In the realm of industrial logistics, a marvel of engineering orchestrates the seamless flow of goods with precision and efficiency. This intricate apparatus, akin to a silent conductor, orchestrates the ballet of materials, silently propelling them along a predefined path. Its significance is underscored by its ubiquity in modern production facilities, serving as the silent backbone of myriad industries.

Within the landscape of manufacturing, this enigmatic contrivance embodies the marriage of form and function, blending mechanical prowess with operational finesse. Its purpose transcends mere transportation; it embodies a synergy of design and utility, fostering the relentless rhythm of production lines across diverse sectors.

At its core lies a symphony of components, harmonizing to choreograph the intricate dance of materials. From the rhythmic hum of motors to the sturdy embrace of rollers, each element plays a vital role in sustaining the relentless cadence of modern industry.

The Essentials of Belt Conveyor Datasheets

In the realm of conveying mechanisms, it is imperative to comprehend the fundamental components that constitute the informational blueprint guiding the operation of these pivotal systems. Within the realm of technical documentation, these foundational documents serve as the compass directing engineers and stakeholders towards a comprehensive understanding of the conveyance apparatus.

Key Components Overview

Delving into the intricacies of conveyance data necessitates a holistic exploration of its primary constituents. These foundational elements lay the groundwork for a thorough comprehension of the conveyance mechanism’s functionality and specifications.

- Performance Metrics: Metrics encapsulating the efficiency, throughput, and operational parameters of the system.

- Material Specifications: Detailed delineation of the materials handled, encompassing properties such as size, density, and abrasiveness.

- Operating Conditions: Insight into the environmental factors influencing the conveyance process, including temperature, humidity, and atmospheric conditions.

Data Presentation Techniques

The effective presentation of conveyance data is a cornerstone of facilitating comprehension and decision-making. Employing appropriate techniques ensures clarity and accessibility for stakeholders across diverse domains.

- Tabular Representation: Utilizing tables to succinctly organize and present critical parameters, facilitating ease of reference and comparison.

- Graphical Illustrations: Incorporating graphs and charts to visually depict trends, correlations, and performance variations, enhancing interpretability.

Understanding Specifications of Transporting Mechanisms

In the realm of material handling, it’s crucial to grasp the intricacies of the criteria that define the functionality and efficiency of conveying systems. These specifications serve as the blueprint guiding the selection, design, and operation of these pivotal mechanisms. Delving into the nuances of these parameters unveils a comprehensive understanding of how transporting systems navigate through diverse industrial landscapes, ensuring seamless material flow and operational reliability.

Key Components and Their Functions

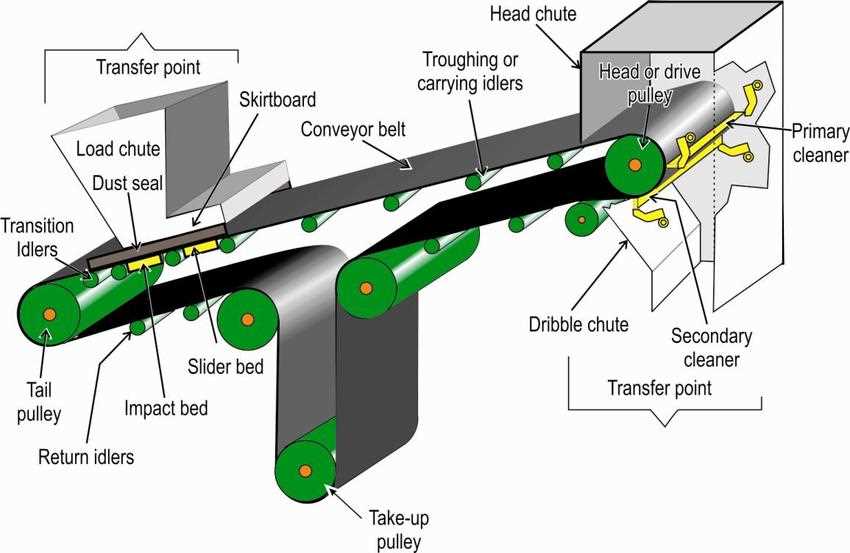

In the realm of transporting mechanisms, various pivotal elements orchestrate the seamless movement of materials along a designated path. These fundamental constituents, each with its distinct role, harmonize to ensure the efficient operation of the conveying apparatus.

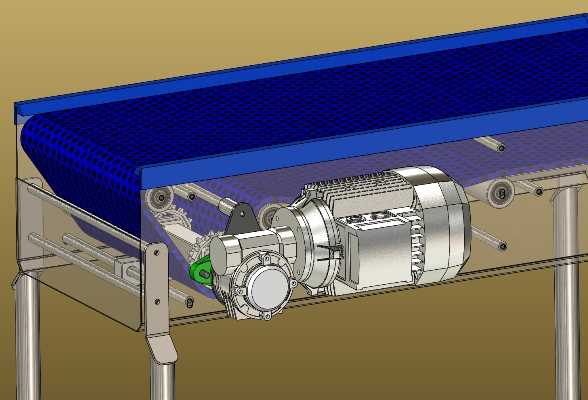

- Drive System: Serves as the propulsive force, compelling the motion of the conveying system through the conversion of energy.

- Rollers: Act as the intermediary contact points between the conveying surface and the transported load, facilitating smooth and controlled movement.

- Idlers: Provide support and guidance to the conveyor belt, maintaining its trajectory and minimizing deviation.

- Frame Structure: Establishes the foundational framework upon which the entire conveyor system is constructed, ensuring stability and structural integrity.

