Exploring the intricacies of an electronic component entails a journey through its nuanced specifications and functionalities. Delving into the technical intricacies of a particular semiconductor device unveils a realm of possibilities and applications.

Today, we embark on a voyage to decipher the essence of a foundational component, a cornerstone of modern electronics. Our focus is on a vital element that orchestrates the flow of current, wielding influence over myriad circuits and systems.

Embark with us as we dissect the essence of this fundamental building block, unraveling its properties and applications.

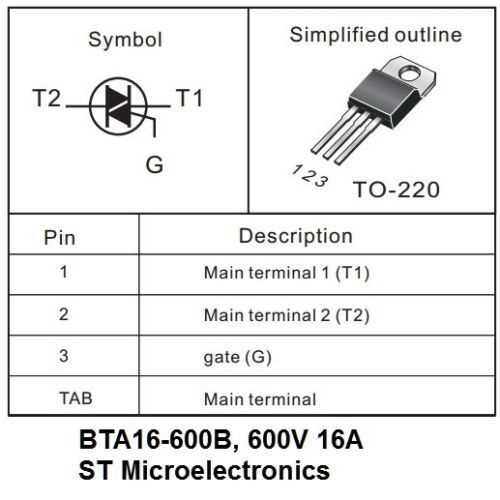

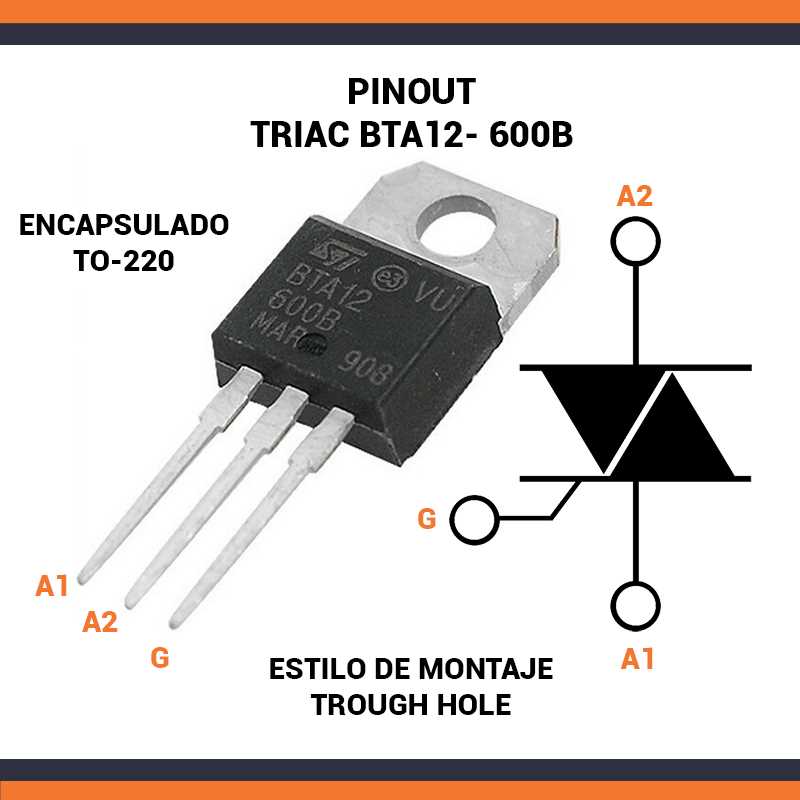

Understanding Vital Specifications of the BTA16 Triac

In this section, we delve into the core specifications crucial for comprehending the functionality and application scope of this electronic component. By dissecting key metrics and characteristics, we aim to provide a comprehensive understanding of the BTA16 Triac’s operational parameters and capabilities.

