When it comes to the production of circuit boards, it is increasingly important to consider eco-friendly options. In an era where sustainability is a top priority, finding alternatives to traditional soldering methods is crucial. This article explores an innovative solution that has been gaining traction in the industry – the Eco Solder M705.

Revolutionizing the Way We Solder

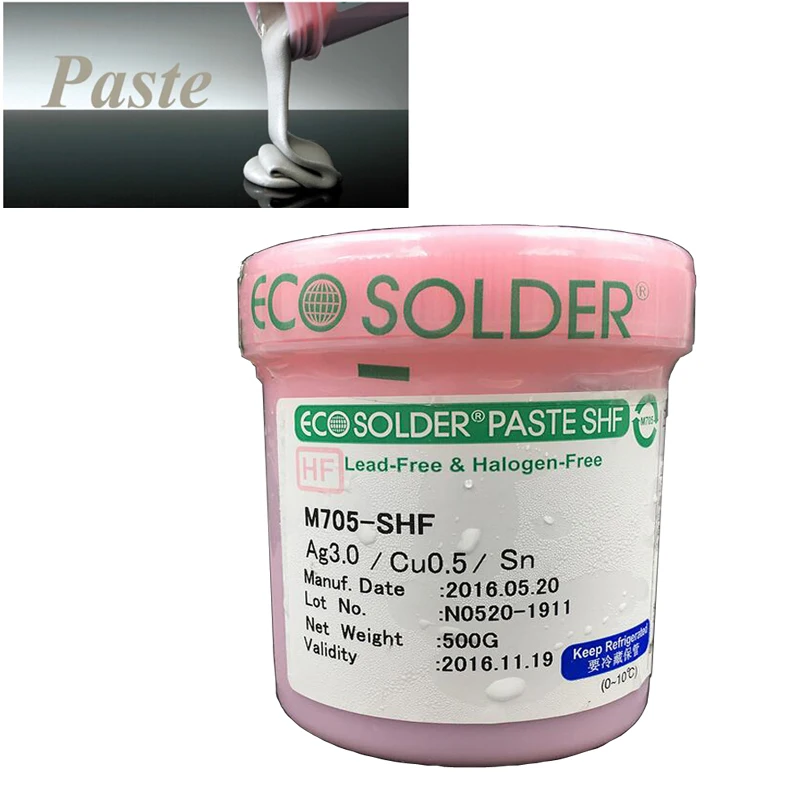

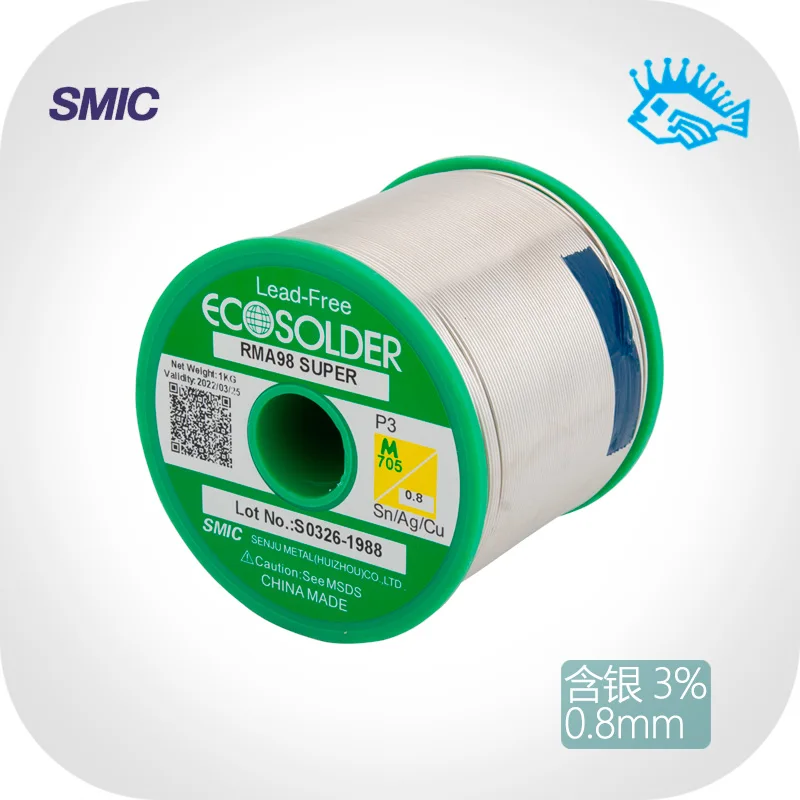

By utilizing advanced techniques and materials, the Eco Solder M705 offers a greener approach to soldering circuit boards. This groundbreaking product not only provides reliable connections but also reduces the environmental impact associated with conventional soldering methods. With its unique composition, the Eco Solder M705 aims to mitigate the use of harmful substances and promote a more sustainable future.

Gone are the days of toxic fumes and hazardous waste produced by traditional soldering processes. With the Eco Solder M705, manufacturers can embrace a cleaner, more responsible approach to circuit board assembly.

