In the realm of intricate instrumentation, there exists a realm of devices meticulously designed to unravel the enigma of motion and displacement with unparalleled accuracy and finesse. These marvels of engineering prowess serve as the bedrock for industries where precision isn’t just a requirement but a mandate, where each fluctuation in position carries significance beyond measure.

Delving into the intricacies of these technological marvels, we embark on a journey to grasp the essence of these precision measurement tools. Their significance transcends mere mechanical components; they are the silent sentinels, meticulously gauging shifts and nuances in motion, transforming these subtle alterations into data that fuels innovation and progress.

Exploring the essence of these instruments, we unravel a world where accuracy isn’t just a virtue but a necessity, where the slightest deviation could spell the difference between success and failure. Through the lens of engineering ingenuity and scientific rigor, we uncover the heartbeat of these devices, pulsating with the rhythm of precision and reliability.

Understanding Documentation for LVDT Sensors

When delving into the intricacies of information pertaining to linear variable differential transformers (LVDTs), it becomes imperative to navigate through the labyrinth of technical documents provided by manufacturers. These documents serve as compasses, guiding engineers and enthusiasts through the maze of specifications, characteristics, and operational parameters intrinsic to LVDT sensors.

The Essence of LVDT Documentation

At the core of comprehending LVDT documentation lies the essence of deciphering technical jargon and unraveling the nuances embedded within. Such documentation encapsulates a wealth of insights, ranging from performance metrics to application guidelines, all essential for leveraging the full potential of LVDT sensors in diverse scenarios.

With an astute understanding of how to interpret these documents, stakeholders can harness the capabilities of LVDT sensors effectively, ensuring optimal performance and seamless integration within various systems and applications.