1. Electrical Characteristics:

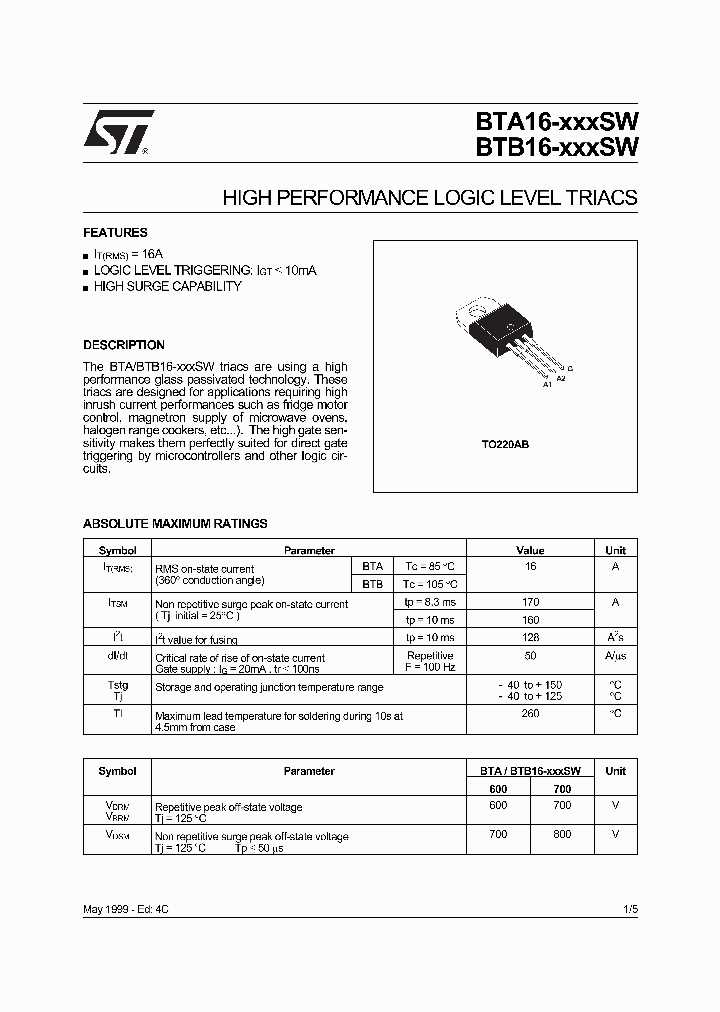

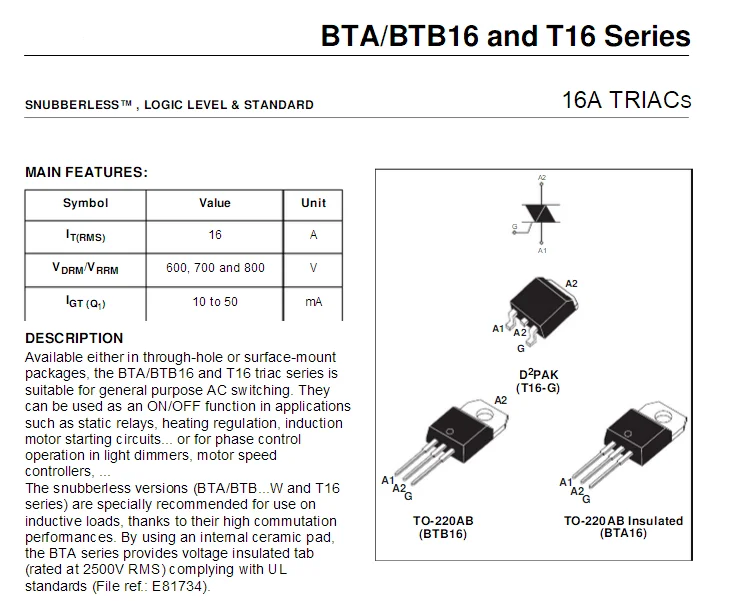

Explore the intrinsic electrical attributes that define the performance of the BTA16 Triac. From voltage and current ratings to trigger and holding currents, these specifications delineate the device’s behavior under various operating conditions. Understanding these characteristics is paramount for precise integration into electronic circuits.