Benefits of Eco Solder M705

The Eco Solder M705 offers numerous advantages that set it apart from conventional soldering options. Primarily, it is designed to minimize the release of harmful substances, such as lead and other heavy metals, during the manufacturing process. By utilizing alternative alloys and fluxes, this innovative soldering solution ensures that the final product is not only safe for the environment but also compliant with stringent regulations.

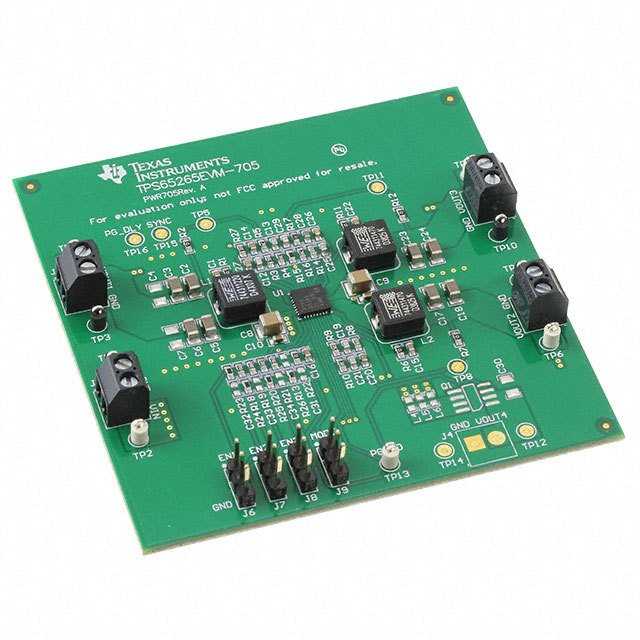

Additionally, the Eco Solder M705 boasts improved heat resistance and overall performance, resulting in higher quality connections and enhanced product durability. This groundbreaking technology opens up new possibilities in the field of circuit board manufacturing, where sustainability and reliability go hand in hand.

The Future of Soldering is Green

A shift towards environmentally friendly alternatives is rapidly gaining momentum across industries, and circuit board manufacturing is no exception. The Eco Solder M705 represents a significant step forward in creating a more sustainable future. By embracing this innovative soldering solution, manufacturers can contribute to the preservation of our planet while maintaining the highest standards of quality and reliability in their products.

Key Specifications of Eco solder m705

In this section, we will discuss the essential features and specifications of the innovative Eco solder m705 product. Designed with environmental sustainability in mind, this high-performance soldering solution offers a range of unique benefits for various applications.

Enhanced Efficiency

One of the standout characteristics of the Eco solder m705 is its exceptional efficiency. With advanced technology and optimized design, this soldering material allows for faster and more precise soldering operations. It enables reduced processing time and increased production output, leading to improved overall efficiency in manufacturing processes.

Eco-friendly Formulation

The formulation of the Eco solder m705 emphasizes environmental responsibility. By utilizing eco-friendly materials and reducing the presence of harmful substances, this product ensures a lower environmental impact compared to traditional soldering solutions. Its composition promotes sustainable manufacturing practices without compromising performance or reliability.

Other notable specifications include:

- Wide temperature range for versatile applications

- Excellent thermal conductivity for efficient heat transfer

- Low melting point for reduced energy consumption

- High tensile strength for durable solder joints

- Minimal solder residue for easy cleanup

In conclusion, the Eco solder m705 offers a compelling set of features and specifications that make it a standout choice for environmentally-conscious soldering applications. Its enhanced efficiency, eco-friendly formulation, and other key specifications ensure optimal performance while minimizing the impact on the environment. With its wide range of applications and high-quality results, the Eco solder m705 sets a new standard in sustainable soldering technology.

Features and Benefits of Eco solder m705

In this section, we will explore the various features and benefits offered by Eco solder m705. This eco-friendly soldering solution provides a range of advantages that make it an ideal choice for electronics manufacturers.

| Features | Benefits |

|---|---|

| 1. Environmentally friendly composition | Minimizes the environmental impact of electronics production |

| 2. High reliability and performance | Ensures the longevity and functionality of soldered connections |

| 3. Excellent thermal conductivity | Facilitates efficient heat transfer during soldering processes |

| 4. Low melting point | Reduces energy consumption and enhances soldering efficiency |

| 5. Compatible with various substrates | Can be used on a wide range of materials, including metals and plastics |

| 6. Non-corrosive formulation | Prevents damage to sensitive components and extends their lifespan |

| 7. Easy to use and handle | Simplifies soldering processes and increases productivity |

| 8. RoHS compliant | Meets the international standards for hazardous substances, ensuring product safety |

Overall, Eco solder m705 offers a comprehensive set of features and benefits that contribute to sustainable and efficient electronics manufacturing. Its environmentally friendly composition, high reliability, excellent thermal conductivity, and compatibility with various substrates make it a top choice for manufacturers looking to reduce their environmental impact while maintaining high-quality soldered connections. Additionally, its low melting point, non-corrosive formulation, ease of use, and RoHS compliance further enhance its appeal in the industry.