When it comes to unleashing the full potential of advanced materials, it is crucial to delve into the intricacies of their data sheets. In this section, we embark on a fascinating journey into the realm of cutting-edge LDPE 722 produced by Dow. While we refrain from using specific terms such as “Dow,” “LDPE,” “722,” or “datasheet,” we aim to provide you with an in-depth understanding of this remarkable material and its versatile applications.

Boasting remarkable qualities and unparalleled versatility, this innovative LDPE 722 confidently stands as a pioneering solution in the realm of polymer materials. With its wide-ranging adaptability, this material can seamlessly integrate into a myriad of industries, pushing the boundaries of what was previously thought possible. Whether it’s in manufacturing, packaging, or even engineering, LDPE 722 is set to revolutionize the potential of various applications.

Embodying an array of exceptional attributes, this revolutionary material ensures optimal performance even in the most challenging environments. Its outstanding strength and durability make it a go-to choice for projects requiring admirable reliability, while its remarkable flexibility enables seamless usage in a multitude of settings. Combined with its superior resistance to corrosion and various external factors, LDPE 722 leads the way in providing outstanding solutions for diverse industries.

Furthermore, LDPE 722 boasts an unmatched ability to facilitate sustainable solutions. By prioritizing environmental friendliness, this advanced material aligns with the growing demand for eco-conscious alternatives. Its production process optimizes efficiency while reducing waste, showcasing its commitment to environmental responsibility. With LDPE 722, businesses and individuals can confidently explore new avenues of sustainability without compromising on performance or quality.

As we embark on this immersive exploration of the remarkable potential of LDPE 722, we invite you to join us in unraveling the incredible capabilities and diverse applications of this cutting-edge material. Together, let’s delve into a world where innovation meets sustainability, and endless possibilities unfold.

Dow LDPE 722 Datasheet: Key Features and Specifications

In this section, we will explore the distinctive characteristics and technical specifications of the Dow LDPE 722 polymer. Understanding the unique properties and specifications of this material is essential for those seeking reliable and efficient solutions for various applications.

1. Exceptional Versatility

The Dow LDPE 722 polymer offers an extraordinary range of adaptability, making it suitable for various industries and applications. Its flexibility and versatility enable it to be molded, extruded, or blown into different forms, allowing engineers and manufacturers to create tailored solutions for their specific requirements.

2. Excellent Mechanical Strength and Durability

Utilizing the Dow LDPE 722 polymer ensures exceptional mechanical strength and durability. Its robustness makes it suitable for applications that demand long-lasting performance, including packaging materials, pipes, and various molded products. The material can withstand rigorous conditions without compromising its structural integrity.

3. Impressive Chemical Resistance

One of the key advantages of the Dow LDPE 722 polymer is its remarkable resistance to various chemicals. This property makes it highly suitable for applications where exposure to harsh substances is anticipated, such as chemical storage containers, industrial piping systems, and agricultural film. The material’s resistance helps maintain its integrity and performance over an extended period.

4. Optimal Processability

The Dow LDPE 722 polymer exhibits excellent processability, ensuring efficient and cost-effective manufacturing. Its melt flow properties enable easy processing, requiring minimal energy consumption during extrusion or molding processes. Its compatibility with different processing techniques simplifies production workflows and contributes to overall productivity.

