Embark on a journey through the intricate details of a cutting-edge electrical propulsion marvel. This enigmatic apparatus, with its robust construction and formidable capabilities, serves as the beating heart of numerous aerial and terrestrial endeavors. Delve into the intricacies of its design and the nuances of its performance as we unravel the layers of innovation beneath its surface.

Explore the intriguing specifications that underpin its functionality, offering a glimpse into the realm of high-speed rotations and electrifying torque. Witness the marriage of precision engineering and relentless power as we dissect the essential characteristics that define its operation. With each parameter scrutinized, a deeper understanding emerges, illuminating the path towards harnessing its full potential.

Prepare to be captivated by the sheer magnitude of its capabilities, poised to revolutionize industries and redefine possibilities. As we navigate through the labyrinth of technical intricacies, the essence of its purpose becomes clearer, resonating with the aspirations of innovators and enthusiasts alike. Join us as we embark on a voyage of discovery, where each specification unveils a new layer of fascination and ignites the imagination.

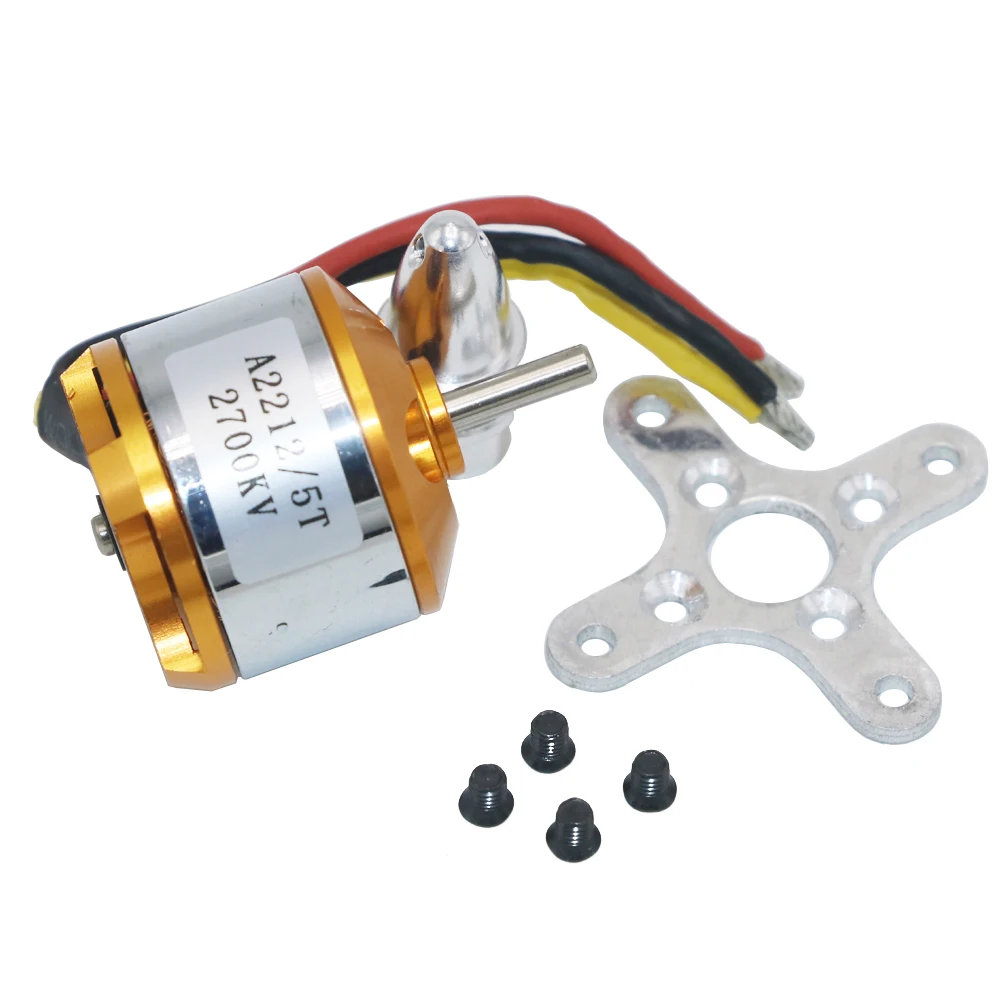

Understanding the Specifications of the A2212 15t 930kv Motor

In this section, we delve into comprehending the intricacies encapsulated within the documentation of the A2212 15t 930kv motor. By dissecting the provided data, we aim to extract insights into its operational characteristics and performance parameters.

