Unlocking the potential of cutting-edge automation technology, this article delves into the intricacies of a formidable mechanical entity that revolutionizes industrial landscapes. Prepare to embark on a journey through the realms of innovation and efficiency as we unravel the capabilities of a pioneering marvel.

Embodied within this mechanical marvel lies a symphony of precision engineering and computational prowess. Seamlessly blending agility with strength, this technological masterpiece redefines the standards of productivity and reliability in modern manufacturing environments.

Discover the dynamic fusion of mechanical finesse and intelligent algorithms propelling industries towards unparalleled efficiency. Within these pages, witness the embodiment of precision, endurance, and adaptability as we decode the essence of industrial excellence.

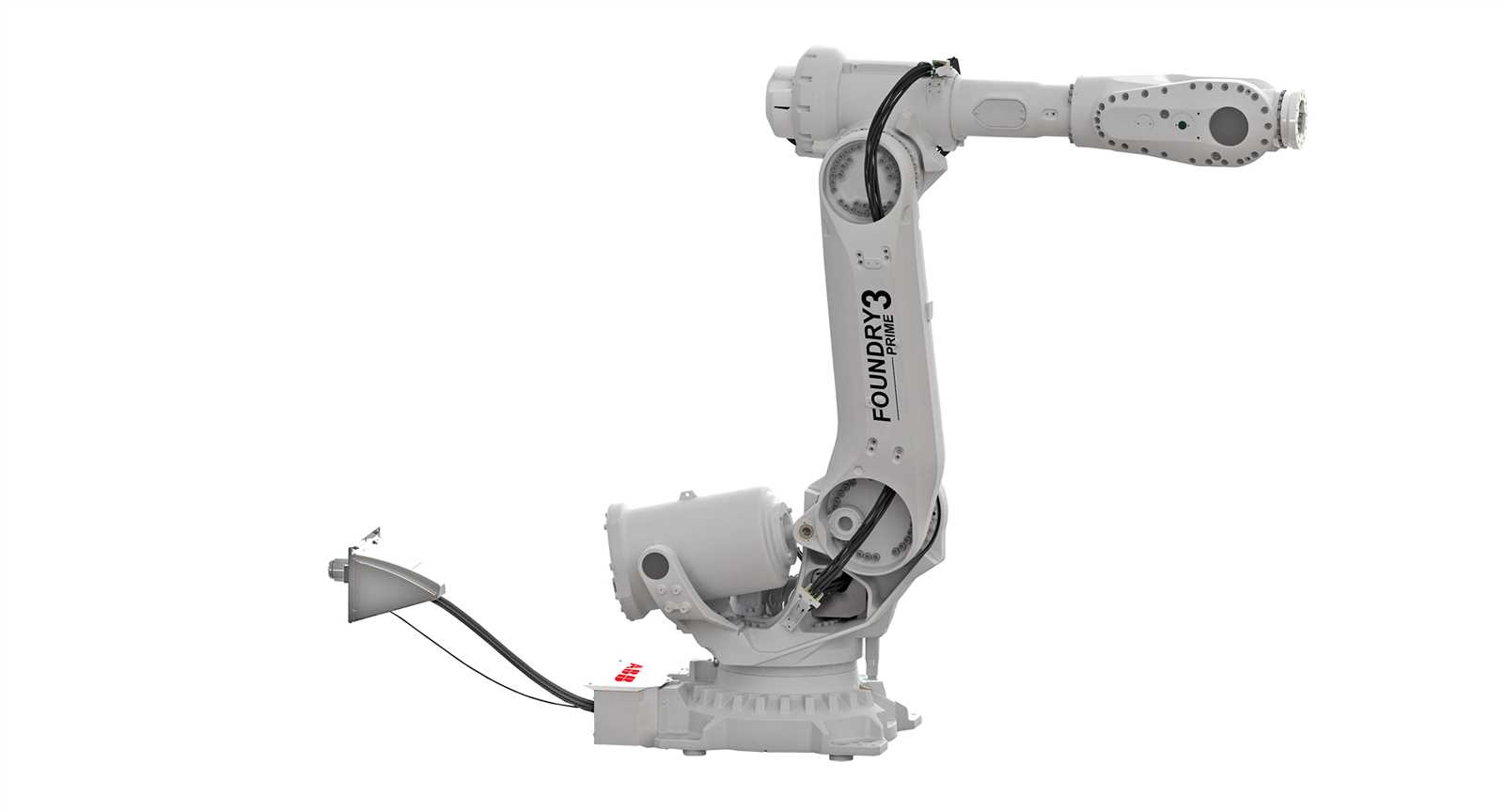

Exploring the Documentation for ABB’s Advanced Robotic System

In this section, we embark on a journey delving into the comprehensive documentation accompanying ABB’s cutting-edge robotic technology. Through thorough examination, we uncover intricate details, operational insights, and technical specifications encapsulating the prowess of this state-of-the-art robotic system.

