In the modern world, the demand for electricity is constantly increasing. Industries, businesses, and households rely on a reliable and efficient source of power to fuel their operations and daily activities. One of the key solutions to meet this demand is through the utilization of advanced gas turbine technology. These innovative machines are at the forefront of power generation, providing a sustainable and cost-effective alternative to traditional energy sources.

Revolutionary Engineering

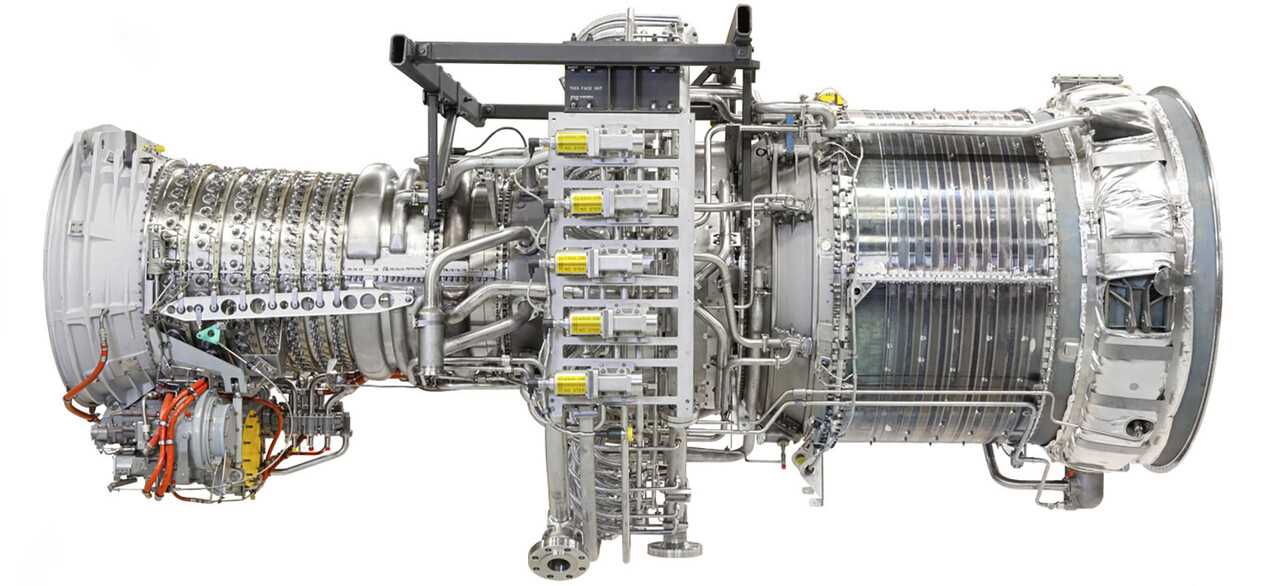

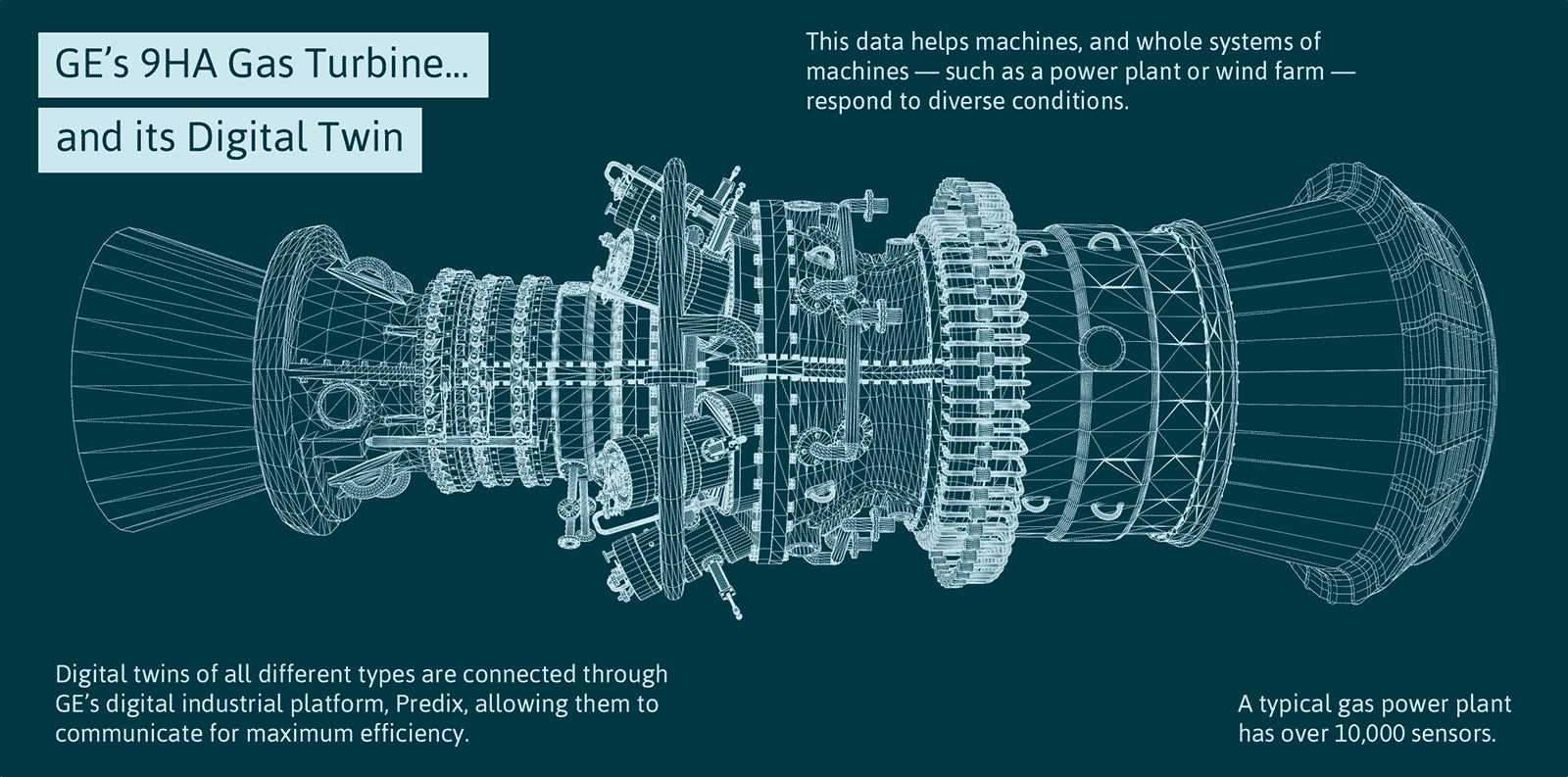

The gas turbine, a marvel of engineering ingenuity, is a versatile and highly efficient device that converts the kinetic energy of a fast-moving gas stream into mechanical energy. This mechanical energy is then converted to electrical energy through an interconnected generator. What sets gas turbines apart from conventional power plants is their ability to start up quickly and reach maximum power output rapidly. With their compact design and high power density, gas turbines offer a remarkable degree of flexibility and can easily adapt to fluctuating electricity demands.

