Discover the intricacies of a marvel in motion engineering, an innovation that transcends traditional mechanisms. Within the realm of precision control, lies a cornerstone component that orchestrates seamless movements with unparalleled finesse. Delve into the realm where precision meets performance, where every motion is a testament to ingenuity.

Embark on a journey through the dynamic landscape of motion technology, where the boundaries of possibility are continuously redefined. Witness the fusion of efficiency and reliability, where each oscillation is meticulously crafted to harmonize with the demands of modern automation.

Unveil the secrets concealed within the Hs 55 motion module, a testament to innovation and ingenuity in motion control. Explore its myriad applications across industries, from robotics to automotive engineering, and witness the transformative power it bestows upon every mechanism it graces.

Understanding the Functionality of Hs 55 Actuator

Exploring the intricate workings of the Hs 55 Actuator unveils a realm of precise motion control and intricate mechanical orchestration. This section delves into the nuanced functionality and operational intricacies inherent to this innovative device, offering insight into its operational dynamics and applications.

Embarking on a journey through the operational mechanics of the Hs 55 Actuator reveals a symphony of intricate components working in unison to translate electrical signals into precise mechanical motion. Within its compact frame lies a network of gears, motors, and sensors, choreographed to execute a diverse array of tasks with remarkable accuracy and efficiency.

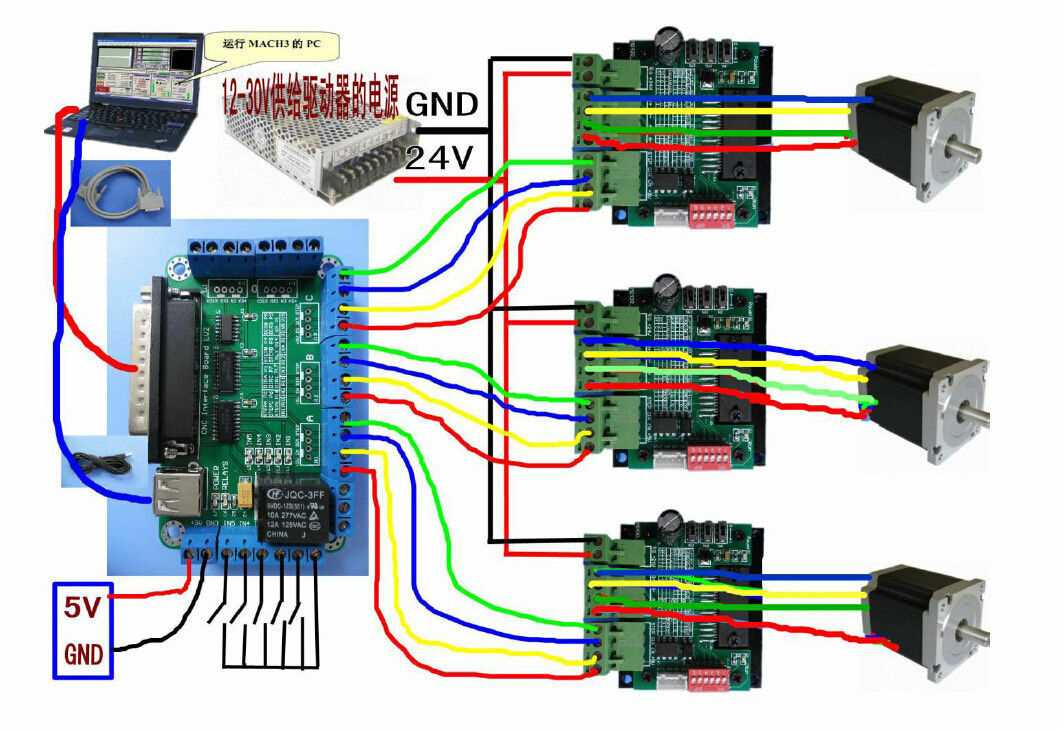

At its core, the Hs 55 Actuator operates on the principle of converting electrical energy into mechanical motion, facilitating the precise positioning of various mechanisms in response to external commands. Its versatile design enables seamless integration into a myriad of applications, ranging from robotics and automation to aerospace and beyond.

