryptic descriptors serve as signposts in our quest for comprehension, guiding us through the maze of electrical characteristics and operational boundaries.

With a keen eye and a discerning mind, we embark on an expedition into the heart of innovation, where the essence of functionality is distilled into a symphony of numerical values and graphical representations. As we unravel the intricacies of this document, we gain insights into the inner workings of a foundational component that underpins the framework of modern electronics.

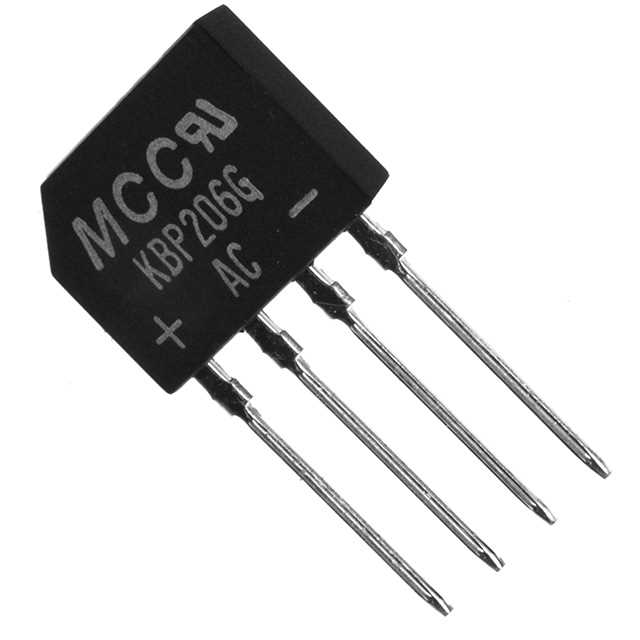

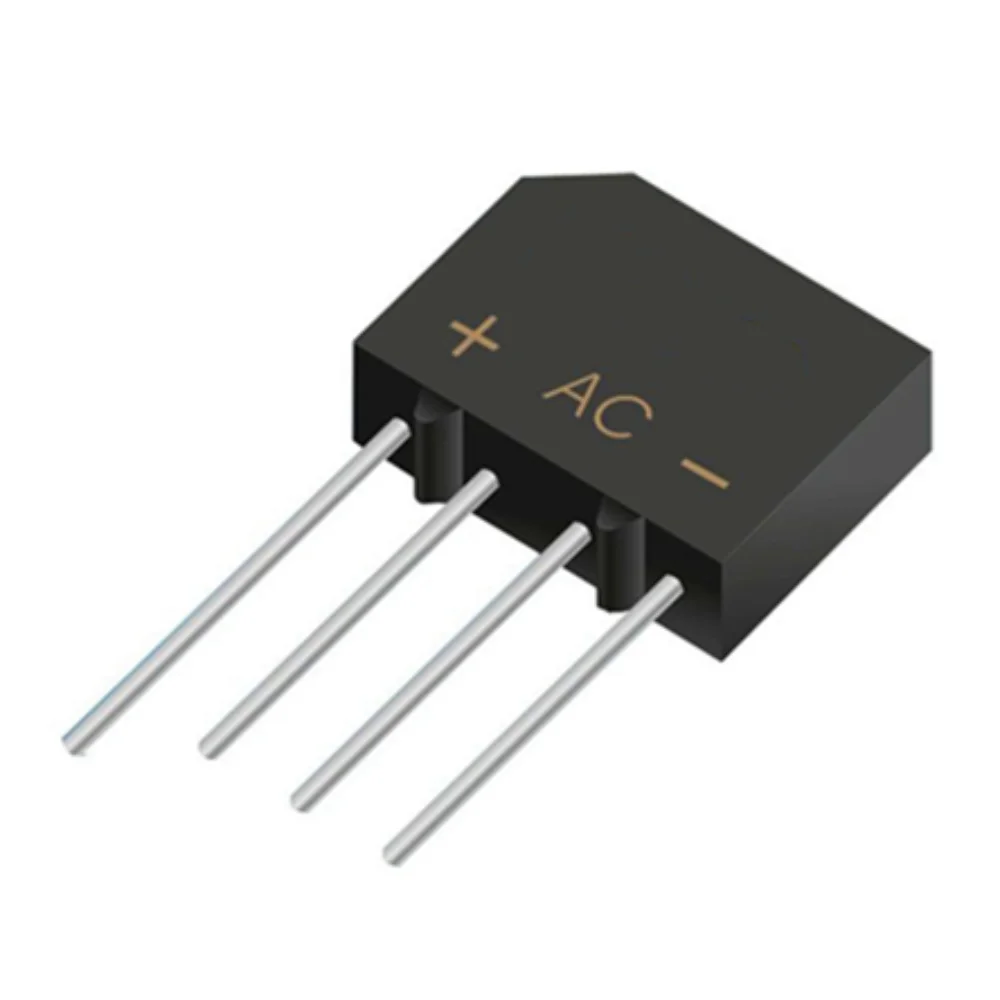

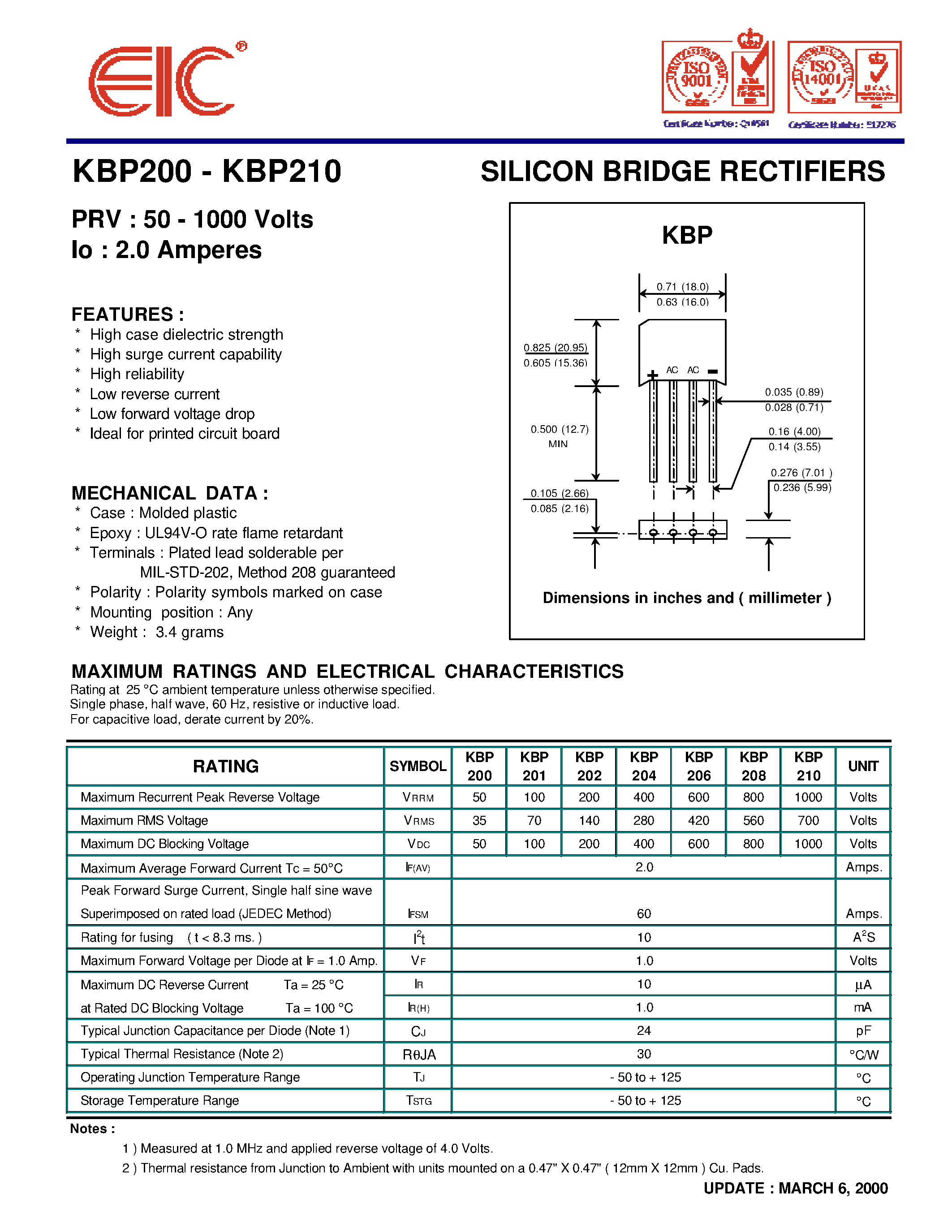

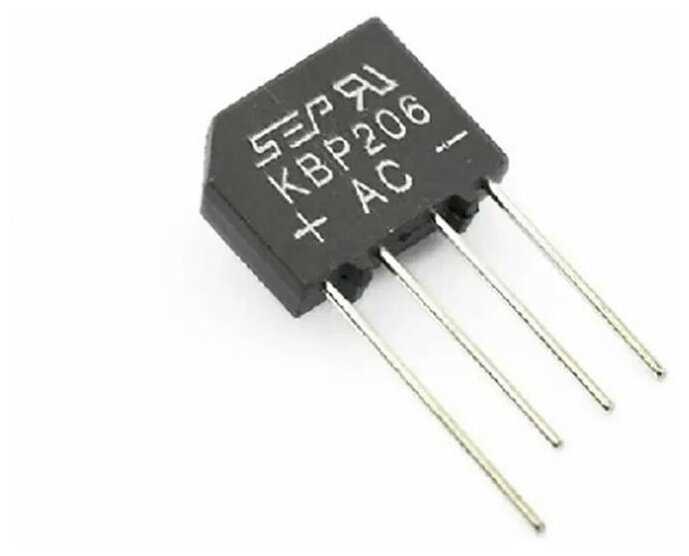

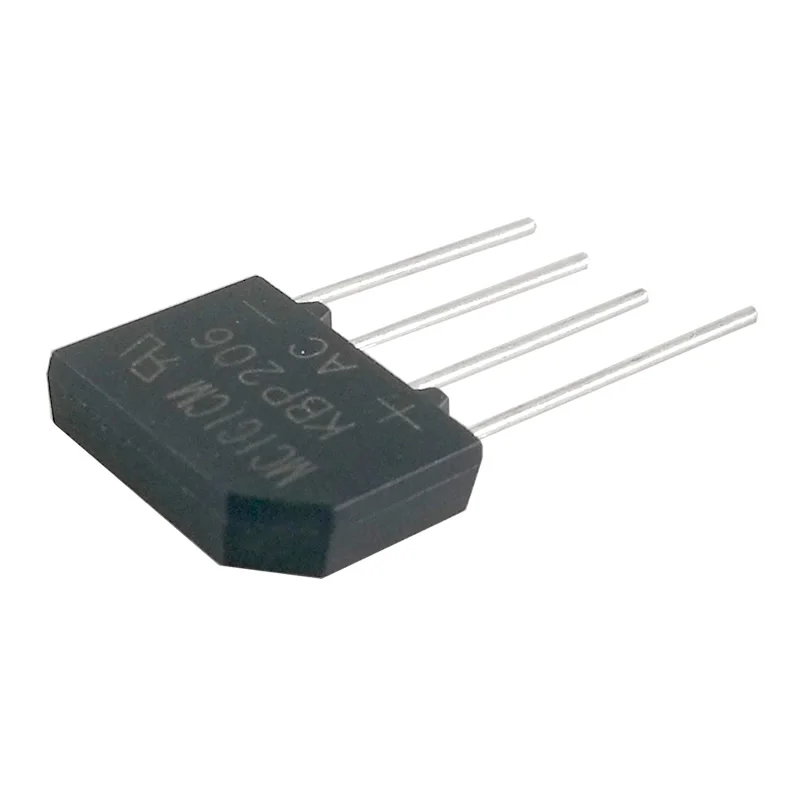

KBP206 Bridge Rectifier Datasheet: Understanding Specifications

In the realm of electronic components, delving into the intricacies of product specifications is paramount for informed decision-making and optimal utilization. In this segment, we embark on an insightful journey to decipher the specifications of the KBP206 bridge rectifier datasheet, unraveling its nuances and implications.