Pioneering Technology

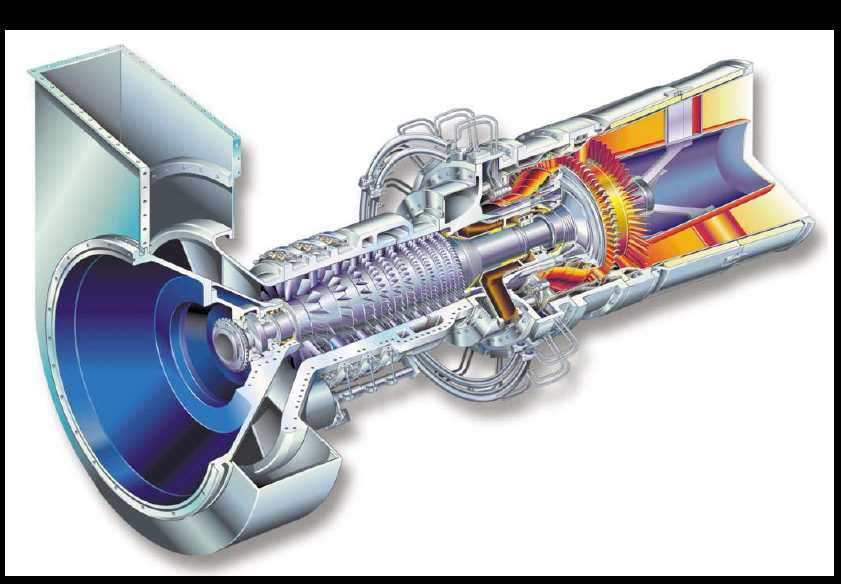

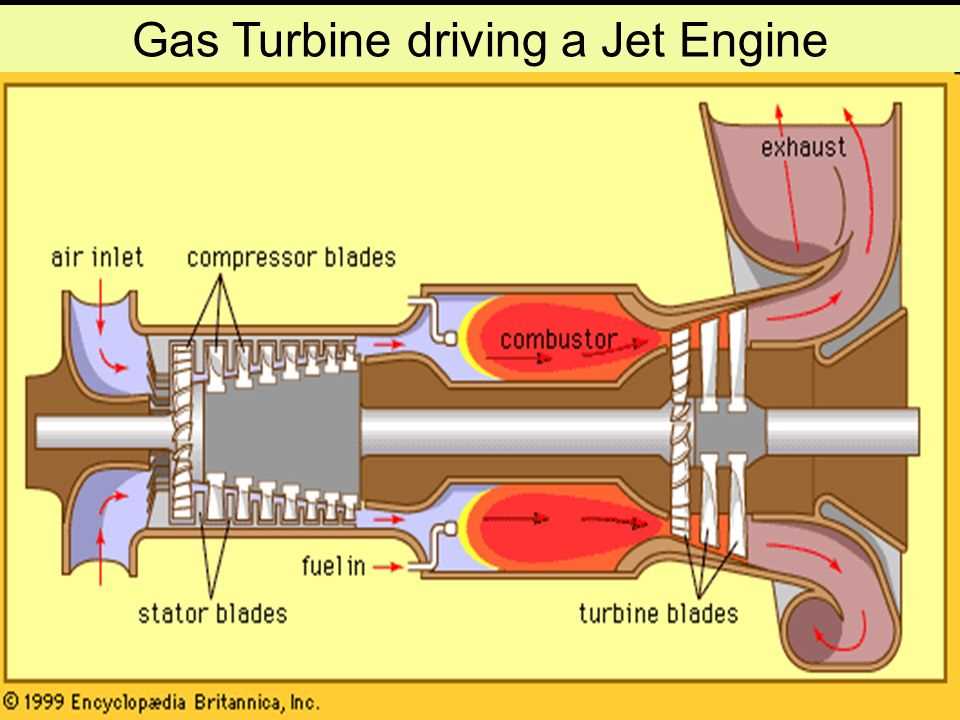

Gas turbines operate on a simple yet ingenious principle: air is compressed, mixed with fuel, and ignited in a combustion chamber. The resulting high-temperature gas expands rapidly, driving the turbine blades and producing rotational motion. This motion, in turn, drives the generator to produce electricity. Combined with advanced control systems, gas turbines offer exceptional efficiency and low emissions, making them a sustainable solution for power generation in an environmentally conscious world. Moreover, their modularity and scalability allow for easy integration into existing power grids, enabling seamless and reliable energy supply.