Furthermore, the functionality of the Hs 55 Actuator extends beyond mere motion control, encompassing features such as feedback mechanisms and torque modulation, which augment its performance and versatility in diverse operational scenarios. Through these advanced capabilities, the Hs 55 Actuator emerges as a cornerstone component in the realm of modern mechatronics.

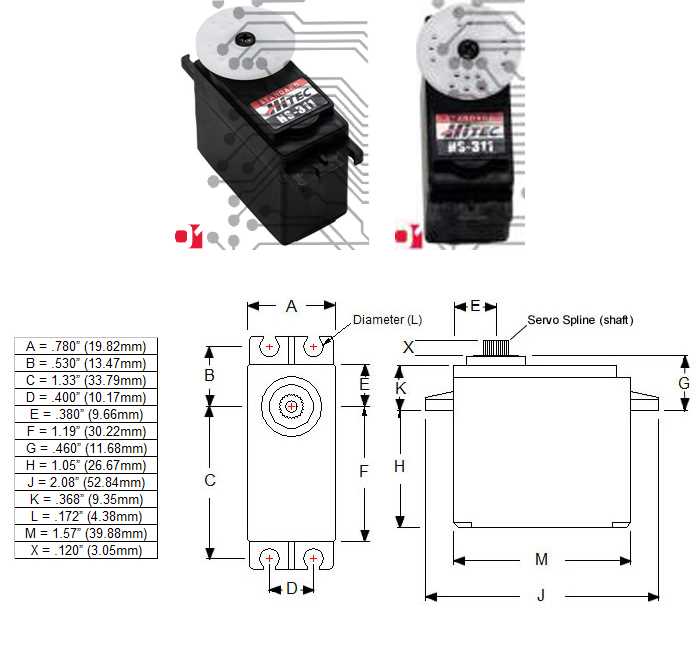

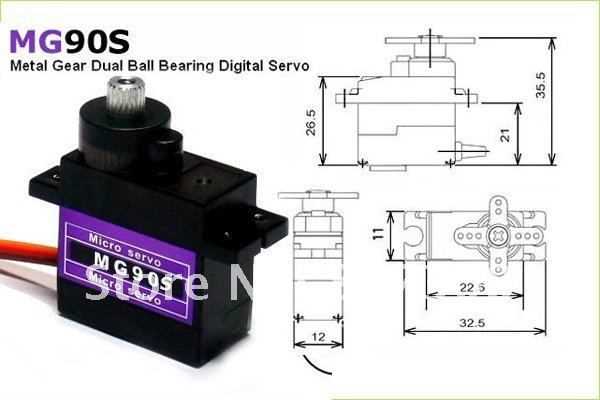

Exploring the Technical Specifications

In this section, we delve into the intricate details and specifications of the Hs 55 mechanism, providing a comprehensive overview of its performance metrics and capabilities. By examining the technical intricacies, we aim to offer insights into the operational characteristics and functionalities of this advanced component.

Performance Metrics

Understanding the operational parameters of the Hs 55 entails an exploration of its performance metrics. This encompasses factors such as speed, torque, and precision, which collectively dictate the efficiency and effectiveness of its functionality. Through detailed analysis, we unveil the dynamic range and responsiveness of this mechanism, shedding light on its ability to execute precise movements with optimal accuracy.

| Parameter | Description |

|---|---|

| Speed | The velocity at which the mechanism operates, measured in units per second (UPS) or degrees per second (DPS). |

| Torque | The rotational force exerted by the mechanism, crucial for overcoming resistance and facilitating movement. |

| Precision | The degree of accuracy and repeatability in positioning, indicative of the mechanism’s ability to achieve desired orientations reliably. |

Functional Capabilities

Beyond mere performance metrics, exploring the technical specifications of the Hs 55 entails an examination of its functional capabilities. This encompasses a range of features, including compatibility with different control systems, voltage requirements, and environmental considerations. By elucidating these aspects, we provide a comprehensive understanding of the versatility and adaptability of this mechanism in various applications.

