Have you ever wondered how seemingly simple devices can have a profound impact on the functioning of complex systems? Imagine a world where signals need to be controlled, circuits need to be switched, and operations need to be synchronized. This is where the fascinating realm of electromechanical switching comes into play.

In the realm of electrical engineering, there exists an essential component that can make or break the efficiency of countless devices and systems: the datasheet relay. This ingenious device serves as a bridge between the digital and physical world, allowing seamless control over electrical currents with precision and reliability.

At its core, a datasheet relay can be seen as a versatile and powerful switch capable of controlling high-voltage circuits or tiny currents with utmost accuracy. Through its electromagnetism-based mechanism, this lesser-known hero of the electronics world offers the ability to isolate, amplify, or redirect signals in a variety of applications, ranging from industrial automation to consumer electronics.

Imagine a world where complex systems can be controlled by a simple click, where electrical signals can be flawlessly directed and transformed at will. Unveiling the secrets behind the datasheet relay is a journey through the wonders of electromechanical engineering, shedding light on the intricacies of this unsung hero that powers our modern world.

An Overview of Datasheet Relay: Key Features and Applications

In this section, we provide a comprehensive overview of the Datasheet Relay, highlighting its essential characteristics and diverse applications. An understanding of the Datasheet Relay’s functionality and versatility is crucial for professionals seeking to harness its power in various industries.

Essential Features: The Datasheet Relay exhibits a range of remarkable attributes that contribute to its widespread popularity and usefulness. With its highly reliable and efficient performance, this cutting-edge electronic device enables seamless communication and control between different components of a system. Its ability to rapidly switch between states, coupled with exceptional signal amplification capabilities, empowers businesses to optimize their operations and enhance overall productivity.

Versatile Applications: The Datasheet Relay finds application in numerous industries, thanks to its adaptability and versatility. From telecommunications to industrial automation, from automotive systems to renewable energy solutions, this advanced relay plays a crucial role in facilitating seamless integration and efficient functioning of complex systems. Its ability to handle high voltage and current levels, coupled with its compact form factor, makes it an ideal choice for various demanding applications.

Moreover, the Datasheet Relay’s robust design and high tolerance for extreme environmental conditions enable its deployment in critical sectors such as aerospace and defense. The relay’s capability to handle rapid switching frequencies and its compatibility with different communication protocols further extend its usability in diverse engineering projects.

In conclusion, the Datasheet Relay offers a multitude of advantages and applications across various industries. Its impressive features and adaptability make it a vital component for establishing seamless communication and control within complex systems. As technology continues to advance, the Datasheet Relay will undoubtedly play an even more significant role in shaping the future of multiple sectors, driving innovation and efficiency.

Understanding the Technical Specifications of Datasheet Relay

Relays are essential components in many electronic systems, serving as switches that enable the control of high-power circuits using low-power signals. To fully comprehend the capabilities and limitations of a relay, it is crucial to delve into the technical specifications provided in its datasheet.