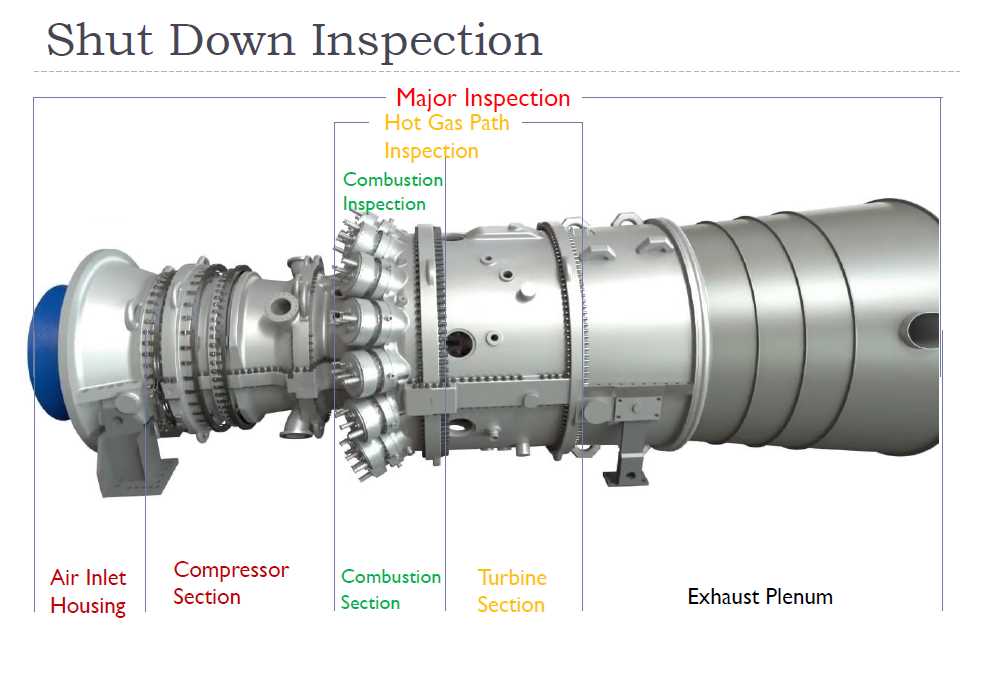

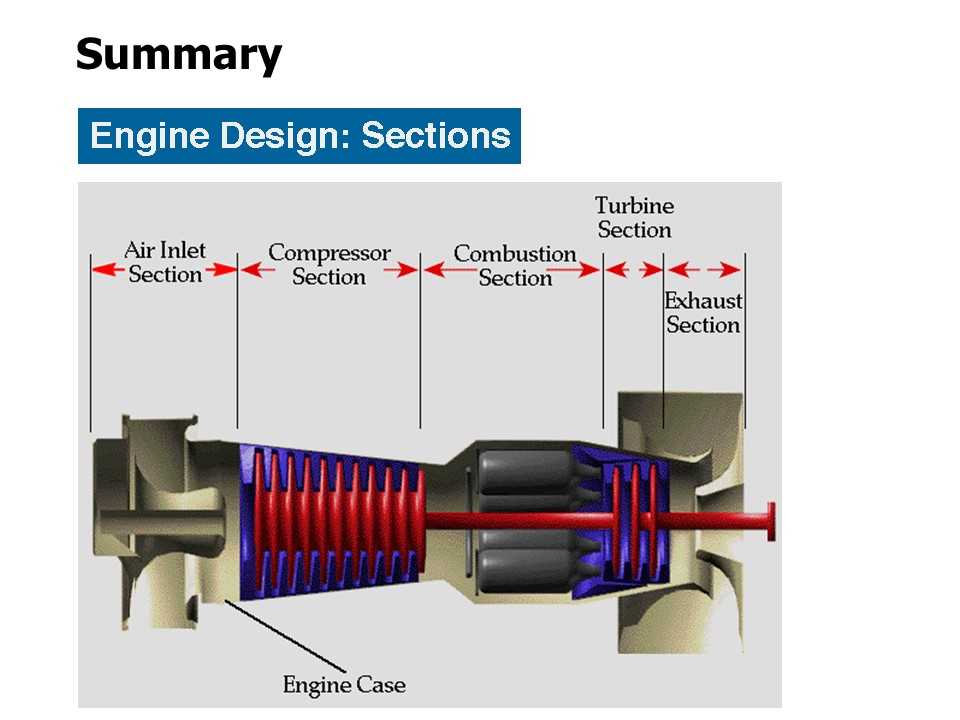

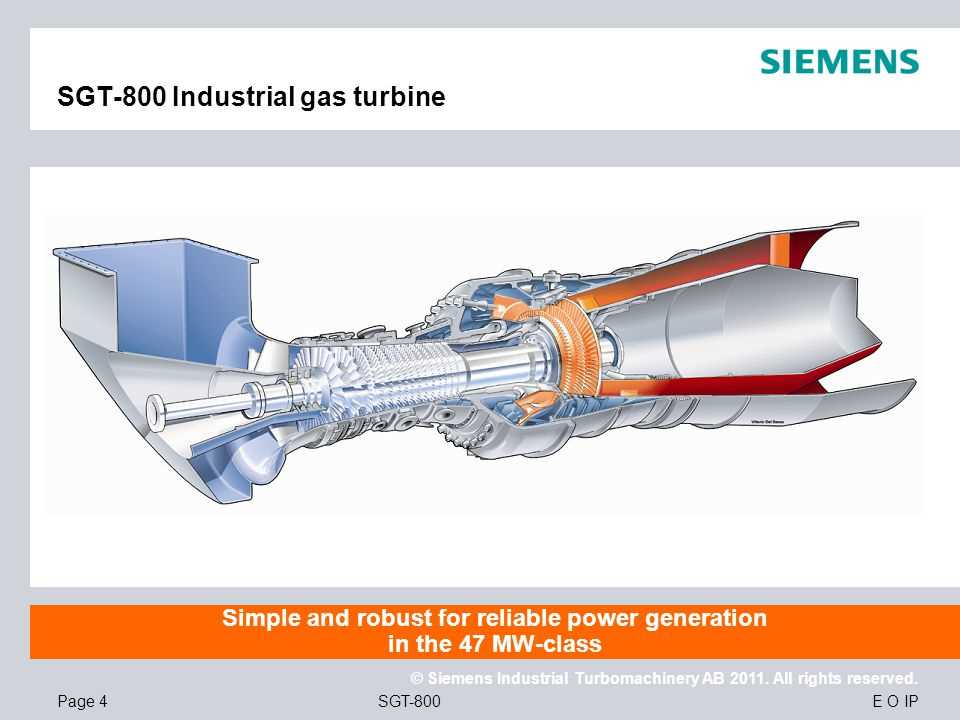

Understanding the Key Components of a Gas Turbine

In this section, we will explore the vital elements that make up a gas turbine, one of the most efficient and powerful sources of mechanical power in many industries. By delving into the intricacies of its design, we can gain a deeper understanding of how these components work together to produce energy from a variety of fuel sources.

