Unveiling the intricacies of modern electro-mechanical wonders, this section delves into the heart of precision-driven innovations, where technology dances with engineering brilliance. Embark on a journey through the realm of dynamic motion control, where every volt pulsates with potential and every rotation heralds a new era of performance.

Discover the meticulous craftsmanship behind these marvels of modern engineering, where precision meets power in a symphony of motion. Peer into the labyrinth of components and specifications, each detail meticulously crafted to orchestrate seamless movement and unparalleled control.

Unlock the secrets hidden within the blueprints of ingenuity, where every line tells a tale of innovation and every curve whispers of efficiency. Journey alongside the pioneers of progress as they redefine the boundaries of what’s possible, one revolution at a time.

The Overview of FS90R Servo Motor Specifications

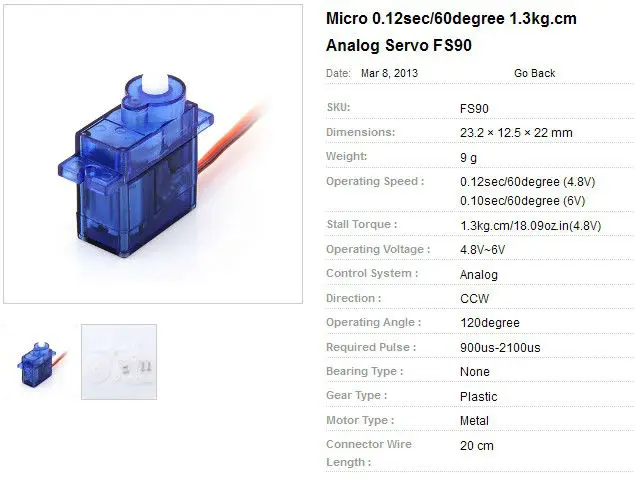

In this section, we will provide a comprehensive overview of the key specifications and characteristics of the FS90R servo motor. Understanding these specifications is essential for effectively utilizing this component in various applications.

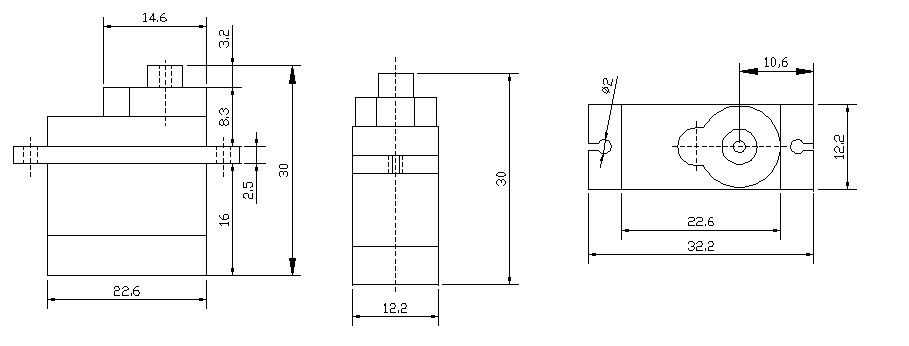

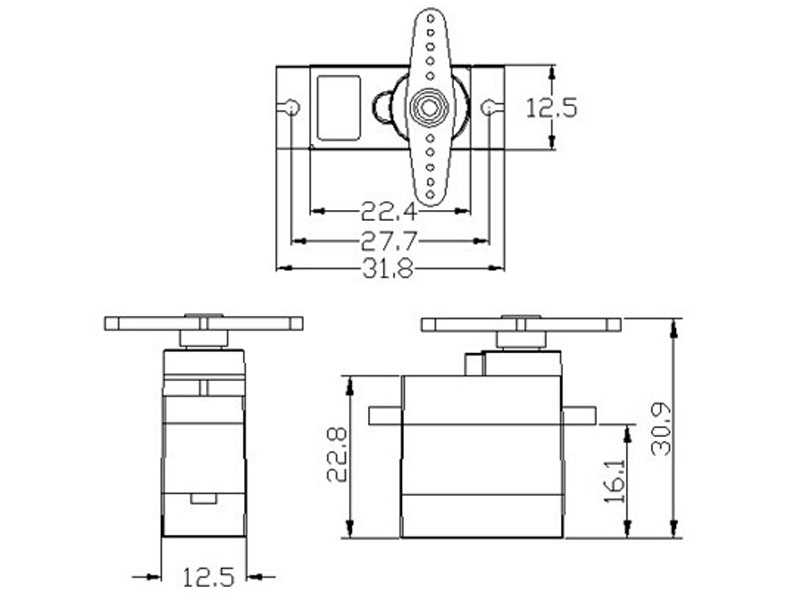

1. Physical Dimensions

- Size and Weight: Details about the physical dimensions and weight of the FS90R, crucial for fitting it into different mechanical setups.

