Explore the cutting-edge features and exceptional performance of a revolutionary material known for its unparalleled efficacy and versatility: the Carboline 891 datasheet. This extraordinary substance has been meticulously designed to meet the highest industry standards and cater to a wide range of applications. With its unrivaled capabilities and superior quality, it has become a go-to choice for professionals across various sectors.

Experience the power of Carboline 891, an innovative solution that embodies strength, durability, and reliability. This remarkable product boasts an array of exceptional properties that ensure its efficiency and effectiveness in the field. From its impressive endurance in harsh environments to its remarkable resistance against corrosion and wear, Carboline 891 provides a solid foundation for success.

Prepare to be fascinated by the multifaceted nature of Carboline 891, as it proves to be a dynamic performer in any given task. With its remarkable tensile strength and exceptional flexibility, this material can effortlessly adapt to diverse project requirements, guaranteeing optimal performance and longevity. Whether it’s protecting critical infrastructure or enhancing the durability of everyday objects, Carboline 891 is the epitome of reliability.

Unleash your creativity and explore the endless possibilities that Carboline 891 offers. Deploy its exceptional features and remarkable capabilities to revolutionize your projects and exceed expectations. With its state-of-the-art composition and unparalleled functionality, Carboline 891 datasheet is the ultimate game-changer that will take your ventures to new heights.

Main Characteristics and Properties of Carboline 891

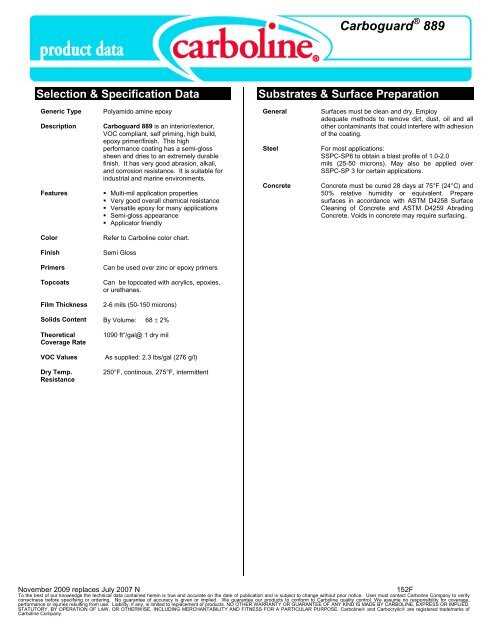

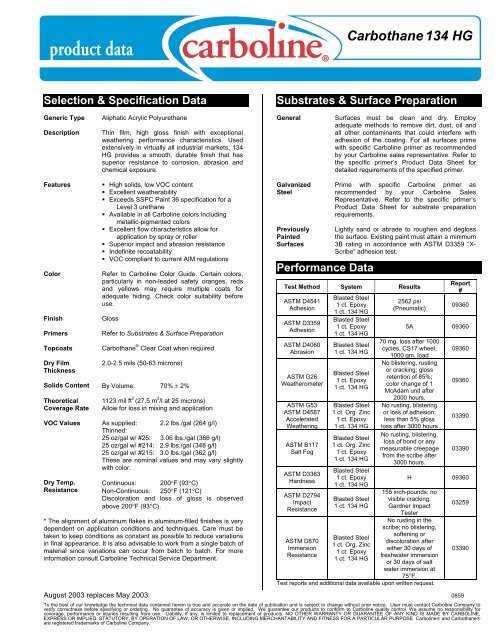

In this section, we will explore the key features and attributes of the remarkable substance known as Carboline 891. This product exhibits a range of unique properties and exceptional characteristics that contribute to its effectiveness and versatility in various applications.

Carboline 891 possesses outstanding qualities, making it highly desirable for numerous industries. With its exceptional performance, this substance proves to be a reliable solution for a wide range of projects. Its remarkable attributes facilitate the achievement of desired results and enhance the overall efficiency and durability of various structures.

One noteworthy aspect of Carboline 891 is its impressive chemical resistance. This substance exhibits an exceptional ability to withstand various corrosive agents, including acids, alkalis, and solvents. It provides long-lasting protection and effectively preserves surfaces, even in harsh environments. The high resistance to chemical degradation ensures the longevity and reliability of structures coated with Carboline 891.

Furthermore, this product demonstrates excellent adhesion properties, allowing it to adhere firmly to different substrates. The strong bond created by Carboline 891 provides increased durability and resistance to abrasion, impact, and weathering. This feature ensures the longevity and integrity of coated surfaces, even in demanding conditions.

