In the realm of industrial automation, the quest for precision, efficiency, and reliability knows no bounds. Within this dynamic landscape, lies a pivotal cornerstone, an electronic ally revered for its prowess in streamlining operations and elevating productivity to unprecedented heights.

Unveiling a mechanical marvel, a symphony of gears and circuits meticulously choreographed to orchestrate the dance of manufacturing prowess, embodying the essence of technological ingenuity.

Enter a realm where metallic giants don the mantle of productivity, where precision is not just a virtue but a mandate, and where the symphony of automation orchestrates a dance of efficiency.

Understanding the ABB IRB 660 Datasheet: Key Specifications Explained

In this section, we delve into the essential details encapsulated within the documentation for the ABB IRB 660 robotic system. Unraveling the intricacies of its technical specifications unveils a roadmap to comprehending its capabilities and functionalities.

Performance Metrics Deciphered

Embark on a journey through the performance metrics outlined within the ABB IRB 660 datasheet. Unravel the intricacies of its operational parameters and delve into the nuanced aspects that define its efficiency and efficacy.

Functional Insights Unveiled

Explore the depths of functional insights concealed within the datasheet of the ABB IRB 660. Navigate through the labyrinth of features and functionalities, discerning their significance in the realm of industrial automation and robotics.

Exploring Technical Parameters

Delve into the intricate intricacies of the technical facets governing the performance and specifications of this innovative robotic system. Within this section, we embark on a journey through the nuanced dimensions that shape its functionality and operational capabilities.

Performance Metrics: Uncover the quantitative measures that gauge the efficiency and effectiveness of this cutting-edge automation solution. From velocity and precision to payload capacity, each parameter plays a pivotal role in defining its operational prowess.

Functional Attributes: Explore the diverse array of functionalities inherent to this advanced robotic platform. From intricate motion control mechanisms to adaptive sensory systems, each component contributes synergistically to its overall performance.

