Delving into the intricate framework of cutting-edge robotic components reveals a world where precision meets innovation. Imagine a portal to the heart of mechanical marvels, where every cog and circuit intertwines in a symphony of engineering brilliance.

Embark on a journey through the labyrinth of technical insight, where the language of schematics and specifications paints a vivid picture of possibility. Within these pages lies the roadmap to understanding the inner workings of advanced mechanisms, each line a testament to the ingenuity fueling modern automation.

Peering beyond the surface, one discovers a realm where knowledge transforms into power. Here, clarity reigns supreme as cryptic diagrams and cryptic terminology give way to comprehension, empowering enthusiasts and professionals alike to harness the full potential of revolutionary technologies.

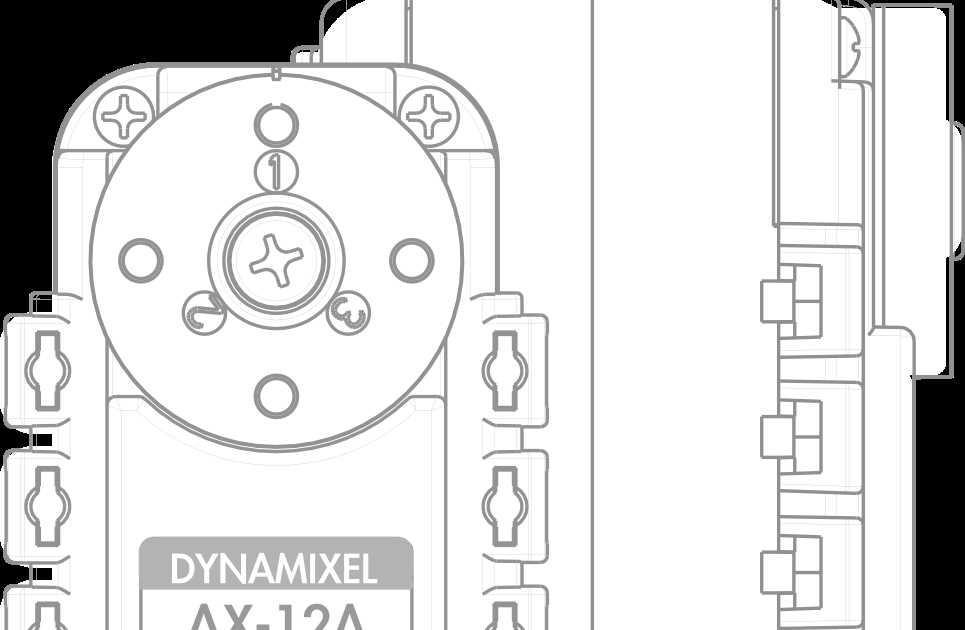

Dynamixel Datasheet Overview

In this section, we provide an insightful exploration into the comprehensive documentation that encapsulates the intricate specifications and functionalities of Dynamixel actuators. Delving into this dossier, we uncover a wealth of information essential for understanding the capabilities and operational nuances of these sophisticated devices.

Functional Specifications

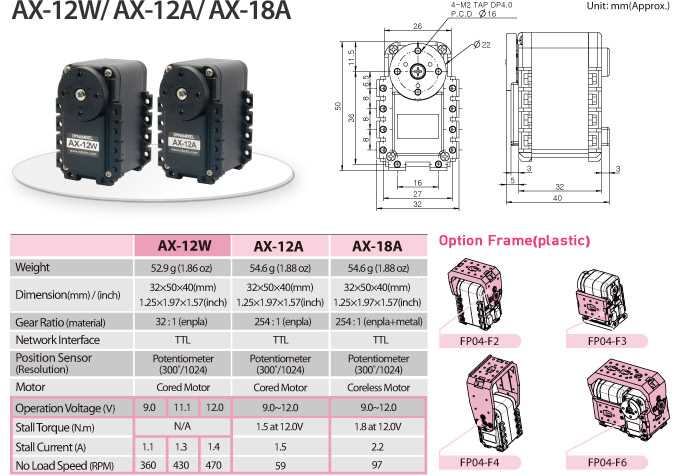

Embarking on our journey through the Dynamixel datasheet, we encounter a meticulous delineation of the functional specifications. This segment elucidates the diverse array of tasks and operations that these actuators can perform, encompassing an extensive spectrum of motion control and sensing functionalities.