Deciphering Performance Metrics

Within the datasheet of the KBP206 bridge rectifier lies a treasure trove of vital performance metrics, each bearing significance in determining the component’s functionality and compatibility with intended applications. These metrics encapsulate parameters such as efficiency, voltage ratings, current capabilities, and temperature tolerances.

Interpreting Operational Characteristics

Beyond mere numerical values, comprehending the operational characteristics delineated within the KBP206 bridge rectifier datasheet is pivotal. Through elucidating terms like forward voltage drop, reverse leakage current, and peak repetitive reverse voltage, one gains insights into the behavior of the component under diverse operating conditions, fostering judicious integration within circuit designs.

Interpreting Electrical Ratings

Understanding the specifications of electronic components involves delving into their electrical ratings. These metrics provide crucial insights into the performance and limitations of the component under various conditions. In this section, we will explore the significance of electrical ratings and how they influence the application and functionality of the component in question.

Deciphering Performance Metrics

Electrical ratings encompass a range of parameters that outline the operating characteristics of a component. These metrics may include voltage ratings, current capacities, temperature limits, and other relevant specifications. Deciphering these ratings requires a nuanced understanding of their implications in real-world scenarios.

Application Considerations

Interpreting electrical ratings involves more than just identifying numerical values; it necessitates consideration of the intended application environment. Factors such as ambient temperature, voltage fluctuations, and load variations can significantly impact the performance and reliability of the component. Therefore, careful evaluation of these ratings in conjunction with the application requirements is paramount for ensuring optimal functionality and longevity.

Application Circuit Design Considerations

When crafting circuits for electronic components, thoughtful consideration must be given to various design aspects to ensure optimal functionality and reliability. This section delves into the key factors to contemplate when devising application circuits for the specified component, fostering robust performance and longevity.

Voltage Regulation

- Ensuring consistent voltage supply is paramount to the seamless operation of electronic systems.

- Stability in voltage levels mitigates the risk of component damage and enhances overall system efficiency.

Current Management

- Efficient current distribution is fundamental for preventing overloading and safeguarding against electrical hazards.

- Strategically managing current flow aids in optimizing the performance and longevity of the circuitry.

By meticulously addressing voltage regulation and current management within the application circuit design, engineers can cultivate resilient systems capable of withstanding diverse operational conditions and delivering consistent performance over time.

Thermal Management Tips for Efficient Operation

In the realm of electronic components, optimizing thermal performance is pivotal for ensuring sustained and reliable functionality. Effective management of heat dissipation enhances overall efficiency and prolongs the lifespan of devices. This section offers insightful strategies to regulate temperature levels and bolster operational efficacy.

1. Enhance Airflow: Adequate ventilation is essential for dissipating heat generated during operation. Utilize strategically positioned fans or vents to facilitate the circulation of air around the components, thus preventing overheating.

2. Opt for Efficient Heat Sinks: Employing high-quality heat sinks can significantly enhance thermal conductivity, efficiently transferring heat away from sensitive components. Choose designs tailored to the specific requirements of your application to maximize effectiveness.

3. Utilize Thermal Interface Materials: Implementing thermal interface materials such as thermal pads or compounds can improve heat transfer between components and heat sinks. Proper application ensures optimal contact and minimizes thermal resistance.

4. Monitor Temperature Levels: Regular monitoring of temperature levels within the system enables proactive management of thermal issues. Utilize temperature sensors or monitoring software to identify potential hotspots and implement corrective measures promptly.

5. Design for Thermal Efficiency: During the design phase, prioritize thermal considerations to mitigate potential heat-related challenges. Optimize component placement, layout, and material selection to minimize thermal gradients and enhance overall efficiency.

6. Consider Ambient Conditions: Factor in ambient temperature and environmental conditions when designing or deploying electronic systems. Account for variations in temperature and humidity to maintain optimal operational parameters.

7. Implement Thermal Management Policies: Establish comprehensive thermal management policies and procedures to guide maintenance and troubleshooting efforts. Regularly inspect and maintain cooling systems to ensure sustained performance and reliability.

By incorporating these thermal management strategies into your design and maintenance practices, you can optimize the performance and longevity of electronic systems, promoting efficient operation and minimizing the risk of thermal-related failures.