Delve into the intricacies of a pivotal component in industrial automation systems with our exploration of the multifaceted IF16 module. This article embarks on a journey through the functionalities and applications of this vital apparatus, shedding light on its role in driving efficiency and precision in industrial processes.

Embark on a comprehensive analysis of the IF16 module, unearthing its capabilities beyond the surface. Discover how this component serves as a linchpin in the seamless integration of disparate systems, fostering synergy and synchronicity across industrial landscapes.

Unravel the innovative engineering behind the IF16 module, deciphering its inner workings and elucidating the mechanisms that underpin its reliability and performance. Through insightful discussions and nuanced insights, gain a deeper understanding of the pivotal role this component plays in the realm of industrial automation.

Exploring the 1756-IF16 Device

In this section, we delve into the comprehensive features and functionalities encapsulated within the 1756-IF16 module, offering a detailed examination of its capabilities and applications. Discover a nuanced understanding of its operational intricacies and potential utilities.

- Introduction to 1756-IF16

- Functional Insights without Technical Jargon

- Performance Evaluation: Unveiling Efficiency Metrics

- Application Scenarios: Real-world Implementations

- Integration Possibilities with Existing Systems

- Comparative Analysis: Benchmarking Against Alternatives

Embark on a journey to comprehend the essence of the 1756-IF16 module, unraveling its significance within industrial automation landscapes. Through a structured exploration, gain profound insights into its diverse functionalities and operational paradigms, empowering informed decision-making and maximizing utility.

Features and Specifications

In this section, we delve into the characteristics and technical details of the product, shedding light on its capabilities and functionalities. Exploring its intricacies unveils a myriad of attributes and performance metrics, offering a comprehensive understanding of its operational scope and potential applications.

Main Features

Highlighted herein are the primary features that define the essence of the device, encompassing its key functionalities and distinguishing characteristics. From fundamental operational aspects to advanced capabilities, these features form the cornerstone of its utility and versatility, catering to diverse industrial requirements.

Technical Specifications

The technical specifications section elucidates the quantitative parameters and performance benchmarks of the product, delineating its operational boundaries and potential performance metrics. Ranging from input/output configurations to data transmission rates, these specifications provide a quantitative framework for assessing the device’s compatibility and suitability for specific applications.

Understanding the 1756-IF16 Analog Input Module

In this section, we delve into the functionality and intricacies of the 1756-IF16 analog input module, exploring its capabilities and applications in various industrial settings. Through a comprehensive analysis, we aim to elucidate the operational principles and features of this module, shedding light on its significance in process control and automation.

Functional Overview

The 1756-IF16 serves as a vital component in industrial control systems, facilitating the acquisition of analog signals for precise monitoring and control. With its ability to interface with a wide range of sensors and transducers, this module enables the conversion of physical parameters into digital data, essential for accurate decision-making and process optimization.

Key Features

The 1756-IF16 module boasts several notable features, including high-resolution analog-to-digital conversion, configurable input ranges, and built-in diagnostics for enhanced reliability. Its modular design allows for seamless integration into Allen Bradley control systems, offering flexibility and scalability to meet diverse application requirements.

| Feature | Description |

|---|---|

| High-Resolution ADC | Provides precise conversion of analog signals into digital format, ensuring accuracy in data acquisition. |

| Configurable Input Ranges | Allows users to tailor input ranges according to specific sensor requirements, enhancing versatility. |

| Built-in Diagnostics | Offers proactive monitoring and fault detection capabilities, minimizing downtime and optimizing maintenance. |

By understanding the functionalities and features of the 1756-IF16 analog input module, users can harness its capabilities to streamline industrial processes, improve system performance, and achieve operational excellence.

Applications and Compatibility

Exploring Usage Scenarios and Interoperability

Within this segment, we delve into the myriad of scenarios where the device in question proves invaluable. Whether in industrial settings or integrated systems, understanding its adaptability and applicability is paramount. Compatibility assessments, on the other hand, shed light on its seamless integration with diverse platforms and components, ensuring a cohesive operational environment.

Practical Implementations:

Unveiling the realm of possibilities, this section illuminates how the product interfaces within industrial frameworks, offering robust solutions without compromise. From control systems to data acquisition, its versatile nature underpins its utility across various domains.

Interconnectivity:

Examining its synergy with complementary devices and software ecosystems, we uncover the symbiotic relationships that foster efficiency and productivity. Compatibility with existing infrastructure becomes a cornerstone, streamlining processes and enhancing overall system coherence.

Future Adaptability:

Anticipating evolving technological landscapes, this segment forecasts the device’s resilience and adaptiveness. Insights into forthcoming advancements and compatibility updates underscore its longevity and relevance in dynamic operational contexts.

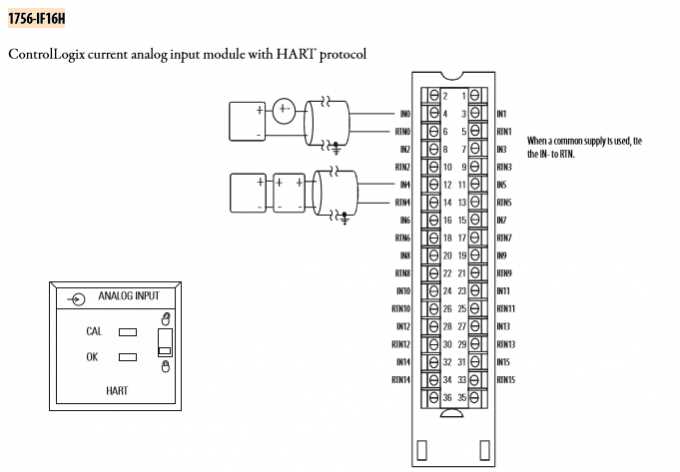

Installation and Configuration of the 1756-IF16 Module

In this section, we will delve into the process of setting up and configuring the 1756-IF16 module, enhancing your understanding of its operational deployment. We’ll explore the steps required for seamless integration and optimal functionality, ensuring a smooth transition into your industrial automation environment.

To commence the installation process, it’s imperative to conduct a comprehensive assessment of your system requirements. This entails evaluating the pertinent factors such as compatibility with existing components, spatial constraints, and connectivity considerations.

- Begin by locating an appropriate slot within the chassis to accommodate the 1756-IF16 module.

- Ensure that the backplane is powered down before proceeding with installation to prevent any potential hazards.

- Align the module with the chosen slot, taking care to observe proper orientation to facilitate secure insertion.

- Gently insert the module into the slot, applying even pressure to ensure a snug fit without causing damage to the connectors.

- Once securely installed, verify the module’s status indicators to confirm successful integration into the system.

With the physical installation completed, attention turns to the configuration aspect, where precise parameterization is pivotal for optimal performance.

- Access the configuration interface through the designated software platform or programming tool.

- Initiate the process by identifying the module within the system architecture, establishing communication channels for seamless interaction.

- Configure input channels according to the specific sensor types and measurement requirements, ensuring accurate data acquisition.

- Calibrate the module as necessary to align with the operational parameters of your industrial process, fine-tuning sensitivity and accuracy settings.

- Validate the configuration settings through rigorous testing procedures, verifying functionality across the designated input channels.

By adhering to these meticulous installation and configuration procedures, you can harness the full potential of the 1756-IF16 module, empowering your industrial automation endeavors with precision and reliability.