2. Thermal Properties:

Dive into the thermal behavior of the BTA16 Triac to grasp its heat dissipation capabilities and thermal resistance. Efficient thermal management ensures reliable operation and longevity, making it imperative to gauge the device’s ability to withstand elevated temperatures without compromising performance.

3. Triggering Mechanism:

Examine the triggering mechanisms employed by the BTA16 Triac, including gate trigger voltage and sensitivity. A nuanced understanding of these specifications elucidates the device’s responsiveness to control signals, facilitating precise control over switching operations in AC circuits.

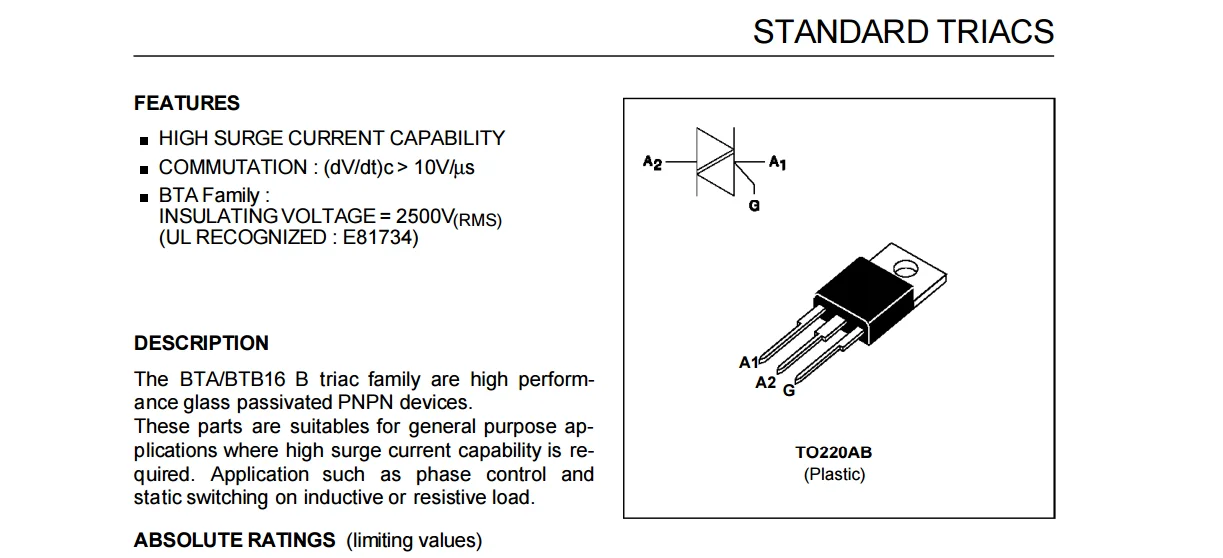

4. Isolation and Safety:

Assess the isolation characteristics and safety features inherent in the BTA16 Triac. Factors such as isolation voltage and insulation resistance dictate the device’s compatibility with diverse applications and ensure compliance with safety standards, underscoring the importance of robust insulation for reliable performance.

5. Application Considerations:

Explore practical considerations and application guidelines for leveraging the BTA16 Triac effectively. From load compatibility to surge handling capacity, understanding how these specifications intersect with real-world usage scenarios is instrumental in harnessing the full potential of this versatile electronic component.

By dissecting these key specifications, engineers and enthusiasts can gain profound insights into the operational nuances and application nuances of the BTA16 Triac, paving the way for optimized circuit design and enhanced performance.

Exploring Electrical Ratings and Thermal Characteristics

In this section, we delve into the intricate details surrounding the electrical specifications and thermal properties of the component under consideration. Understanding these aspects is paramount for ensuring optimal performance and reliability in various applications.

Electrical Ratings: The component’s electrical ratings encompass a range of parameters that dictate its operational boundaries and capabilities. These include but are not limited to voltage tolerances, current handling capacities, and power dissipation characteristics. Mastery of these ratings enables engineers to design circuits that operate safely within specified limits, preventing potential damage or failure.