The flexibility of Carboline 891 is another remarkable characteristic worth highlighting. This substance exhibits superior flexibility, enabling it to withstand structural movement and accommodate expansion and contraction. It remains intact and does not crack or peel, ensuring long-lasting protection and reducing the need for frequent maintenance or repairs.

Additionally, Carboline 891 offers outstanding fire protection properties. This substance acts as an effective barrier against flames and heat, significantly reducing the spread and intensity of fires. Its fire-resistant properties contribute to the safety and security of structures, providing valuable time for evacuation and minimizing potential damage.

In summary, Carboline 891 showcases a range of exceptional characteristics and properties that make it an ideal choice for a variety of applications. Its impressive chemical resistance, strong adhesion, flexibility, and fire protection capabilities contribute to the durability, safety, and longevity of coated structures. The application of Carboline 891 ensures reliable and long-lasting results, making it a favored choice in numerous industries.

Application Guidelines and Best Practices for Carboline 891

In this section, we will explore the recommended application guidelines and best practices for the advanced coating known as Carboline 891. By following these guidelines, users can optimize the performance and longevity of their coating projects while ensuring efficient and effective application methods. It is crucial to follow these guidelines to achieve the desired results and extend the service life of Carboline 891 coating.

To begin, proper surface preparation is key to the success of any coating project. Prior to applying Carboline 891, the substrate should be thoroughly cleaned and free from any contaminants. This includes removing dirt, dust, grease, rust, and old coatings. A clean and properly prepared surface ensures optimum adhesion and performance of the Carboline 891 coating.

Once the surface is properly prepared, the next step is to ensure the coating is applied at the correct temperature and humidity levels. Carboline 891 is designed to be applied within a specific temperature range to ensure optimal curing and adhesion properties. It is important to closely monitor the ambient temperature and humidity levels during application to avoid any potential issues or deviations from the recommended guidelines.

In terms of application methods, Carboline 891 can be applied using various techniques, including brush, roller, or spray. The choice of application method depends on factors such as the size and complexity of the project, as well as the desired finish. Regardless of the method chosen, it is crucial to follow the manufacturer’s recommendations for the suitable application technique to achieve the desired results.

Furthermore, it is essential to ensure proper ventilation during the application of Carboline 891. Adequate airflow helps facilitate proper drying and curing of the coating, leading to excellent performance and longevity. This is especially important when working in enclosed spaces or areas with limited ventilation.

| Key Guidelines and Best Practices |

|---|

| 1. Thoroughly clean and prepare the surface before applying Carboline 891 |

| 2. Monitor and maintain the correct temperature and humidity levels during application |

| 3. Follow the manufacturer’s recommendations for the application method |

| 4. Ensure proper ventilation during the application process |

By following these application guidelines and best practices, users can maximize the effectiveness and durability of Carboline 891 coating. It is important to note that these recommendations are intended to serve as general guidelines and may vary depending on specific project requirements. Consulting the Carboline 891 datasheet and seeking advice from technical experts are highly recommended to ensure proper application and achieve optimal results.

Health and Safety Precautions: Handling and Storage of Carboline 891

In this section, we will provide important information regarding the safe handling and storage practices for Carboline 891. It is crucial to be knowledgeable about the necessary precautions to ensure the well-being of individuals working with this product.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | To minimize the potential risks associated with handling Carboline 891, proper PPE must be utilized, including but not limited to, gloves, safety goggles, and protective clothing. These protective measures will aid in reducing exposure to the product and safeguarding one’s health. |

| Ventilation | Working in a well-ventilated area is essential when dealing with Carboline 891. Adequate ventilation will assist in preventing the accumulation of potentially hazardous vapors or gases, thereby maintaining a safe working environment. |

| Handling | During the handling of Carboline 891, it is vital to exercise caution and avoid any contact with the eyes, skin, or clothing. In case of accidental exposure, it is advised to rinse thoroughly with water and seek medical attention when necessary. |

| Storage | Proper storage conditions play a vital role in maintaining the integrity of Carboline 891. It should be stored in a cool, dry, well-ventilated area, away from sources of ignition and incompatible materials. The containers must be tightly sealed and clearly labeled to avoid any potential confusion or accident. |

| Spill and Disposal Procedures | In the event of a spill or leakage, immediate action should be taken to contain and clean it up properly. Absorbent materials should be used for containment, and the waste should be disposed of in accordance with local regulations and guidelines. |

| Emergency Measures | In case of an emergency or if someone experiences adverse health effects due to exposure to Carboline 891, it is essential to provide immediate first aid and seek medical assistance. Keeping emergency contact numbers readily available is highly recommended. |