Delving into the realm of precise temperature measurement has become an indispensable practice in industries across the globe. In this era of advancements, understanding the mechanisms behind accurate thermocouple measurements is crucial for engineers and technicians. One such remarkable device, highly regarded for its dependable performance, is the K type thermosensitive element.

Embodying the essence of reliability and precision, the K type thermosensitive element possesses numerous attributes that set it apart from other temperature measurement techniques. Its ability to precisely detect and convert temperature variations into electrical voltage provides an invaluable tool for industries involved in critical processes. Resilient and versatile, this remarkable device demonstrates exceptional resilience in harsh environmental conditions.

The K type thermosensitive element, also known as the K type thermocouple, employs innovative technological principles to deliver highly accurate and stable voltage outputs in response to temperature variations. Functioning on the basis of the Seebeck effect, this thermocouple generates an electromagnetic force originating from the temperature difference between its two dissimilar metal wires, resulting in an electrical potential proportional to the temperature change. Its unique composition, consisting of chromel and alumel alloys, ensures durability as well as precise temperature sensing capabilities.

Engineered to withstand extreme ranges, the K type thermosensitive element exhibits commendable longevity, making it a preferred choice across diverse industries. Due to its reliability and compatibility with a wide range of measuring instruments, this thermocouple has become an indispensable component in various applications, including process controls, heating systems, and scientific research. Its accurate temperature measurement enables precise control over temperature-dependent reactions, contributing towards a higher level of efficiency and productivity.

Understanding the Principle and Construction of K Type Thermocouples

In this section, we will explore the underlying principles and intricacies involved in the design and structure of K Type Thermocouples. These devices play a crucial role in temperature measurement and are widely used in various industries and applications.

