Unveiling the essence of a renowned polymer’s intricate composition, this segment delves into the technical intricacies of a material synonymous with precision and reliability. Without explicitly naming the compound, this discourse navigates through the labyrinth of its formulation and properties, offering insights into its multifaceted utility across diverse industries.

Embarking on a journey through the fabric of innovation, we dissect the intricacies of a polymer renowned for its versatility and resilience. Within the following paragraphs, we unravel the enigmatic blend of constituents that endow this substance with its remarkable characteristics, laying bare its potential for myriad applications.

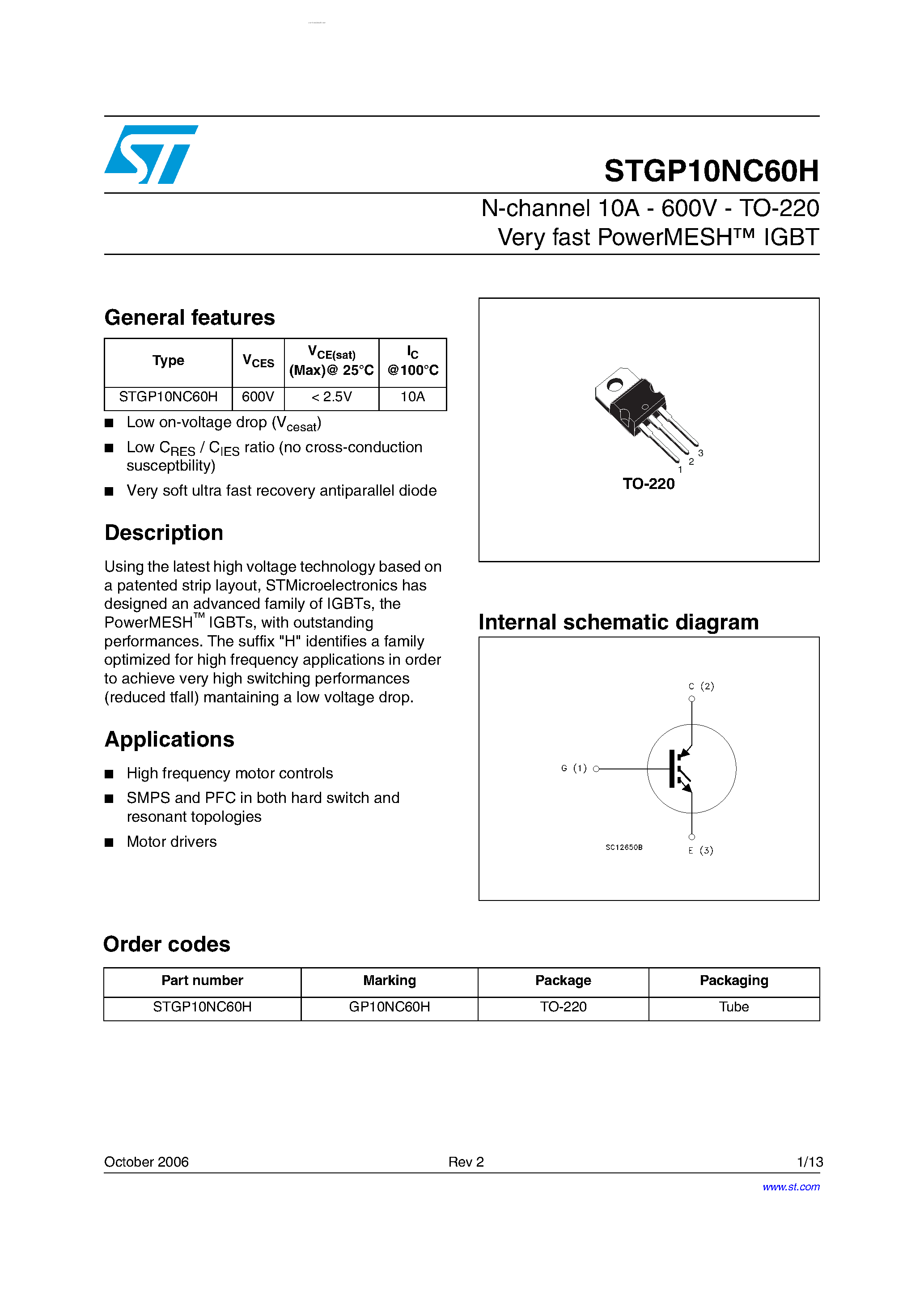

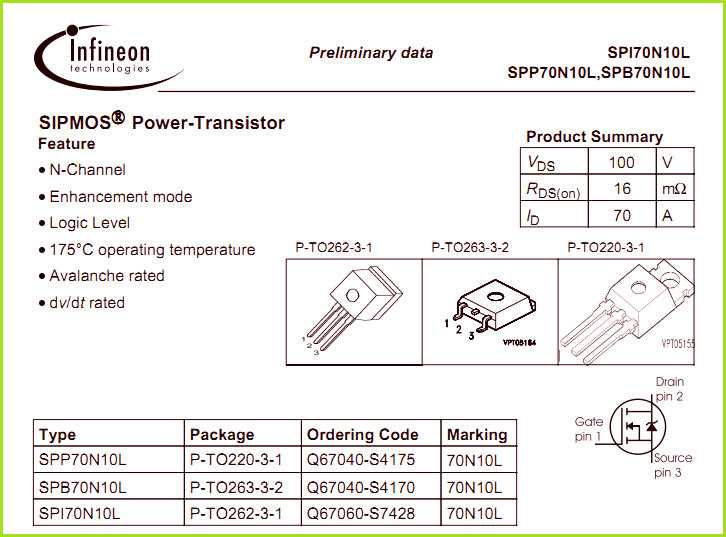

Peering into the molecular tapestry of this compound, we uncover the secrets that render it indispensable in engineering and manufacturing realms. Without divulging its specific nomenclature, we scrutinize the data sheet that serves as a roadmap to its performance metrics, heralding a deeper understanding of its capabilities and limitations.

Understanding Delrin 100 nc010: Properties and Applications

In this section, we delve into the characteristics and potential uses of a polymer renowned for its versatile attributes. Exploring the myriad of features and practical uses, we aim to elucidate the essence of this material, shedding light on its applicability across diverse industries and contexts.

Key Attributes

- Physical Characteristics

- Mechanical Strengths

- Chemical Resistance

- Thermal Stability

- Electrical Properties

Examining its physical, mechanical, chemical, thermal, and electrical traits reveals a multifaceted material capable of withstanding various environmental conditions and operational demands. Through a comprehensive analysis, we uncover the intrinsic qualities that underpin its utility.

Applications

- Engineering Components

- Automotive Parts

- Consumer Goods

- Medical Devices

- Manufacturing Tools

Furthermore, we explore the expansive realm of applications wherein this polymer finds integration. From precision engineering to everyday consumer products, its adaptability manifests in a plethora of industries, fostering innovation and efficiency.

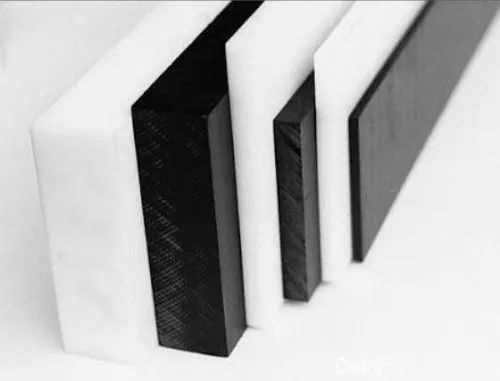