Analyzing Contact Ratings

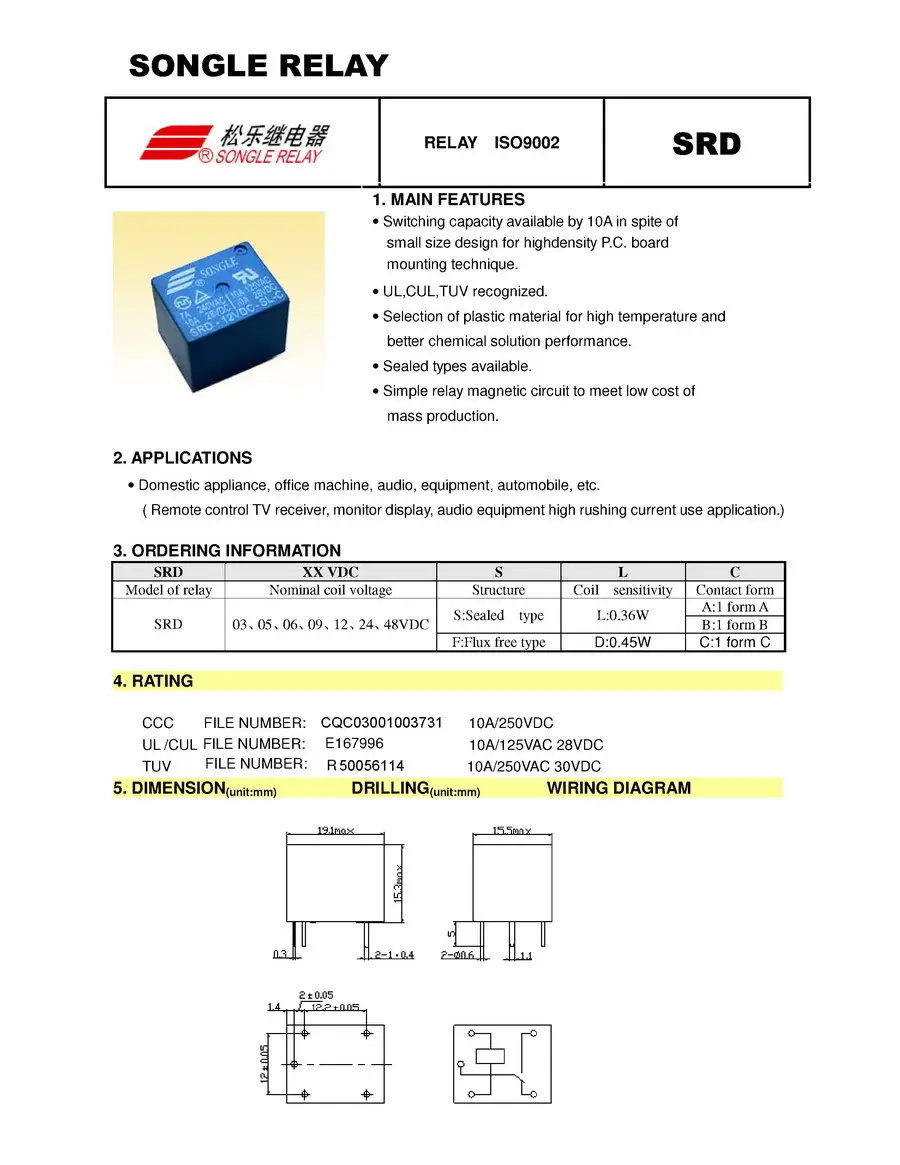

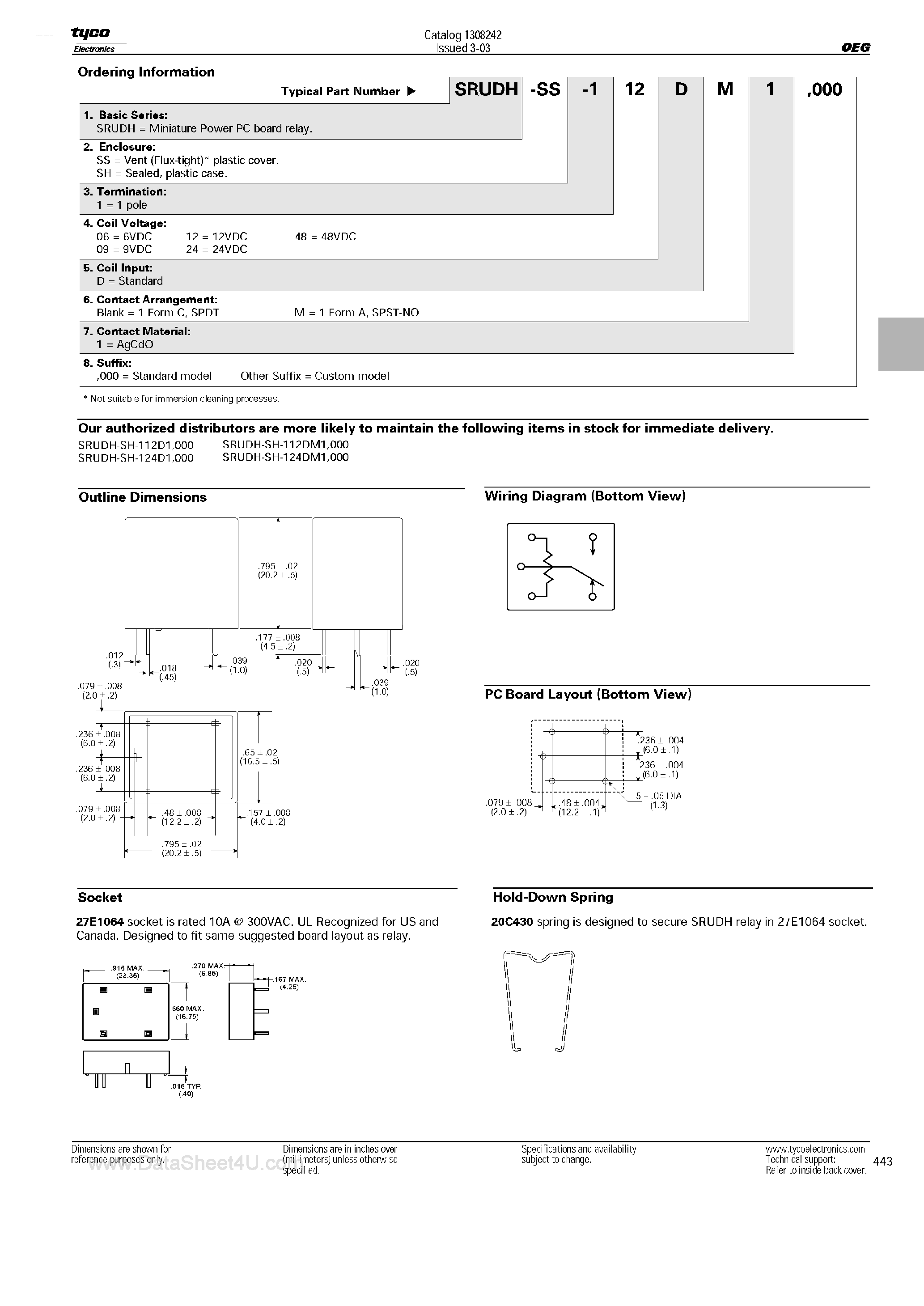

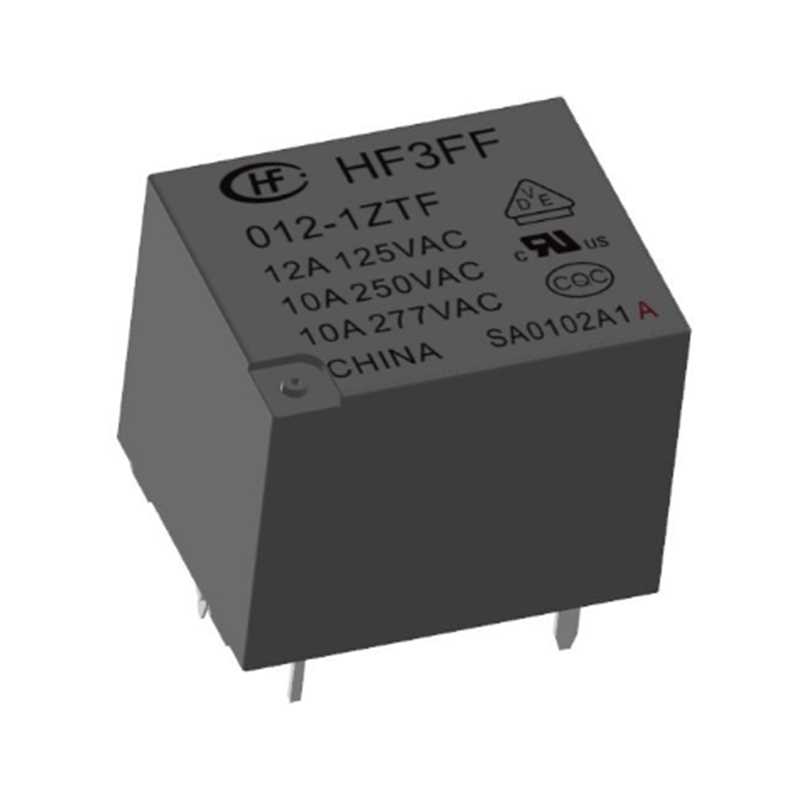

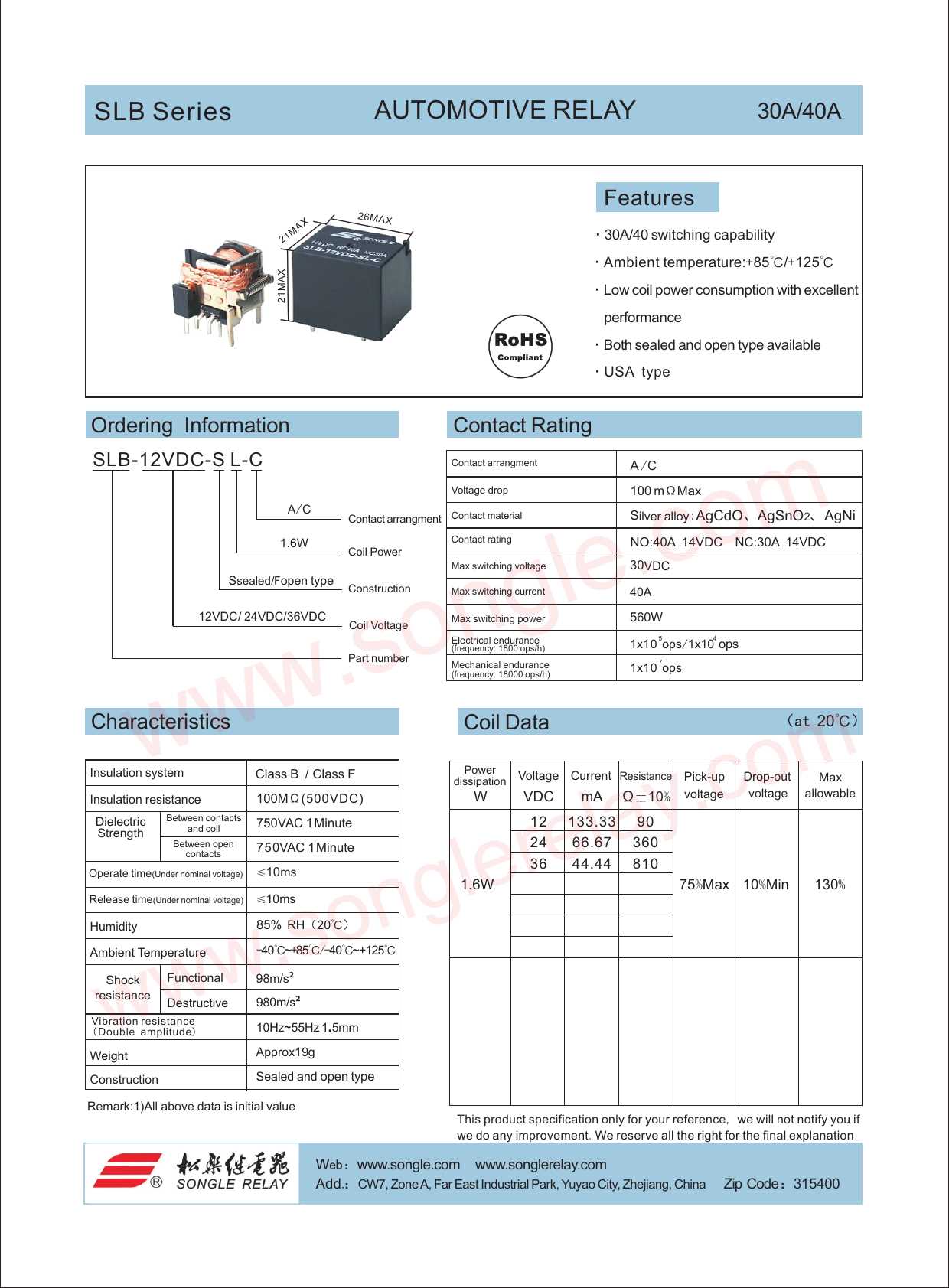

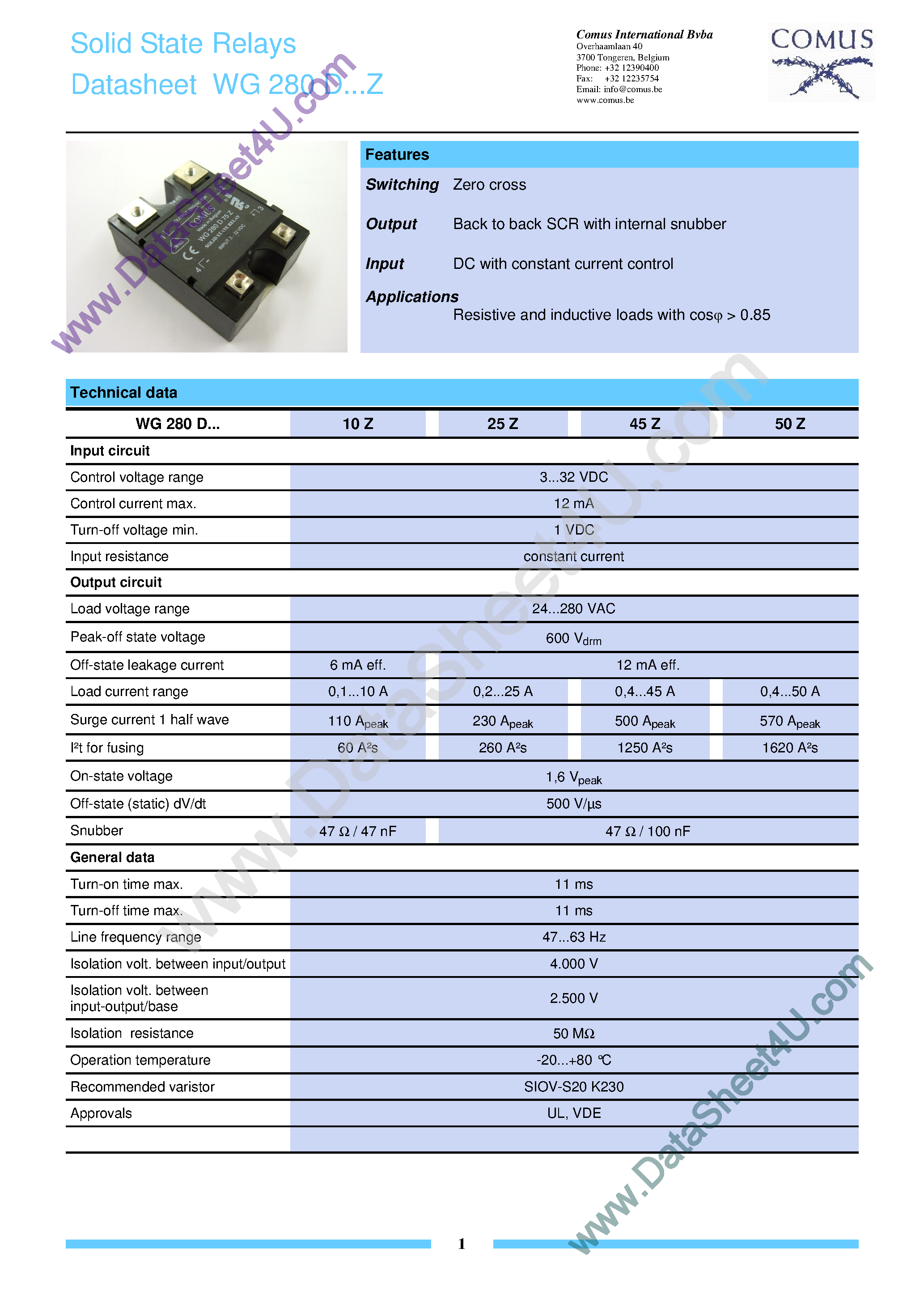

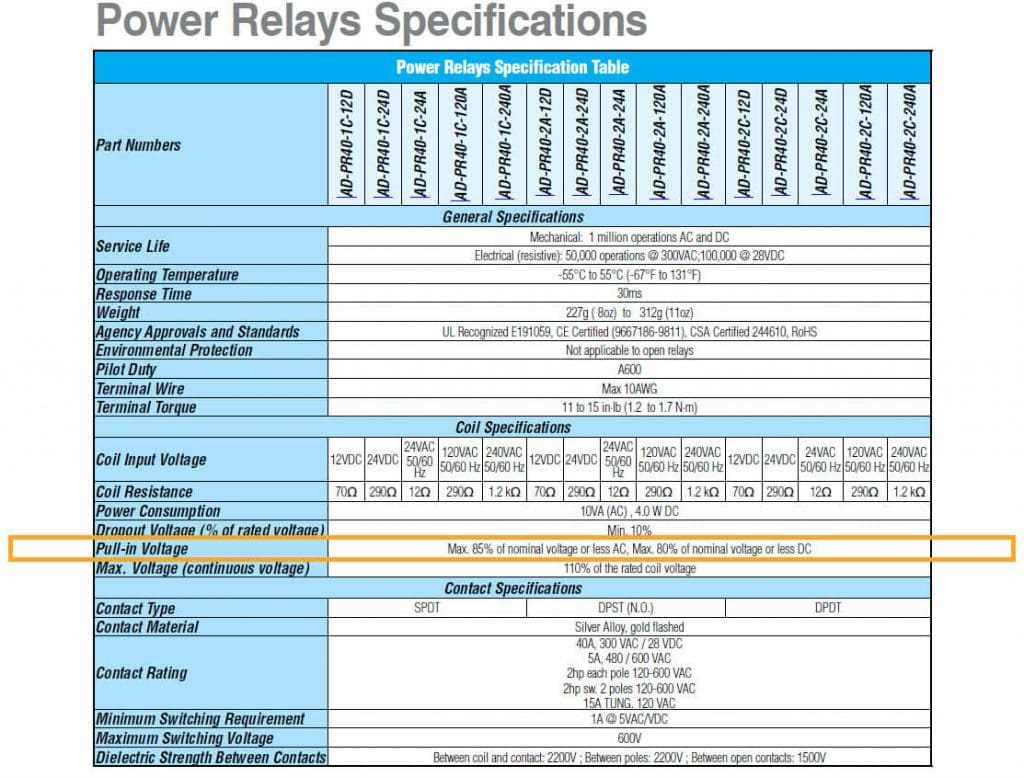

One of the primary aspects to consider when examining a relay’s datasheet is the contact ratings. The contact ratings refer to the maximum current and voltage that the relay’s contacts can handle without compromising their functionality or durability. These ratings provide guidance on the suitability of the relay for specific applications, allowing engineers to choose a relay that can safely handle the expected power levels.

Moreover, understanding the different types of contact ratings, such as resistive, inductive, and capacitive, is essential for accurate relay selection. Each rating indicates the relay’s ability to handle different types of loads, ensuring reliable operation and preventing potential damage to the contacts.

Interpreting Coil Parameters

Aside from contact ratings, coil parameters are another vital aspect of a relay’s technical specifications. These parameters provide information about the relay’s coil, which is responsible for energizing the relay and enabling the switching action.

The coil voltage is an essential parameter that determines the minimum and maximum voltages required to activate the relay. Understanding the coil voltage range is crucial to ensure compatibility with the designed control circuit and power supply limitations.

Additionally, the coil resistance, measured in ohms, plays a significant role in determining the power consumption and heat dissipation of the relay. It is important to consider this parameter to guarantee optimal performance while preventing overheating and energy waste.