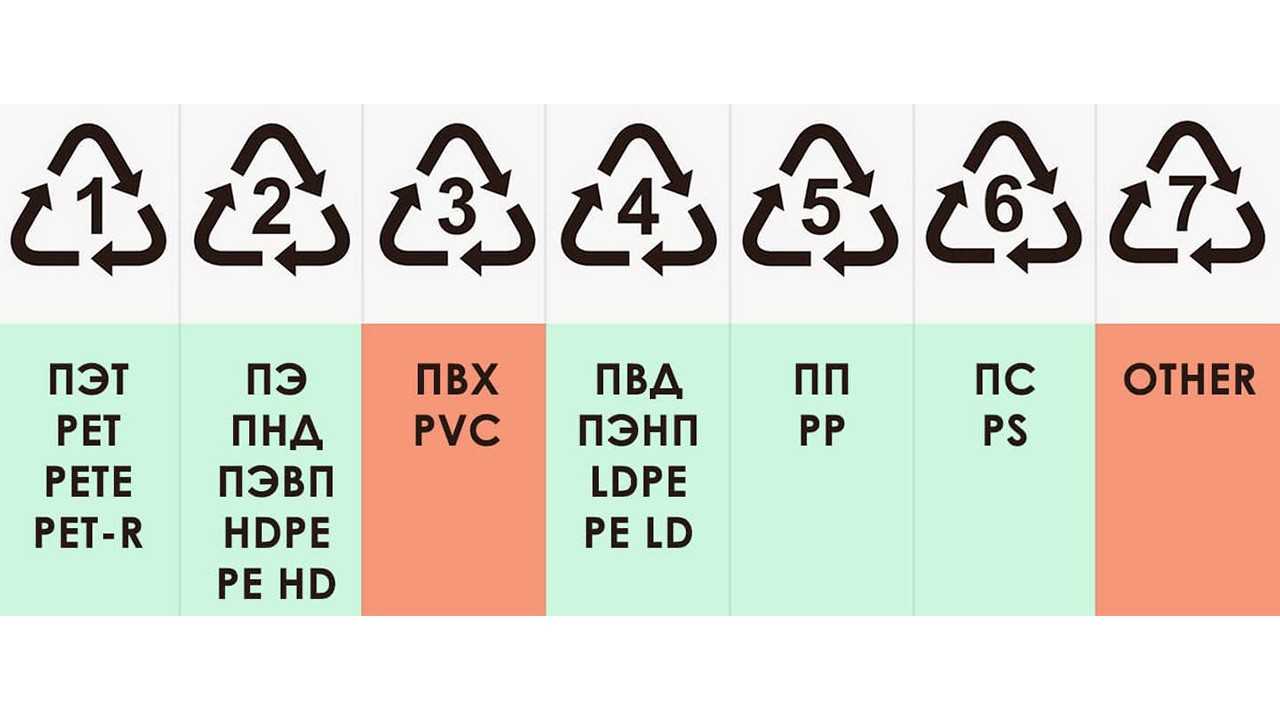

5. Environmental Consciousness

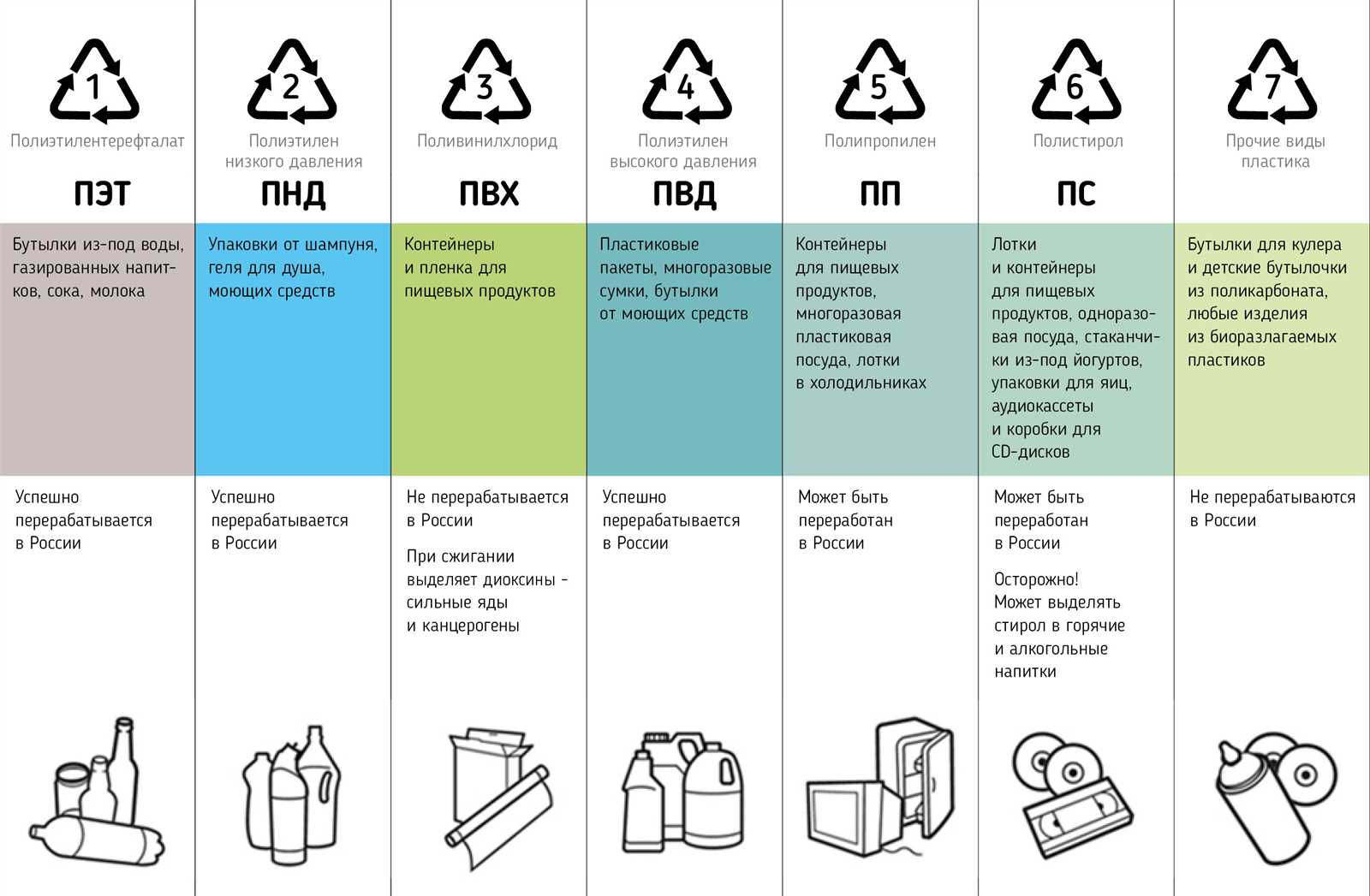

Choosing the Dow LDPE 722 polymer aligns with sustainable practices due to its recyclability and resource efficiency. This material offers a lower environmental impact compared to other alternatives, reducing waste generation and promoting a circular economy. Its unique blend of performance and eco-friendliness is a valuable attribute for environmentally conscious industries.

By understanding the key features and specifications of Dow LDPE 722, manufacturers and engineers can confidently select this polymer for diverse applications. Its versatility, strength, chemical resistance, processability, and eco-friendliness make it a reliable choice for industries seeking high-performance materials.

Overview of Dow LDPE 722: Applications and Benefits

In this section, we will provide an overview of the versatile Dow LDPE 722 and explore its wide range of applications and the numerous benefits it offers. LDPE 722 is a high-quality polymer known for its exceptional performance and reliability in various industries.

Applications

Dow LDPE 722 finds extensive use in packaging, where its properties make it suitable for both flexible and rigid packaging applications. The polymer offers excellent film clarity and toughness, making it ideal for packaging materials used in food, beverages, personal care products, and more. Its exceptional seal strength ensures product integrity and extends the shelf life of packaged goods.

Moreover, LDPE 722 is commonly used in the manufacturing of plastic bags, wraps, and liners, providing reliable protection for a wide range of products. It is also utilized in the production of squeeze bottles, jugs, and containers, thanks to its excellent rigidity and resistance to impact.