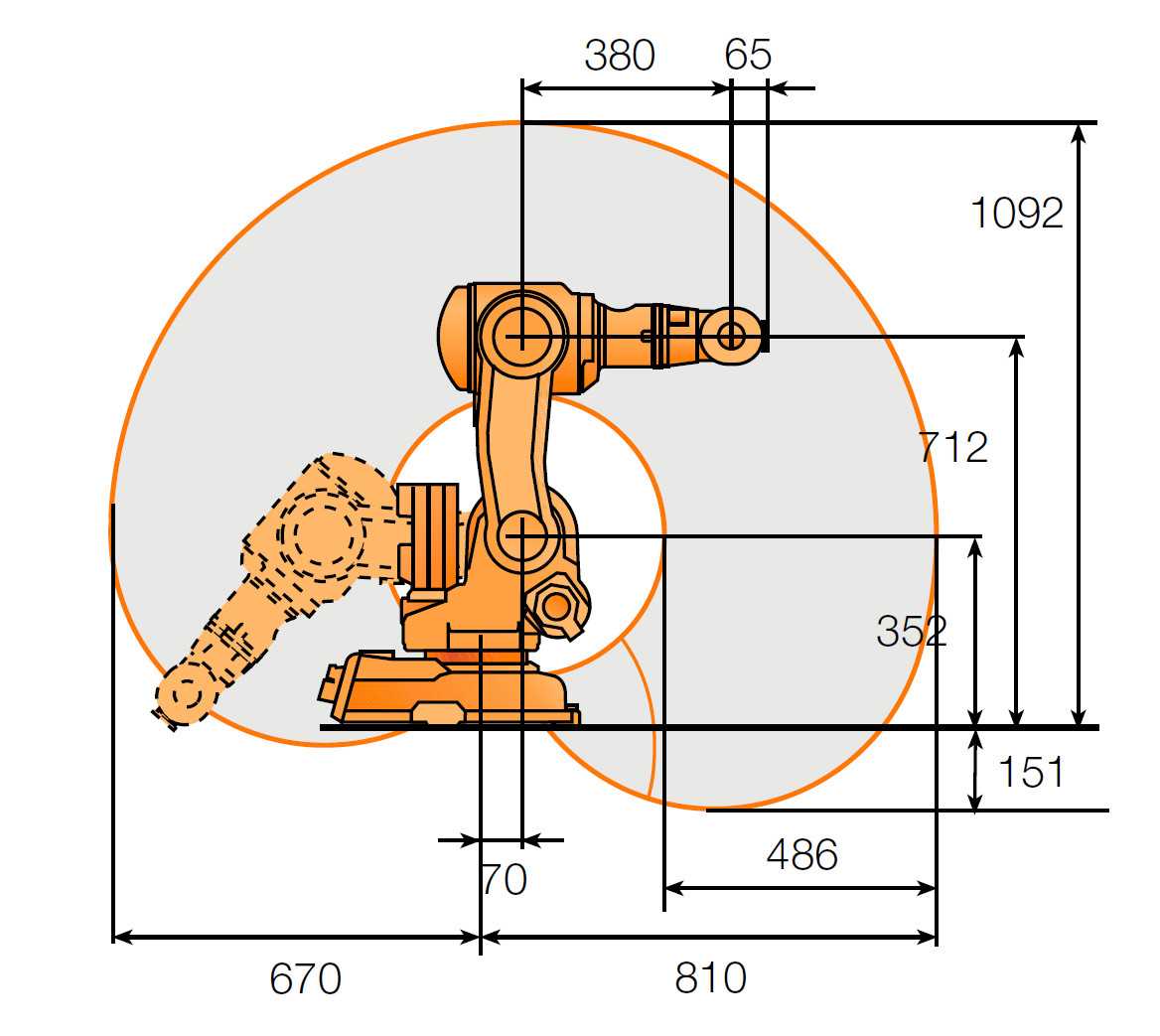

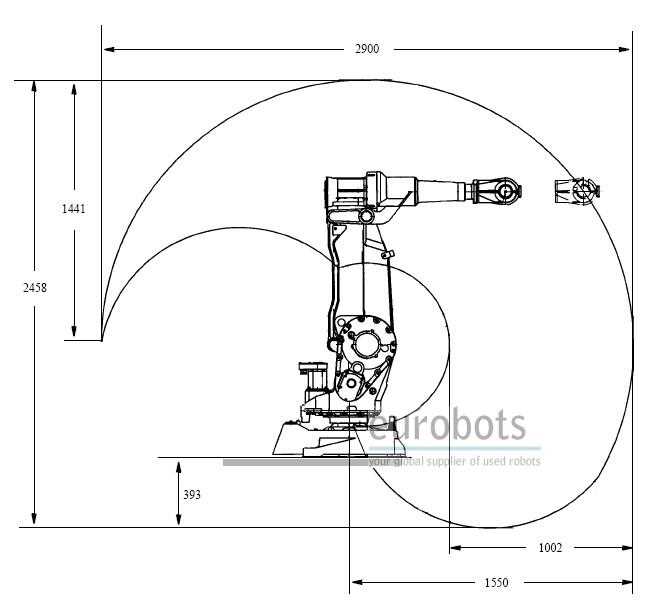

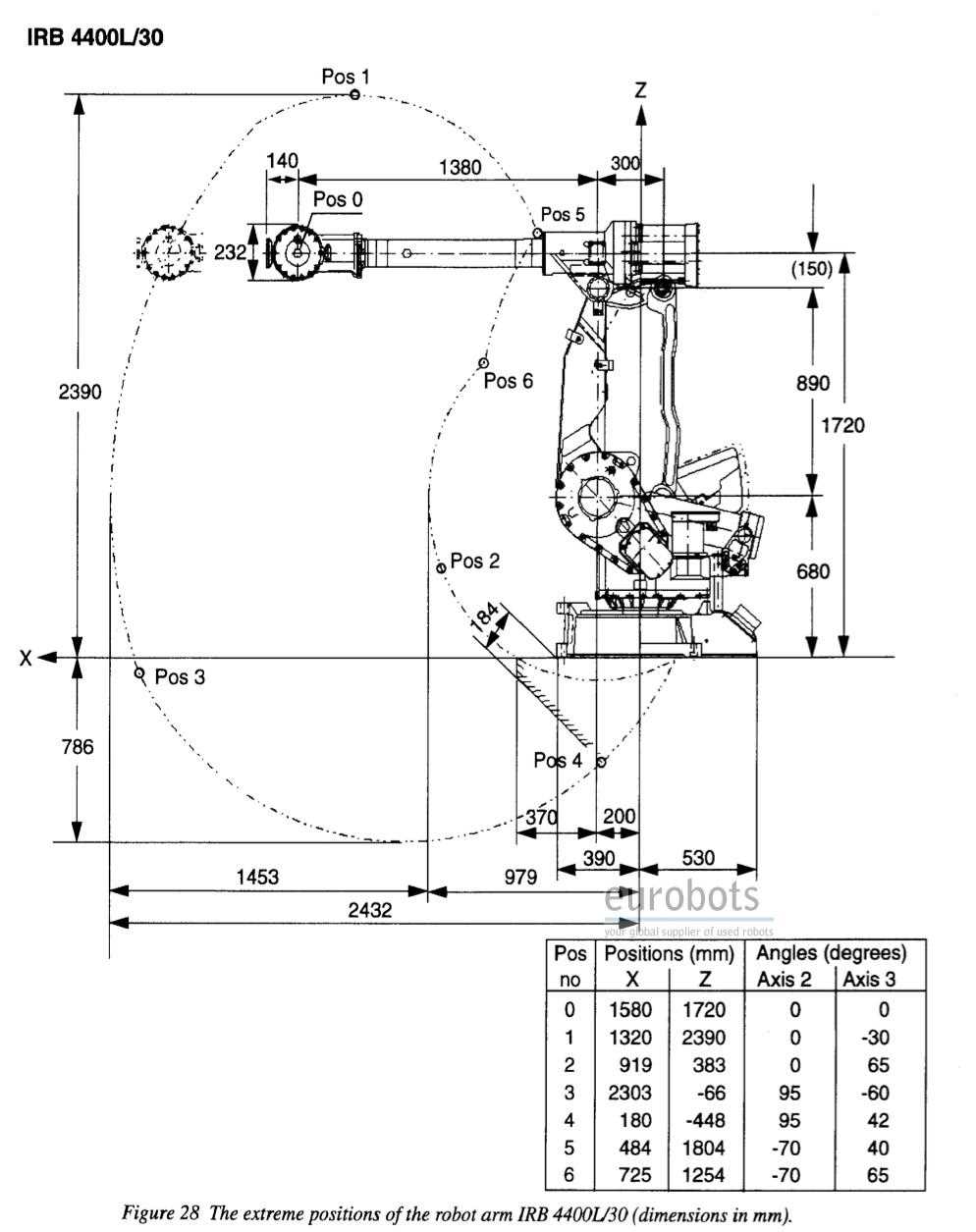

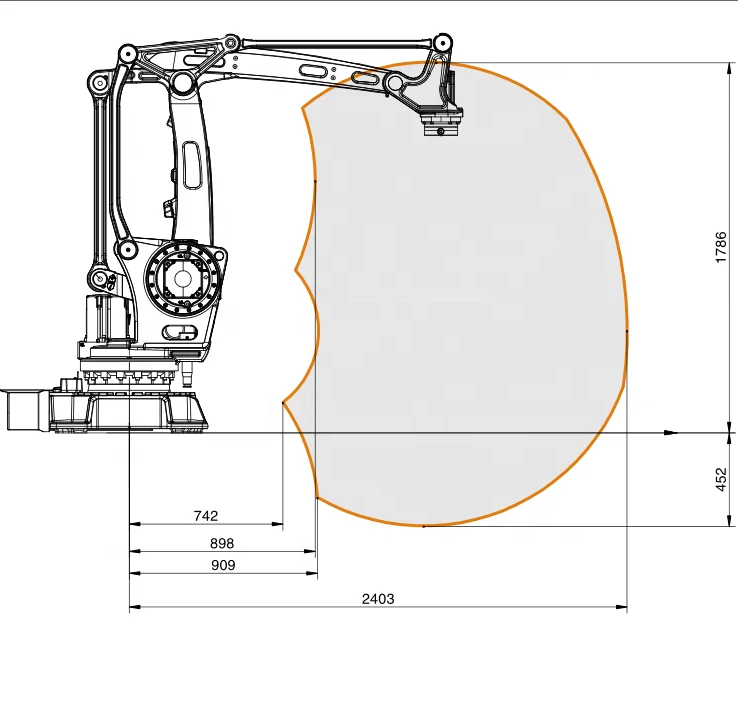

Technical Specifications: Delve into the detailed specifications that underpin the design and engineering of this state-of-the-art robotic apparatus. From dimensions and weight distribution to power requirements and connectivity options, every aspect is meticulously crafted to optimize performance and versatility.

Operational Capabilities: Examine the operational boundaries and capabilities that define the scope of application for this sophisticated automation solution. Whether it’s precision assembly tasks or dynamic material handling challenges, understanding its operational envelope is essential for maximizing productivity and efficiency.

Integration Flexibility: Explore the adaptability and integration capabilities of this robotic system within diverse industrial environments. From seamless interfacing with existing automation infrastructure to compatibility with advanced control systems, its versatility ensures seamless integration into various operational workflows.

Functional Capabilities Overview

Exploring the functionalities and operational prowess of the referenced technology, this segment delves into its versatile array of features and capabilities, aimed at enhancing operational efficiency and performance. Without delving into specific nomenclature, this section elucidates the broad spectrum of functionalities inherent within the system, showcasing its adaptability and utility across diverse industrial contexts.

- Robust Operational Framework