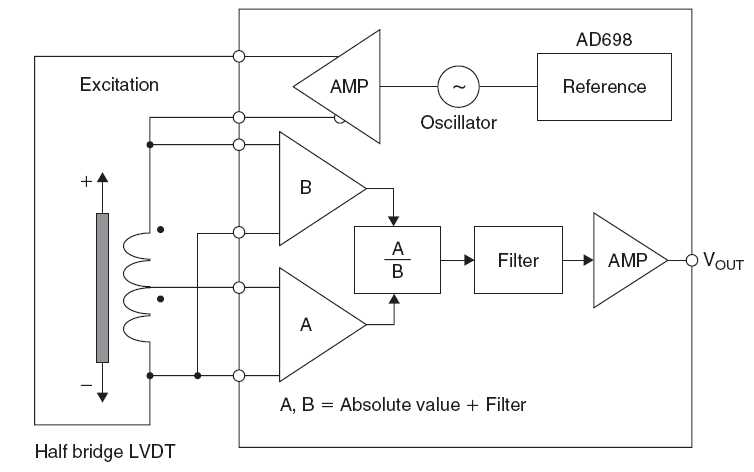

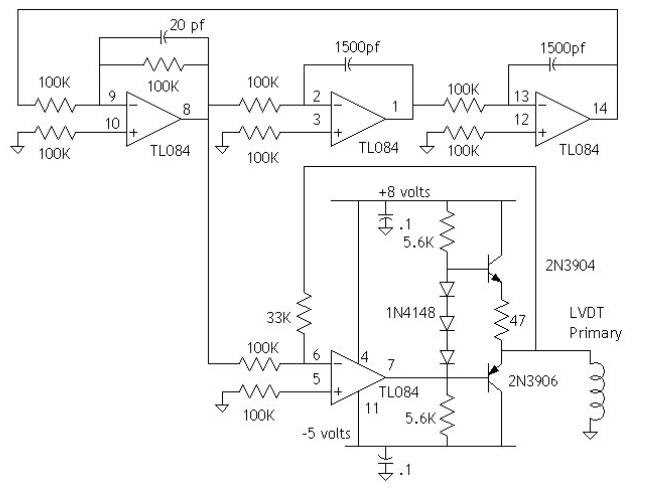

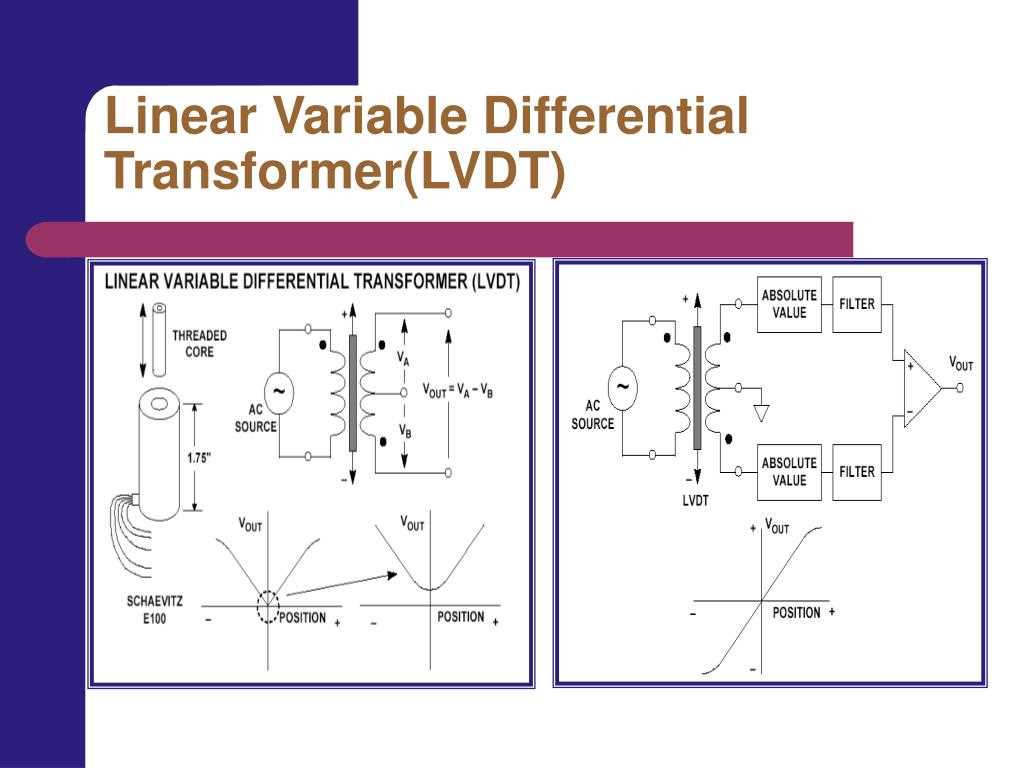

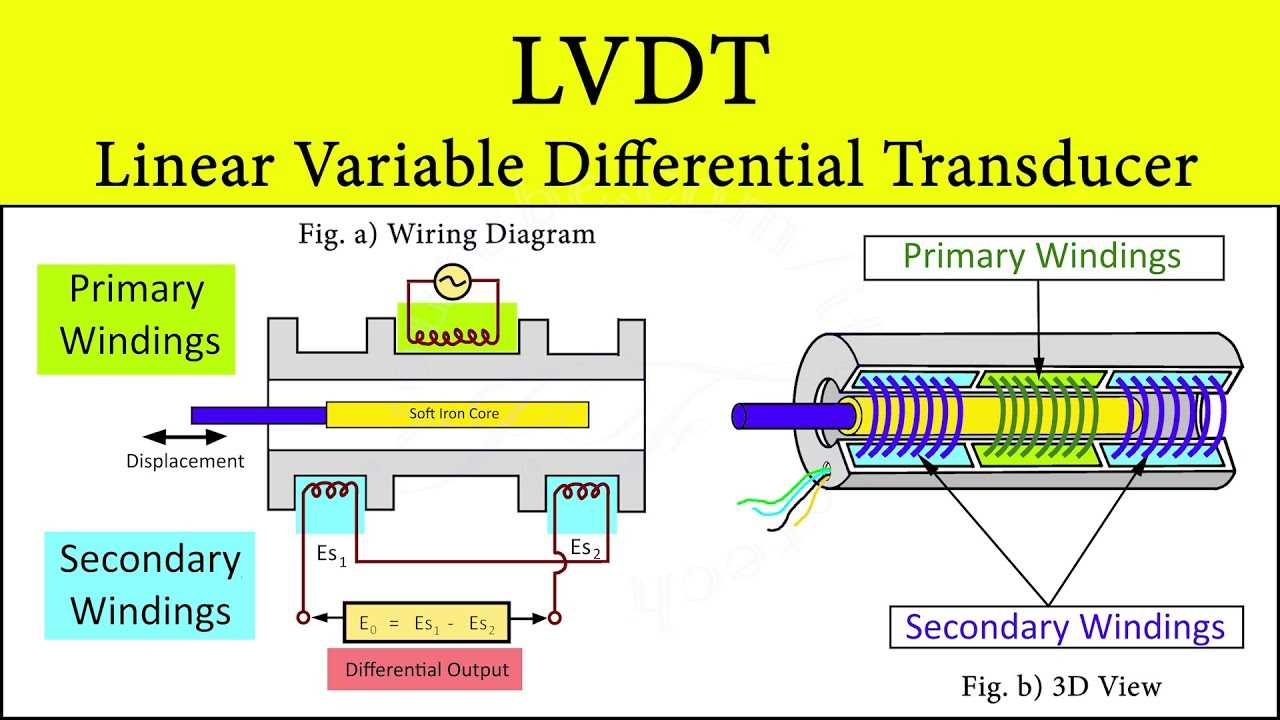

The Basics: Understanding Specifications of Linear Variable Differential Transformers

When delving into the intricacies of linear variable differential transformers (LVDTs), it’s crucial to grasp the fundamental aspects of their specifications. These specifications serve as a roadmap, guiding engineers and enthusiasts alike through the labyrinth of technical details, ensuring a comprehensive understanding of the device’s capabilities and limitations.

1. Operational Range

At the heart of LVDT specifications lies the operational range, delineating the span within which the device functions optimally. This parameter elucidates