Embark on a journey into the realm of engineering documentation, where intricacies unfold through the meticulous crafting of technical specifications. Delve into the blueprints of innovation as we navigate through the intricacies of industrial standards and requirements.

Within this domain lies a treasure trove of information, a roadmap to precision and efficiency. Dive deep into the heart of technical discourse, where every detail serves as a crucial piece in the puzzle of industrial design and implementation.

Prepare to decipher the language of engineering mastery, where parameters and performance metrics converge to define the essence of excellence. Join us as we unravel the intricacies of industry norms, shedding light on the significance of meticulous data presentation and interpretation.

Understanding Technical Documents for Machinery: Core Elements and Parameters

In the realm of industrial machinery, deciphering technical documents forms a cornerstone for informed decision-making and seamless operations. Let’s delve into the essential components and pivotal parameters encapsulated within these documents, providing a compass for navigating complex machinery landscapes.

The Anatomy of Machinery Documentation

Within the labyrinth of technical literature lies a roadmap delineating the intricacies of machinery design and operation. These documents serve as conduits of knowledge, encapsulating vital details ranging from performance specifications to safety protocols.

Exploring Core Parameters

Central to comprehending machinery documentation are its core parameters, the veritable building blocks of functionality and performance. From operational thresholds to material specifications, each parameter intertwines to sculpt the machinery’s identity and capabilities.