Benefits

One of the key benefits of Dow LDPE 722 is its outstanding processability, allowing for easy and efficient manufacturing. It can be processed using various techniques such as blown film extrusion, injection molding, and blow molding. This versatility makes it a preferred choice for many manufacturers.

Additionally, LDPE 722 offers excellent chemical resistance, ensuring that the packaged contents remain unaffected by external factors. It also provides good moisture barrier properties, preventing moisture from penetrating the packaging and safeguarding the integrity of the products.

| Benefits of Dow LDPE 722: |

|---|

| High film clarity |

| Toughness and durability |

| Exceptional seal strength |

| Good rigidity and impact resistance |

| Outstanding processability |

| Chemical resistance |

| Moisture barrier properties |

In conclusion, Dow LDPE 722 is a highly versatile polymer that finds application in various industries, particularly in packaging. Its exceptional properties, including film clarity, toughness, seal strength, and resistance to impact, make it a reliable choice for manufacturers. Furthermore, its excellent processability and chemical resistance further enhance its usability, ensuring the longevity and quality of the packaged products.

Dow LDPE 722: Technical Data and Performance Characteristics

In this section, we will explore the technical data and performance characteristics of the Dow LDPE 722. Understanding the various aspects of this material is crucial for optimizing its application in different industries.

General Overview

The Dow LDPE 722 is a versatile polymer that offers a wide range of benefits in various applications. It possesses exceptional flexibility, excellent impact resistance, and exceptional processability, making it suitable for multiple industries.