Thermal Characteristics: Thermal considerations play a crucial role in the performance and longevity of the component. Heat dissipation, thermal resistance, and maximum operating temperatures are among the key factors to be evaluated. Efficient thermal management ensures that the component remains within acceptable temperature ranges, minimizing the risk of thermal runaway and ensuring stable operation over extended periods.

By exploring these electrical and thermal attributes in depth, engineers can make informed decisions regarding the integration and utilization of the component in diverse electronic designs.

Interpreting Triggering and Holding Current Parameters

Understanding the activation and maintenance thresholds in semiconductor devices like the component in question involves delving into specific electrical characteristics. These parameters play a pivotal role in governing the functionality and stability of the device, dictating the onset and sustenance of its operational state. In this section, we aim to elucidate the significance and implications of the triggering and holding currents, shedding light on their role in ensuring the proper functioning of the component.

- Triggering Current: This critical parameter delineates the minimum current magnitude required to initiate the switching action within the semiconductor device. Analogous to igniting a spark to initiate a larger combustion process, the triggering current serves as the catalyst for activating the device, transitioning it from a non-conducting to a conducting state. Understanding this threshold provides insights into the conditions necessary for reliable operation and optimal performance.

- Holding Current: Complementary to the triggering current, the holding current signifies the minimum current magnitude essential for maintaining the conducting state once triggered. It acts as a stabilizing force, preventing inadvertent deactivation or oscillations that could compromise the device’s functionality. By comprehending this parameter, engineers can ascertain the sustained operational requirements and design circuits accordingly to ensure stability and longevity.

Delving deeper into the nuances of these parameters unveils their intricate interplay with external factors such as temperature, voltage, and load conditions. Analyzing their behavior under varying circumstances empowers designers to optimize performance, enhance reliability, and mitigate potential risks associated with improper operation. Through meticulous examination and interpretation of triggering and holding currents, a comprehensive understanding of the component’s behavior emerges, fostering informed decision-making and efficient utilization in diverse applications.

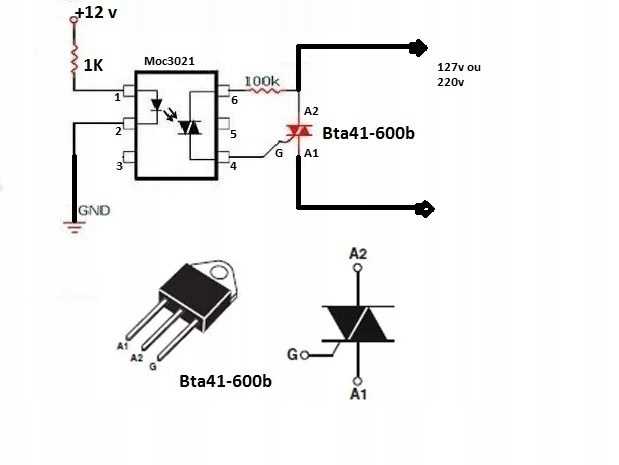

Practical Application Guidelines for Utilizing BTA16 Triac Specifications

In this section, we delve into the pragmatic facets of employing the specifications provided in the BTA16 Triac documentation. Exploring the operational nuances and effective utilization methods, we offer insights into leveraging the outlined parameters to optimize device performance and ensure seamless integration within various circuit configurations.