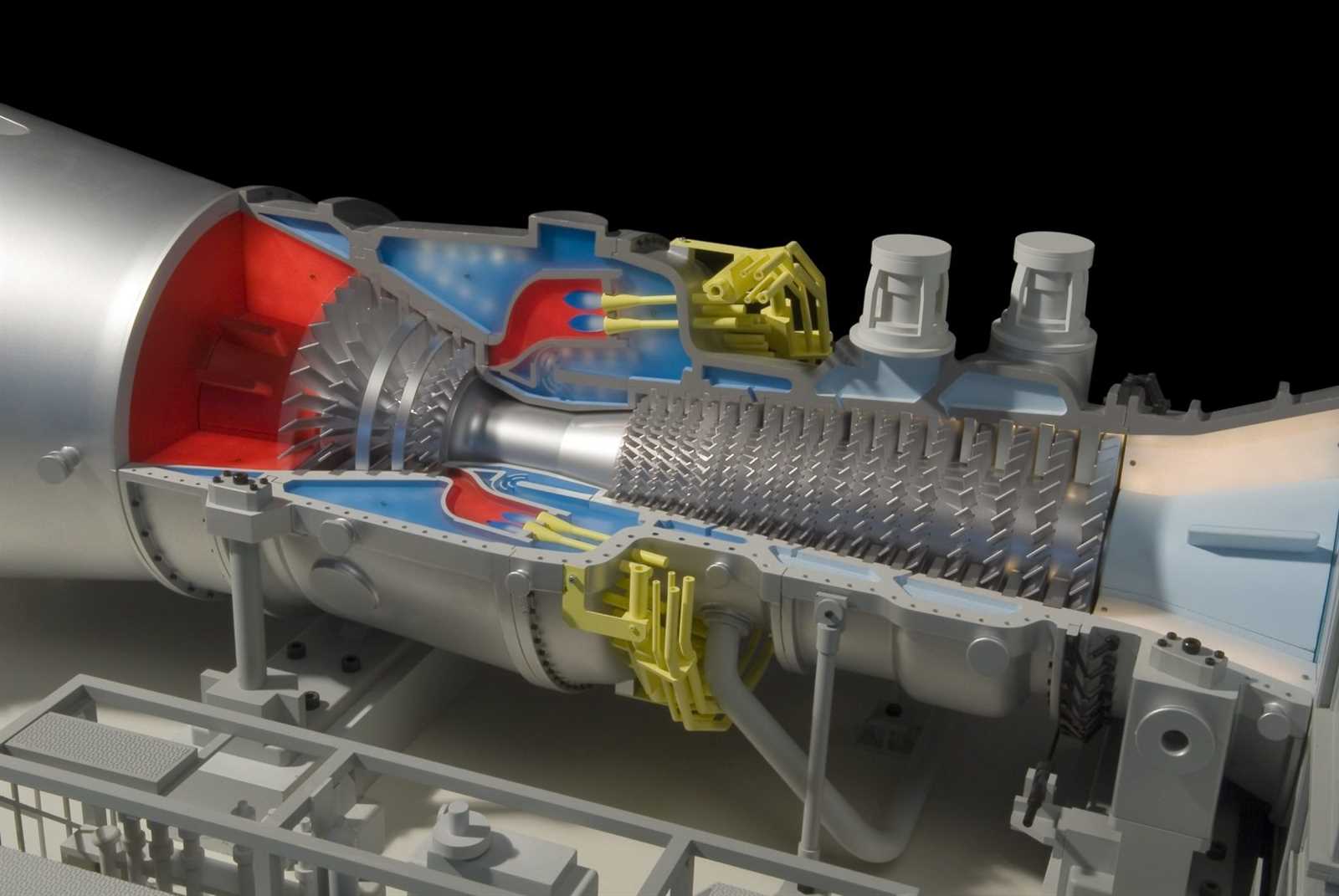

The Combustor

One of the central components of a gas turbine is the combustor, which plays a crucial role in the combustion process. This chamber is where the fuel-air mixture undergoes ignition, generating a controlled release of energy. The combustor must carefully balance the air-to-fuel ratio, ensuring optimal combustion efficiency while minimizing emissions. It relies on advanced technologies such as pre-mixing systems and flame stabilization methods to achieve these objectives.