| Unveiling Technical Attributes | Unlocking Operational Capabilities |

| Discovering the intricate mechanisms and engineering marvels that power this robotic system. | Exploring the vast array of tasks and applications this system is primed to undertake with precision and efficiency. |

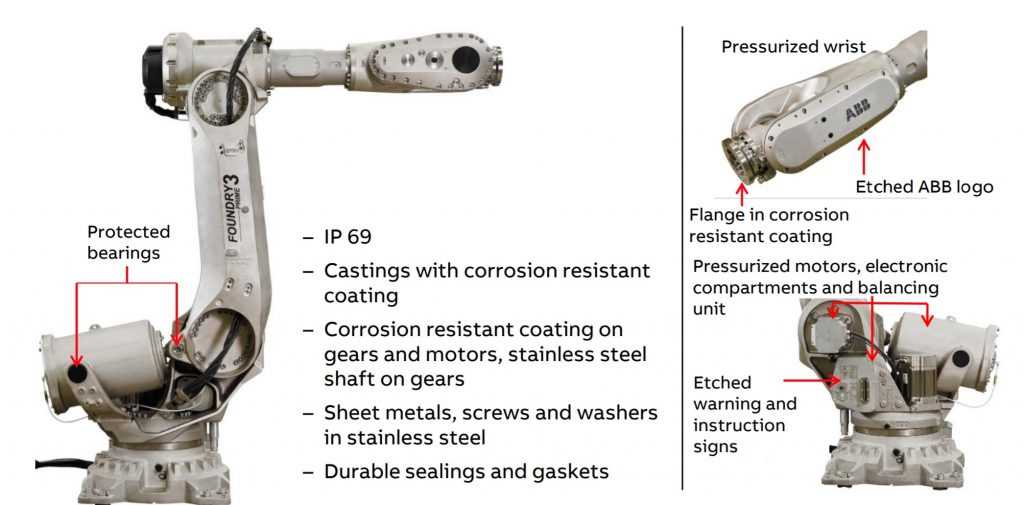

| Examining the robustness of its construction and the finesse of its components, highlighting its reliability and durability. | Unraveling the versatility inherent in its design, enabling seamless adaptation to diverse industrial environments and tasks. |

| Scrutinizing the performance metrics and operational parameters that define its functionality and efficacy. | Deciphering the intuitive control interfaces and programming capabilities facilitating seamless integration and operation. |

This exploration aims to provide a comprehensive understanding of the capabilities, intricacies, and potential applications of ABB’s advanced robotic system, empowering users to harness its full potential in revolutionizing industrial automation.

Understanding the Technical Specifications

In this section, we delve into comprehending the intricate details and performance indicators of the cutting-edge robotic system, offering insight into its capabilities and functionalities beyond mere nomenclature.

