With the rapid advancements in technology, the need for precise measurement and monitoring of rotary positions has become increasingly important across various industries. In order to accurately track and control movements in devices and machinery, engineers rely on rotary position sensors. These sensors, often referred to as incremental encoders, provide crucial data regarding rotational speed, direction, and position.

When it comes to understanding the key performance metrics and capabilities of a rotary position sensor, a comprehensive analysis of its technical specifications is essential. This article aims to shed light on the fundamental aspects that make up a rotary position sensor datasheet. By exploring the intricate details encompassing various parameters, we can establish a better understanding of the sensor’s functionality and its potential applications across different fields.

Throughout this article, we will delve into the intricacies of the technical datasheet, examining critical aspects such as resolution, accuracy, operating voltage, and output signals. By providing a detailed overview of these parameters, readers will gain insights into the sensor’s capabilities, allowing them to make informed decisions when selecting a rotary position sensor for their specific application needs.

Understanding the Basics

In this section, we will explore the fundamental concepts and principles related to the operation and functionality of a device commonly used in various industries. By gaining an understanding of these basics, you will be equipped to comprehend the intricate workings of this innovative technology, without delving into complex technical terms. Let’s dive in and unravel the essentials.

Introduction

Before delving into the technical details, it is crucial to establish a foundational understanding of how this device functions. By grasping the fundamentals, you will uncover the inner workings that facilitate its efficient performance, enabling accurate measurements or control in a variety of applications.

Key Components

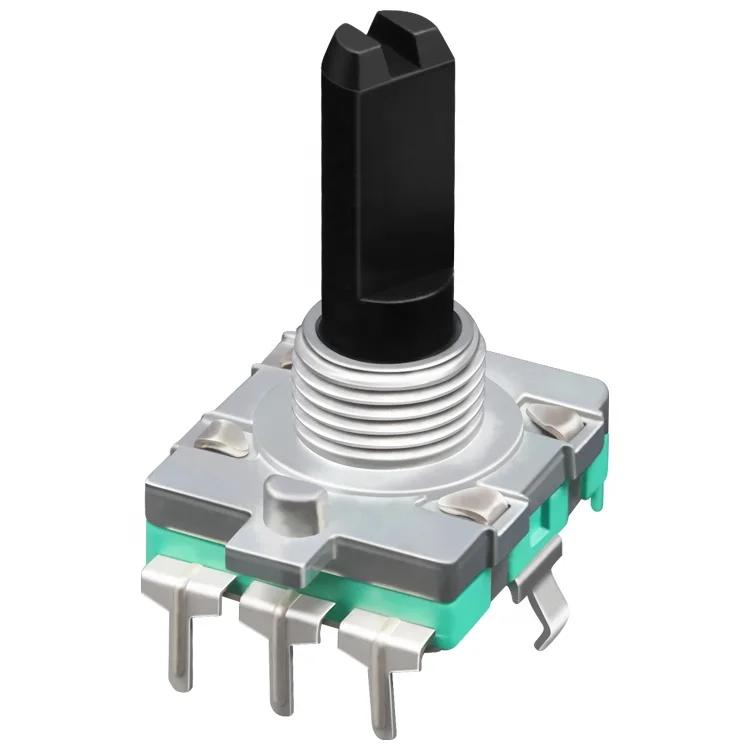

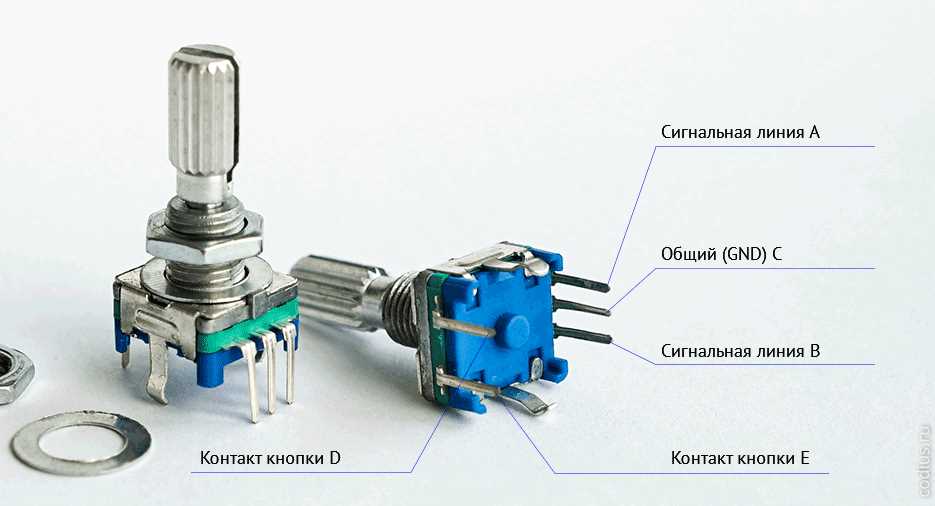

At its core, this device comprises several vital components that work cohesively to accomplish its intended purpose. Understanding the role each component plays is critical to comprehending the overall functioning of the device and its broader application possibilities.