The Significance of Technical Specifications in Machinery Engineering

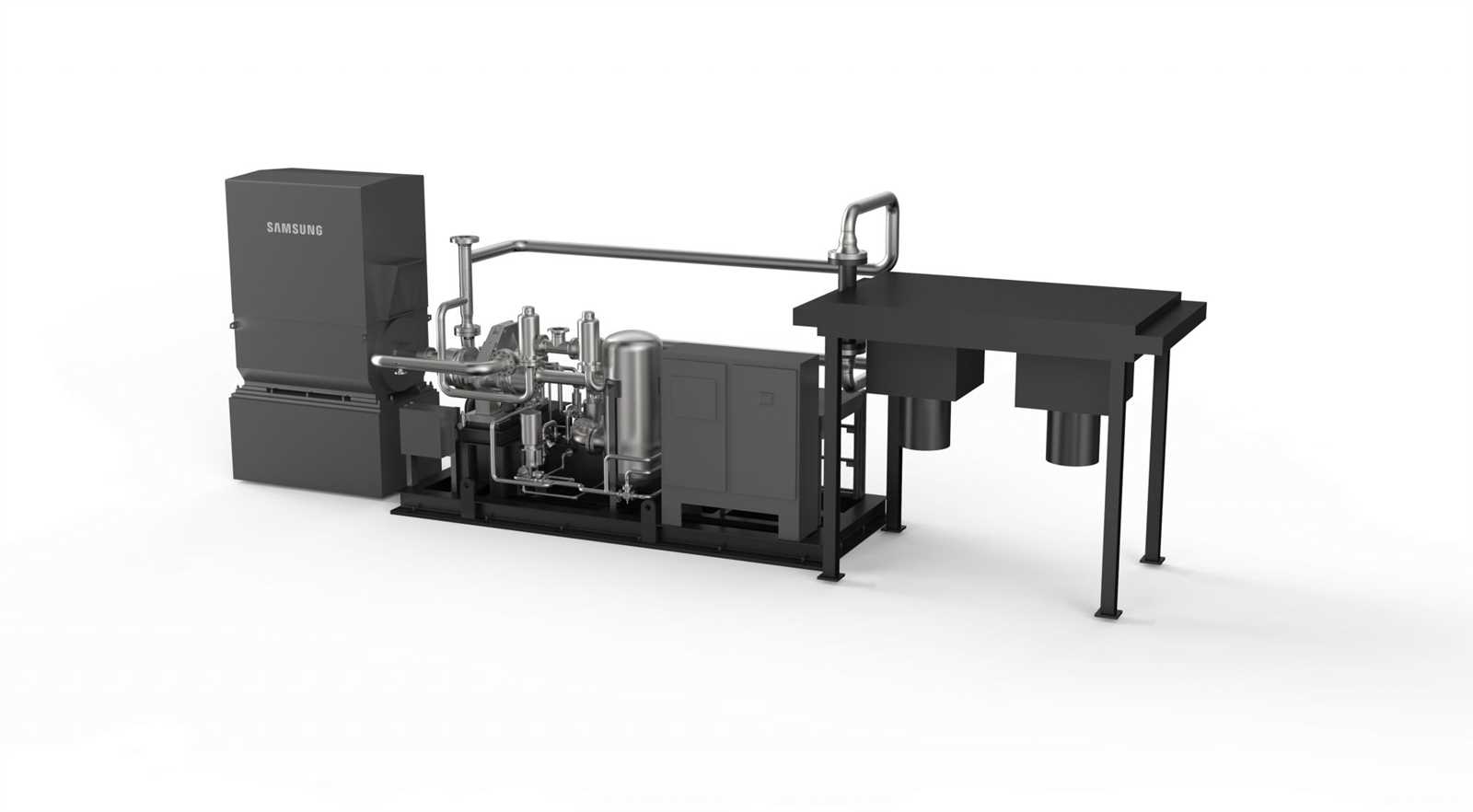

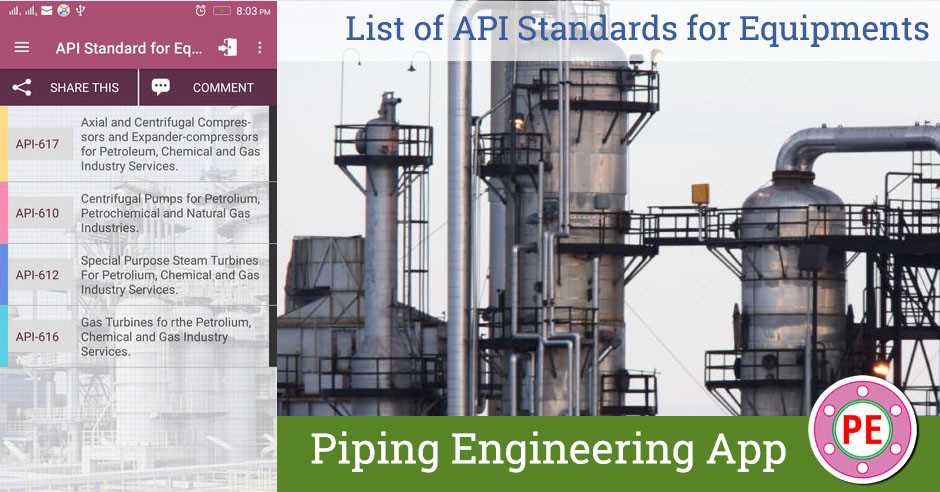

Understanding the intricacies of machinery design requires meticulous attention to detail and adherence to industry standards. Amidst the myriad of technical specifications governing equipment fabrication and performance, one document stands out for its indispensable role: the API 617 datasheet. This cornerstone of engineering blueprints encapsulates critical parameters and guidelines essential for ensuring the reliability, efficiency, and safety of industrial machinery.

Guiding Principles for Design Excellence

Thorough Analysis: A comprehensive examination of equipment requirements demands more than just surface-level scrutiny. API 617 datasheets delve deep into the nuances of mechanical systems, providing engineers with a roadmap for precision engineering.

Performance Optimization: Beyond mere compliance, these datasheets serve as catalysts for innovation and optimization. By aligning design decisions with API 617 standards, engineers can unlock the full potential of machinery, enhancing operational efficiency and longevity.

Embracing the guidance outlined within API 617 datasheets empowers engineers to navigate the complex terrain of machinery design with confidence and proficiency, ultimately shaping the landscape of industrial innovation.