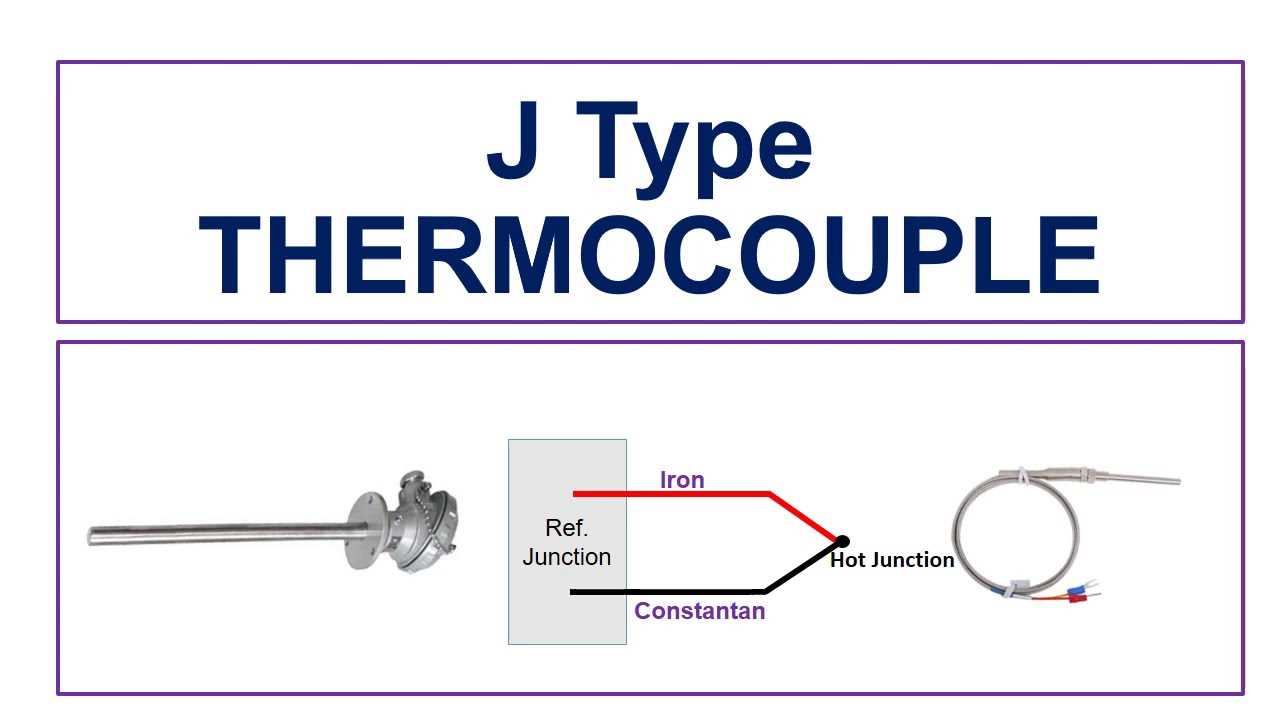

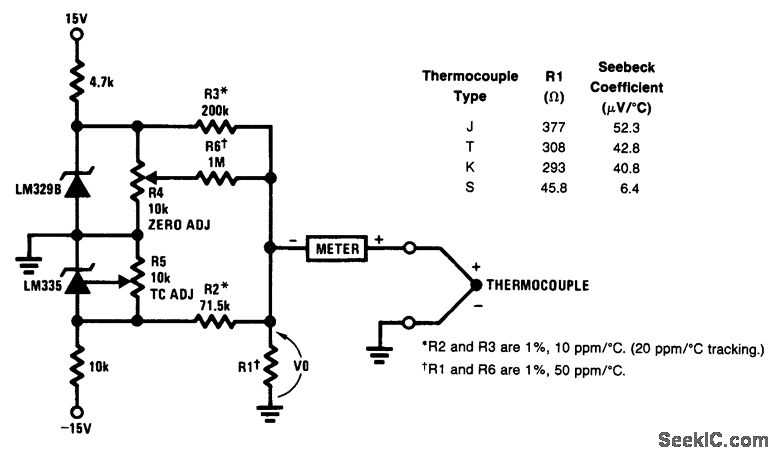

A K Type Thermocouple is based on the phenomenon of thermoelectric effect, which involves the generation of an electromotive force (EMF) when two dissimilar metal junctions are exposed to a temperature gradient. The construction of K Type Thermocouples utilizes a combination of specific materials to ensure accuracy and reliability in temperature sensing.