Other coil parameters, such as nominal power consumption and pick-up/drop-out voltages, further provide valuable insights into the operational characteristics of the relay. By carefully analyzing these parameters, engineers can select the most suitable relay for their specific application requirements.

In conclusion, understanding the technical specifications of a datasheet relay is crucial for successful relay selection and proper utilization in electronic systems. By examining the contact ratings and coil parameters, engineers can make informed decisions to ensure reliable and efficient performance while avoiding potential risks or malfunctions.

Exploring the Technical Parameters

In this section, we will delve into the various technical parameters that are essential for understanding the functionality and performance of a relay. By examining these parameters, we can gain a comprehensive understanding of how the relay operates and how it can be effectively utilized in different scenarios.

The Power Handling Capacity

One of the fundamental parameters to consider when analyzing a relay is its power handling capacity. This parameter determines the maximum amount of power that the relay can safely handle without causing any damage or malfunction. It is crucial to select a relay with a power handling capacity that matches the requirements of the specific application to ensure reliable and efficient operation.

The Contact Ratings

Another important aspect to consider is the contact ratings of the relay. The contact ratings provide information about the maximum voltage and current that the relay contacts can withstand. Understanding these ratings is crucial in determining whether the relay is suitable for a particular application. It is important to select a relay with contact ratings that can handle the expected voltage and current levels to ensure safe and reliable operation.

Additionally, there are several other technical parameters to explore, such as the coil voltage, coil resistance, contact configuration, and switching time. These parameters play a crucial role in determining the compatibility and performance of the relay in various applications.

In conclusion, by understanding and analyzing these technical parameters, we can make informed decisions when selecting a relay for a specific application. This knowledge allows us to choose the most suitable relay that will meet the requirements and ensure optimal performance.

How to Properly Use and Install Datasheet Relay in Your Circuit

Relays are an essential component in many electrical circuits, providing a reliable way to control the flow of electricity. Understanding how to correctly use and install a datasheet relay in your circuit is crucial for ensuring the efficiency and safety of your electrical system.

Relay Functionality

Before delving into the specifics of using and installing a datasheet relay, it is important to understand its basic functionality. A relay acts as a switch that can be controlled by an external electrical signal. When the signal is present, the relay’s internal mechanism, consisting of electromagnetic coils, switches on or off the circuit. This allows the flow of current to be redirected or cut off as required, providing control over the connected devices or systems.