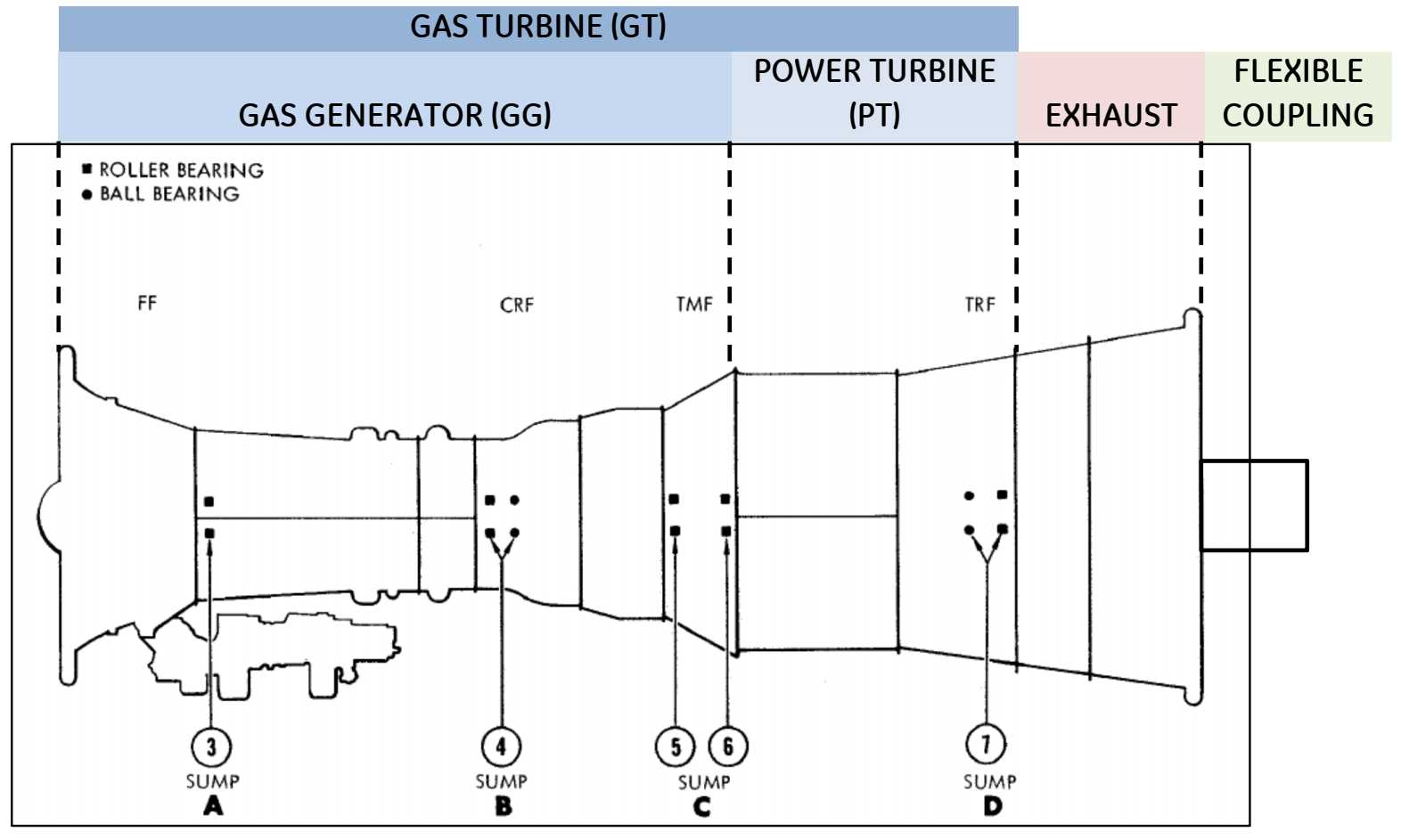

The Blades and Rotor

The blades and rotor assembly constitute another vital part of a gas turbine. These components are responsible for extracting energy from the combustion gases and converting it into mechanical power. The high-velocity gases pass through a series of rotating blades, causing the rotor to spin at high speeds. Their aerodynamic design and precise engineering allow for maximum energy extraction, while withstanding extreme temperatures and pressures. The rotor is connected to the shaft, which transfers the rotational motion to the generator or other driven equipment.

Efficiency and Reliability

The efficiency and reliability of a gas turbine depend on the seamless interaction of its key components. The combustor’s ability to efficiently burn fuel, combined with the aerodynamics of the blades and rotor, forms the foundation for optimal performance. Moreover, meticulous maintenance and monitoring of these components are crucial to ensure their longevity and prevent any potential failures that could lead to downtime and costly repairs.

By comprehending the inner workings of a gas turbine’s key components, we can appreciate the intricate engineering and design principles that contribute to its efficiency and reliability. This knowledge is essential for professionals in the energy industry and those seeking a deeper understanding of this versatile power generation technology.

Important Specifications to Consider in Gas Turbine Datasheets

When evaluating gas turbine equipment, it is crucial to thoroughly review the technical specifications provided in the datasheets. These specifications, which encompass a variety of parameters and performance indicators, can give valuable insights into the turbine’s capabilities and suitability for specific applications. This article highlights some of the key specifications that should be carefully evaluated when reviewing gas turbine datasheets.

1. Power Output

The power output specification indicates the maximum amount of electrical or mechanical power that the gas turbine can generate. This parameter is crucial as it determines the turbine’s capacity to meet the energy demands of the intended application. The power output is typically measured in watts, kilowatts, or megawatts.