- Control System: Governs the operational parameters of the conveyor, regulating speed, direction, and overall functionality.

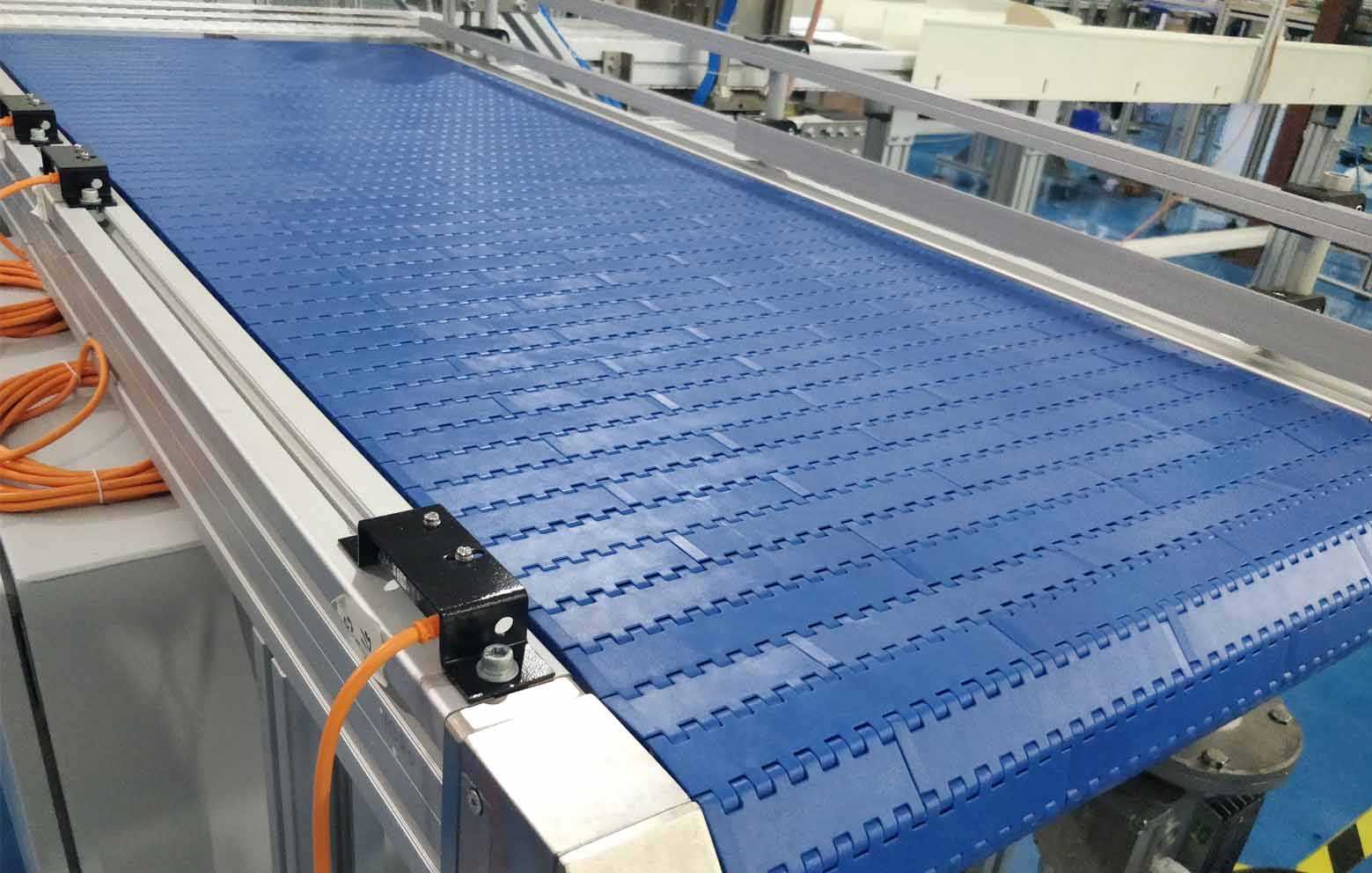

- Belting Material: Forms the conveyor’s surface, offering durability, traction, and compatibility with diverse materials being transported.

- Cleaners and Scrapers: Maintain the cleanliness of the conveying surface, preventing material buildup and optimizing operational efficiency.

- Take-Up Device: Adjusts the tension of the conveyor belt, compensating for stretching and ensuring proper alignment.

Together, these components constitute the intricate machinery that epitomizes the essence of efficient material handling, embodying synergy and precision in their collective operation.

Optimizing Performance and Maintenance Tips

In this section, we’ll explore strategies for enhancing the efficiency and longevity of your equipment, along with methods for ensuring smooth operations and reducing downtime.

Regular Inspections and Lubrication

Consistent examination and appropriate lubrication of mechanical components are fundamental practices in prolonging the functionality of your machinery. Implementing a structured inspection schedule helps identify potential issues before they escalate, while adequate lubrication reduces friction and wear, thus extending the lifespan of critical parts.

Efficient Material Handling Techniques

Employing efficient material handling techniques can significantly impact overall system performance. Streamlining loading and unloading processes, optimizing conveyor speeds, and minimizing unnecessary stops can enhance throughput and reduce energy consumption, leading to improved operational efficiency.

- Ensure proper alignment of material on the conveyor.

- Implement automated systems for consistent material flow.

- Regularly clean conveyor belts and remove debris to prevent jams.

By incorporating these strategies into your maintenance routine, you can maximize the productivity and reliability of your equipment, ultimately driving greater efficiency and cost-effectiveness.