Embark on a journey into the realm of cutting-edge automation as we delve into the intricate functionalities and capabilities of a renowned robotic marvel. This exploration transcends mere technical specifications, offering a comprehensive insight into the innovative technologies driving modern industrial solutions.

Discover a fusion of precision engineering and intelligent design, where efficiency meets adaptability in a symphony of mechanical prowess. Delve into a narrative that unfolds the unparalleled capabilities of robotic systems, reshaping industries and redefining productivity benchmarks.

Unravel the complexities of robotic intelligence as we navigate through a landscape of seamless integration and dynamic performance. Witness firsthand the synergy between form and function, as each component synergizes to orchestrate a symphony of productivity.

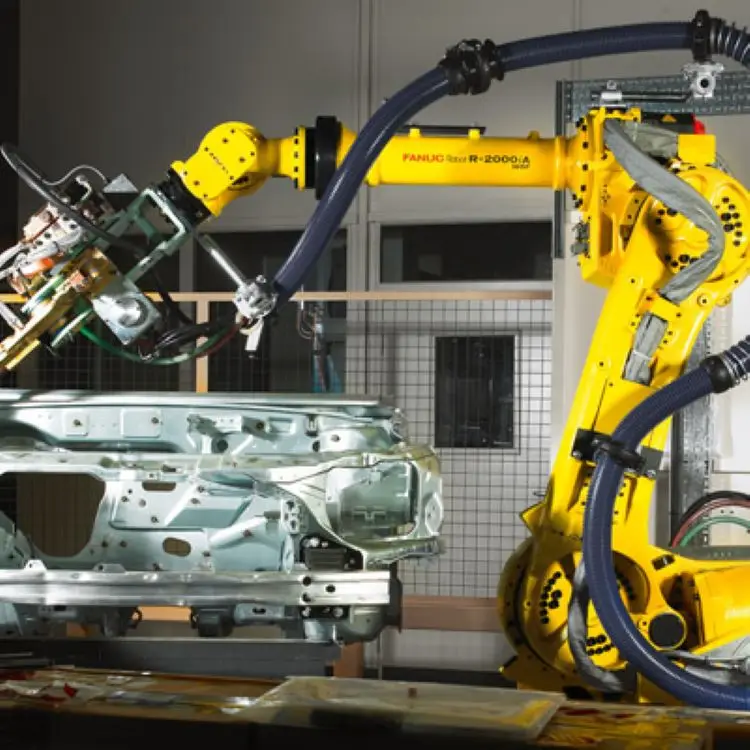

Fanuc R2000ic 165f Datasheet Overview

In this section, we provide an extensive analysis of the specifications and features of the robotic arm model R2000ic 165f by Fanuc. We delve into the intricate details and performance metrics, offering insights into its capabilities and applications.

| Model | R2000ic 165f |

| Type | Robotic Arm |

| Application | Industrial Automation |

| Payload Capacity | 165 kilograms |

| Reach | 2000 millimeters |

| Control System | Integrated |

| Accuracy | Precision Engineering |

This overview section aims to provide a comprehensive understanding of the capabilities and specifications of the R2000ic 165f model, aiding decision-making processes for potential users across various industries.

Understanding the Specifications

In delving into the intricacies of this robotic marvel, it’s pivotal to unravel the intricate tapestry of its specifications. These parameters serve as the compass guiding us through the capabilities and limitations of this technological behemoth. Let’s embark on a journey to decipher the essence of its operational boundaries and performance benchmarks.

Performance Metrics

Embarking on an exploration of this machine’s prowess, we dissect the array of performance metrics that define its operational finesse. From speed to payload capacity, each metric encapsulates a facet of its potential, offering insight into its efficiency and adaptability across various applications.

Functional Parameters

Beyond sheer performance, understanding the functional parameters delineates the realm within which this robotic entity operates. From reach to repeatability, these parameters delineate the spatial and operational constraints, shedding light on its maneuverability and precision in executing tasks.

Key Features and Capabilities

In this section, we delve into the remarkable attributes and functionalities that define the prowess of this cutting-edge robotic system. Explore the myriad of capabilities and distinctive features that propel productivity, efficiency, and innovation in industrial automation.

Advanced Performance

Discover unparalleled performance benchmarks achieved through sophisticated engineering and precision technology. Unleash the potential for seamless integration and optimized operations, elevating manufacturing processes to new heights of excellence.

Innovative Functionality

Experience a spectrum of innovative functionalities designed to streamline operations and enhance versatility. From intuitive programming interfaces to adaptive motion control, explore the dynamic capabilities that empower users to meet evolving industry demands with ease.

Optimizing Performance with the Advanced Robotic Arm

In the pursuit of enhancing operational efficiency and maximizing productivity, it is imperative to delve into the intricacies of leveraging cutting-edge robotic technology. This section explores the strategic approaches and techniques to optimize the performance of the innovative robotic arm, unlocking its full potential in various industrial applications.

Unlocking Efficiency: Delving into the operational nuances of this state-of-the-art robotic arm unveils a myriad of avenues for streamlining processes and elevating performance benchmarks. By fine-tuning operational parameters and implementing tailored strategies, businesses can harness the true power of automation, facilitating seamless workflows and driving unparalleled efficiency gains.

Enhancing Precision: Precision is paramount in today’s competitive landscape, where even the slightest deviation can have significant ramifications. Through meticulous calibration and rigorous quality control measures, organizations can ensure the utmost precision in every task executed by the robotic arm. This precision not only enhances product quality but also minimizes wastage and optimizes resource utilization.

Maximizing Throughput: The throughput of industrial processes serves as a key determinant of overall productivity and profitability. By optimizing cycle times, minimizing downtime, and orchestrating synchronized operations, businesses can achieve remarkable gains in throughput, accelerating production rates without compromising on quality or safety standards.

Adapting to Dynamic Environments: In today’s dynamic business landscape, adaptability is indispensable. The robust capabilities of the robotic arm enable seamless integration into diverse operational environments, empowering businesses to swiftly respond to evolving market demands and capitalize on emerging opportunities with agility and resilience.

Empowering Personnel: Automation does not replace human expertise; rather, it augments it. By leveraging the robotic arm as a collaborative tool, organizations can empower personnel to focus on high-value tasks that require human ingenuity and creativity, fostering a culture of innovation and driving continuous improvement initiatives.

Through a holistic approach encompassing optimization strategies, precision engineering, and human-robot collaboration, businesses can unlock the full potential of the advanced robotic arm, catapulting their operations to new heights of efficiency and competitiveness in the digital age.

Enhancing Efficiency in Industrial Applications

In the realm of industrial operations, the quest for enhanced efficiency stands as a paramount objective. Advancements in automation technology continuously drive this pursuit, offering innovative solutions to streamline processes, optimize resource utilization, and bolster productivity.

Optimized Workflow Management

Efficiency in industrial applications hinges upon meticulous workflow management. Through the integration of advanced robotics and intelligent systems, industries can orchestrate seamless operations, minimizing downtime and maximizing output.

Resource Allocation and Utilization

Effective resource allocation forms the bedrock of operational efficiency. Leveraging cutting-edge technologies enables industries to precisely allocate resources, minimize waste, and enhance overall productivity. Whether it be through predictive maintenance strategies or real-time monitoring systems, optimizing resource utilization remains pivotal in driving efficiency gains.

- Integration of predictive maintenance strategies

- Real-time monitoring systems

- Advanced analytics for data-driven decision-making