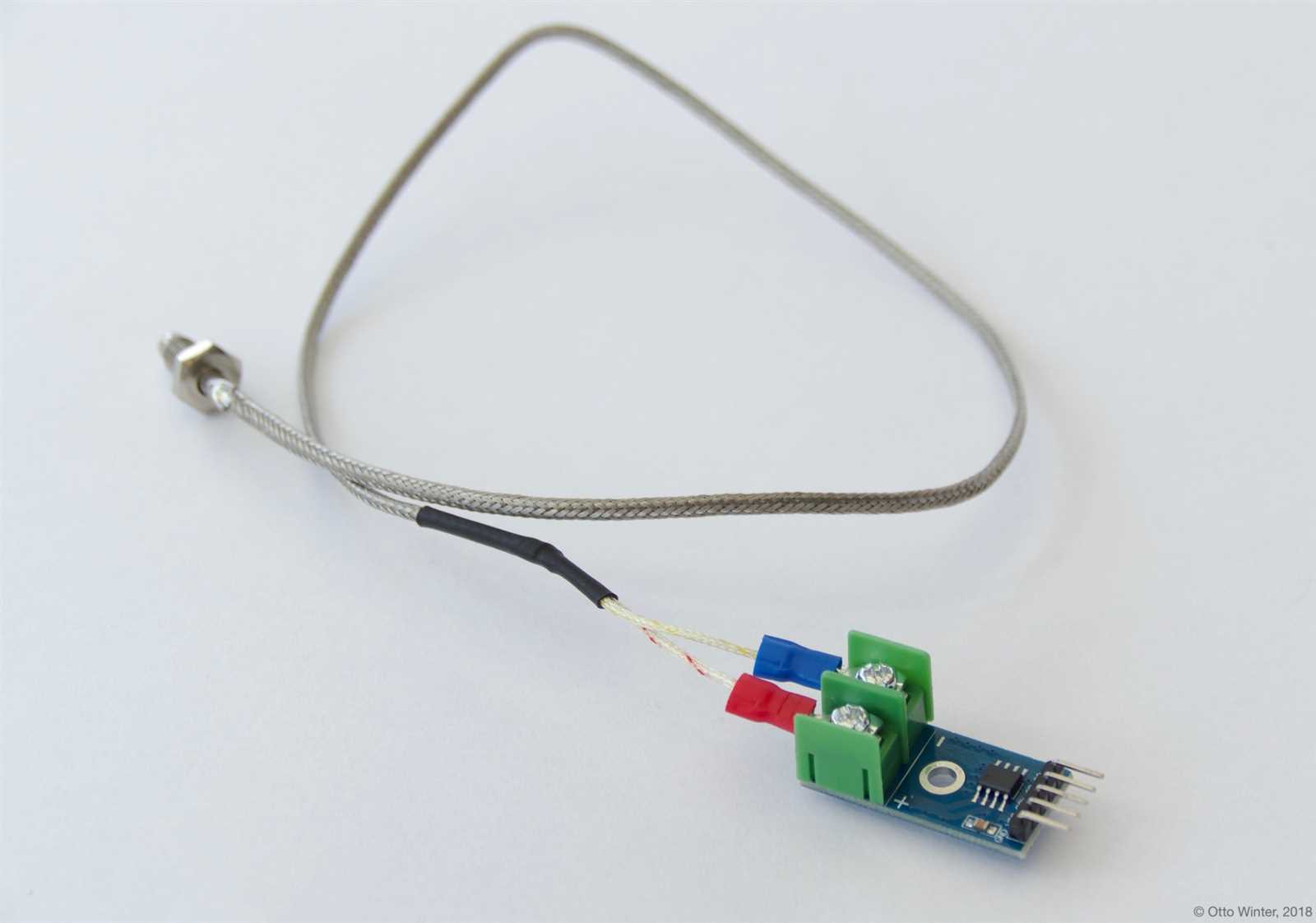

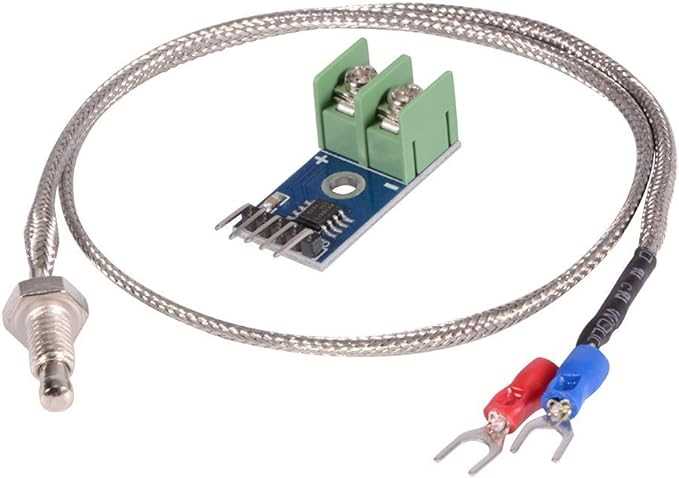

One of the key components of a K Type Thermocouple is the thermocouple element. It consists of two wires made of different metal alloys, typically nickel-chromium and nickel-aluminum. These wires are carefully selected for their unique thermoelectric properties and compatibility with the desired temperature range.