Performance Metrics

Beyond the realm of mere functionality lies a realm of performance metrics, meticulously outlined within the datasheet. Here, we delve into the realms of speed, torque, precision, and other performance benchmarks, unraveling the capabilities and limitations of Dynamixel actuators in various operational contexts.

| Parameter | Description |

|---|---|

| Speed | The velocity at which the actuator can perform movements, typically measured in radians per second or degrees per second. |

| Torque | The rotational force exerted by the actuator, often expressed in Newton-meters (Nm) or ounce-inches. |

| Precision | The degree of accuracy and repeatability in positioning and motion control tasks, crucial for applications demanding high precision. |

| Communication Interface | The protocol or interface through which the actuator communicates with external devices, such as UART, RS-485, or CAN. |

Understanding Key Specifications

In delving into the intricacies of this document section, we embark on a journey through the vital elements that compose the essence of the device’s operational blueprint. Herein lies an exploration of the fundamental metrics and descriptors that encapsulate its capabilities and potentialities.

The Core Metrics

At the heart of comprehending the device’s prowess are the core metrics, serving as the bedrock upon which its functionality stands. These metrics, akin to the cardinal points on a compass, provide guidance and orientation in understanding its performance characteristics.

Analyzing Performance Indicators

Delving deeper, we scrutinize the performance indicators that offer insights into the device’s operational efficiency and efficacy. Through the lens of these indicators, we decipher the nuances that define its behavior under various conditions, unraveling the intricacies of its operational dynamics.

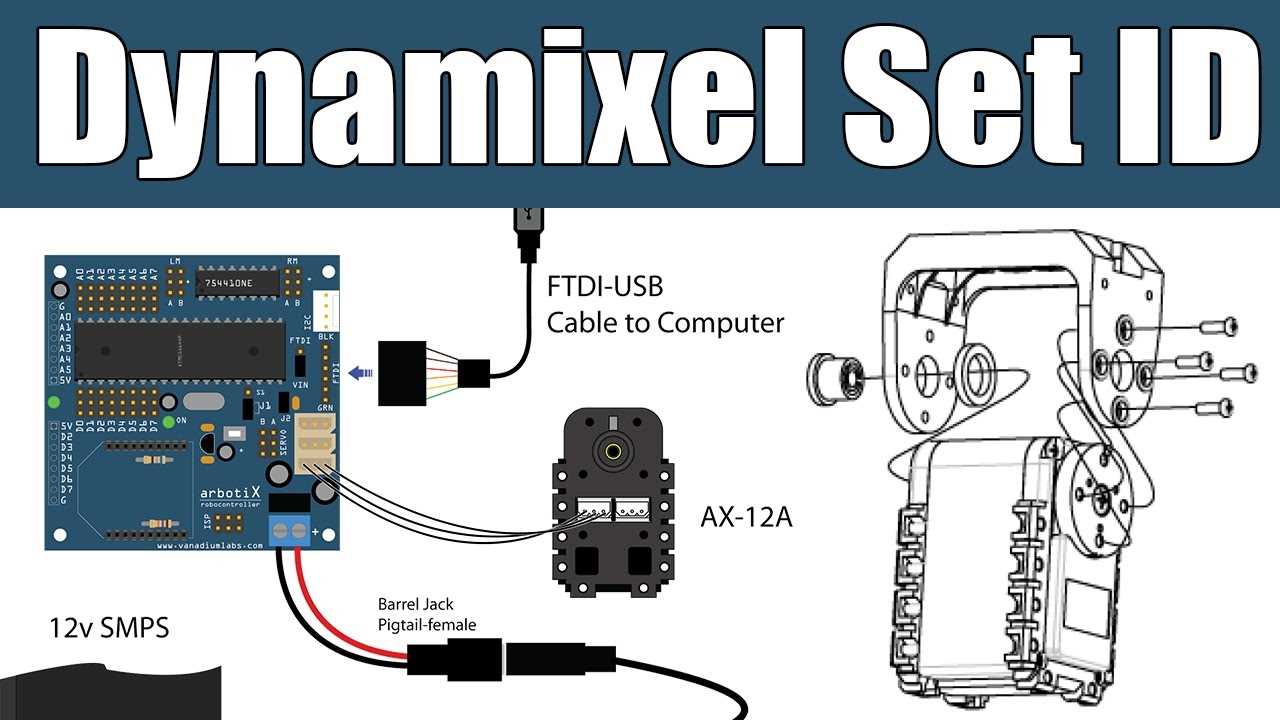

Interpreting Control and Communication Protocols

In this section, we delve into the intricacies of understanding the mechanisms governing the interaction and exchange of information within the system. By dissecting the control and communication protocols, we aim to illuminate the pathways through which commands are transmitted and actions executed, fostering a comprehensive comprehension of the underlying processes.