the permissible limits of displacement or movement that the LVDT can accurately measure, offering insights into its applicability across various scenarios.

2. Sensitivity and Resolution

Sensitivity and resolution are twin pillars upon which the efficacy of an LVDT rests. Sensitivity denotes the device’s responsiveness to changes in input, while resolution elucidates the smallest discernible change it can detect. Understanding these specifications empowers users to gauge the LVDT’s precision and tailor its usage to suit specific measurement requirements.

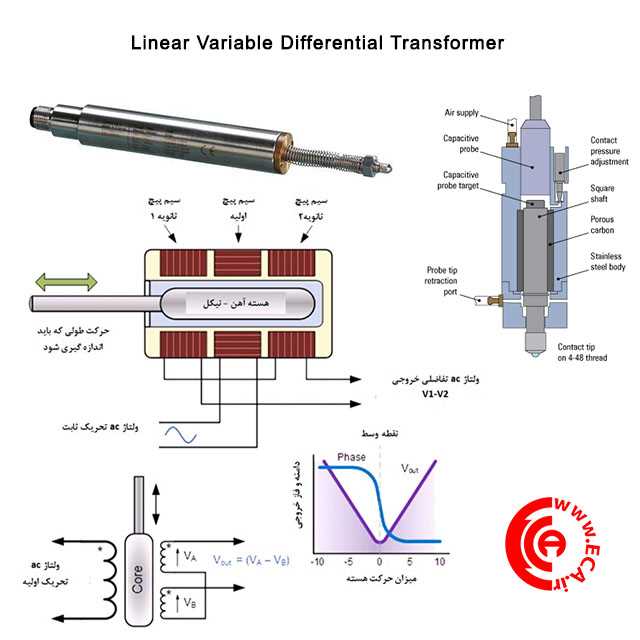

- Linearity: Reflects the degree to which the LVDT’s output adheres to a linear relationship with input displacement, influencing the accuracy of measurements across the operational range.