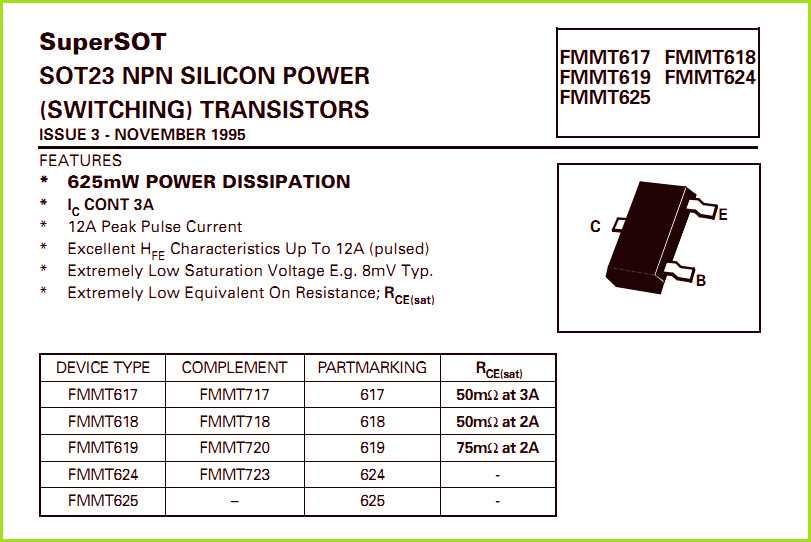

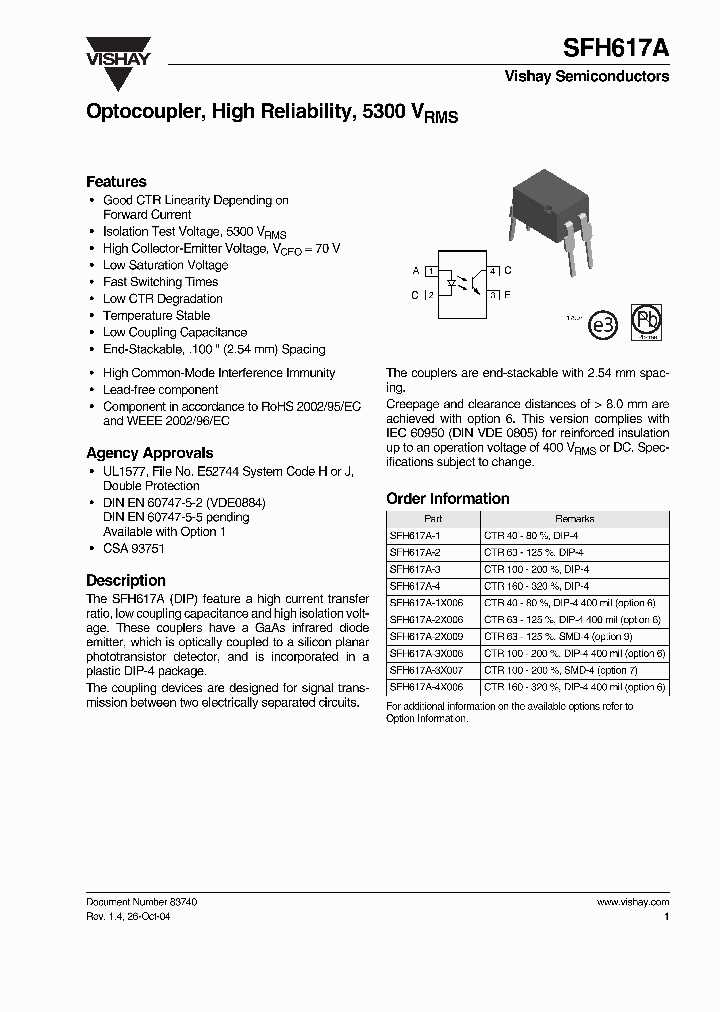

Deciphering Key Parameters: RPM, Pressure, and Temperature

In the realm of technical specifications, certain metrics hold pivotal significance, serving as the bedrock for operational assessments and performance evaluations. Within the domain under scrutiny, the triad of Rotational Speed (RPM), Pressure, and Temperature emerges as the cornerstone elements, intricately interwoven to delineate the operational landscape. Understanding the nuances and implications of these fundamental parameters is indispensable for grasping the essence of the subject matter.

RPM (Revolutions Per Minute) stands as a testament to the dynamic motion coursing through the system, embodying the velocity at which components rotate and interact within the operational framework. It encapsulates the rhythm of mechanical orchestration, offering insights into the efficiency, stability, and limitations of the system’s rotational dynamics.