| Protocol | Description |

|---|---|

| Control Protocol | The control protocol serves as the conduit through which directives are conveyed to the system, orchestrating the execution of desired actions. It establishes a standardized framework for command transmission, ensuring clarity and coherence in communication. |

| Communication Protocol | Operating in tandem with the control protocol, the communication protocol governs the exchange of information between components within the system. Through established conventions and formats, it facilitates seamless interaction, enabling efficient data transmission and reception. |

| Interpretation Strategies | Understanding and interpreting these protocols require a nuanced approach. By deciphering the syntax and semantics embedded within the commands and data structures, one can discern the underlying intentions and functionalities, paving the way for effective utilization of the system. |

By elucidating the nuances of control and communication protocols, we empower users to navigate the intricacies of system operation with confidence and clarity. Through a comprehensive grasp of these fundamental frameworks, users can harness the full potential of the system, realizing their objectives with precision and efficacy.

Optimizing Actuator Performance

Enhancing the efficiency and responsiveness of your actuator system is crucial for achieving optimal performance in various applications. This section delves into strategies and techniques to maximize the capabilities of your actuator, ensuring smooth operation and precise control.

- 1. Fine-tuning Control Parameters:

- 2. Implementing Feedback Mechanisms:

- 3. Employing Efficient Communication Protocols:

- 4. Utilizing Power Management Techniques:

- 5. Employing Dynamic Load Balancing:

Adjusting control parameters allows for meticulous customization of the actuator’s behavior, enabling it to adapt seamlessly to diverse operating conditions. By refining parameters such as gain, damping, and sensitivity, users can tailor the actuator’s response to specific tasks, thereby optimizing overall performance.

Integrating feedback mechanisms, such as position, velocity, and torque sensors, provides real-time data on the actuator’s state and environmental variables. This information facilitates precise control adjustments, enhancing stability, accuracy, and safety during operation. Employing advanced feedback systems can mitigate errors and improve overall system performance.

The choice of communication protocol significantly influences the speed and reliability of data transmission between the controller and actuator. Utilizing high-speed and robust protocols, such as CAN (Controller Area Network) or Ethernet, minimizes latency and ensures timely command execution. Optimal communication protocols are essential for achieving responsive and synchronized actuator performance in complex control systems.

Efficient power management is vital for maximizing the longevity and performance of the actuator system. Implementing energy-efficient components, such as low-power motors and voltage regulators, reduces power consumption and minimizes heat dissipation. Moreover, incorporating smart power management algorithms optimizes energy utilization, prolonging the actuator’s operational lifespan while maintaining peak performance.

Dynamic load balancing distributes the workload evenly across multiple actuators within a system, preventing overload and optimizing resource utilization. By intelligently redistributing tasks based on real-time feedback and environmental conditions, dynamic load balancing enhances system efficiency, responsiveness, and reliability. This approach ensures consistent performance even under varying operational demands.

Tuning Parameters for Optimized Performance

When striving for optimal functionality in the realm of servo motors, understanding and fine-tuning operational parameters is paramount. This section delves into the intricacies of parameter adjustment to enhance efficiency and effectiveness without compromising stability or longevity.

1. Fine-tuning Velocity Profiles

One of the fundamental aspects of optimizing servo motor performance lies in refining velocity profiles. By adjusting parameters related to acceleration and deceleration rates, one can tailor the motion characteristics to suit specific application requirements. Fine-tuning velocity profiles not only improves responsiveness but also mitigates unnecessary wear and tear on mechanical components.

2. Optimizing PID Control

Proportional-Integral-Derivative (PID) control forms the backbone of servo motor operation, regulating position and velocity feedback loops. Optimal PID parameter configuration is essential for achieving desired performance metrics such as responsiveness, stability, and accuracy. By carefully adjusting proportional, integral, and derivative gains, operators can strike a balance between responsiveness and stability, ensuring smooth and precise motion control.

- Adjusting Proportional Gain: Fine-tuning proportional gain influences the system’s response to error, directly impacting speed and stability. Higher proportional gains lead to faster error correction but may introduce oscillations if set too aggressively.

- Tweaking Integral Gain: Integral gain adjustment focuses on eliminating steady-state error by integrating cumulative error over time. However, excessive integral gain can result in overshooting and instability.

- Refining Derivative Gain: Derivative gain adjustment dampens transient response, smoothing out fluctuations in the system. However, excessive derivative gain can amplify noise and induce instability.

By iteratively adjusting these PID parameters and observing system behavior, operators can achieve an optimal balance between responsiveness, stability, and accuracy tailored to the specific requirements of the application.