Functional Parameters Overview

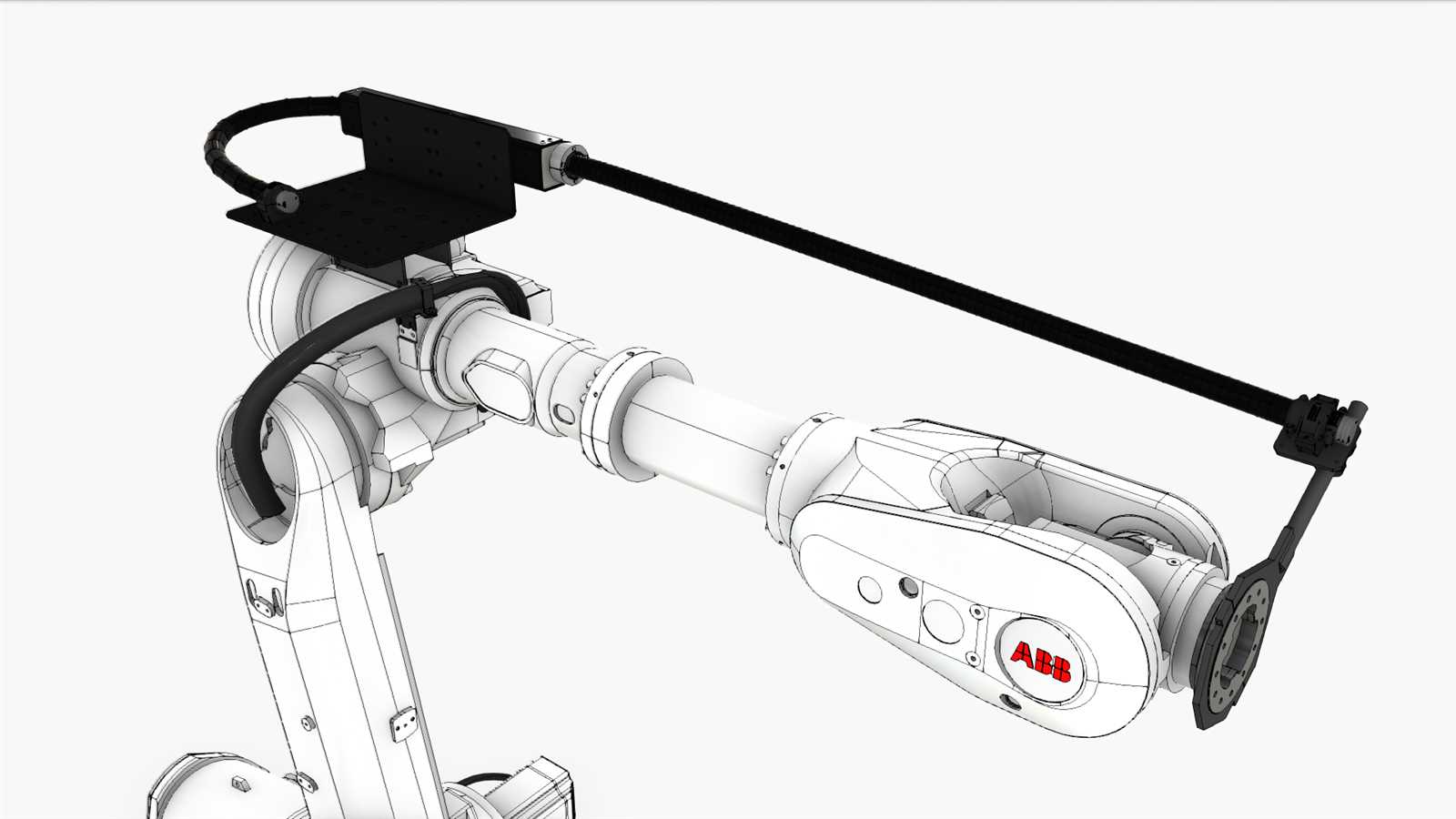

Let’s embark on an exploration of the functional parameters that encapsulate the essence of this advanced machinery. We will dissect the operational aspects, elucidating how each component synergizes to optimize performance and efficiency.

