In the realm of industrial innovation, there exists a realm where precision meets efficiency, where automation intertwines seamlessly with human ingenuity. Within this domain lies a technological masterpiece, a pinnacle of robotic prowess that revolutionizes manufacturing landscapes and redefines production paradigms.

Embrace a journey through the realms of cutting-edge automation, where intricate mechanisms meld with sophisticated algorithms to orchestrate a symphony of productivity. Unveil the intricate tapestry of innovation woven by the fusion of mechanical dexterity and digital intelligence, where every movement is choreographed with meticulous precision.

Step into the future of manufacturing as we delve into the essence of this marvel, dissecting its capabilities, unraveling its potential, and deciphering the language of efficiency it speaks. Join us in an exploration beyond the realms of conventional machinery, where every cog and line of code harmonize to propel industries towards unparalleled heights of success.

The Core Features of Fanuc R-30iB Datasheet

In exploring the essence of the pivotal documentation surrounding the R-30iB system, we delve into its fundamental characteristics and functionalities, elucidating the quintessence that underpins its operational prowess.

1. Foundational Attributes

Embodied within the fabric of this technological marvel lie foundational attributes that serve as the bedrock of its functionality. These encompass…

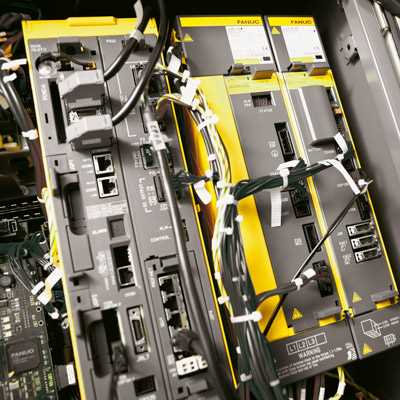

2. Key Components and Capabilities

Unveiling the intricate components and capabilities intrinsic to the R-30iB, this section sheds light on the core mechanisms and functionalities driving its performance excellence. From its robust hardware architecture to its sophisticated software algorithms, each element synergizes harmoniously to manifest a symphony of precision and efficiency.

Exploring the Technical Specifications

In this section, we delve into the intricate technical details and specifications of the cutting-edge robotic system, shedding light on its capabilities and functionalities. Through a comprehensive examination of its engineering intricacies, we aim to provide a nuanced understanding of its performance metrics and operational parameters.

| Feature | Aspect |

|---|---|

| Operating Parameters | Discover the operational boundaries and environmental constraints within which the system functions optimally, encompassing factors such as temperature range, humidity tolerance, and power requirements. |

| Performance Metrics | Uncover the quantitative measures of the system’s performance, including speed, accuracy, repeatability, and payload capacity, providing insights into its efficiency and reliability in various applications. |

| Communication Protocols | Examine the communication interfaces and protocols supported by the system, facilitating seamless integration with other automation components and enabling efficient data exchange within industrial networks. |

| Motion Control | Explore the motion control capabilities of the system, encompassing aspects such as axis configurations, motion range, acceleration/deceleration profiles, and trajectory planning algorithms, crucial for precise and dynamic movement execution. |