Technical Overview

Beginning with a technical overview, we aim to elucidate the fundamental aspects of this motor’s functionality. Through an exploration of its design principles and operating mechanisms, we seek to provide a comprehensive understanding of its capabilities.

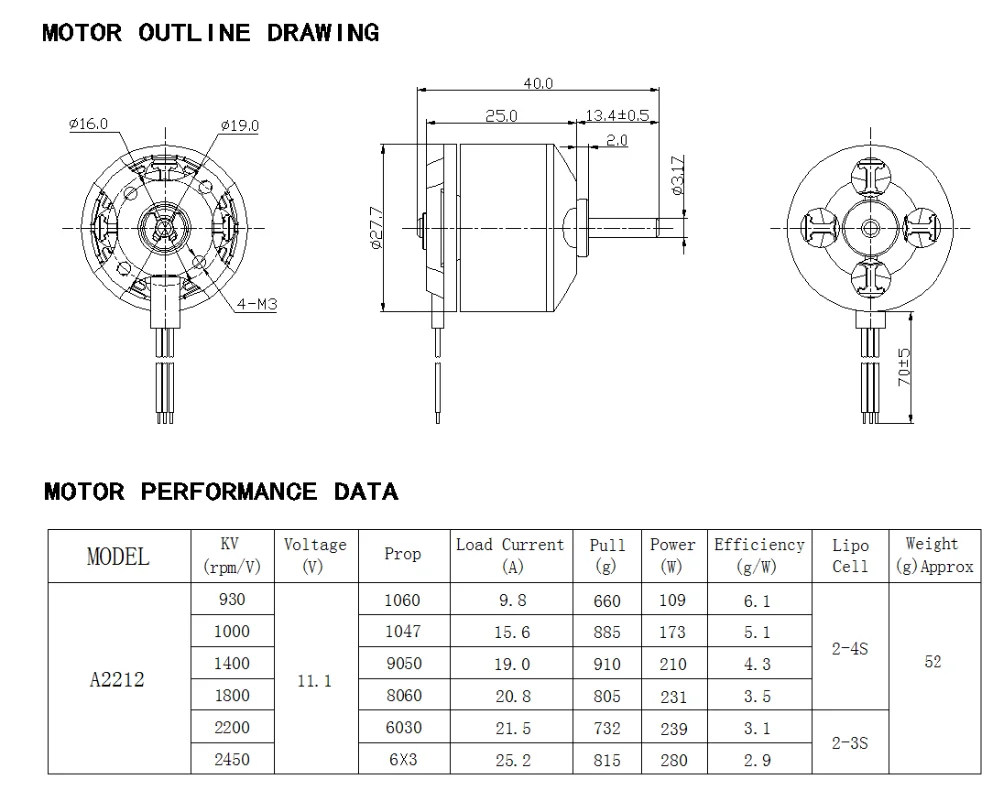

Performance Metrics

Furthermore, we scrutinize the performance metrics outlined within the datasheet, deciphering the implications of various specifications on the motor’s efficiency, torque generation, and overall suitability for diverse applications.