- Mounting Options: Information regarding mounting configurations, including compatible brackets or fixtures.

2. Electrical Specifications

- Operating Voltage Range: The range of voltage within which the FS90R operates optimally, ensuring stable performance.

- Current Draw: Details about the current consumption under various load conditions, aiding in power supply selection.

- Control Signal: Description of the control signal requirements, such as pulse width modulation (PWM) frequency and duty cycle.

3. Performance Characteristics

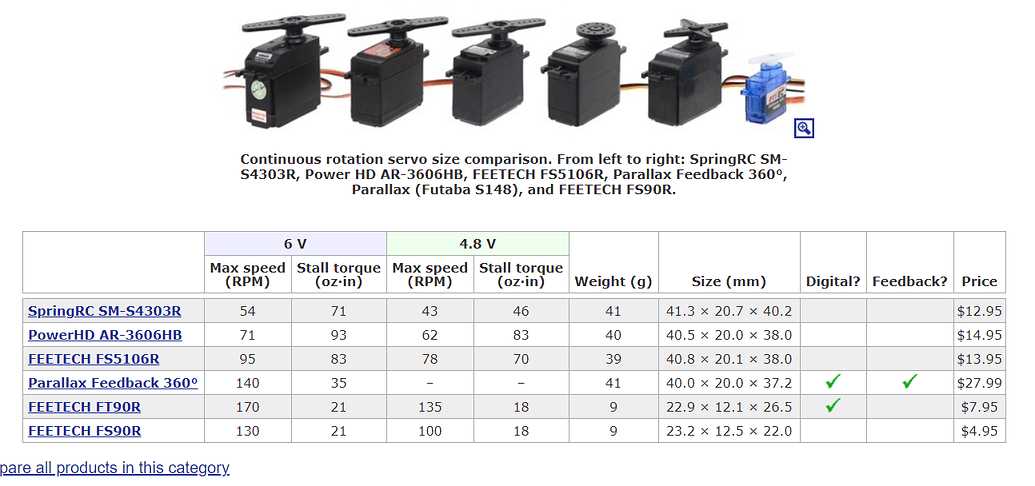

- Torque Output: The maximum torque that the FS90R can deliver, influencing its suitability for different tasks.

- Speed Range: Range of achievable speeds, providing insight into its responsiveness and versatility.

- Precision and Accuracy: Information on precision and accuracy levels, critical for applications demanding high positional accuracy.

4. Environmental Considerations

- Operating Temperature Range: The temperature range in which the FS90R can operate reliably.

- Environmental Protection: Details about protection against moisture, dust, and other environmental factors.

5. Additional Features

- Feedback Mechanism: Description of any built-in feedback mechanism for position sensing and control.

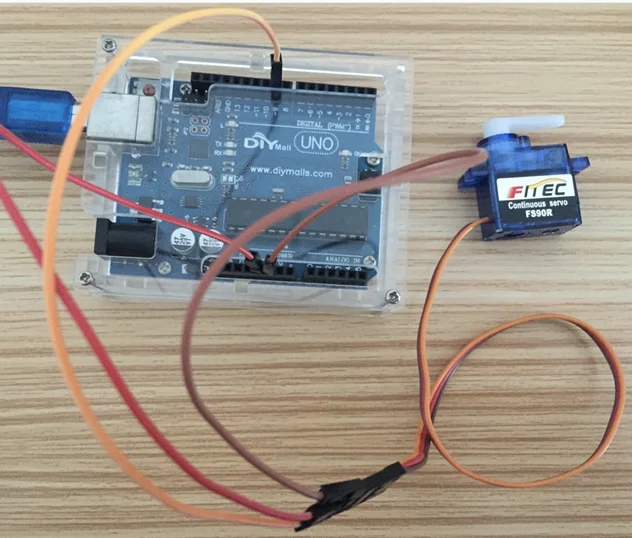

- Compatibility: Information about compatibility with commonly used microcontrollers or motor control systems.

- Special Functions: Any unique or advanced functions offered by the FS90R, enhancing its utility in specific applications.

Understanding the specifications outlined in this section is essential for engineers and hobbyists alike to leverage the capabilities of the FS90R servo motor effectively.

Understanding Key Specifications and Features

In exploring the intricacies of the FS90R servo motor datasheet, it’s essential to delve into the nuanced array of specifications and features that define its performance and functionality. This section elucidates the pivotal aspects that govern the operational capabilities and potential applications of this sophisticated electromechanical device.