Exploring the Mechanical Properties of Delrin 100 nc010

Investigating the Structural Characteristics

In this section, we delve into the intrinsic qualities and structural composition of a polymer renowned for its resilience and versatility. By scrutinizing its molecular arrangement and intermolecular forces, we aim to unravel the intricate mechanisms underlying its mechanical behavior.

Unveiling Performance Under Stress

Here, we embark on a journey to unveil how this material responds to external forces and pressures. Through meticulous testing and analysis, we uncover its ability to withstand various loads and deformations, shedding light on its mechanical robustness and endurance.

Exploring Flexibility and Rigidity

This segment delves into the dichotomy of flexibility and rigidity exhibited by the material, elucidating its capacity to adapt to dynamic environments while maintaining structural integrity. By examining its modulus of elasticity and yield strength, we gain insights into its diverse applications across industries.

Understanding Friction and Wear Resistance

Here, we delve into the material’s interaction with external surfaces, elucidating its frictional characteristics and resistance to wear over time. Through empirical observations and theoretical models, we unravel the factors governing its tribological performance, paving the way for enhanced durability in real-world applications.

Assessing Temperature Stability

In this section, we explore how the material responds to fluctuations in temperature, assessing its thermal expansion coefficients and heat resistance. By understanding its behavior across a spectrum of temperatures, we discern its suitability for applications in both extreme and ambient conditions.

Evaluating Impact Strength

Finally, we scrutinize the material’s ability to withstand sudden impacts and shocks, evaluating its impact strength and resilience. Through controlled experiments and simulations, we delineate the mechanisms underlying its ability to absorb energy and mitigate damage, thereby ensuring long-term reliability in demanding environments.

Applications of Polyoxymethylene Material in Various Industries

In this section, we explore the diverse utilization of a versatile polymer in numerous sectors, showcasing its adaptability and significance in modern manufacturing.