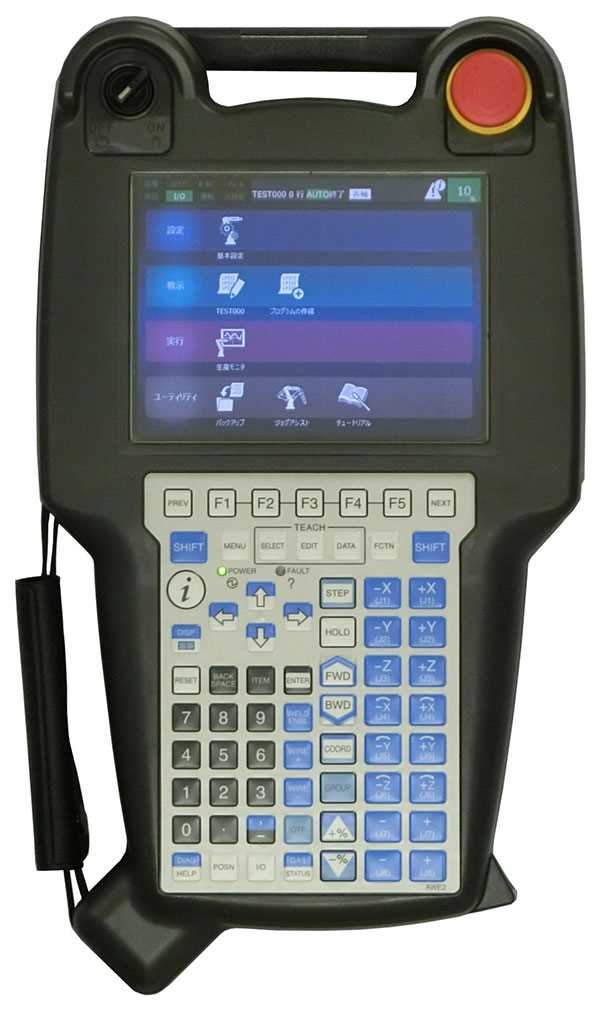

| Programming Interface | Evaluate the programming interface provided by the system, including programming languages, software tools, and APIs, empowering users to customize and optimize robotic operations according to specific application requirements. |

| Safety Features | Assess the safety mechanisms integrated into the system, ranging from collision detection and emergency stop functionality to safety-certified components and compliance with industry standards, ensuring a secure operating environment for human operators and surrounding equipment. |

By dissecting the technical specifications of this advanced robotic platform, we aim to provide engineers, technicians, and enthusiasts with a deeper understanding of its capabilities and functionalities, fostering innovation and informed decision-making in the realm of industrial automation.

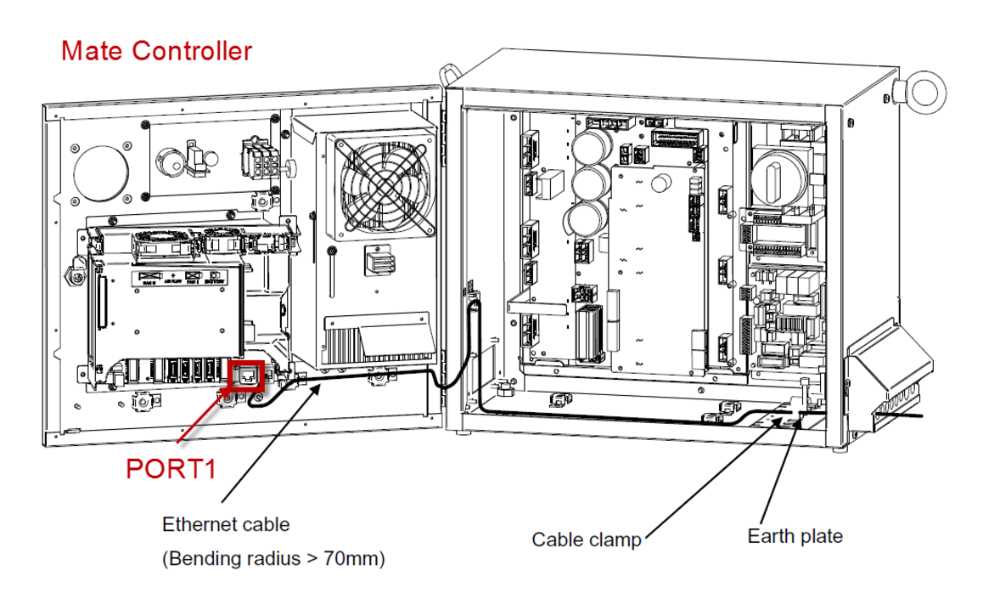

Understanding Connectivity and Compatibility

In this section, we delve into the intricate network of connections and the seamless integration of components within the framework of the R-30iB series. Our focus lies on comprehending the interplay of various interfaces and the harmonious coexistence of diverse technologies, fostering a robust ecosystem of automation.