Performance Metrics Deconstruction

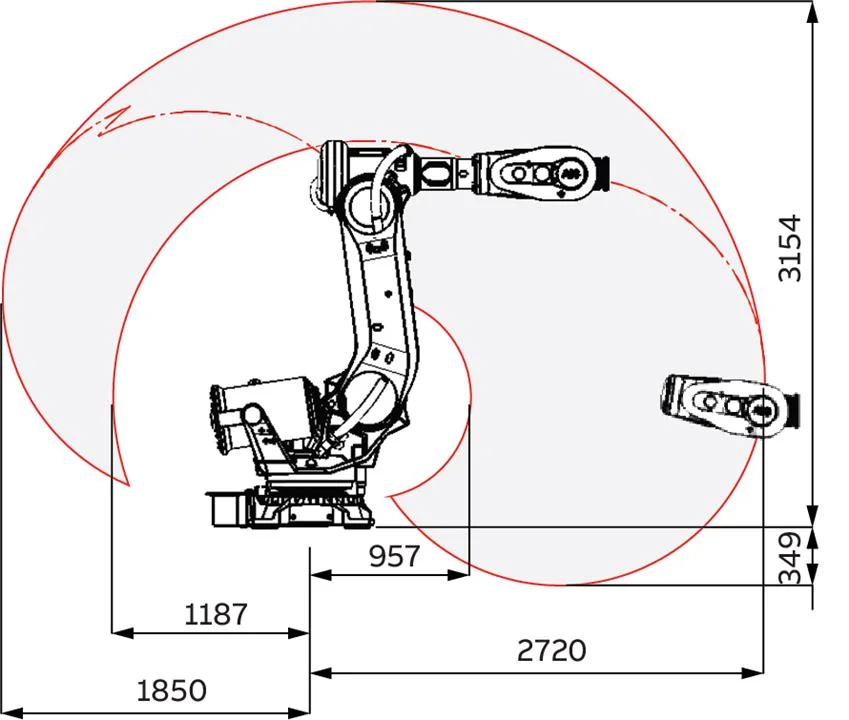

Here, we embark on a journey to deconstruct the labyrinth of performance metrics, unraveling the significance of each criterion in delineating the prowess of the robotic system. From speed and precision to payload capacity and reach, we decipher the language of technical specifications.

Applications and Industries Implementing Advanced Robotic Solutions

In this section, we delve into the diverse array of applications and industries leveraging cutting-edge robotic technology for enhanced productivity and efficiency. From automotive manufacturing to food processing, the versatility and precision of these robotic solutions are revolutionizing traditional processes.

Streamlining Automotive Production Processes

Automotive assembly lines have embraced innovative robotic systems to optimize production workflows, ensuring consistent quality and swift manufacturing cycles. These robots undertake tasks ranging from welding and painting to assembly, augmenting human labor with unparalleled accuracy and speed.

Enhancing Precision in Electronics Manufacturing

The electronics industry relies heavily on robotic automation to achieve intricate soldering, component placement, and circuit board assembly. These robots operate with microscopic precision, contributing to the seamless production of complex electronic devices while minimizing errors and waste.

Comparative Analysis with Alternative Robotic Solutions

When examining the landscape of robotic systems, it becomes evident that the market offers a plethora of options beyond the specific model under scrutiny. This section aims to delve into a comparative analysis of various robotic solutions, shedding light on their respective strengths, weaknesses, and applicability across diverse industrial settings.

Performance Metrics

One of the primary aspects under scrutiny involves evaluating the performance metrics of alternative robotic systems. This encompasses factors such as speed, precision, payload capacity, and flexibility. Each system exhibits distinct capabilities in these domains, influencing their suitability for particular tasks and industries.

Technological Advancements

Furthermore, a comparative examination entails assessing the technological advancements embedded within competing robotic solutions. This encompasses innovations in sensing technology, control algorithms, human-machine interaction interfaces, and adaptive capabilities. Understanding the technological prowess of each system provides insights into their potential for seamless integration into evolving manufacturing paradigms.