- Dynamic Task Execution

- Efficient Workload Management

- Adaptive Control Mechanisms

- Intelligent Decision-Making Capabilities

- Seamless Integration with Existing Systems

Furthermore, this overview highlights the system’s ability to streamline processes, optimize resource utilization, and facilitate seamless interaction with peripheral systems, thereby augmenting overall operational efficacy. Through a nuanced exploration of its functional repertoire, this section provides insights into the potential applications and advantages of leveraging such advanced technological solutions.

Application Insights and Utilization Scenarios

In this section, we delve into the practical applications and scenarios where the ABB IRB 660 finds its niche. Exploring various contexts where this robotic system demonstrates its versatility and effectiveness reveals the breadth of its potential utilization. From industrial automation to intricate manufacturing processes, the capabilities of this cutting-edge technology are manifold.

Industrial Automation: One realm where the ABB IRB 660 shines is in the realm of industrial automation. With its advanced capabilities in handling repetitive tasks with precision and efficiency, it revolutionizes production lines across diverse industries. Its adaptability and robustness make it a cornerstone in the quest for streamlined manufacturing processes.

Assembly Line Optimization: The integration of the ABB IRB 660 into assembly lines redefines efficiency and accuracy. Its seamless coordination with other machinery ensures a smooth workflow, reducing errors and enhancing productivity. Whether it’s automotive assembly or electronics manufacturing, this robotic solution elevates the standards of assembly line operations.

Material Handling: Another area where the ABB IRB 660 demonstrates its prowess is in material handling tasks. From lifting heavy loads to delicately manipulating fragile components, its dexterity and strength make it indispensable in warehouse logistics and distribution centers. By automating mundane and labor-intensive tasks, it frees human resources for more strategic roles.

Precision Machining: In precision machining applications, the ABB IRB 660 plays a crucial role in achieving impeccable results. With its ability to execute intricate movements with unparalleled accuracy, it ensures consistent quality in manufacturing processes such as CNC machining and metal fabrication. Its speed and precision reduce production time and minimize wastage, leading to cost savings and enhanced competitiveness.

Collaborative Robotics: Beyond traditional industrial settings, the ABB IRB 660 also offers opportunities for collaborative robotics applications. Its advanced safety features enable it to work alongside human operators, augmenting their capabilities and improving workplace ergonomics. From assisting in intricate surgeries to enhancing logistics in healthcare facilities, its potential for collaborative endeavors is vast and promising.

Exploring these diverse insights and utilization scenarios sheds light on the transformative impact of the ABB IRB 660 in various industries. Its adaptability, precision, and efficiency position it as a cornerstone technology in the era of automation and innovation.