Interfacing Technologies

Exploring the realm of connectivity entails an examination of the manifold interfaces that facilitate communication and control. From Ethernet to fieldbus protocols, each conduit serves as a conduit for data exchange, enabling the orchestration of robotic operations with precision and efficiency.

Compatibility Matrix

A pivotal aspect of optimizing operational efficiency is discerning the compatibility matrix of the R-30iB series with peripheral devices and software ecosystems. Through meticulous scrutiny of compatibility specifications, stakeholders can streamline integration efforts and harness the full potential of their automation infrastructure.

| Component | Compatible Interfaces |

|---|---|

| Peripheral Devices | Ethernet, USB, Serial |

| Software Ecosystems | ROS, LabVIEW, MATLAB |

Unlocking Efficiency: Applications of Advanced Robotics Data

In this section, we delve into the myriad ways that harnessing the power of cutting-edge robotics information can revolutionize industrial operations. By tapping into the wealth of insights provided by advanced robotic systems, businesses can streamline processes, optimize performance, and drive unprecedented levels of efficiency.

From enhancing production workflows to refining supply chain logistics, the utilization of sophisticated robotic data offers a pathway to heightened productivity and cost-effectiveness. By leveraging the wealth of insights embedded within these intricate systems, organizations can unlock untapped potential and propel themselves towards a future of unparalleled operational excellence.

Optimizing Industrial Automation Processes

In the realm of industrial automation, enhancing operational efficiency and productivity stands as a paramount objective. This section delves into strategies and methodologies aimed at refining and streamlining automation workflows, fostering smoother operations, and bolstering overall performance.

Maximizing Efficiency: Within the intricate framework of industrial automation, the quest for optimal efficiency remains constant. This entails a meticulous examination of processes, identifying potential bottlenecks, and implementing solutions to mitigate them. By honing in on efficiency drivers, organizations can unlock significant gains in productivity and resource utilization.

Streamlining Workflows: A seamless workflow is the cornerstone of successful automation initiatives. This involves orchestrating a synchronized interplay between various components, from machinery and robotics to software systems and data analytics. Through systematic optimization, companies can streamline operations, minimize downtime, and expedite production cycles.

Embracing Innovation: The landscape of industrial automation is continuously evolving, driven by rapid technological advancements and innovative breakthroughs. Embracing cutting-edge technologies such as artificial intelligence, machine learning, and Internet of Things (IoT) enables organizations to harness newfound capabilities, paving the way for enhanced automation performance and adaptability.

Enhancing Flexibility: In the dynamic realm of manufacturing, agility reigns supreme. By fostering flexibility within automation processes, businesses can swiftly respond to changing market demands and evolving customer preferences. This entails deploying modular solutions, adaptive control systems, and agile manufacturing practices to facilitate seamless transitions and accommodate diverse production scenarios.

Optimizing Resource Allocation: Effective resource management lies at the heart of efficient automation operations. By optimizing resource allocation, organizations can allocate manpower, materials, and machinery in a manner that maximizes output while minimizing waste. Leveraging data-driven insights and predictive analytics empowers decision-makers to optimize resource utilization and drive continuous improvement.

Cultivating a Culture of Continuous Improvement: Sustainable success in industrial automation hinges on a culture of perpetual innovation and improvement. By fostering a collaborative environment where experimentation, feedback, and iteration are encouraged, organizations can fuel ongoing enhancements and drive operational excellence. This entails fostering a mindset of continuous learning, embracing failure as a stepping stone to success, and championing a relentless pursuit of excellence.

Optimizing industrial automation processes entails a multifaceted approach, encompassing technological innovation, operational refinement, and organizational agility. By embracing the principles outlined in this section, businesses can unlock newfound efficiencies, drive competitive advantage, and thrive in an increasingly dynamic marketplace.