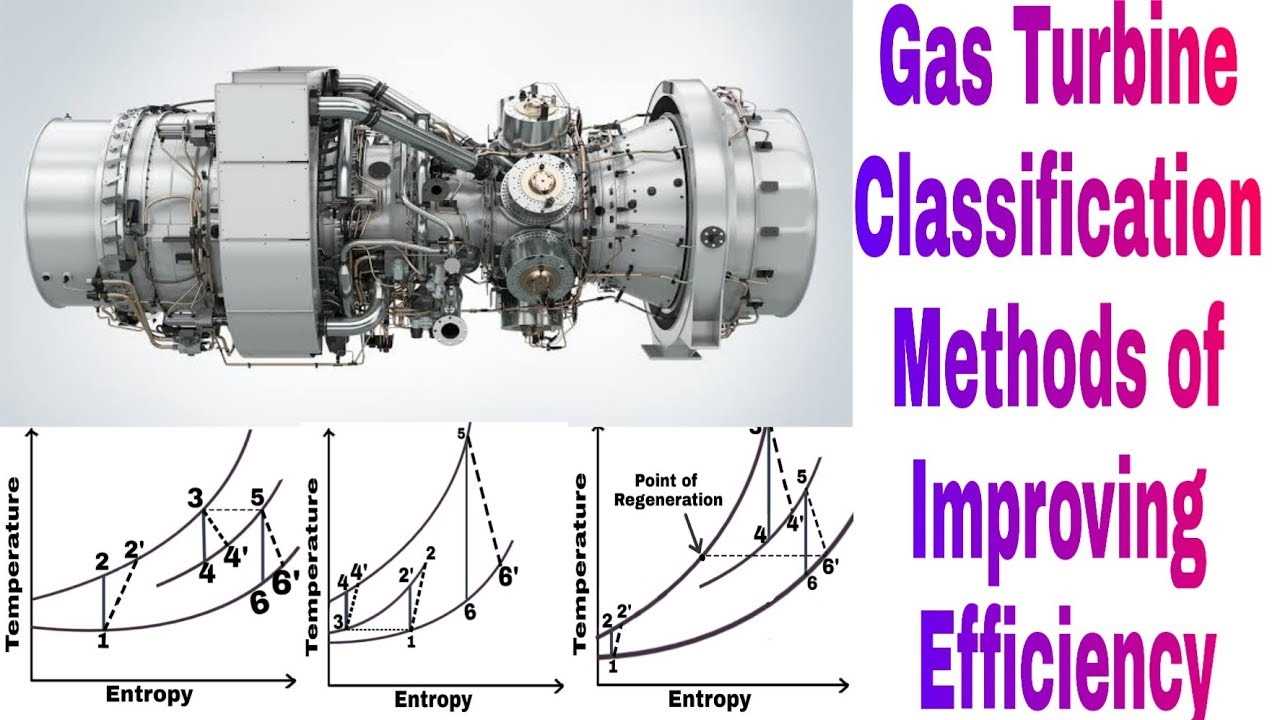

2. Efficiency

The efficiency specification measures the turbine’s ability to convert the chemical energy of fuel into useful mechanical or electrical energy. A higher efficiency means that the turbine can generate more power while utilizing the same amount of fuel. It is essential to consider efficiency to optimize operational costs and reduce environmental impact.

Another important factor to consider is the fuel type and compatibility with the gas turbine. The datasheet should provide information on the specific fuels that the turbine can operate with, such as natural gas, diesel, or renewable fuels.