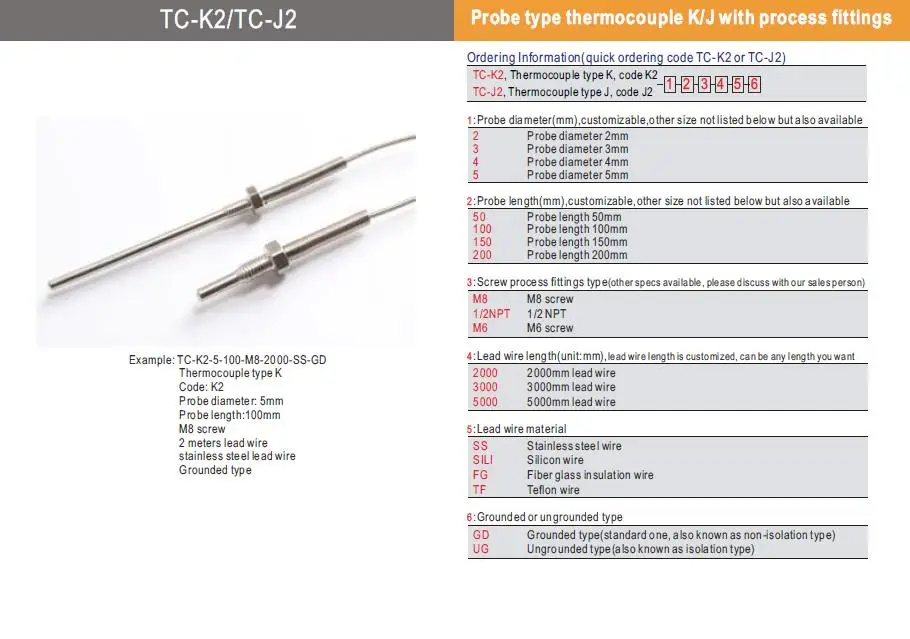

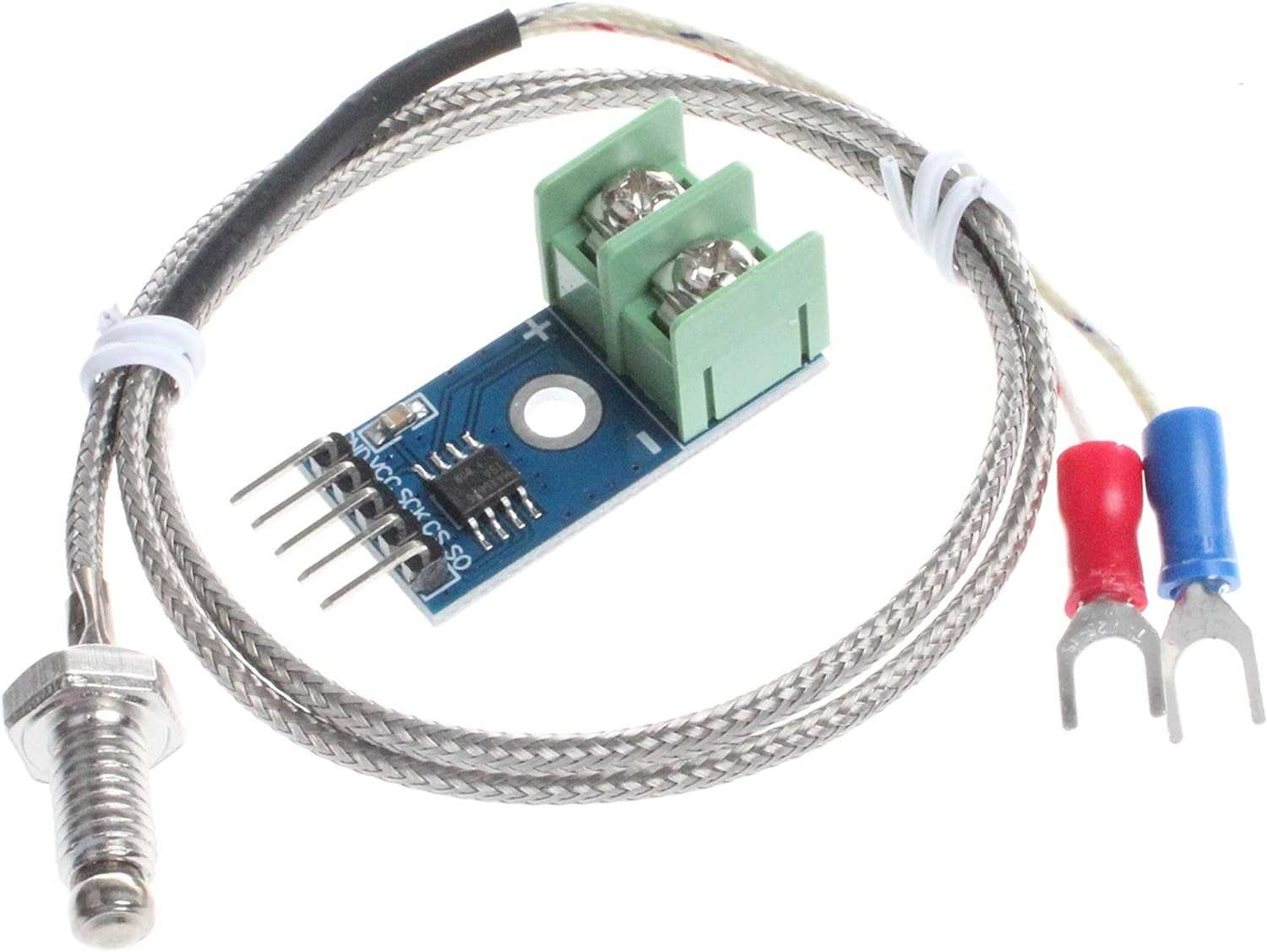

The thermocouple element is enclosed within a protective sheath, which serves multiple purposes. Firstly, it provides mechanical support and insulation to the sensitive wires, shielding them from external factors that could affect their performance. Secondly, it acts as a barrier to protect the thermocouple from harsh environments, such as high temperatures, corrosive gases, or abrasive substances.

Furthermore, a reference junction or cold junction is an essential part of K Type Thermocouples. It is located at the opposite end of the thermocouple element and serves as a baseline temperature reference. By accurately measuring this reference temperature, alongside the temperature at the sensing junction, the accurate temperature difference can be determined.

To enhance the overall performance and accuracy, K Type Thermocouples may also feature additional elements such as insulation materials, terminal blocks, and connectors. These elements contribute to the overall stability, ease of installation, and longevity of the thermocouple sensor.

| Key Features: | Benefits: |

|---|---|

| Thermoelectric effect | Accurate temperature measurement |

| Unique metal alloy combination | Optimal thermocouple response |

| Protective sheath | Mechanical support and environmental shielding |

| Reference junction | Baseline temperature measurement |

| Additional elements | Enhanced performance and ease of installation |

By comprehending the principles and construction of K Type Thermocouples, we can fully grasp their significance in temperature measurement and appreciate their engineering intricacies. This knowledge enables us to utilize these sensors effectively in different applications and ensures accurate temperature monitoring in various industries.

Key Specifications and Performance Characteristics of K Type Thermocouples

The following section provides an overview of the important specifications and performance characteristics associated with K Type thermocouples. These parameters play a crucial role in determining the accuracy and reliability of temperature measurements in various applications.

Temperature Range

Wide Operational Range: K Type thermocouples exhibit an impressive temperature range, making them suitable for applications that require accurate temperature measurements in both high and low temperature environments. They can withstand extreme temperatures ranging from beyond 1000°C to below -200°C.

Sensitivity and Accuracy

High Sensitivity: K Type thermocouples are known for their excellent sensitivity, allowing them to detect even minute changes in temperature. This makes them suitable for applications where precise temperature control is crucial.

Accuracy: K Type thermocouples offer a high level of accuracy in temperature measurements, ensuring reliable and consistent results. With proper calibration and installation techniques, they can achieve accuracies within a few degrees Celsius.

Other important performance characteristics of K Type thermocouples include their robustness, response time, and compatibility with various measuring instruments. These thermocouples are widely used in industries such as manufacturing, aerospace, and automotive, where accurate temperature monitoring plays a vital role in maintaining efficiency and safety.