| Component | Description |

|---|---|

| Signal Generator | Serves as the source of the electrical signal used in the encoding process, generating distinct pulses that encode precise movements or positions. |

| Disc/Cylinder | A rotating component with specially designed patterns that interacts with the sensor, translating physical motion into electrical signals. |

| Sensor | Responsible for detecting changes in the patterns on the rotating disc/cylinder, converting them into electrical signals that can be interpreted for measurement or control. |

By understanding the functionality of these key components and their interplay, you will gain insights into the intricate mechanisms that make this device a valuable tool in industrial applications.

In summary, this section provides a comprehensive foundation to enhance your comprehension of this innovative technology. By exploring the fundamental principles and components, you are better equipped to grasp the complexities underlying the operations of this device and its potential functionality in various industries.

Key Specifications to Consider

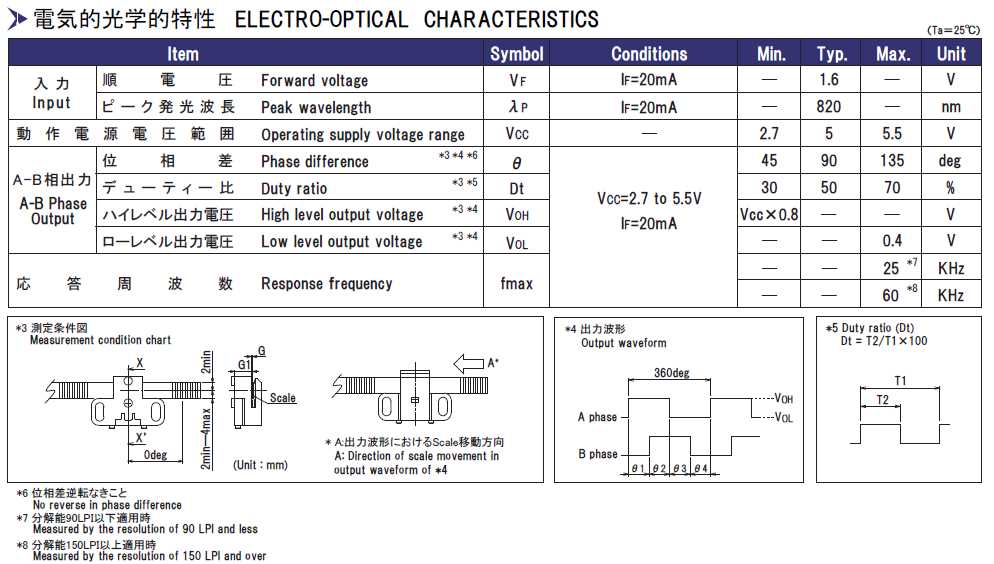

When exploring the specifications of an incremental encoder datasheet, it is important to pay attention to certain key elements that can greatly impact the overall performance and functionality of the device. By considering these specifications, you can ensure that the chosen encoder meets the specific requirements and objectives of your application.

| Resolution | Appropriate resolution selection is critical for achieving the desired level of accuracy and precision in the measurement or control system. Assess the encoder’s resolution capabilities to ensure it can provide the necessary level of detail for your application. |

| Output Signal Type | The output signal type of the encoder determines the compatibility with the receiving electronics. Common output signal types include quadrature, analog, or digital signals. Selecting the most suitable output signal type is crucial for seamless integration and data processing. |

| Operating Speed Range | Understanding the encoder’s specified operating speed range is vital to ensure it can keep up with the dynamic nature of your application. Consider the maximum speed requirement of your system and ensure that the encoder can operate reliably within that range. |

| Accuracy and Precision | Accuracy and precision are key factors in determining the reliability of an incremental encoder. Look for specifications related to error rates, linearity, and repeatability to assess the encoder’s ability to consistently deliver accurate and precise measurements. |

| Environmental Conditions | Evaluate the encoder’s ability to withstand the specific environmental conditions in which it will be used. Pay attention to specifications related to temperature range, humidity, shock resistance, and ingress protection to ensure the encoder can operate optimally in its intended environment. |

By carefully considering these key specifications, you can confidently select an incremental encoder that aligns with your application requirements and delivers reliable and accurate performance.