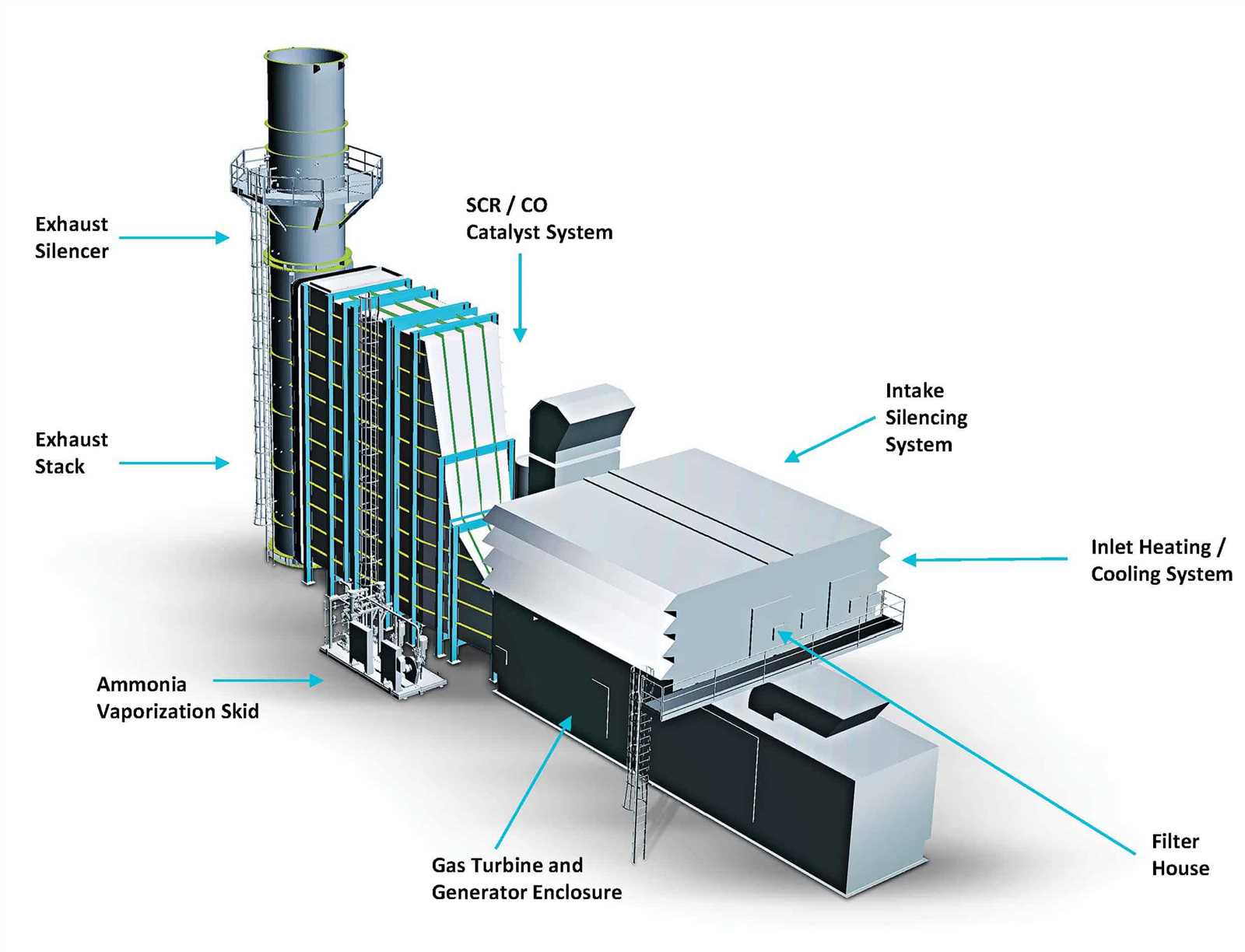

Additionally, the air intake system specification should be assessed to ensure that it meets the requirements for the specific operating conditions. This specification includes details about the air filtration, pressure ratios, and temperature limits, ensuring optimal performance and longevity of the turbine.

Furthermore, the control system specifications outline the features and capabilities of the turbine’s control system. This includes information on monitoring and control interfaces, communication protocols, and safety systems. Evaluating these specifications is crucial to ensure the ease of operation, integration, and overall safety of the gas turbine.

In conclusion, when reviewing gas turbine datasheets, it is essential to carefully consider important specifications such as power output, efficiency, fuel compatibility, air intake system, and control system capabilities. Taking these specifications into account will help determine the suitability of the gas turbine for specific applications, optimize performance, and guide informed decision-making.

How to Interpret Performance Data in Gas Turbine Datasheets

In this section, we will explore the methods for effectively understanding the information provided in gas turbine datasheets. By delving into the details and deciphering the data presented, readers can gain valuable insights into the performance capabilities of these dynamic machines without getting lost in technical jargon.

1. Familiarize Yourself with Key Performance Parameters

Before diving into the data, it is important to become acquainted with the key performance parameters used in gas turbine datasheets. These parameters may include power output, efficiency, heat rate, exhaust temperature, and emission levels. Understanding how these parameters contribute to the overall performance of the gas turbine will enable you to make informed decisions when comparing and evaluating different models.

2. Compare Performance Data Across Different Operating Conditions

Gas turbine performance can vary significantly under different operating conditions. Therefore, it is crucial to pay attention to data presented at various load levels, ambient temperatures, and fuel qualities. By comparing and analyzing performance data across different operating conditions, you can ensure that the selected gas turbine will meet the required performance criteria consistently and reliably.

3. Analyze Performance Curves and Maps

Performance curves and maps provide a graphical representation of a gas turbine’s performance under varying operating conditions. These visual tools allow users to quickly identify trends and understand how the gas turbine will perform at different points on the map. By carefully examining these curves and maps, you can gain valuable insights into the turbine’s efficiency range, power output limits, and overall operating characteristics.

4. Take Into Account Site-Specific Factors

Gas turbine performance can also be influenced by site-specific factors such as ambient temperature, elevation, and air quality. When interpreting the performance data, it is essential to consider these site-specific conditions and assess how they might impact the turbine’s performance. This will help ensure that the selected gas turbine is well-suited for the intended installation site and will deliver optimum results.

By following these guidelines and paying attention to the key performance parameters, operating conditions, performance curves, and site-specific factors, readers can effectively interpret the performance data provided in gas turbine datasheets. Armed with this knowledge, the selection and evaluation process becomes more streamlined, enabling informed decisions and successful integration of these powerful machines into various applications.