Automotive Industry Implementations

One sector that extensively employs this resilient material is the automotive industry, where it finds application in various components ranging from gears and bearings to fuel systems. Its high strength, low friction, and resistance to wear make it an ideal choice for enhancing the durability and performance of automotive parts.

Medical Device Utilization

Another significant domain benefiting from the properties of this polymer is the medical sector. Here, it serves in the production of surgical instruments, orthopedic implants, and drug delivery devices. Its biocompatibility, coupled with its ability to withstand sterilization processes, makes it indispensable in ensuring the safety and efficacy of medical equipment.

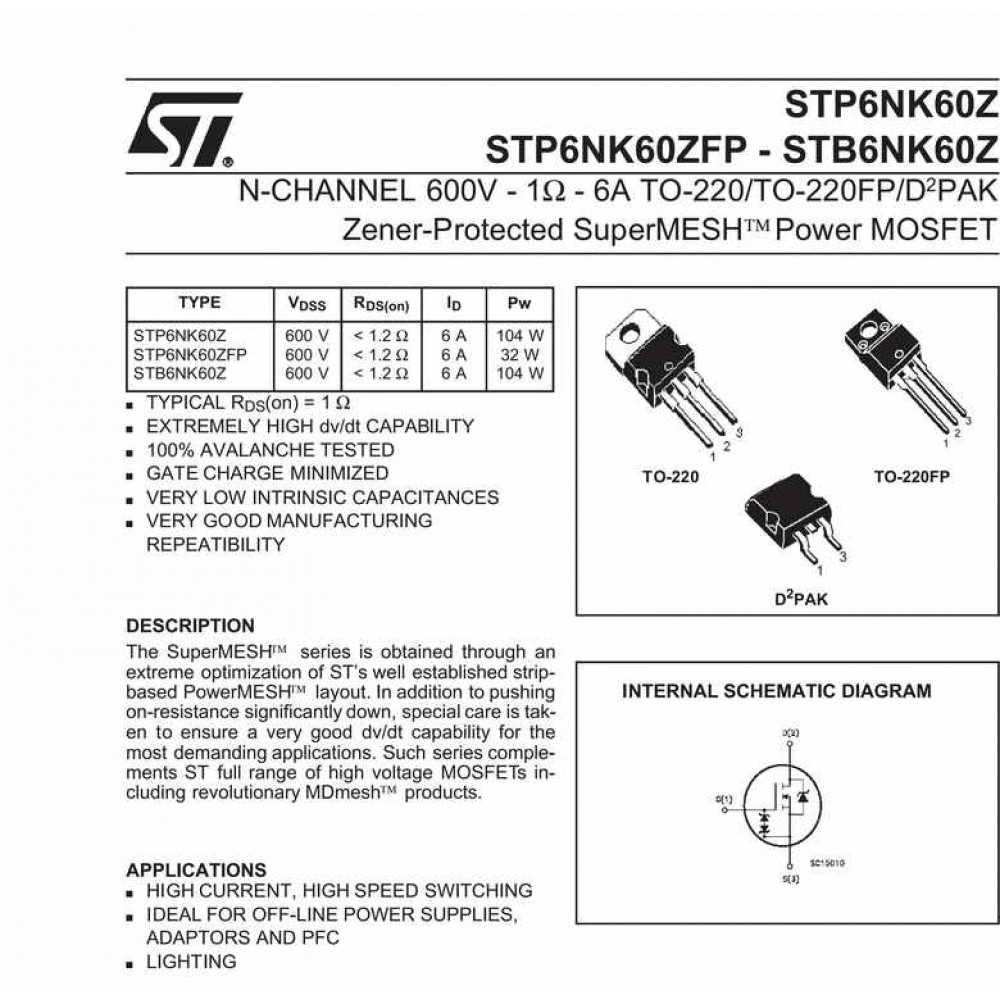

Chemical Resistance and Durability of Delrin 100 nc010

In this section, we delve into the resilience and robustness exhibited by the material referred to as Delrin 100 nc010 in the face of various chemical exposures. Exploring its ability to withstand corrosive environments and maintain structural integrity under diverse conditions is pivotal for understanding its suitability across industrial applications.

Resilience Against Chemical Challenges

Examining the material’s resilience against chemical agents reveals its capacity to endure harsh environments without compromising its structural integrity. Whether facing acidic compounds, alkalis, or solvents, this material demonstrates remarkable resistance, ensuring longevity and reliability in demanding settings.

Durability in Varied Conditions

The durability of this material underpins its versatility across industries, showcasing its ability to maintain performance even when subjected to fluctuating temperatures, pressure variations, and exposure to challenging chemicals. Its enduring nature instills confidence in its applicability in critical systems where reliability is paramount.