Performance Metrics

First and foremost, comprehending the performance metrics is imperative to gauge the efficacy of the FS90R servo motor. These metrics encompass various parameters such as torque output, rotational speed, precision, and efficiency. Each metric delineates the motor’s capacity to deliver controlled motion and achieve desired positioning with accuracy and reliability.

Functional Characteristics

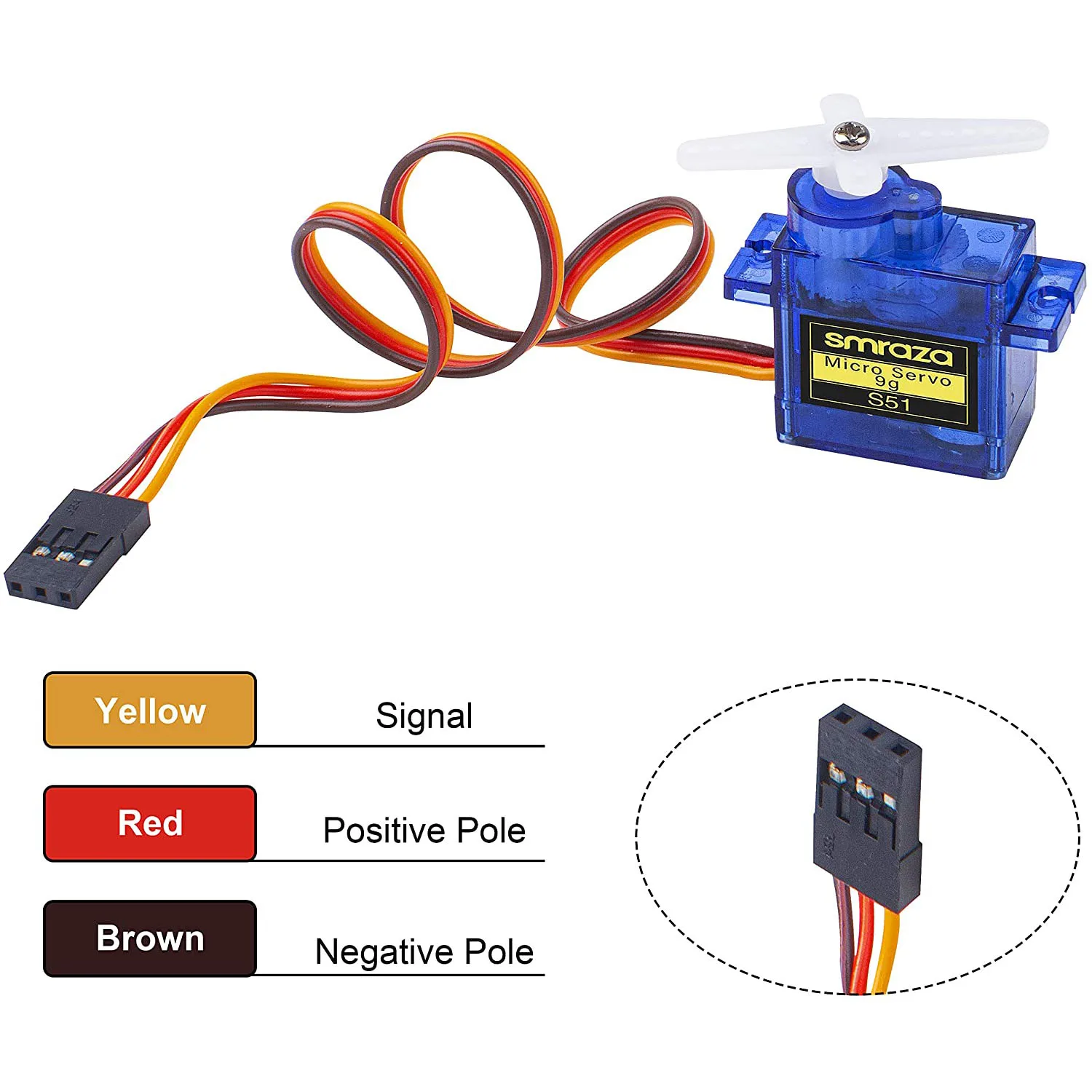

Beyond performance metrics, understanding the functional characteristics elucidates the operational intricacies of the FS90R servo motor. These characteristics encompass control interfaces, communication protocols, power requirements, and compatibility with auxiliary components. Delving into these aspects unveils the motor’s adaptability to diverse control systems and integration possibilities within broader electromechanical frameworks.

- Torque Output: Indicates the rotational force exerted by the motor.

- Rotational Speed: Denotes the velocity at which the motor shaft rotates.