Applications and Benefits of K Type Thermocouple Sensors

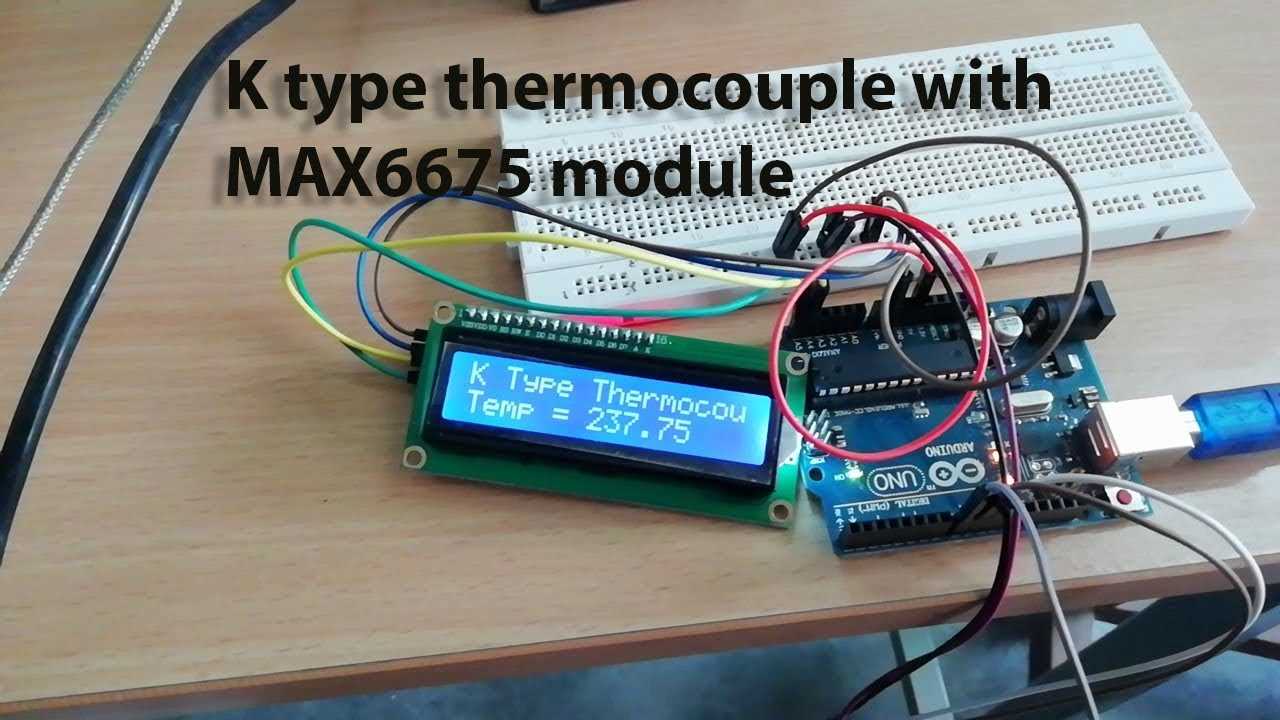

When it comes to temperature measurement, K type thermocouple sensors have proved to be an indispensable tool in various industries. These versatile devices are renowned for their accuracy, durability, and ability to measure a wide range of temperatures. Whether it is for industrial processes, scientific experiments, or even home appliances, K type thermocouple sensors offer numerous applications and benefits.

1. Industrial Applications

K type thermocouple sensors find extensive use in various industrial applications. They are widely employed in manufacturing processes, such as metal smelting, plastic extrusion, and chemical reactions. Due to their high-temperature capabilities, these sensors provide accurate and reliable measurements in harsh industrial environments. Furthermore, their small size and fast response time make them suitable for monitoring temperature in confined spaces or on moving objects.

2. Scientific and Research Applications

In scientific and research fields, K type thermocouple sensors play an essential role in conducting experiments and gathering temperature data. They are commonly used in laboratories to measure temperature changes in chemical reactions, biological samples, and other scientific processes. Their robustness and compatibility with various measurement instruments make them a preferred choice for researchers and scientists.

3. HVAC and Energy Management

K type thermocouple sensors also find application in heating, ventilation, and air conditioning (HVAC) systems and energy management. As these sensors can withstand high temperatures, they are ideal for measuring and controlling the temperature of heating or cooling systems. By accurately monitoring and adjusting temperature levels, K type thermocouple sensors contribute to energy efficiency and optimization in buildings and industrial facilities.

4. Automotive and Aerospace

In the automotive and aerospace industries, K type thermocouple sensors are used for temperature monitoring in engines, exhaust systems, and various components. Their ability to withstand extreme conditions and provide real-time data makes them pivotal in ensuring reliable performance and preventing overheating. These sensors contribute to maintaining the safety and efficiency of vehicles and aircraft.

In conclusion, the applications and benefits of K type thermocouple sensors are vast and versatile. Their accuracy, durability, and adaptability make them an invaluable tool in various industries, research, and everyday temperature measurement needs. With their wide temperature range capabilities, these sensors provide crucial data that aids in optimizing processes, ensuring safety, and improving energy efficiency.