Applications and Implementation Examples

In this section, we explore various practical scenarios and real-world applications where the Hs 55 actuator can be effectively employed. Through detailed illustrations and case studies, we delve into the versatility and adaptability of this innovative mechanism, showcasing its utility across diverse fields.

| Application | Implementation Example |

|---|---|

| Robotics | Utilizing the Hs 55 actuator in robotic arm assemblies for precise movement and manipulation tasks, enhancing efficiency in manufacturing and automation processes. |

| Aerospace | Integration of the Hs 55 component in flight control systems of unmanned aerial vehicles (UAVs), ensuring stability and agility during aerial maneuvers and surveillance missions. |

| Medical Devices | Incorporating the Hs 55 actuator in medical equipment such as surgical robots and prosthetic limbs, facilitating delicate procedures and restoring mobility for individuals with physical impairments. |

| Automotive | Deploying the Hs 55 mechanism in vehicle steering and braking systems, enhancing responsiveness and safety features in modern automobiles. |

| Consumer Electronics | Integration of the Hs 55 actuator in consumer gadgets like cameras and drones, enabling precise positioning and stabilization for capturing high-quality images and videos. |

These examples merely scratch the surface of the myriad applications where the Hs 55 mechanism proves invaluable. Its robust design, coupled with advanced control capabilities, makes it a preferred choice for engineers and designers seeking reliable actuation solutions in a wide range of industries.

Tips for Enhancing Performance and Longevity

To ensure optimal operation and prolong the lifespan of your Hs 55 actuator, it’s essential to implement certain practices that promote efficiency and resilience. By adhering to these guidelines, you can maximize functionality and enhance durability without compromising on performance.

1. Calibration Precision: Fine-tuning your device with utmost accuracy is fundamental in achieving consistent and reliable results. Adjusting settings meticulously ensures smooth operation and minimizes wear and tear over time.

2. Maintenance Regimen: Establishing a regular maintenance routine is key to preserving the integrity of your equipment. Conducting thorough inspections, cleaning components, and addressing any signs of wear promptly can prevent potential malfunctions and extend the lifespan of your system.

3. Load Management: Mindful handling of workload distribution is crucial for preventing strain on your mechanism. Balancing loads appropriately and avoiding excessive stress on components can prevent premature degradation and optimize overall performance.

4. Temperature Regulation: Maintaining optimal operating temperatures is vital for sustaining peak performance levels. Implementing measures to mitigate overheating or extreme cold can safeguard against potential damage and ensure consistent functionality in diverse environmental conditions.

5. Lubrication Strategy: Utilizing suitable lubricants and applying them at regular intervals is essential for reducing friction and minimizing component wear. Proper lubrication prolongs the lifespan of moving parts and enhances overall efficiency.

6. Voltage Stability: Ensuring stable voltage supply is critical for preventing fluctuations that could compromise performance. Implementing voltage regulation measures helps maintain consistent power delivery, safeguarding against potential damage and optimizing functionality.

7. Environmental Considerations: Assessing and mitigating environmental factors that may impact operation is paramount. Shielding the device from moisture, dust, and other contaminants, as well as considering factors like humidity and vibration, can enhance longevity and reliability.

8. Regular Evaluation: Periodically assessing system performance and functionality allows for timely identification of issues and implementation of corrective measures. Conducting regular evaluations helps detect potential problems early, preventing further damage and optimizing long-term durability.

By incorporating these strategies into your maintenance and operation practices, you can effectively optimize the performance and longevity of your Hs 55 actuator, ensuring reliable functionality and maximizing return on investment.