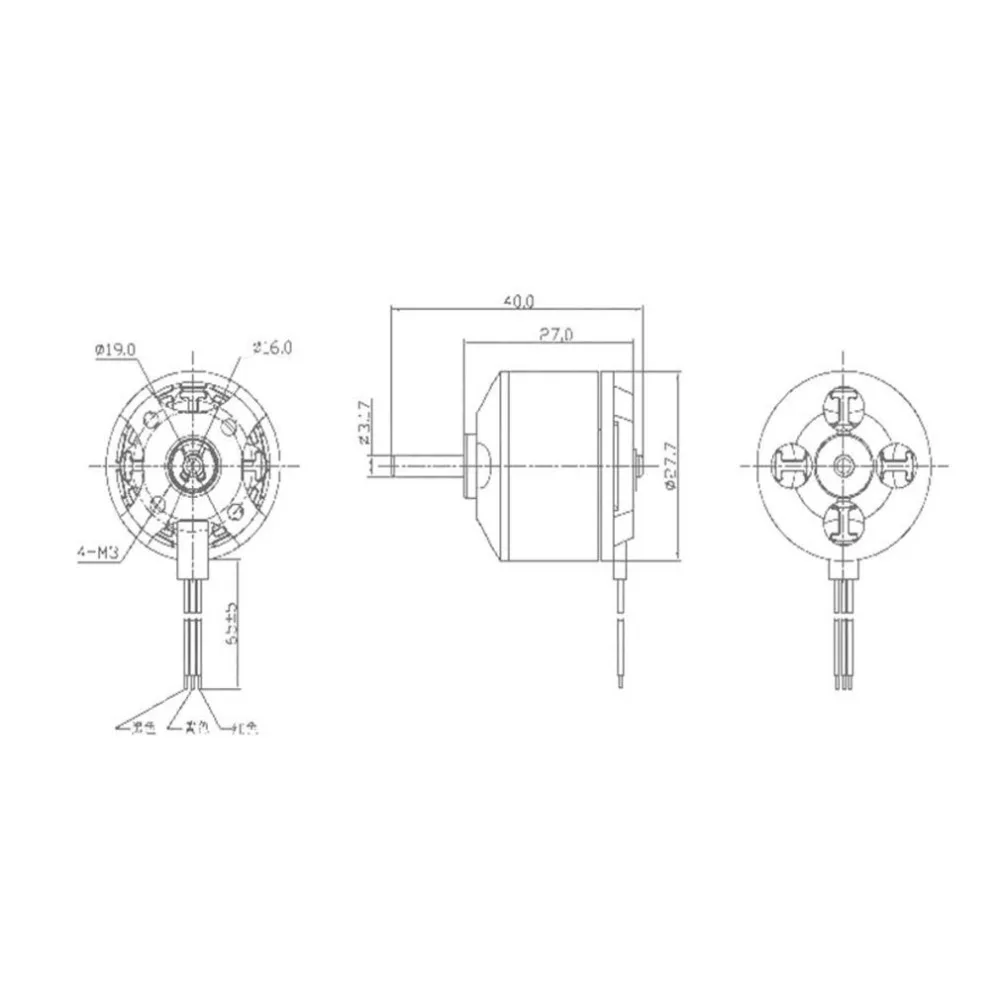

| Parameter | Description |

|---|---|

| Operating Voltage | The range of voltages within which the motor operates optimally. |

| Maximum Current | The highest current the motor can handle without sustaining damage. |

| Thrust Efficiency | The ratio of thrust produced to the electrical power consumed. |

| Dimensions | The physical measurements of the motor, including diameter and length. |

| Weight | The mass of the motor, affecting overall system weight and balance. |

Deciphering Technical Specifications

Understanding the intricacies of technical specifications is paramount for grasping the essence of electronic components and devices. Delving into the details entails deciphering a labyrinth of information, extracting vital insights crucial for informed decision-making.

Decoding the intricacies: In the realm of technical documentation, unraveling the specifications of components involves navigating through a myriad of parameters and characteristics. Each specification serves as a clue, shedding light on the performance, capabilities, and compatibility of the device in question.

Unveiling performance metrics: Behind every specification lies a story of functionality and efficiency. Analyzing performance metrics offers a glimpse into the operational prowess of the component, unveiling its potential applications and limitations.

Interpreting compatibility: Compatibility specifications serve as the cornerstone of integration within electronic systems. Understanding compatibility requirements ensures seamless interoperability, fostering synergy among interconnected components.

Exploring application insights: Beyond the numerical values, technical specifications harbor valuable insights into the practical applications of a component. Each parameter provides a glimpse into its intended use cases, guiding engineers and enthusiasts alike towards optimal utilization.