Proper Usage and Installation

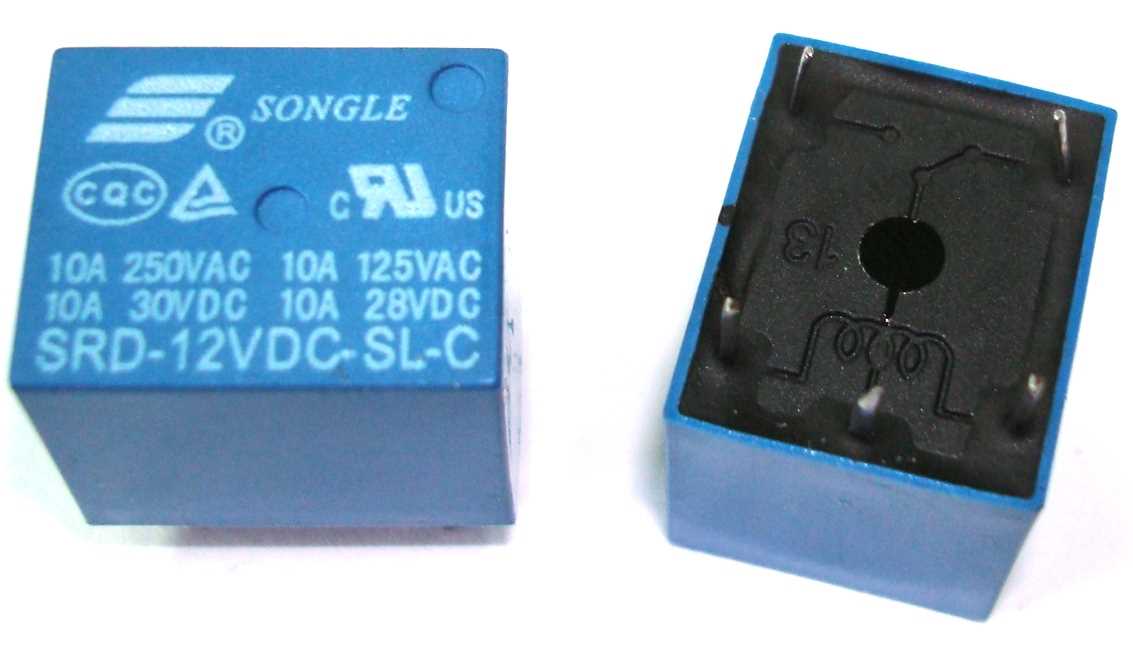

When incorporating a datasheet relay into your circuit, several key considerations need to be taken into account. Firstly, it is essential to carefully review the relay’s datasheet, as it contains critical information about its electrical ratings, pin configuration, and operational limitations. This information will guide you in choosing the appropriate relay for your circuit.

Once the relay selection is done, proper wiring is of utmost importance. Ensuring that the relay’s contacts are correctly connected to the circuitry components guarantees the intended functionality. It is recommended to use a reliable and robust method for connecting wires, such as soldering or crimping, to prevent loose connections that may result in erroneous operation or even safety hazards. Additionally, paying attention to the orientation of the relay and aligning it correctly with the circuit layout will prevent any potential complications during installation.

| Pin Configuration | Description |

|---|---|

| Coil | The pins responsible for energizing the relay’s coil, controlling its switching functionality. |

| Normally Open (NO) | The pins normally not connected, but close the circuit when the relay is energized. |

| Normally Closed (NC) | The pins normally connected, but open the circuit when the relay is energized. |

Lastly, it is advisable to test the relay’s functionality before fully integrating it into the circuit. This can be done by applying a suitable electrical signal to the coil pins and observing the switching behavior of the relay’s contacts. Verifying proper operation in this manner ensures that any potential issues are identified and rectified before the relay is put into regular use.

By following these guidelines for proper usage and installation, you can effectively incorporate a datasheet relay into your circuit, enabling precise control and protection of your electrical system.

Installation Guide and Best Practices

In this section, we will discuss the essential steps and recommended techniques for installing and setting up the device, ensuring its optimal performance and longevity. Proper installation is crucial to maximize the efficiency and reliability of the equipment. Following the best practices outlined here will help to achieve seamless operation and avoid potential issues down the line.

Pre-Installation Considerations

Before beginning the installation process, it is important to assess the environment and requirements of the relay. This includes the identification of suitable mounting locations, consideration of temperature and humidity conditions, and evaluation of power and signal requirements. Adequate planning and preparation will contribute to a smooth installation process.

Installation Steps

1. Mounting: Securely fasten the relay in the designated location using appropriate hardware to ensure stability and vibration resistance.

2. Wiring: Connect the necessary power and signal cables according to the provided specifications and instructions. Follow proper wire routing techniques to avoid interference and minimize the risk of damage.

3. Grounding: Establish a reliable grounding connection to prevent electrical faults and ensure safety. Consult the device documentation for grounding requirements specific to your installation.

4. Configuration: Properly configure the relay settings according to the desired application and operational parameters. Refer to the user manual for detailed instructions on customization and setup.

5. Testing and Verification: Before putting the relay into operation, perform thorough testing and verification to ensure all connections are secure and functioning correctly. Validate the performance of the relay through various test scenarios.

6. Regular Maintenance: Implement a regular maintenance schedule to keep the relay operating at its best. This may include cleaning, inspection, and, if necessary, recalibration. Adhering to the manufacturer’s recommended maintenance guidelines will extend the lifespan of the device.

By following these installation best practices, users can achieve a successful and efficient setup of the relay, promoting reliable and uninterrupted operation over an extended period of time.