- Precision: Refers to the motor’s ability to achieve and maintain precise positional accuracy.

- Efficiency: Measures the motor’s effectiveness in converting electrical energy into mechanical work.

- Control Interfaces: Describes the interfaces through which the motor can be manipulated and controlled.

- Communication Protocols: Specifies the protocols utilized for communication between the motor and external devices.

- Power Requirements: Outlines the voltage and current specifications necessary for optimal motor performance.

- Compatibility: Explores the motor’s compatibility with various control systems and auxiliary components.

By elucidating these key specifications and features, a comprehensive understanding of the FS90R servo motor emerges, empowering engineers and enthusiasts alike to harness its capabilities effectively in diverse applications.

Exploring Applications of FS90R Servo Motor

Unveiling the Versatility of this Precision Control Component

The FS90R servo motor, with its intricate engineering and precise control capabilities, offers a myriad of applications across various industries. From robotics to automation, this dynamic component serves as the backbone for a plethora of innovative solutions.

Enhancing Robotic Manipulation

One of the primary applications of the FS90R servo motor lies in its role within robotic systems. With its ability to provide accurate and controlled movement, it enables robots to perform intricate tasks with finesse. Whether it’s gripping objects, navigating environments, or executing complex maneuvers, the FS90R empowers robots to achieve unparalleled precision.

Driving Automation Systems

In the realm of automation, the FS90R servo motor plays a pivotal role in driving efficiency and productivity. By integrating seamlessly into automated processes, it facilitates smooth and reliable operation across various industries. From manufacturing lines to assembly plants, its precise control enables automation systems to function with unmatched accuracy and consistency.

Empowering Remote Control Mechanisms

Beyond robotics and automation, the FS90R servo motor finds applications in remote control systems. Whether it’s unmanned aerial vehicles (UAVs), remote-controlled vehicles, or surveillance mechanisms, this component provides the necessary control for remote operations. Its responsiveness and accuracy make it an indispensable component for enabling remote control in diverse scenarios.

Enabling Dynamic Camera Control

Additionally, the FS90R servo motor lends itself to applications in camera control systems. From stabilizing camera movements to enabling precise panning and tilting, it enhances the capabilities of surveillance cameras, cinematography rigs, and other imaging devices. Its smooth operation ensures fluid motion capture and precise framing in various filming and monitoring scenarios.

Facilitating Educational Projects

Furthermore, the FS90R servo motor serves as an educational tool, introducing students and enthusiasts to the principles of robotics and control systems. Its accessibility and versatility make it an ideal component for hands-on learning experiences, fostering exploration and innovation in STEM (Science, Technology, Engineering, and Mathematics) fields.

In essence, the FS90R servo motor transcends its mechanical nature to become a cornerstone of modern technological advancement, driving innovation across a spectrum of applications.

Integration in Robotics, Automation, and Beyond

In the realm of automated systems and robotic applications, the fusion of advanced technologies is pivotal for achieving seamless operations and optimal performance. This section delves into the intricate interplay between cutting-edge innovations, exploring their integration within the landscape of robotics, automation, and beyond.

The Nexus of Robotics and Automation

Within the dynamic ecosystem of robotics and automation, the convergence of diverse technologies propels the evolution of intelligent systems. Through synergistic integration, mechanisms akin to the Fs90r servo motor transcend conventional boundaries, orchestrating intricate maneuvers with precision and finesse. Such amalgamation not only enhances operational efficiency but also fosters adaptability in navigating complex environments.

Expanding Horizons: Beyond Traditional Applications

Extending beyond traditional confines, the integration of sophisticated components catalyzes innovation across multifaceted domains. From industrial automation to biomedical engineering, the seamless assimilation of advanced functionalities reshapes the landscape of technological advancement. This fusion heralds a new era of possibilities, where automated solutions transcend conventional paradigms, heralding transformative breakthroughs across diverse sectors.

Tips for Maximizing the Utility of Technical Specifications

When delving into the intricacies of engineering components, understanding how to effectively navigate technical documentation is paramount. In the realm of motion control mechanisms, adept utilization of comprehensive specifications can significantly streamline the design and implementation process.

1. Grasp the Functional Essence

Conceptualizing the fundamental operations of the device described within the documentation is foundational. Instead of merely skimming through the text, endeavor to comprehend the essence of its functionalities. This comprehension lays the groundwork for subsequent analysis and application.

2. Deciphering Performance Metrics

Within the labyrinth of technical jargon lie critical indicators of performance. Engage in a meticulous examination of parameters such as torque, speed, and power consumption. By discerning the nuances of these metrics, you pave the way for informed decision-making during the integration phase.