Conclusion: Navigating through technical specifications requires a blend of precision and intuition. By deciphering the intricacies embedded within datasheets and documentation, one can unlock the full potential of electronic components, paving the way for innovation and progress.

Optimizing Performance for UAV Applications

In the realm of unmanned aerial vehicles (UAVs), achieving optimal performance is paramount for a successful mission. This section delves into strategies and techniques to enhance the efficiency, agility, and overall capabilities of drones, without delving into specific model specifications.

Enhancing Efficiency

Efficiency stands as a cornerstone for any UAV operation, dictating endurance and range. By refining propulsion systems and power management, operators can maximize flight time and minimize energy consumption. Strategies may include fine-tuning motor parameters, optimizing battery configurations, and implementing aerodynamic enhancements to reduce drag and improve overall efficiency.

Boosting Agility and Maneuverability

Agility and maneuverability are crucial for navigating complex environments and executing precise missions. Techniques such as adjusting control algorithms, optimizing weight distribution, and employing advanced stabilization systems can significantly enhance a drone’s agility. Additionally, advancements in sensor technology and real-time data processing enable rapid response to dynamic scenarios, ensuring smooth and precise flight control.

Embracing a holistic approach to performance optimization empowers UAV operators to push the boundaries of aerial capabilities, unlocking new opportunities for exploration, surveillance, and beyond.

Troubleshooting Common Issues and Solutions

Encountering challenges with your motor setup is not uncommon, but understanding how to diagnose and resolve these issues is crucial for optimal performance. This section provides a comprehensive guide to identifying and addressing common difficulties that may arise during operation. By recognizing symptoms and implementing effective solutions, you can ensure smooth functionality and maximize the efficiency of your system.

1. Erratic Performance:

One prevalent issue users may face is irregular motor behavior, characterized by inconsistent speed or unexpected fluctuations in power output. This problem could stem from various factors, such as improper calibration, electrical interference, or mechanical obstructions. To troubleshoot this issue, start by checking the connections for any loose wiring or damaged components. Additionally, verify that the motor is correctly configured and calibrated according to the manufacturer’s recommendations. If electrical interference is suspected, consider relocating the motor or utilizing shielding materials to minimize external disturbances.

2. Overheating:

Excessive heat generation within the motor assembly can lead to performance degradation and potential damage to internal components. Common causes of overheating include prolonged operation at high throttle levels, inadequate cooling mechanisms, or insufficient ventilation. To mitigate this issue, ensure proper airflow around the motor and implement effective cooling solutions, such as heat sinks or fans. Additionally, monitor operating temperatures closely and adjust throttle settings as necessary to prevent overheating during prolonged use.

3. Vibrations and Noise:

Unusual vibrations or noise originating from the motor assembly may indicate underlying mechanical issues that require attention. These disturbances can result from imbalanced propellers, misaligned motor mounts, or worn bearings. To address this problem, carefully inspect the entire system for any signs of wear or misalignment. Replace damaged components and recalibrate the motor assembly to optimize performance and minimize vibrations. Additionally, ensure that all fasteners are securely tightened to prevent loosening during operation.

4. Inadequate Power Output:

If your motor fails to deliver the expected power output, several factors may be contributing to this issue. Insufficient battery voltage, worn out propellers, or incorrect motor timing could all affect performance. Begin troubleshooting by checking the battery voltage and ensuring that it meets the recommended specifications for your motor setup. Replace worn or damaged propellers, and verify that the motor timing is correctly adjusted according to the manufacturer’s guidelines. By addressing these potential issues, you can optimize power delivery and enhance overall system performance.

5. Electrical Failures:

Electrical failures within the motor assembly can result from various causes, including short circuits, overloading, or voltage spikes. To diagnose and resolve these issues, inspect the wiring and connections for any signs of damage or corrosion. Replace any faulty components and utilize appropriate circuit protection devices, such as fuses or circuit breakers, to safeguard against electrical faults. Additionally, consider implementing surge suppression measures to protect sensitive electronics from voltage fluctuations or transient surges.

By following these troubleshooting guidelines and implementing appropriate solutions, you can effectively address common issues encountered with motor setups and ensure optimal performance and reliability in your applications.