Pressure, akin to the force exerted by invisible hands, exerts its influence across every facet of the operational continuum. It manifests as the driving force propelling the system forward, navigating through challenges and constraints, while also serving as a barometer of resilience and adaptability.

Temperature, the silent conductor orchestrating the symphony of molecular kinetics, underscores the thermal equilibrium governing the system’s demeanor. From the delicate balance of heat dissipation to the thresholds of material integrity, temperature serves as both a catalyst for performance enhancement and a harbinger of potential hazards.

As we delve deeper into the intricacies of these parameters, we embark on a journey of comprehension and exploration, unraveling the mysteries veiled within the numerical realms. By deciphering the essence of RPM, Pressure, and Temperature, we unlock the gates to a deeper understanding of the operational intricacies, paving the path towards optimization and innovation.

Best Practices for Leveraging Technical Specifications in Engineering Projects

When embarking on engineering endeavors, the effective utilization of technical specifications plays a pivotal role in ensuring project success. In this section, we delve into the paramount importance of methodically integrating and interpreting technical documentation for optimal project outcomes.

First and foremost, it is imperative to meticulously scrutinize and comprehend the intricacies embedded within the provided technical literature. Thorough comprehension fosters a comprehensive understanding of the operational parameters and design constraints, laying a robust foundation for subsequent project phases.

Furthermore, fostering a collaborative environment among multidisciplinary teams facilitates the holistic interpretation of technical specifications. Encouraging open dialogue and knowledge sharing among engineers, designers, and stakeholders cultivates a synergy that enriches the interpretation process, ensuring all perspectives are considered and addressed.

Equally crucial is the judicious application of acquired knowledge from technical specifications to the design and implementation phases. Integrating insights gleaned from datasheets into the engineering workflow enables informed decision-making, mitigating risks and optimizing performance parameters.

Moreover, the iterative nature of engineering projects necessitates continuous reference to and validation against technical specifications. Regularly revisiting and cross-referencing datasheets throughout the project lifecycle serves as a safeguard against deviations from prescribed standards, fostering adherence to best practices and regulatory compliance.

In conclusion, the conscientious utilization of technical specifications, synonymous with API 617 datasheets in this context, epitomizes a cornerstone of successful engineering projects. By embracing a systematic approach to interpretation, application, and validation, engineering endeavors are poised to achieve optimal outcomes while adhering to industry standards and best practices.

Optimizing Machinery Performance Through Accurate Data Interpretation

In the realm of industrial machinery, enhancing operational efficiency and longevity relies heavily on the ability to decipher and leverage data effectively. The process of optimizing machinery performance through precise data interpretation is a cornerstone of modern engineering practices, driving advancements and ensuring sustainable productivity.

The Power of Insightful Analysis

Unlocking the full potential of machinery entails more than just monitoring its performance; it necessitates a deep understanding of the data generated by various components and systems. By delving into these datasets with a discerning eye, engineers can identify patterns, anomalies, and optimization opportunities that might otherwise go unnoticed.

Through insightful analysis, engineers can pinpoint inefficiencies, diagnose underlying issues, and devise targeted strategies to improve machinery performance. From detecting early signs of wear and tear to optimizing operational parameters, every insight gleaned from accurate data interpretation contributes to the overall efficiency and reliability of industrial systems.

Strategies for Effective Implementation

-

Establishing Clear Performance Metrics: Define measurable metrics that align with the specific goals of machinery optimization, providing a tangible basis for data interpretation and evaluation.

-

Utilizing Advanced Monitoring Technologies: Embrace cutting-edge sensor technology and data acquisition systems to gather real-time information on machinery performance, enabling proactive decision-making and timely interventions.

-

Implementing Predictive Maintenance Practices: Leverage predictive analytics and machine learning algorithms to anticipate potential failures and schedule maintenance activities preemptively, minimizing downtime and maximizing operational uptime.

-

Fostering a Culture of Continuous Improvement: Cultivate an environment where data-driven insights are valued and integrated into decision-making processes at all levels of the organization, fostering innovation and driving ongoing performance enhancements.

By incorporating these strategies into their approach to data interpretation, engineers can optimize machinery performance, enhance reliability, and propel industrial operations towards greater efficiency and competitiveness.