Choosing the Right Encoder for Your Application

When it comes to selecting the perfect device for measuring position and motion in your application, the choice of the ideal encoder plays a pivotal role. With various options available in the market, finding the right fit can be a challenging task that requires careful consideration.

First and foremost, it is important to understand the specific requirements and demands of your application. Each application has its own unique set of needs, such as accuracy, resolution, speed, and environmental conditions. By closely examining these factors, you can determine the type of encoder that will best meet your requirements.

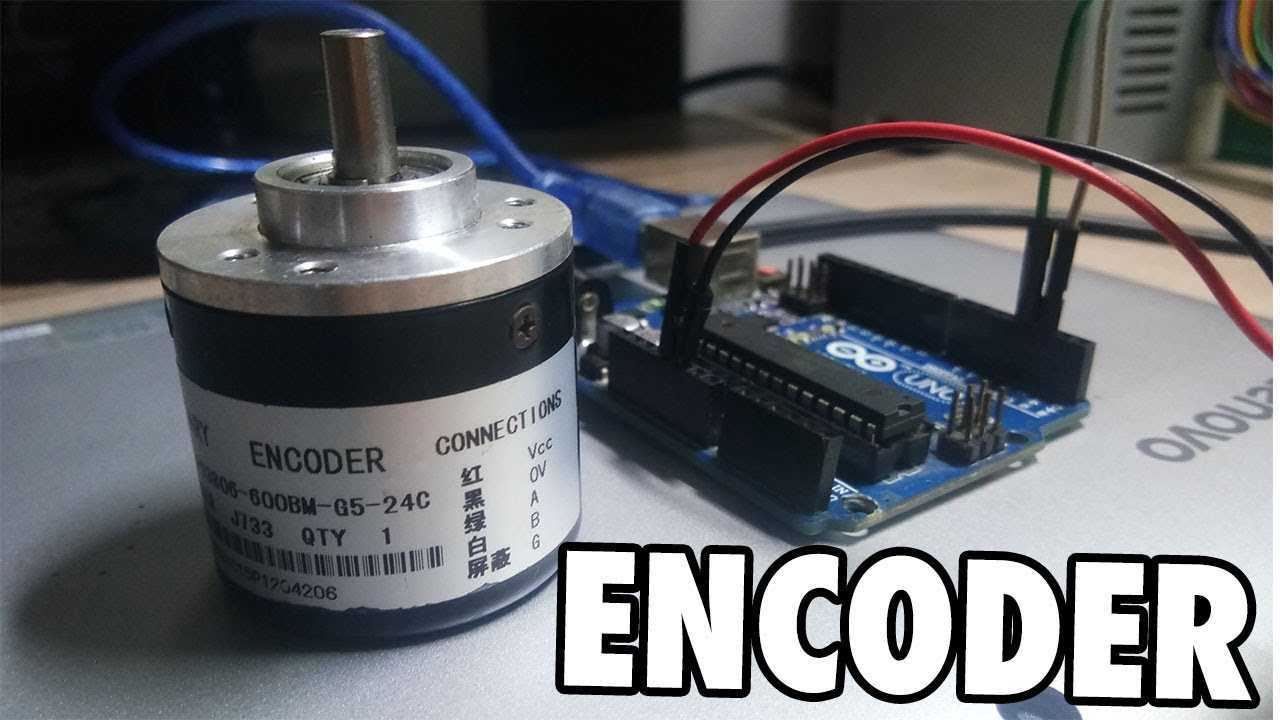

An encoder is a device that converts motion or position into an electrical signal. There are different types of encoders available, each with its own distinct advantages and limitations. One type is the incremental encoder, which provides information about motion and position changes by generating a series of electrical pulses. This type is commonly used in various applications, ranging from robotics to industrial machinery.

Another type is the absolute encoder, which provides an absolute position value without the need for a reference point. This type is often preferred in applications where accuracy is crucial and where maintaining position is vital, such as in scientific instruments or medical equipment.

Furthermore, it is vital to evaluate the environmental conditions under which the encoder will be operating. Factors such as temperature extremes, humidity, vibration, and shock can influence the performance and durability of the device. Therefore, it is essential to choose an encoder that can withstand such conditions to ensure reliable and long-lasting operation.

In addition, considering the required resolution and speed of your application is crucial. The resolution refers to the ability of the encoder to detect small changes in position, while the speed determines the maximum rate at which the encoder can accurately measure motion. Understanding these requirements will help you select an encoder that can deliver the necessary precision and performance.

In conclusion, selecting the right encoder for your application requires a careful assessment of your specific needs, considering factors such as accuracy, resolution, speed, and environmental conditions. By choosing the appropriate encoder type and understanding its limitations and advantages, you can ensure optimal performance and reliability in your application.