- Frequency Response: Characterizes the device’s ability to accurately capture rapid changes in displacement, crucial for dynamic applications demanding real-time monitoring.

- Temperature Stability: Highlights the LVDT’s resilience to fluctuations in temperature, ensuring consistent performance across diverse environmental conditions.

By deciphering these specifications with acumen, engineers can harness the full potential of LVDTs, leveraging their unique capabilities to fuel innovation across industries.

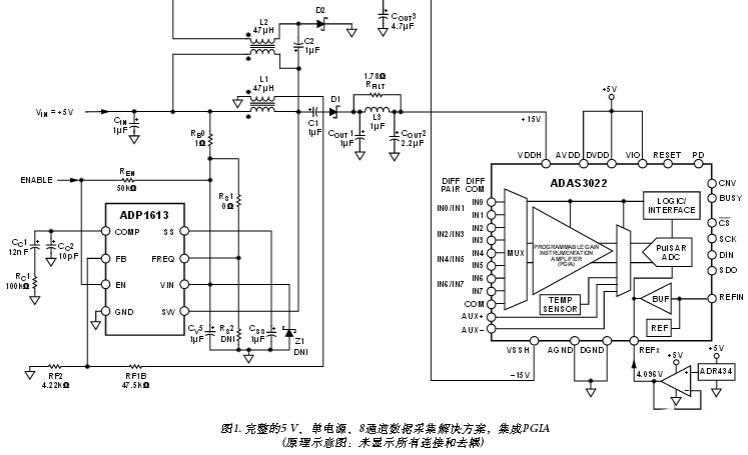

Applications and Benefits of Cutting-Edge LVDT Technology

In the realm of sensing and measurement, the utilization of cutting-edge LVDT technology opens pathways to a myriad of applications and brings forth numerous advantages. This section delves into the diverse domains where this technology finds its niche and elucidates the distinctive benefits it offers.

Industrial Automation

Revolutionizing industrial processes: LVDT technology plays a pivotal role in industrial automation, facilitating precise and reliable measurement of parameters such as displacement, pressure, and force. Its seamless integration enhances efficiency, accuracy, and safety across diverse manufacturing environments.

Aviation and Aerospace

Elevating aerospace standards: In the aerospace industry, the adoption of LVDT technology ensures critical performance metrics are meticulously monitored and maintained. From flight control systems to engine monitoring, LVDTs provide unparalleled precision and durability, bolstering the safety and reliability of airborne operations.

With its versatility and robustness, LVDT technology transcends conventional measurement methodologies, empowering various sectors with unparalleled accuracy and efficiency. The inherent advantages of this technology propel innovation and set new benchmarks in the realms of engineering, research, and beyond.

Troubleshooting Tips: Deciphering Irregularities in Kavlico LVDT Documentation

Understanding the nuances of documentation for precision instruments is paramount to ensure accurate interpretation and troubleshooting. In this section, we delve into strategies for deciphering anomalies within Kavlico LVDT datasheets. By grasping common pitfalls and employing effective troubleshooting techniques, engineers can streamline their analysis process and enhance overall system performance.

Unraveling Ambiguous Specifications

Contextual Analysis: When confronted with seemingly conflicting or unclear specifications, it’s essential to dissect the context surrounding the parameters. Identifying dependencies, environmental factors, and operational constraints can provide valuable insights into reconciling apparent anomalies.

Tip: Utilize comparative analysis techniques, referencing similar datasheets or industry standards to validate and contextualize ambiguous specifications.

Resolving Discrepancies in Performance Curves

Data Correlation: Discrepancies between expected and observed performance curves often necessitate meticulous scrutiny. By cross-referencing theoretical models with empirical data and conducting thorough calibration checks, discrepancies can be effectively resolved, ensuring alignment between expected and actual performance.

Tip: Employ signal processing techniques and statistical analysis to identify trends, outliers, and underlying patterns within performance data, facilitating accurate interpretation and troubleshooting.