Understanding Operational Parameters

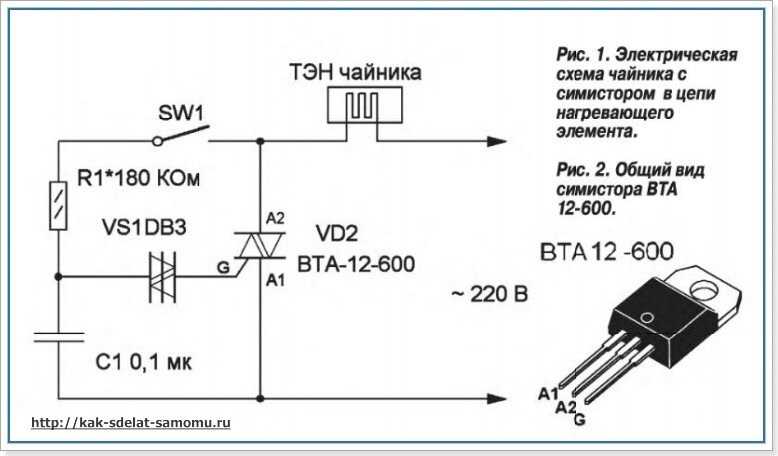

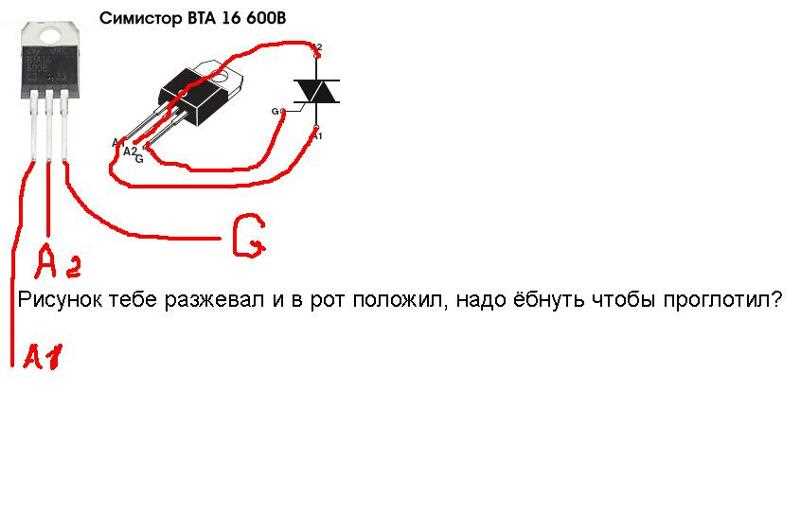

Before embarking on the application journey, it’s imperative to grasp the intricacies of the operational parameters elucidated in the documentation. By comprehending the functional characteristics, including voltage ratings, current capabilities, and triggering mechanisms, users can tailor their applications to align with the Triac’s specifications, thereby enhancing reliability and functionality.

Optimizing Circuit Design

Achieving optimal performance necessitates meticulous attention to circuit design considerations. From layout planning to component selection, each aspect plays a pivotal role in determining the overall efficiency and stability of the system. By adhering to recommended guidelines and leveraging the provided data, engineers can design circuits that harness the full potential of the BTA16 Triac, facilitating seamless operation across diverse applications.

Implementing Proper Heat Sink Design for Enhanced Performance

In the realm of electronic component optimization, ensuring efficient thermal management is paramount to achieving optimal functionality and longevity. This section delves into the intricacies of implementing effective heat sink designs to bolster overall performance and reliability.

Heat dissipation poses a significant challenge in electronic circuits, particularly in components characterized by high power consumption and continuous operation. To address this challenge, meticulous attention must be paid to the design and integration of heat sinks. These devices serve as vital conduits for thermal energy transfer, effectively dissipating excess heat away from critical components.

| Key Considerations | Guiding Principles |

| 1. Thermal Conductivity | Maximizing the heat sink’s ability to conduct and disperse thermal energy efficiently. |

| 2. Surface Area | Optimizing the surface area for enhanced heat dissipation without compromising spatial constraints. |

| 3. Material Selection | Choosing materials with high thermal conductivity and corrosion resistance to ensure prolonged effectiveness. |

| 4. Mounting Technique | Employing secure and efficient mounting methods to establish robust thermal interfaces between the heat sink and the component. |

| 5. Airflow Management | Strategically managing airflow patterns to facilitate optimal heat transfer and dissipation. |

By adhering to these fundamental principles and considerations, engineers can design and implement heat sink solutions tailored to the specific requirements and operating conditions of electronic circuits. The judicious application of heat sink technology not only enhances performance but also fortifies the reliability and longevity of electronic systems.