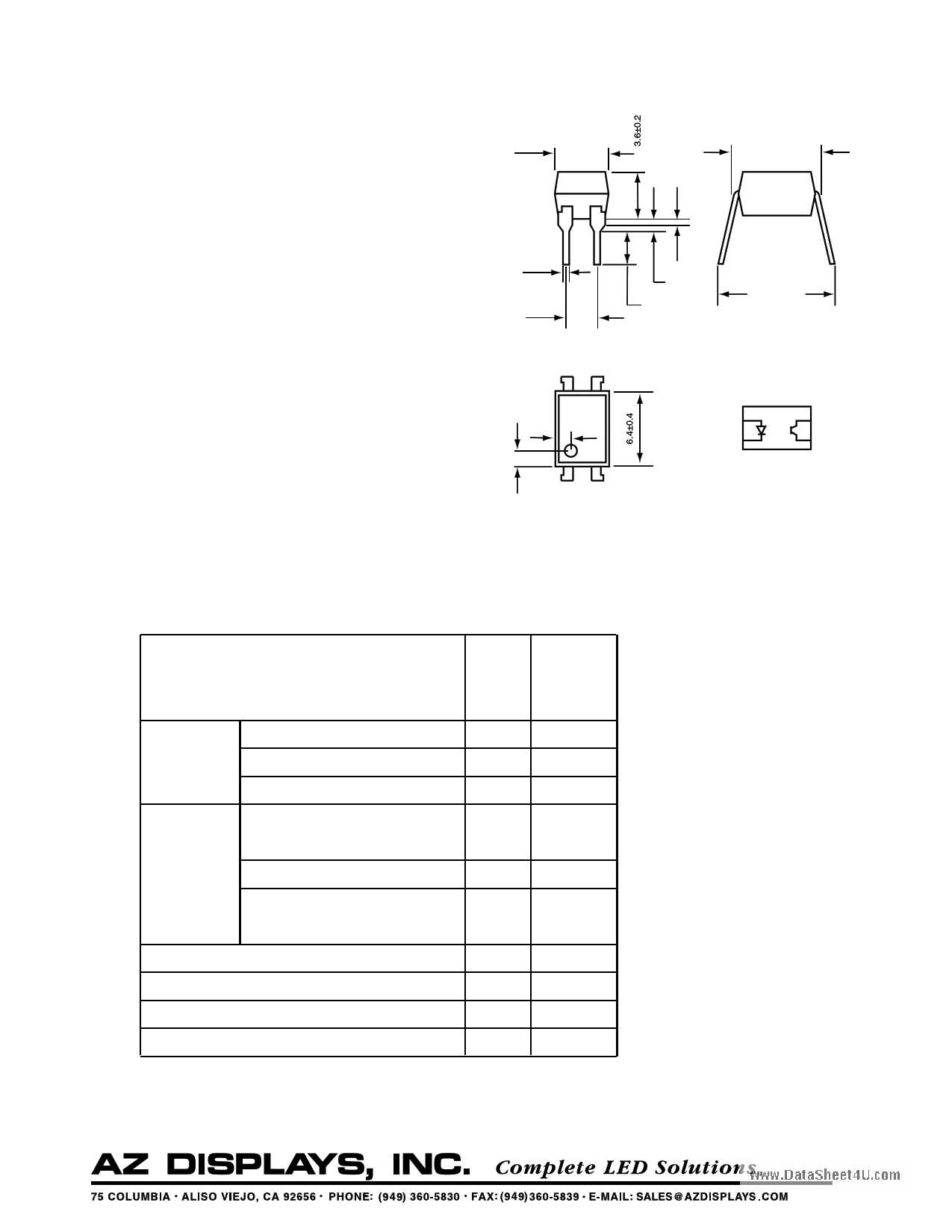

Physical Properties

The physical properties of Dow LDPE 722 play a significant role in determining its performance characteristics. With its high tensile strength, low density, and remarkable elongation at break, this material exhibits outstanding durability and can withstand demanding conditions.

Moreover, the melt flow rate (MFR) of Dow LDPE 722 is carefully engineered to ensure smooth and efficient processing. The low MFR allows for improved control during extrusion, injection molding, and blow molding processes.

Performance Characteristics

One of the notable performance characteristics of Dow LDPE 722 is its excellent chemical resistance. This material is known for its ability to withstand exposure to various chemicals, including acids, bases, and solvents, without compromising its integrity.

Furthermore, the Dow LDPE 722 demonstrates exceptional heat resistance, making it suitable for applications where temperature fluctuations may occur. Its excellent thermal stability ensures reliable performance even in challenging environments.

The material also exhibits superior electrical insulation properties, making it an ideal choice for electrical and electronic applications. Its insulating properties help prevent electrical leakage and ensure the safety and reliability of the equipment.

Additionally, Dow LDPE 722 offers enhanced UV resistance, protecting the material and the products made from it from the damaging effects of UV radiation. This characteristic prolongs the lifespan of the material, making it suitable for outdoor applications.

In conclusion, Dow LDPE 722 is a high-performance polymer that possesses exceptional physical properties and offers numerous benefits in various applications. Its flexibility, impact resistance, and processability, combined with its chemical resistance, heat resistance, electrical insulation properties, and UV resistance, make it a versatile material for a wide range of industries.